30ХГСА – decoding of steel grade

Steel 30KhGSA belongs to the group of alloy steels. Its composition is regulated by GOST 4543-71, according to which each letter and number indicates a certain content of certain chemical elements:

- The number 30 means carbon content of 0.28-0.34%. Carbon increases hardness and strength in steels, but reduces ductility and weldability.

- X – chromium (0.8-1.1%) increases the hardenability, corrosion resistance and heat resistance of the alloy. Has a positive effect on abrasive wear resistance.

- G – manganese (0.8-1.1%) removes harmful impurities of oxygen and sulfur. Reduces the risk of scale and cracking during heat treatment. Improves surface quality. In addition, it helps to increase the steel’s ductility and weldability.

- C – silicon, like manganese, is a strong deoxidizing agent. Increases ductility without reducing strength. Increases the susceptibility of steel to heat treatment.

- The letter "A" stands for improved. This means that the steel has been hardened and tempered. Features of hardening include heating the steel to a temperature of 870 ºС and subsequent rapid cooling in oil or water. Thus, a transformation of the internal structure occurs, which helps to increase the mechanical characteristics of 30KhGSA by 2.9 times. Quenching stresses are removed by high tempering: heating to 540-560 ºС. In addition to stress relief, a parallel increase in elastic properties occurs.

- Sulfur (up to 0.25%) and phosphorus (up to 0.25%) are classified as harmful impurities. The sizes of their molecules are too large compared to all of the above elements. Being built into the crystalline network of steel, sulfur and phosphorus reduce its stability, thereby reducing the strength of the alloy.

- 30KhGSA also contains a certain percentage of copper and nickel. But their content is so small that they do not affect the characteristics of steel.

30KhGSA is the Russian designation for the steel grade.

Analogs

There are the following foreign analogues:

- Poland 30HGSA.

- Bulgaria 30ChGSA.

- Czech Republic 14331.

Read also: How to repair a screwdriver battery

Steel grade 30KhGSA - characteristics, explanation, application

Structural steel 30KhGSA was developed in the early 40s of the last century and became a real discovery, ensuring the leading role of the Soviet Union in the field of aircraft construction. Today the alloy has become available for use in other industries.

Decoding the brand

The chemical composition of the alloy is specified by GOST 4543-71, which determines the content of the main alloying additives indicated in the marking.

Decoding the steel grade 30KhGSA indicates that it belongs to the class of medium alloy alloys. The first two numbers, from left to right, indicate the concentration of carbon needed to make the metal hard.

At the same time, carbon reduces the ductility of steel, so its content does not exceed 0.28-0.34%.

The numbers are followed by letters indicating the main alloying elements, the concentration of which varies within 1%:

- chromium is added to increase the corrosion resistance and heat resistance of steel;

- manganese and silicon are strong deoxidizers; they also increase ductility and reduce the risk of cracking of the alloy.

The letter “A” indicated at the very end of the abbreviation indicates the high quality of the material.

It contains small impurities of copper and nickel, but their concentration is too low to significantly affect the properties of the alloy.

Sulfur and phosphorus impurities reduce the strength of the metal by being embedded in the nodes of the crystal lattice. It is impossible to completely remove these impurities, but their content is minimal - no more than 0.25%.

According to GOST, this alloy can be replaced with analogues:

- 40HFA;

- 35ХМ;

- 25ХГСА;

- 40ХН;

- 35ХГСА.

Among foreign analogues:

- 14331 – Czech Republic;

- 30ChGSA – Bulgaria;

- 30HGSA, 30HGS – Poland.

The product range consists of:

- from pipes of different diameters;

- forged blanks;

- sheets of various thicknesses;

- long products;

- strip iron;

- calibrated and ground rods.

Product range

- Pipes.

- Forged blanks and forgings.

- Strip iron.

- Sheets are thick and thin.

- Rolled products – long products, shaped products.

- The rods are calibrated and ground.

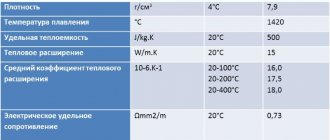

Physical and mechanical properties of the alloy

The physical properties of 30KhGSA steel depend on the chemical composition:

- density fluctuates depending on the ambient temperature and averages 7850 kg/m3;

- melting point - 1500 degrees, which indicates resistance to heat;

- modulus of elasticity at 20 degrees. – 2.15*10-5MPa, decreases with increasing temperature;

- heat capacity – 38 W/(m*deg);

- electrical resistivity, 109–210 Ohm*m;

- thermal conductivity is 30-38 W/m K;

- specific heat capacity – 496 J/kg*K.

Alloy 30KhGSA demonstrates excellent mechanical characteristics, which do not decrease until the temperature rises to 400°C:

- the high strength of the metal is indicated by the value of the maximum impact load - 980 MPa;

- yield strength – 820 MPa, more than twice as high as some brands of stainless steel;

- impact strength indicator – 127 KJ/m2;

- high ductility is indicated by the relative elongation parameter – 11%;

- endurance limit – 490 MPa;

- hardness – 45-50 units on the Rockwell scale.

Technological qualities

The ability of the alloy to undergo cold plastic deformation is limited. But it excellently withstands hot plastic deformation in the temperature range of 1100-850 degrees. However, with rapid temperature changes, cracks tend to form. Therefore, the mode is selected:

- slow heating up to 830 degrees;

- hot deformation procedures;

- slow cooling in sand or oven.

After the deformation process, a softening heat treatment is applied by annealing at 740°C followed by further cooling at 500°C, first in a furnace and then in air.

Steel is not highly corrosion resistant. When used in conditions of high humidity, rusting processes develop on its surface. To prevent them, a special galvanic coating based on chromium and zinc is often applied to the surface of products. But it must be protected from mechanical damage.

Application area

The mechanical properties of steel determine the technology of its use:

- due to its high ductility, the alloy is subjected to stamping and forging operations;

- good elastic properties facilitate cutting technologies - countersinking or milling;

- welding is performed in fast mode when heated to 250 degrees, which reduces the risk of cracks.

Due to its excellent characteristics, the use of 30KhGSA steel covers many industries:

- in construction, fasteners are made from it - nuts, bolts;

- in the aircraft industry, the alloy serves as a raw material for the production of consumables;

- in the mechanical engineering industry they produce units that experience variable loads - shafts, gears;

- knife production – for the production of high-quality blades.

The alloy is also used when it is necessary to manufacture products with complex configurations operating under the following conditions:

- constant mechanical impact;

- variable loads;

- low temperatures.

Heat treatment

The problem of improving the mechanical properties of 30KhGSA steel and increasing its service life can be solved in different ways:

- the use of more expensive elements for alloying;

- choosing a rational heat treatment mode.

In the first option, the cost of production will increase significantly. Therefore, the optimal heat treatment mode is selected, as a result of which the strength characteristics of the alloy are significantly increased. Heat treatment mainly consists of two stages.

Hardening is carried out in oil with exposure for 5 minutes at a temperature of 880 degrees. During the hardening process, the structure of the material changes and the crystal lattice is rearranged, resulting in internal stresses. As hardness increases, the brittleness of steel simultaneously increases.

Internal stress can be eliminated by subsequent tempering in water at 540 degrees. Tempering is also used for welded structures. To achieve higher strength characteristics, re-hardening is sometimes carried out. It allows you to increase many indicators by up to 40%.

The structure of the alloy can also be improved by the forging process. The process is carried out after preheating the part to 1240 degrees. Depending on the size of the product, the cooling medium is selected.

Advantages and disadvantages

Steel grade 30KhGSA belongs to the structural group. At one time it received another name - “chromansil”, derived from the names of the main additives. The alloy has its pros and cons. Its wide demand in the aircraft and engineering industries is due to its high strength characteristics:

- high resistance to shock loads;

- good viscosity indicators;

- high hardness;

- wear resistance;

- fairly good weldability;

- stability of mechanical characteristics under constant thermal influence not exceeding 400 degrees.

In addition, the availability of alloying elements ensures the low cost of the alloy.

The disadvantages of steel are expressed in its relatively low punctureability, which is calculated by the depth of penetration of the hardened layer into the volume of the part. It is 25-40 mm. The alloy is also sensitive to the formation of flakes - internal cracks that worsen the mechanical properties of the material. Special heat treatment partially reduces the risk of their occurrence.

Even with some disadvantages, 30KhGSA steel is significantly superior to conventional alloys in strength and endurance.

Hardenability

Hardness HRCе.

Distance from the end, mm / HRC e

| 1.5 | 4.5 | ||||||||

| 50.5-55 | 49-54 | 47.5-53 | 46-52.5 | 41.5-52 | 38-51 | 36-48.5 | 35.5-46.5 | 33-44.5 | 30-43 |

Quantity of martensite, % Critical dia. in water, mm Crit.dia. in oil, mm Crete. hardness, HRCе

| 60-91 | 34-60 | 38-43 |

| 40-68 | 18-40 | 43-48 |

Steel 30KhGSA. Physical properties

Test temperature, °C Modulus of normal elasticity, E, GPa Density, pn, kg/cm3 Thermal conductivity coefficient W/(m °C) Spec. electrical resistance (p, NOm m) Test temperature, °C Coefficient of linear expansion (a, 10-6 1/°C) Specific heat capacity (C, J/(kg °C))

| 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | |

| 215 | 211 | 203 | 196 | 184 | 173 | 164 | 143 | 125 | |

| 7850 | 7830 | 7800 | 7760 | 7730 | 7700 | 7670 | |||

| 210 | |||||||||

| 20- 100 | 20- 200 | 20- 300 | 20- 400 | 20- 500 | 20- 600 | 20- 700 | 20- 800 | 20- 900 | 20- 1000 |

| 11.7 | 12.3 | 12.9 | 13.4 | 13.7 | 14.0 | 14.3 | 12.9 | ||

| 496 | 504 | 512 | 533 | 554 | 584 | 622 | 693 |

Chemical properties

Marking 30ХГСА does not belong to the category of corrosion-resistant materials. Under the influence of the aqueous environment, rust begins to appear on the surface of the alloy.

Corrosion resistance is increased by using special galvanic coatings based on chromium and zinc. They are applied by electrolysis.

Areas of use

Steel grade 30KhGSA is actively used in various industries.

Most often it is used for the production of fastening elements, which are common in the construction of various buildings and structures.

The features of this steel allow them to withstand variable loads. However, due to their low corrosion resistance, such fasteners are limited in places of use.

In aircraft manufacturing, this alloy is used in the production of flanges, shafts and other parts. It is not suitable for the manufacture of critical parts - only for consumables. The alloy has also gained great popularity in mechanical engineering. It is there that metal products have to experience regular variable loads.

Technological properties

The high ductility of steel allows the use of stamping and forging for its processing.

The elastic properties of steel also facilitate cutting: milling, countersinking, etc. To increase the productivity of this process, the steel is pre-annealed.

30KhGSA belongs to the 2nd group of weldability. Features of welding include the need to heat the steel to 250 ºС, which reduces the likelihood of cracks forming. Subject to these conditions, welds can withstand loads from 300 to 490 MPa, depending on the type of load.

Application

- Welded structures.

- Frame coverings, solid bodies.

- Fastening elements.

- Fan blades.

- Axles, levers, shafts and much more.

Price

such an alloying element as chromium increases the cost of 30ХГСА in the secondary metal market. The price of a kilogram of steel scrap is 40-50 rubles. This is higher than regular carbon steel, but lower than stainless steel. A more accurate cost value depends on factors such as:

- Scrap surface quality.

- Scope of delivery.

- Dimensions of scrap.

:

/5 —

| Share on social networks: |

Mechanical characteristics

Grade 30KhGSA differs from conventional structural steels in its increased strength and resistance to impact loads. The yield strength is 820 MPa. For comparison, stainless steel 12Х18Н10Т “flows” already at 400 MPa. Complete destruction of steel occurs at a load of 980 MPa. Impact strength is 127 KJm2.

It has high plastic properties: relative elongation 11% and contraction 50%. Stable when working under variable loads. The endurance limit of 30KhGSA is exactly 2 times greater than steel 45 and has a value of 490 MPa. Wear-resistant. Hardness is in the range of 45-50 units on the Rockwell scale.

Steel retains its mechanical characteristics at temperatures up to 400 C.

Heat treatment of alloy 30KhGSA

To improve the performance characteristics of the resulting products, heat treatment is carried out, thereby increasing strength and hardness. For steel 30KhGSA the following heat treatment is used:

- Hardening is aimed at changing the qualities of the surface layer. It is recommended to harden steel at a temperature of 880 degrees Celsius. Cooling is carried out in oil, which eliminates the possibility of surface and structural deformations.

- Hardening involves restructuring the crystal lattice. Such a process causes the appearance of internal stresses, which subsequently lead to the appearance of structural cracks. Tempering at a temperature of 540 degrees Celsius allows you to solve a similar problem. The low heating temperature allows the use of water as a cooling medium.

- Forging improves the structure of the material. At the beginning of the process, the workpiece is heated to a temperature of 1240 degrees Celsius. Cooling is carried out in the open air or in another environment - it all depends on the size of the workpiece.

To improve the quality of the material, a variety of equipment can be used. The characteristics of the chemical composition are determined by the fact that the processing of workpieces is carried out using special equipment.

Technological properties

The high ductility of steel allows the use of stamping and forging for its processing.

The elastic properties of steel also facilitate cutting: milling, countersinking, etc. To increase the productivity of this process, the steel is pre-annealed.

30KhGSA belongs to the 2nd group of weldability. Features of welding include the need to heat the steel to 250 ºС, which reduces the likelihood of cracks forming. Subject to these conditions, welds can withstand loads from 300 to 490 MPa, depending on the type of load.

Application

Steel 30KhGSA, the use of which is related to the chemical composition and basic qualities, is found in various industries. Most often, alloy steel is used in the following cases:

- In the construction field, fasteners that are used under variable loads have become widespread. Low corrosion resistance determines that fastening materials can only be used to protect the device.

- In the aircraft industry, the alloy is used as a consumable material in the manufacture of shafts, flanges and other parts. It is worth considering that the alloy is not used to create critical elements.

- In the mechanical engineering field it is used to create elements that operate under constant or variable loads.

The cost of the raw materials used largely depends on what kind of scrap was used. There are foreign analogues on sale, for example, 14331 (Czech Republic) and 30ChGSA (Bulgaria). Their chemical composition and basic qualities are largely similar.

Application Types

Thanks to all the above characteristics, 30KhGSA has enormous practical application for various industries:

- In construction, 30KhGSA is used to make fasteners that are subject to alternating bending. This includes anchor bolts, nuts, studs, etc.

- It is still used in the aircraft industry as a material for the manufacture of aircraft consumable parts: flanges, shafts, etc.

- In mechanical engineering, 30KhGSA has found application in the production of highly critical products operating under variable loads: gears, spindles, shafts, pushers, etc.

Read also: Do-it-yourself garden waste shredder

The content of an alloying element such as chromium increases the cost of 30ХГСА in the secondary metal market. The price of a kilogram of steel scrap is 40-50 rubles. This is higher than regular carbon steel, but lower than stainless steel. A more accurate cost value depends on factors such as:

- Scrap surface quality.

- Scope of delivery.

- Dimensions of scrap.

Rate this article:

Chemical composition,% (GOST 4543-71)

Purpose - various upgradeable parts: shafts, axles, gears, casing flanges, compressor blades operating at temperatures up to 200°C, levers, pushers, critical welded structures operating under alternating loads, fasteners operating at low temperatures

Steel condition and heat treatment

Forging temperature, °C: beginning 1240, end 800. Sections up to 50 mm are cooled in air, 51-100 mm - in boxes.

Weldability - limited weldability. Welding methods: RDS, ADS under submerged arc and gas shield, ArDS, EShS. Preheating and subsequent heat treatment are recommended. CTS without restrictions.

Cutting machinability - in the hot-rolled state at HB 207-217 and w=710 MPa, Kv b. Art. = 0.75; Kv tv. spl,=0.85.

Mechanical properties at elevated temperatures

Bar. Quenching 880°C, oil. Vacation 560°C

Sample 5 mm in diameter, 25 mm long, rolled. Deformation speed 2 mm/min. Strain rate 0.0013 1/s

Hardenability (GOST 4543-71)

Distance from the end, mm

Critical hardness, HRCе

Critical diameter, mm

Influence of alloying elements.

Chromium dissolves in ferrite and cementite, having a beneficial effect on the mechanical properties of steel: it increases strength and toughness (not significantly), and cold resistance during heat treatment; increases the quenching and tempering temperature, significantly increases hardenability (due to strengthening of ferrite and increasing the stability of carbides of the Me3C type); reduces the tendency for grain growth when heated (due to the formation of carbides of alloying elements of increased stability).

Manganese strengthens ferrite and increases the stability of Me3C type carbides, which results in a significant increase in strength and a slight increase in toughness; The quenching and tempering temperature increases slightly, hardenability increases significantly, and sensitivity to overheating also increases.

Read also: Which Bosch washing machine is the best?

Silicon has a positive effect on the structure, mechanical and technological properties of steel: it reduces the critical cooling rate and increases hardenability; reduces the rate of martensite decomposition; strongly strengthening ferrite, increases the strength, hardness and elastic properties of steel; increases corrosion resistance; reduces viscosity. This effect of silicon on properties is associated with its effect on the matrix phase (-solution) and carbides. Silicon is capable of creating directional ionic bonds in a solid solution, which should increase friction stress in the crystal lattice and thereby increase the resistance to dislocation movement, especially at small plastic deformations (strengthening effect).

Disadvantages of steel 30KhGSA: 1)

flake-sensitive (to prevent hot deformation, long exposure at 250°C is recommended);

2)

prone to temper brittleness (prevented by faster cooling during tempering, and with high tempering you can get by with the addition of 0.3% Mo or 1% W);

3)

limited weldability.

The properties of structural medium alloy steel can be improved by additional alloying. In addition to steel 30KhGSA, steels 30KhGSNA, 30KhGT, 30Kh5MSFA are used.

Alloying elements - silicon and manganese - greatly strengthen ferrite and help increase the strength characteristics of steel after heat treatment. The effect of additional alloying with chromium, molybdenum, vanadium, and nickel is manifested primarily in a decrease in the critical cooling rate and an increase in hardenability; Nickel reduces grain size. Carbide-forming elements - chromium, molybdenum and vanadium - prevent decarburization when heated for hardening. In addition, the introduction of molybdenum and vanadium contributes to a further increase in strength, as it leads to the formation of highly dispersed particles of MC carbide (based on VC) during the decomposition of martensite during the tempering process.

Steel 30hgsa: application

This high quality structural alloy was originally developed for the aircraft industry. Engineers at the All-Russian Institute of Aviation Materials made a real breakthrough, creating steel, which is still difficult to find a worthy analogue today. Parts for aircraft were and continue to be produced from it: flanges, axles, shafts, skin elements, etc.

Steel 30xgsa demonstrates its excellent qualities under conditions of low temperatures (up to 200 o C) and alternating loads. The excellent qualities of chromansil made it popular not only in aircraft, but also in mechanical engineering, where the 30xgsa alloy is used for the manufacture of various improved parts: suspension arms, pushers, various welded structures, etc. Alloys 25khgsa, 35khgsa, 35khm, 40khfa and 40khn are most often used as analogues of this grade of metal.

Currently, you can purchase 30xgsa steel in the form of rolled products produced in accordance with GOST standards:

- GOST 1051-73, 7417-75, 8559-75, 8560-78 and 10702-78 – calibrated rod

- GOST 14955-77 – silver and ground rod

- GOSTs 13663-68, 9567-75, 8734-75, 21729-76, 8732-78, 8731-87 and 8733-87 – pipes

- GOST 11268-76 – thin sheet

- GOST 11269-76 – thick sheet

- GOST 8479-70 and 1133-71 – forgings and forged blanks

- GOST 103-76 – stripes