Issues discussed in the material:

- What are the stages of processing stainless steel?

- What types of stainless steel processing are used?

- What is stainless steel turning?

- How stainless steel is finished

Processing stainless steel makes it possible to provide products made from this material with the necessary properties and qualities, and also helps to improve their appearance. Various technologies can be used for this. Competent selection of optimal methods for processing stainless steel allows us to produce various parts in accordance with the requirements of customers.

Satin stainless steel is a popular processing method.

Stainless steel is often used for the manufacture of industrial design products and all kinds of decorative elements. In most cases, such parts are satin-finished (polished, grinded). This type of processing is considered quite practical and at the same time guarantees high results. After the operation, the surface of stainless steel products acquires a “satin” appearance.

Grinding allows you to mask almost any defects present on stainless steel structures, making the flaws less noticeable.

Satin finishing of the material can be done using pneumatic devices or manually. In the first case, the following tools are used:

- sanding belts;

- belt pneumatic file;

- drum belt sander.

Satin finishing of stainless steel material

Manual polishing is performed using sanding sheets and a special grinder.

In large industries, grinding is almost always carried out using special units. And private workshops use polishing in the manufacture of stainless steel products and structures. Processing steel with it looks like this:

- Burn marks and welds are removed from the surface of the product.

- Mark the joining marks on the structure with a special protective tape made of aluminum. It must be glued to the part to be polished in 2-3 layers.

- Then part of the product is processed by hand grinding using reciprocating movements. Note! Don't put too much pressure on the sander.

- After processing of one part of the part is completed, aluminum tape is placed on it. After this, the adjacent zone is polished.

Sanding sheets are used in situations where the use of sanding is impractical, as well as when it is necessary to restore a surface damaged during satin finishing. In this case, you should select the correct grain size of the tool. This is usually done on a rough part.

This is interesting: Welding stainless steel at home: options, tips, videos

Stainless steel turning

Many different parts are now produced from stainless steel, and the material itself is more suitable for loads than carbon steel: if you look at modern mechanisms, carbon steel has an extremely low level of strength. Stainless steel has good resistance to high temperatures and aggressive environments, but it is precisely because of its high level of strength and durability that some difficulties arise during machining on a lathe.

Stainless steel, along with carbon steel, have virtually the same hardness and tensile strength.

But identity is characteristic only of mechanical meanings.

Their differences come down to microstructure, the ability to harden during processing and resistance to rust.

If cutting is carried out, the stainless steel will first begin to deform elastically, after which the processing of stainless steel becomes easier, as it enters the hardening stage. At this point, cutting it can only be done with increased effort. Ordinary steel can also survive these stages, but a high level of hardening is characteristic only of high-alloy steel.

What difficulties arise when turning stainless steels? This concerns strain hardening, chip removal and tool life.

- Viscosity;

- low level of thermal conductivity;

- preservation of properties;

- abrasive compounds;

- uneven hardening.

Certain difficulties during the processing of steel are caused by the fact that steel is a fairly plastic material, especially the heat-resistant grade. That is, the chips will not break off, but will begin to curl into a long spiral.

Impact of temperature

In operational terms, thermal conductivity plays into the hands, but this imposes some difficulties on processing.

In the place where cutting is performed, the temperature increases rapidly, so it becomes necessary to cool the material using special liquids.

They are required to eliminate heat, prevent the formation of hardening and make work easier.

When processing with a working tool, hardening begins to appear, due to which it deteriorates faster. Therefore, high speeds and certain tools are required to work on alloy steels.

The choice of exposure temperature depends on the chemical composition

The strength characteristics and hardness of the material remain the same even if the material is exposed to high temperatures. This is especially true for heat-resistant steel grades.

It is also necessary to take into account the formation of work hardening, due to which the tools deteriorate quite quickly, which leads not only to damage to the cutters, but also limits the processing speed.

Stainless steel is characterized by carbide and intermetallic compounds, the size of which is microscopic. Due to their increased strength, they can be compared to abrasive.

The cutters simply begin to wear down during operation, so they need to be constantly adjusted and sharpened.

When turning steel, a lot of friction is generated, more than when working with a carbon alloy.

Under the action of turning, the alloy begins to harden unevenly. If small parts are processed, this does not affect them much. However, if you are processing a shaft or large parts, this can become a problem.

How chips are removed

Machining stainless steel becomes more difficult when long spiral chips accumulate.

Since the material becomes stronger during deformation, this has led to the development of special tool designs.

Intensive processing, characterized by the use of a cooling lubricant, can also be used.

Steel filings

The instructions state that the lubricant is supplied under high pressure from inside the cutter, which leads to the following: the temperature of the cutter is almost instantly and significantly reduced, the chips are removed from the tool (allowing it to maintain its condition) and the chips are simply crushed into small elements that are easily washed out of the processing area.

If we are talking about turning, then in this regard the steel is often cooled by high pressure. The solution is sprayed in the area where the treatment is to be carried out.

The liquid will begin to evaporate, thereby cooling the material, that is, “taking away” excess heat from it. But this process requires a lot of cooling liquid.

In this case, the service life of the cutter is extended by about 6 times.

Using a chipbreaker and cooling

The defense and precision industries have adopted the following guidelines: CO2 is used for cooling at -78 degrees. This method, although the most expensive, is also the most effective.

The shape of the chipbreaker also plays a significant role.

To generate as little heat as possible, it must have a positive geometry.

Thanks to the rake angle, the self-reinforcement of the product is reduced and a sagging appears on the cutter itself.

When turning alloy steel, a special chipbreaker is required.

This tool can also be universal, capable of affecting a variety of metals.

So, cutting is now as follows: finishing, semi-finishing and roughing, and in each case one or another model of chipbreaker is used.

Features of steel self-strengthening during deformation

The austenitic variety of stainless steel is the most self-strengthening, and this imposes some difficulties on the procedure for its processing.

After all, the cutter begins to wear out quickly due to the hardening of the material. If special cutting blades are used, then the problem is more manageable.

Such plates are characterized by sharper working edges, which makes it possible to quickly process the material without leading to self-hardening of the steel and the formation of sagging.

This is where step-by-step work comes into play. A more effective solution: removing 3 mm in two approaches, rather than in one - all 6 mm.

Experts say that it is necessary to remove unequal layers - 4 and 2 mm.

on the topic: How to process STAINLESS STEEL on a lathe

Chip removal

Stainless steel shavings form long spirals

The accumulation of long spiral chips disrupts the machining process. Therefore, taking into account the ability of stainless steel to harden during deformation, special designs of chipbreakers are being developed. In addition, intensive surface treatment with cooling lubricant is used.

Lubricant is supplied from inside the torch under high pressure to:

- quickly and noticeably reduce the temperature of the torch;

- remove the chips away from the cutter so as not to accelerate its wear;

- crush the chips into small particles that are easier to wash away from the work area.

High-pressure cooling is widely used in turning stainless steel products. The solution is sprayed directly into the treatment area. When the liquid hits a hot surface, it evaporates and takes away some of the heat. The surface cools down. The disadvantage of this method is the high consumption of coolant. But the service life of the tool increases six times.

In the defense and high-precision industries, steel is cooled with carbon dioxide during processing at a temperature of -78 degrees. This is the most expensive and most effective way.

The shape of the chipbreaker is also very important. Its geometry should be positive to reduce heat generation. A positive rake angle reduces self-hardening of the material and the appearance of bead on the cutter surface, eliminating the main causes of damage during steel turning.

Only a specialized chipbreaker should be used for alloy steels, although chipbreakers are usually produced as universal chipbreakers for working with a wide variety of metals. We produce special chipbreakers and cutters for finishing, roughing and semi-finish cutting of stainless steel. They produce the best results and increase productivity.

Features of processing stainless steel on lathes

Stainless steel has been processed for more than 100 years, but this procedure is still fraught with technological difficulties. Many parts are made from stainless steel, gradually replacing carbon steel, which can no longer withstand increasing loads: for modern mechanisms, the strength threshold of carbon steels is too low. The strength and durability of stainless steel, which does not change its properties at high temperature, pressure and exposure to aggressive environments, entails the complexity of its mechanical processing.

Features of stainless steel processing

processing a stainless steel part on a lathe

The hardness and tensile strength of stainless steel and carbon steel are almost the same. However, only the mechanical values coincide. The microstructure, ability to harden during processing, and corrosion resistance are different.

When processing by cutting, stainless steel is first elastically deformed, then processed easily, after which it enters the hardening stage. At this stage, cutting is only possible with a significant increase in effort. All these stages go through during processing and ordinary steel, but high-alloy steel is strengthened much more noticeably.

The main problems in steel turning are:

- strain hardening;

- removal of chips;

- working tool resource.

Viscosity. The plasticity of steel, especially characteristic of heat-resistant grades, adds additional complexity to processing. The chips do not break off, like carbon steel, but curl in a long spiral.

Low thermal conductivity. The weak thermal conductivity of stainless steel is its advantage when used, but its disadvantage when processed. At the cutting site, the temperature increases significantly, so it is necessary to cool the metal using special liquids. They not only eliminate heat, but also prevent the formation of hardening and facilitate processing. Hardening appears on the working tool, changes its shape and renders it unusable. Therefore, alloy steels are most often processed at low speeds and with special tools.

Saving properties. When exposed to heat, steel does not lose its hardness and strength. This property is most pronounced in heat-resistant steels and, in combination with work hardening, it causes rapid failure of cutters and does not allow them to work at high speeds.

Abrasive compounds. Stainless steel contains microscopic carbide and intermetallic compounds. Increased hardness makes them like an abrasive. The cutters are worn down and require constant editing and sharpening. Friction during turning of stainless steel is an order of magnitude greater than during turning of carbon alloys.

Uneven hardening. During the turning process, the material is hardened unevenly. This is not very important when processing small parts. But it will seriously affect the quality of the shaft or other large part.

Grinding and polishing process

The presented alloy is used not only for the production of various parts, but also for the manufacture of decorative items. To ensure a beautiful appearance of stainless steel surfaces, a procedure of grinding and polishing is carried out.

Grinding

This process allows you to eliminate or reduce the severity of defects on the surface layer of the material. It is performed manually or using automated machines (if a large amount of work needs to be done). The most commonly used machines are:

- belt pneumatic file;

- devices on which sanding belts are attached;

- drum-tape machine.

At home, stainless steel is polished using abrasive sheets. All work is carried out in the following sequence:

- removal of welds and burns;

- limiting the treated area of metal using aluminum tape (2-3 layers);

- carrying out translational and reciprocal movements using hand tools, while it is necessary to control the pressure on stainless steel;

- removing the aluminum tape and sanding subsequent areas of the product.

To avoid damaging the material when grinding stainless steel, you must first select the grain size of the abrasive belt. For this purpose, rough metal blanks are used. Products are also processed using a petal wheel.

Polishing

Polishing stainless steel gives it a metallic shine and makes it look attractive. This procedure is also performed manually or on automatic machines. Chemical, electrical and plasma polishing is also used. At home, mechanical methods are more common.

Polishing stainless steel is the final stage of working with the presented material, giving it a marketable appearance. It is done in production or at home using a felt wheel.

Polishing stainless steel - variations

Features of turning corrosion-resistant steel

Corrosion-resistant steel is indispensable in the construction of mechanisms and products, as well as in the construction of structures that are subject to heavy loads and aggressive environments. But processing stainless steel, whether mechanical or turning, is a process with some difficulties. It is impossible to completely transfer the processing methods of ordinary carbon steel to grades of corrosion-resistant metals. This will reduce the productivity of the process and deteriorate the quality of the product in the end.

The main difficulties in working with stainless steel wheels are difficulties in removing chips, hardening from deformation, and reduced capabilities of cutting tools. If earlier these problems could be partly solved by cutting at low speed, today such a solution does not suit modern production. For this reason, engineers are tirelessly developing new technologies and tools that could make it easier to process corrosion-resistant steels.

How to Remove Stainless Steel Chips

As a result of turning, long, twisted chips will be created. Its accumulation complicates the process. To remove stainless steel chips, you can use a cutting tool that provides an internal coolant supply under pressure, which is effective, especially for high-alloy steels. Using this tool it is possible to achieve:

- effective cooling of the cutting edge;

- breaking the chips into small pieces, which at the exit facilitates its rapid removal from the cutting area.

The disadvantage of this method is the high consumption of cooling liquid. Carbon dioxide cooling will be the most expensive and effective. This option is used in high-precision production and the military industry. The chipbreaker device is important in turning stainless steel. A specially designed tool for corrosion-resistant steels must have a positive outer angle, which reduces self-hardening and steel build-up on the cutting edge.

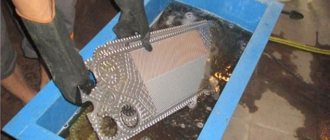

Etching – perfectly hides marks after welding stainless steel

The etching procedure for stainless steel is also performed quite often. It is used after heat treatment, cold and hot deformation of steel. This operation removes defects formed on the surface of stainless steel during various types of heat treatment and the use of a welding machine. Etching removes traces of scale and tarnish. In addition, it helps to renew the passive layer on steel products, which protects the metal from the negative effects of elevated temperatures.

In industrial conditions, etching is carried out using molten alkaline compounds or solutions of (aqueous) acids without or with electrolysis. If acid is used, the operation is performed in two stages. First, the stainless steel is placed in a bath with a sulfuric acid solution, then in a nitric acid solution. Alkaline etching involves treating steel with molten caustic soda. It does not change the structure of the metal and at the same time perfectly destroys the oxide film on its surface.

In everyday life and in small private workshops, etching is performed using special paste-like compositions. The procedure can be carried out even by an untrained person. Etching paste is a jelly-like transparent liquid. It is made from hydrofluoric and nitric acid. Such compositions do not contain potentially unsafe hydrochloric acid and chlorides harmful to human health.

Stainless steel pickling paste

The etching paste is applied to the cleaned product (it should be washed and thoroughly degreased with any suitable means) and left on the surface for a certain time (it is indicated on the packaging). In most cases, stainless steel processing occurs within 10–60 minutes. After this, the etching paste is washed off. For these purposes, use a large amount of ordinary water.

Etching paste is manufactured by different companies. The following compositions are popular in the domestic market:

- SAROX TS-K 2000 is a paste that can be used on any stainless steel surfaces (including vertical ones). It guarantees an attractive appearance of the weld and reliable protection of the metal from temperature influences. This etching paste cleans stainless steel in just 10 minutes.

- Avesta BlueOne is a composition for effectively restoring stainless surfaces, removing traces of corrosion and welding from them, and adding shine to products. Treatment of steel with this paste should last about 45 minutes. In this case, the ambient temperature cannot be less than +5°.

- Stain Clean from ESAB is a paste with an excellent etching effect. It does not require any preparation; the composition is ready for use straight from the bottle.

Important! Any paste is applied to a previously cleaned surface using an acid-resistant brush and a plastic spatula.

How to sharpen stainless steel

25 minutes ago, xoxol said:

this is coolterribly expensive and rare alloy

in 1989, one solder cost 980 rubles (minus twenty for an IZH-Planet Sport motorcycle)

Absolutely right!

For the defense industry in the USSR, nothing was expensive and nothing was a pity either!

And at our factory we used to have a lot of cutters with such soldering!

The tool shop made a lot of them!

Simple cutters, but with VRK15 - through, thrust, cutting - our procurement shop consumed a lot of them, 40-60 pieces per month - all of each size and type came out.

Now they make much fewer of them, because almost all operations of the procurement shop have been transferred to imported plates, as have all CNC machines in the main production shops.

But somehow I had to sharpen the stainless steel for impact and I decided to install a Sandvik plate and I was convinced that it works much better than even the VRK15!

I was convinced of this myself!

But our turners on universal machines with imported plates and tool holders somehow don’t really want to work with them.

I tell them - take imported plates and holders!

Answer - It will break or be stolen (yes, this happens) and you will deduct them from me!

Because behind the floor of holders and plates - they can and do deduct money from them, because they are an imported product and are sold as an expensive tool , but they do not have their own factory production for cutters, as well as for domestic cutters!

And also because they remember Soviet cutting holders with plates!

As for the Soviet prefabricated cutters with replaceable carbide plates, I can say about this that all the old turners from my factory rate them extremely low and simply spit about them when they hear about them! Indeed, as part of “rationalization” and “savings”, every 5-7 years companies began to widely introduce progressive metal-cutting tools. Those same Soviet prefabricated cutters and milling cutters with replaceable carbide plates. Which however did not work normally! And indeed they were only suitable for peeling and preparation work!

I used to have Soviet prefabricated cutters with replaceable carbide inserts lying around in my workshop - quite a lot and no one wanted to take them! And even then, the procurement shop of our plant until the mid-2000s required brazed metal-cutting tools, including the work of our own tool shop from that same VRK15. For roughing and preparation work! And I tried my best to push away from Soviet prefabricated cutters and milling cutters with replaceable carbide plates with my hands and feet.

On 12/24/2020 at 10:24 am, hiro said:

I use replaceable inserts CCMT09, made by KORLOY PC9030, they cut great, the chips crumble like seeds.

In fact, your video posted here about turning stainless steel with plates from KORLOY confirms all this.

I don’t know how long I would sharpen such stainless steel pancakes!

At least with cutters from VRK15!

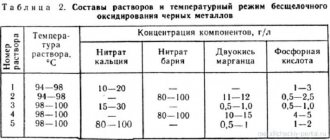

Metal bluing

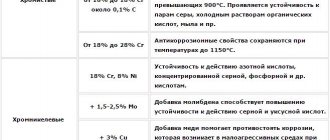

Metal bluing can be done not only in production, but also at home. In this case, the part changes its shade. The presented procedure ensures a beautiful appearance of the product and also improves its anti-corrosion properties. During bluing, the surface of stainless steel is covered with a very thin protective layer. There are several ways to process the material:

Metal bluing

- Alkaline. The process requires an alkaline solution containing an oxidation catalyst. Moreover, the processing is carried out at high temperatures: up to 150 degrees.

- Thermal. Here you need an appropriate environment and elevated temperature: a superheated atmosphere, an ammonia-alcohol solution in a vapor state (but a small layer of varnish is first applied to the surface).

- Acidic. A physicochemical or electrochemical method is needed here.

To make the stainless steel surface smooth and shiny, bluing is carried out in oil. When using chemicals, oxides or the metal itself act as surface dyes. This operation involves the interaction of stainless steel with liquid solutions of metal salts.

Metal bluing agent

With this method, the most dense and close merging of the surface of the product with the paint film occurs. The composition used for bluing contains different components and consistency. It also has a different texture.

You can carry out the procedure at home, but its quality will not be as good as the factory one. It uses saltpeter, citric or phosphoric acid. In any case, the procedure must be approached responsibly and carefully.

This is interesting: Carbon structural steels: classification, properties, application

Cutting tool for turning stainless steel

The main working part of lathes is a cutter; in addition, drills, countersinks, reamers, and dies can be used.

Turning cutters are distinguished by purpose:

- Pass-through - straight and bent. Used to produce cylindrical surfaces.

- Scoring – for processing ends.

- Boring – to obtain a hole of the required diameter.

- Cutting - used for cutting stainless steel workpieces into dimensional pieces.

- Thread-cutting machines – for producing internal and external threads.

- Shaped – for processing shaped surfaces.

To work with corrosion-resistant steels, as well as hard metals such as titanium and its alloys, not only solid, but also composite cutters are used. One of the materials in demand for the manufacture of inserts for cutters is CBN - an artificial alternative to diamond, which is cubic boron crystals. Such cutters are usually used on hardened steels. The effect of their use can be obtained only in the absence of vibrations and beating.

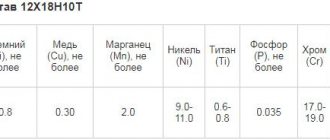

Also, in the manufacture of cutting inserts for working on stainless steel, the following types of hard alloys are used:

- “wear-resistant” – T30K4, T15K6;

- more viscous, but less wear-resistant - T5K7, T5K10;

- having significant viscosity and insensitivity to impacts - VK8, VK6A.

For finishing and finishing processing, mineral ceramics are used.

Stainless steel processing process

Processing stainless steel is a difficult process. To make certain objects or parts, it must be cut, bent, and passed through a lathe. During processing of the material, it is necessary to monitor strain hardening, try to quickly remove chips, and take into account the service life of the tools used in the process. Processing stainless steel is a precise process during which certain rules and sequences of actions must be followed. There are other challenges when working with stainless steel.

Viscosity of the material. It is quite plastic, so the chips curl into a spiral of considerable length during cutting.

Low level of thermal conductivity. While this property is an advantage in use, it only gets in the way when processing stainless steel. During cutting, you have to cool the product with special liquids to avoid hardening and heat. Alloy particles remain on the tools, quickly rendering them unusable.

Saving properties. Turning of stainless steel is not accompanied by some loss of strength and hardness due to exposure to high temperatures. Such qualities are inherent in heat-resistant materials. This leads to breakdown of working equipment.

Presence of abrasive compounds. Stainless steel contains microscopic compounds of carbide and intermetals. They impart abrasive properties to the alloy, which damage the cutters.

Uneven hardening . This quality is very difficult when making large parts. They become less quality.

Types of stainless steel processing

The most modern type of cutting workpieces is laser cutting. A thin laser beam heats the surface of the metal and cuts it. The technology is suitable not only for stainless steel, but also for other metals, regardless of their physical properties. The method ensures a low percentage of defects, since only thermal effects are used and do not harm the stainless steel.

Waterjet method

Waterjet cutting uses high pressure water with abrasive substances in it. The technology is based on the separation of metal particles under a large flow of solids. Metal cutting process:

- Water supply to a large tank.

- Mixing water and abrasive, sand is most often used.

- Supplying the solution to the nozzle.

- Exposure of metal sheets to water.

Waterjet metal processing method

Stamping

Cold forming is the processing of stainless steel using dies. Allows you to get identical products. With this method it is possible:

- punch holes in stainless steel;

- make a carving;

- bend the parts;

- make an engraving.

Punching machines are capable of producing metal structures of any shape: shop windows, gratings, fences, shelving, advertising stands, furniture.

Stamping in a single-strand closed die

Turning method

Turning stainless steel allows you to obtain workpieces of complex shapes. You can install special devices on a lathe that give the desired result:

- drill;

- cutters;

- incisors;

- dies.

The forward movement of the cutters along the stainless steel cuts the sheet into the desired shapes. This work is carried out under the supervision of a master, who takes into account the technical specifications, size and shape of the workpiece.

Milling

Milling of stainless steel produces gears, complex holes and recesses. A rotating cutter performs work on a fixed part. Milling machines are controlled by a person or CNC.

Up and down milling relative to the part

Locksmith work

Metalworking is not the last place in metal processing. They are performed manually or using machines and metalworking tools. During this work, the workpieces are combined into a single mechanism. Work process:

- Marking of metal structures. Produced on a plane or in three-dimensional space.

- Removing metal residues from workpieces.

- Editing and bending structures to give the desired shape.

- Scraping is a polishing method for better fit of structural parts.

- Drilling and tapping.

- Connecting all the parts.

- Soldering or applying welded joints.

Sanding and polishing (satinizing)

Thanks to a whole list of advantages, stainless steel is equally successfully used for the manufacture of products for both practical and purely decorative purposes. To give their surface an attractive appearance, as well as to achieve the required level of roughness, they are often subjected to grinding and polishing, which are referred to by one general term - satin. These processing methods received this name due to the fact that after their implementation, the surface of the stainless steel resembles satin or satin fabric in its texture.

Processing a weld seam on a stainless steel begins with removing the surface to small scratches using a grinder with a flap wheel

In addition to giving the surface of a stainless steel product an attractive appearance, grinding can eliminate surface defects in the metal or make them almost invisible. Both grinding and polishing of stainless steel can be done manually or using special devices powered by an electric or pneumatic drive. The most common devices used for grinding include:

- belt type pneumatic file;

- drum-belt type sander;

- other devices that require the use of sanding belts.

At home, sanding is most often done by hand, which may require sanding sheets or tools called sanders. Unlike the conditions of home workshops, in manufacturing enterprises, stainless steel grinding is carried out using special equipment.

Stainless steel grinding begins with grit 180, then 320 and 600, and ends with polishing with a felt wheel.

When hand grinding tools are used to grind stainless steel, the processing is performed in the following sequence.

- If stainless steel parts were connected by welding, then burn marks and weld seams are removed from their surface.

- The part of the surface that will be sanded first should be limited using adhesive aluminum tape (it is glued in two or three layers).

- The area of the surface that is not sealed with protective tape is processed using a reciprocating grinding motion, and the pressure exerted on the tool should not be too strong.

- After achieving the required grinding result, the already processed part is sealed with aluminum tape, and the area that borders it is subjected to processing.

In cases where the use of grinding is impractical, grinding sheets are used to process stainless steel. To correctly select such a grinding tool based on its grain size, use trial rough parts.

For grinding and polishing stainless steel, lathes on which special wheels are installed can also be used. You can perform such finishing operations using a lathe both in production and at home, if such equipment is available in your home workshop. To effectively perform these technological operations, even the simplest models of lathes can be used.

» data-lazy-type=»iframe» src=»data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7″>

Processing stainless steel on a lathe

Work processes in modern installations and assemblies take place under significant loads on all structural elements. The operation of parts at high speeds, pressure and temperatures leads to the fact that elements made of conventional structural steels quickly fail.

To work in such conditions, special alloys are required, which include stainless steel. High strength, heat resistance and good anti-corrosion properties are the main characteristics of stainless steel.

However, these properties of alloys also have negative sides: the strength characteristics of stainless steel do not change under the influence of pressure and temperature, which entails the complexity of machining.

Self-hardening of stainless steel and selection of cutting tools

Self-strengthening is the most important characteristic of stainless steel, which can cause additional difficulties during processing. The more the material is hardened, the faster the tool wears out. When using special cutting inserts, this problem is not so pronounced: their working edges are sharper than usual, and the surfaces wear out longer.

The impact of self-hardening can be minimized by gradually removing layers of metal. The most effective way is to remove 3 mm of steel in two steps. Experts often recommend removing unequal layers in the first and second approaches.

As mentioned above, self-hardening leads to rapid wear of the cutters. In order to increase the service life of tools, special edge shapes for stainless steel are being developed. Two types of cutting tools are used:

- cutters with CVD coated diamond;

- cutters with an edge coated with physically cooled diamond (PVD) diamond.

Carbide cutters with plates coated with boron nitrite have the highest wear resistance.

The cutting speed of stainless steel is set using the same method as when processing conventional structural alloys. However, when making calculations, it is necessary to take into account a number of features of stainless steel processing.

Ways to optimize the stainless steel processing process

In production conditions, a number of techniques are used to minimize the negative impact of the characteristics of stainless steel on the process of its processing. This:

- increasing the spindle rotation speed and reducing the layer removed, making the treated surface more rough;

- the use of acid as a lubricant, which increases the wear resistance of the cutters by an order of magnitude;

- introduction of weak currents into the processing zone, which will allow controlling the processes of electrodiffusion and oxidative wear of the tool;

- exposure of the cutting zone to ultrasonic vibrations, which reduces plastic deformation and the coefficient of friction.

The structure and mechanical characteristics of the material can be influenced using special heat treatment.

Source: https://m-ser.ru/articles/tokarnaya-obrabotka-nerzhaveyushchey-stali/

Features of grinding and polishing

The final processing of the metal is grinding the surface to a smooth state. It is necessary to give the product an attractive appearance, since stainless steel structures often perform decorative functions. Mechanical polishing makes processing defects invisible to the consumer. Performed manually and using electric or pneumatic tools.

Ways to improve chip removal

Turning is a process that produces long, twisted chips, the accumulation of which makes work difficult. To remove chips from stainless steels, it is proposed to use a cutting tool with an internal coolant supply under pressure, which is especially effective for high-alloy steels. The use of such a tool provides:

- effective cooling of the cutting edge;

- breaking chips into small particles, facilitating their rapid removal from the cutting area.

The disadvantage of this method is the high consumption of coolant. In high-precision production and in the military industry, the most expensive and effective method is used - cooling using carbon dioxide.

Read also: DIY plywood door photo

The design of the chipbreaker plays an important role in processing stainless steel on a lathe. Specialized tools for corrosion-resistant steels must have a positive outer angle, which reduces self-hardening and metal build-up on the cutting edge.

Why contact us

We treat all clients with respect and carry out tasks of any size equally scrupulously.

Our production facilities allow us to process various materials:

- non-ferrous metals;

- cast iron;

- stainless steel.

When completing an order, our specialists use all known methods of metal machining. Modern equipment of the latest generation makes it possible to achieve maximum compliance with the original drawings.

The advantage of contacting our specialists is compliance with GOST and all technological standards. Strict quality control is carried out at every stage of work, so we guarantee our customers a conscientiously completed product.

Thanks to the experience of our craftsmen, the output is an exemplary product that meets the most demanding requirements. At the same time, we start from a strong material base and focus on innovative technological developments.

We work with customers from all regions of Russia. If you want to place an order for metalworking, our managers are ready to listen to all the conditions. If necessary, the client is provided with free specialized consultation.

Articles on topics: Metal products, Metalworking, Welding, Laser cutting, Metal structures, Plasma cutting, Metal bending, Cabinets, Properties of metals, Mechanical processing, Painting

Satin finishing is... What is Satin finishing?

Satin finishing is a decorative treatment of metal by mechanical, chemical or electrochemical methods to obtain a semi-shiny surface from micro-irregularities. Encyclopedic dictionary of metallurgy. - M.: Intermet Engineering. Editor-in-Chief N.P. Lyakishev. 2000.

Synonyms:

- satin finishing

- weldability

See what “Satinizing” is in other dictionaries:

- satin - calendering, satin Dictionary of Russian synonyms. satin noun, number of synonyms: 2 • calendering (6) • ... Dictionary of synonyms

- satin - I, cf. satiner, German satinieren. Action by sign. verb satin. BAS 1. Lex. Toll 1864: satin; BAS 1: satining ... Historical Dictionary of Gallicisms of the Russian Language

- SATINING - adding shine and gloss to paper, cat. for this purpose they are placed between polished. zinc boards and passed between rollers. Dictionary of foreign words included in the Russian language. Pavlenkov F., 1907 ... Dictionary of foreign words of the Russian language

- satin finishing - Decorative processing of the base metal and (or) coating by mechanical, chemical or electrochemical methods to obtain a semi-shiny surface due to micro-irregularities. Metal coating topics. and non-metal... Technical Translator's Guide

- Satining - (from the French satin satin) is the same as calendering. See also: Paper glazing ... Advertising and printing

- satin finishing atitikmenys: engl. satin finishing rus. satin ... Chemijos terminų aiškinamasis žodynas

- Satin coating - in wallpaper production, see Wallpaper production... Encyclopedic Dictionary F.A. Brockhaus and I.A. Efron

- Satin - cf. process of action on ness. Ch. satin Efremova's Explanatory Dictionary. T. F. Efremova. 2000 ... Modern explanatory dictionary of the Russian language by Efremova

- satinization - satinization, I ... Russian spelling dictionary

- NDP. Satinizing paper (cardboard) - 40. Polishing paper (cardboard) Giving paper (cardboard) a gloss using a friction or polishing calender, machine or cylinder of a paper (cardboard) machine Source: GOST production*: Production of paper and cardboard. Terms and... Dictionary-reference book of terms of normative and technical documentation

Electrochemical (galvanic) etching

To carry it out, it is necessary to perform a number of procedures.

Preparation of the solution . Prepare an aqueous solution of the acid chosen for etching. It is necessary to carefully calculate its percentage.

Surface preparation. It is necessary to perform degreasing using any method so that the protective varnish adheres well to the stainless steel. After processing, it is not recommended to touch the workpiece so as not to cause peeling of the varnish and, as a result, uneven surface treatment.

Creation of a protective layer . It is necessary to apply a protective layer to areas that do not need etching. In industry, special compounds are used for this, which can also be used for home processing (subject to safety precautions). You can also cook a protective varnish at home, consisting of tar and rosin dissolved in turpentine.

Etching . When carrying out electrochemical etching of stainless steel, the workpiece is lowered into a previously prepared solution, after which voltage is applied to the created electrical circuit. In this circuit, the anode is a workpiece with a connected positive electrode; any steel plate is used as a cathode.

The duration is determined by the type of part, carefully observing the condition of the workpiece, but not more than a few minutes. After this, turn off the voltage, remove the etched part from the solution and carefully neutralize the acid using reagents.

Cleaning stainless steel . Clean stainless steel from residual solutions using special means that do not affect the characteristics of the metal.

Equipment for working with corrosion-resistant steels

Lathes on which it is planned to cut stainless steel workpieces are subject to a set of requirements, such as:

- increased rigidity of the mechanisms, allowing them to absorb high cutting forces;

- high resistance to vibration of the “machine – cutting tool – workpiece” system under significant shock loads;

- machine power reserve to ensure significant feed.

CNC machines provide the greatest dimensional accuracy and minimal roughness; they are especially effective when processing workpieces with a complex surface with curved generatrices.

Modern technological methods used when processing stainless steel on lathes include the introduction into the cutting zone:

- ultrasonic vibrations that reduce friction;

- weak currents, allowing to reduce electrodiffusion and oxidative wear of the tool.