04.09.2020 Author: VT-METALL

Issues discussed in the material:

- Description of structural steel

- Classification of structural steels

- Areas of application of structural steel

- Advantages and disadvantages of structural steels

- How to choose structural steel by its markings

Structural steel is in great demand today. It is indispensable in the manufacture of industrial mechanisms and the construction of building structures, as it has high strength, ductility and resistance to destruction.

This material is also used in other areas of human activity. For example, it is used to produce parts for various types of machine tools, hot-rolled ordinary products, springs, leaf springs, small fasteners and much more. However, when choosing structural steel, keep in mind that it comes in different types, each with its own physical and chemical characteristics.

Description of structural steel

Structures and mechanisms used in industry or construction must meet increased strength requirements. For their manufacture, a material with special technological qualities is used. The use of metal with the required properties is the basis for the safe operation of the entire structure in a variety of conditions. Depending on the chemical, physical and mechanical characteristics, such a material may be structural steel.

The key feature of this metal is its ability to withstand constant and variable loads. Often it is also expected to have wear resistance or anti-corrosion properties. Sometimes the requirements are met by ordinary carbon structural steel. But in some cases, its qualities need to be supplemented or enhanced by doping with special chemical elements.

We recommend articles on metalworking

- Steel grades: classification and interpretation

- Aluminum grades and areas of their application

- Defects in metal products: causes and search methods

The structure of steels of this type includes such useful additives as iron, silicon, copper, manganese and other substances, but carbon plays the main role in them. It is this that gives the structural metal key properties and determines the degree of its strength. The concentration of this element determines the object’s resistance to cold brittleness, its ability to withstand production loads and withstand various weather conditions.

Structural steel is divided into several classes depending on the level of harmful impurities in them - sulfur and phosphorus. The higher it is, the lower the threshold of cold brittleness and red brittleness of the material.

There is a classification based on the concentration in S and P alloys:

- less than 0.05% is structural steel of ordinary quality;

- less than 0.035% – high-quality structural steel;

- less than 0.025% – high-quality steel;

- less than 0.015% – especially high-quality steels.

Definition

Steel is an alloy consisting of iron and carbon. The quality of a material means a combination of properties that depend on production technology, forming its chemical composition, homogeneity of structure, mechanical properties and manufacturability. The term construction applies to structural low-carbon, low-alloy or unalloyed steel, which is used for the construction of metal structures by welding, riveting and other connections.

When constructing objects that require special strength, so-called alloy steels can be used; chemical elements are added to their composition to increase the physical properties of the material.

The main requirements for construction steel are standard strength parameters, good weldability, and significant ductility. The carbon content has a huge impact on the properties of the material. Its increased concentration in the alloy composition affects brittleness and deterioration of weldability. But along with this, properties such as yield strength and temporary resistance increase.

Of no small importance is the presence of harmful natural impurities in the compound (phosphorus, sulfur and others), which seriously affect the quality of the final product.

Classifications of structural steels

There are other ways to classify steels of this type. If we take Russian brands as a basis, we can highlight:

- Unalloyed carbon steels produced in accordance with GOST 1050.

- Low-alloy structural steels with the addition of carbon, manufactured in accordance with GOST 5058 - this type of material is in demand in construction.

- Medium alloy steels regulated by GOST 4543.

- High-quality spring steel, the requirements for which are reflected in GOST 14959.

- Special structural steels - this group includes high-alloy steels with anti-corrosion properties and special characteristics. The guidelines for their production, as a rule, are determined by the specifications of the manufacturing companies. The chemical composition of such materials often allows them to be classified as iron-based alloys rather than steels.

The key feature that allows us to classify steel as a structural type is the proportion of carbon in the composition of the finished alloy. But its definition is not so simple: if the minimum concentration of a given substance in a product is clearly indicated and is 0.05%, then the maximum is a “floating” value and varies between 0.7% and 0.85%. It is worth noting that in some cases the same proportion of carbon in the metal is characteristic of tool steels.

Selecting a grade of construction steel

All types of metal building structures are divided, according to current norms and regulations, into nine groups (SNiP 1I-B.3-72). Each group is formed based on operating conditions, installation and type of connection of elements. Therefore, metal alloy grades are chosen based on the following important factors:

- minimum temperature conditions for the operation of the structure;

- dynamic and vibration loads.

SNiP allows the use of several grades of steel for each group of structures. Typically, elements made from boiling steel are not recommended for use in the construction of structures that experience severe dynamic loads and are operated in low temperature conditions. The presence of gas bubbles formed during the production of the alloy concentrates the stress. For such structures, the calmer look of steel, more fully deoxidized, is suitable, but its cost is more expensive. The golden mean is occupied by semi-quiet steel.

The production technology of steel used in construction is constantly being improved, increasing its quality and characteristics, which ensures the strength and reliability of any of the most complex structures.

- Wall kit

Areas of application of structural steel

Structural steels enriched with carbon can rightfully be considered a universal material - their scope of application extends from the production of building structures and mechanisms to parts of equipment and machines. This versatility of this type of alloy is due to the complex of its qualitative characteristics.

The use of alloyed structural steels is of great importance in the field of mechanical engineering, construction, and also in production work. The fact is that they have unique chemical, physical and mechanical properties. These characteristics of the material are determined by the content of a particular substance in the alloy.

The properties of low-alloy structural steel make it possible to use the material for the production of locomotives and cars for railway transport, trams or subways, the manufacture of field and agricultural equipment, the construction of engineering structures and structures - in short, in conditions of increased instability of loads and temperatures.

Heat-resistant steel can withstand up to +6,000 °C. Therefore, it is used to make elements of devices that operate for a long time, as well as parts subject to constant loads and high thermal effects.

Bearing structural steel is used to make elements subject to variable point loads - these are the places where balls, rollers and ring raceways come into contact in mechanisms of the same name.

Spring or spring-spring steel is used for the manufacture of springs, springs, bellows, etc.

Large batches of small parts and fasteners are produced from automatic steel using automatic machines.

Classification of steel by purpose

According to their purpose, steels and alloys are classified into structural, tool and steels with special physical and chemical properties.

Structural steels

Structural steels are usually divided into construction steels, cold forming steels, cemented steels, improveable steels, high-strength steels, spring steels, ball bearing steels, automatic steels, corrosion-resistant steels, heat-resistant steels, heat-resistant steels, and wear-resistant steels.

Construction steels

Construction steels include carbon steels of ordinary quality, as well as low-alloy steels. The main requirement for construction steels is their good weldability. For example: S255, S345T, S390K, S440D.

Cold forming steels

For cold stamping, rolled sheets of low-carbon high-quality steel grades 08Yu, 08ps and 08kp are used.

Case-hardened steels

Case-hardened steels are used for the manufacture of parts that operate under conditions of surface wear and experience dynamic loads. Cementable steels include low-carbon steels containing 0.1-0.3% carbon (such as 15, 20, 25), as well as some alloy steels (15Х, 20Х, 15ХФ, 20ХН 12ХНЗА, 18Х2Н4ВА, 18Х2Н4МА, 18ХГТ, ЗОХГТ, 20ХГР).

Improved steels

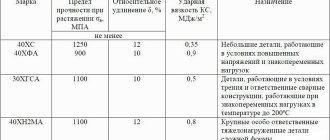

Improved steels include steels that are subjected to improvement - heat treatment, which consists of hardening and high tempering. These include medium-carbon steels (35, 40, 45, 50), chromium steels (40Х, 45Х, 50Х), chromium steels with boron (ZOXRA, 40ХР), chromium-nickel, chromium-silicon-manganese, chromium-nickel-molybdenum steels.

High strength steels

High-strength steels are steels in which, by selecting the chemical composition and heat treatment, a tensile strength approximately twice that of conventional structural steels is achieved. This level of strength can be obtained in medium-carbon alloy steels - such as ZOKHGSN2A, 40KHN2MA, ZOKHGSA, 38KHNZMA, OZN18K9M5T, 04KHIN9M2D2TYU.

Spring steels

Spring (spring) steels retain elastic properties for a long time, since they have a high elastic limit, high resistance to fracture and fatigue. Spring steels include carbon steels (65, 70) and steels alloyed with elements that increase the elastic limit - silicon, manganese, chromium, tungsten, vanadium, boron (60S2, 50KhGS, 60S2KhFA, 55KhGR).

Bearing steels

Bearing (ball bearing) steels have high strength, wear resistance, and endurance. Bearings are subject to increased requirements for the absence of various inclusions, macro- and microporosity. Typically, ball bearing steels are characterized by a high carbon content (about 1%) and the presence of chromium (ShKh9, ShKh15).

Automatic steels

Automatic steels are used for the manufacture of non-critical mass-produced parts (screws, bolts, nuts, etc.) > processed on automatic machines. An effective metallurgical technique for increasing cutting machinability is the introduction of sulfur, selenium, tellurium, and lead into steel, which promotes the formation of short and brittle chips and also reduces friction between the cutter and the chips. The disadvantage of free-flowing steels is reduced ductility. Automatic steels include steels such as A12, A20, AZO, A40G, AS11, AS40, ATs45G2, ASTSZOKHM, AS20KhGNM.

Wear-resistant steels

Wear-resistant steels are used for parts operating under conditions of abrasive friction, high pressure and impacts (crossings of railway tracks, track tracks of tracked vehicles, jaws of crushers, scoops of earth-moving machines, excavator buckets, etc.) - An example of wear-resistant steel is high-manganese steel 110G13L.

Corrosion-resistant (stainless) steels

Corrosion-resistant (stainless) steels are alloy steels with a high content of chromium (at least 12%) and nickel. Chromium forms a protective (passive) oxide film on the surface of the product. Carbon is an undesirable element in stainless steels, and the more chromium, the greater the corrosion resistance. The structure for the most typical alloys for this purpose can be:

- ferritic-carbide and martensitic (12X13, 20X13, 20X17N2, 30X13, 40X13, 95X18 - for mildly aggressive environments (air, water, steam);

- ferritic (15X28) - for solutions of nitric and phosphoric acids;

- austenitic (12Х18НУТ) - in sea water, organic and nitric acids, weak alkalis;

- maraging-aging (YUKh17N13MZT, 09Kh15N8Yu) - in phosphoric, acetic and lactic acids.

Alloy 06KhN28MT can be used in conditions of hot (up to 60°C) phosphoric and sulfuric (concentrations up to 20%) acids. Corrosion-resistant steels and alloys are classified depending on the aggressiveness of the environment in which they are used and according to their main consumer properties into corrosion-resistant, heat-resistant, heat-resistant and cryogenic.

Corrosion-resistant steels

Products made from corrosion-resistant steels (turbine blades, hydraulic press valves, springs, carburetor needles, discs, shafts, pipes, etc.) operate at operating temperatures up to 550°C.

Heat-resistant steels

Heat-resistant steels are capable of operating under load at high temperatures for a certain time and at the same time have sufficient heat resistance. These steels and alloys are used for the manufacture of pipes, valves, steam and gas turbine parts (rotors, blades, disks, etc.). For heat-resistant and heat-resistant engineering steels, low-carbon steels (0.1-0.45% C) and high-alloy steels (Si, Cr, Ni, Co, etc.) are used. Heat-resistant steels and alloys necessarily contain nickel in their composition, which provides a significant increase in the limit of long-term corrosion strength with a slight increase in the yield strength and tensile strength, and manganese. They can be additionally alloyed with molybdenum, tungsten, niobium, titanium, boron, iodine, etc. Thus, microalloying with boron, as well as rare earth and some alkaline earth metals, increases characteristics such as torsional speed, ductility and toughness at high temperatures. The operating temperatures of modern heat-resistant alloys are approximately 45-80% of the melting point. These steels are classified according to operating temperature (GOST 20072-74): at 400-550°C - 15ХМ, 12Х1МФ, 25Х2М1Ф, 20ХЗМВФ; at 500-600°C - 15Х5М, 40ХУС2М, 20Х13; at 600-650°C - 12Х18Н9Т, 45Х14Н14В2М, УХЦН23ТЗМР, ХН60У, ХН70У, ХН77ТУР, ХН56ВМКУ, ХН62МВКУ.

Heat-resistant steels

Heat-resistant (scale-resistant) steels are resistant to chemical destruction of the surface in gas environments, including sulfur-containing ones, at temperatures of +550-1200°C in air, furnace gases (15X5, 15X6SM, 40X9S2, ZOKH13N7S2, 12X17, 15X28), oxidizing and carburizing environments (20Х20Н14С2, 20Х23Н18) and operate in an unloaded or lightly loaded state, as they can exhibit creep when large loads are applied. Heat-resistant steels are characterized by the temperature at which intense oxidation begins. The magnitude of this temperature is determined by the chromium content in the alloy. Yes, at . 15% Cr, the operating temperature of products is +950°C, and at 25% Cr up to +130CGS. Heat-resistant steels are also alloyed with nickel, silicon, and aluminum.

Cryogenic steels

Cryogenic engineering steels and alloys (GOST 5632-72) in terms of chemical composition are low-carbon (0.10% C) and high-alloy (Cr, N1, Mn, etc.) steels of the austenitic class (08Х18НУ, 12Х18НУТ, OZH20N16AG6, OZH13AP9, etc.) . The main consumer properties of these steels are ductility and toughness, which either do not change or decrease slightly with decreasing temperature (from +20 to -196°C), i.e. There is no sharp decrease in viscosity, characteristic of cold brittleness. Cryogenic engineering steels are classified according to operating temperature in the range from -196 to -296°C and are used for the manufacture of cryogenic equipment parts.

Tool steels

According to their intended purpose, tool steels are divided into steels for cutting and measuring instruments, and die steels.

Steels for cutting tools

Steels for cutting tools must be able to maintain high hardness and cutting ability for a long time, including when heated. Carbon, alloy tool, and high-speed steels are used as steels for cutting tools.

Carbon tool steels

Carbon tool steels contain 0.65-1.32% carbon. For example, steel grades U7, U7A, U13, U13A. This group, in addition to unalloyed carbon tool steels, also conventionally includes steels with a small content of alloying elements, which are not very different from carbon steels.

Alloy tool steels

This group of steels includes steels containing alloying elements in an amount of 1-3%. Alloy tool steels have increased (compared to carbon tool steels) heat resistance - up to +300°C. The most widely used steels are 9ХС (drills, cutters, countersinks), KhVG (broaches, reamers), KhVGS (mills, countersinks, large-diameter drills).

High speed steels

High-speed steels are used for the manufacture of various cutting tools operating at high cutting speeds, as they have high heat resistance - up to +650°C. The most widely used high-speed steel grades are R9, R18, R6M5, R9F5, RYUK5F5.

Steels for measuring instruments

Tool steels for measuring instruments (plates, gauges, templates), in addition to hardness and wear resistance, must maintain dimensional stability and be well ground. Typically, U8...U12, X, 12X1, KhVG, Kh12F1 steels are used. Measuring brackets, scales, rulers and other flat and long instruments are made from sheet steel 15, 15X. To obtain a working surface with high hardness and wear resistance, tools are subjected to carburization and hardening.

Die steels

Die steels have high hardness and wear resistance, hardenability and heat resistance.

Steels for cold forming dies

These steels must have high hardness, wear resistance and strength, combined with sufficient toughness, and must also be heat resistant. For example Х12Ф1, Х12М, Х6ВФ, 6Х5ВЗМФС, 7ХГ2ВМ. In many cases, high-speed steels are used to make cold-forming dies.

Steels for hot forming dies

These steels must have high mechanical properties (strength and toughness) at elevated temperatures and have wear resistance, scale resistance, heat resistance and high thermal conductivity. Examples of such steels are steels 5ХНМ, 5ХНВ, 4ХЗВМФ, 4Х5В2ФС, ЗХ2В8Ф, 4Х2В5МФ.

Roll steels

These steels are used for work, support and other rolls of rolling mills, bandages of composite support rolls, knives for cold cutting of metal, trimming dies and punches. Roll steels include steel grades such as 90ХФ, 9Х1, 55Х, 60ХН, 7Х2СМФ.

Advantages and disadvantages of structural steels

The advantages of structural steel are revealed only after heat treatment of products made from this alloy, so they are necessarily exposed to temperature. The main advantages of this procedure:

- After quenching and tempering of a part made of structural steel, its ability to resist plastic deformation is enhanced and even surpasses carbon alloys in this (at the same carbon concentration).

- Under the same conditions, structural metal is calcined more strongly than carbon metal. Therefore, it is better to make external elements of large thickness from alloyed structural steel. The composition of such an alloy should allow the part to be calcined through.

- When heat treating steel of this type, “soft” coolants – oils – can be used. This technology significantly reduces the risk of cracking or warping during hardening.

- After heat treatment and alloying procedures, structural steel acquires an additional reserve of toughness, and the threshold for its cold brittleness increases. Thus, equipment with parts made of this material becomes more reliable.

Disadvantages of structural steel:

- A significant portion of products made from this material are subject to reversible temper brittleness.

- After exposure to temperature, the structural metal becomes softer and its fatigue resistance decreases.

- As a result of forging and rolling, structural steel elements acquire a stitch structure. In addition, in places of deformation, their properties become heterogeneous. Such material is subsequently difficult to cut.

- In a structural material alloyed with nickel, flakes can form - light spots in the fracture. In cross section, they can appear in the form of cracks of different directions. This phenomenon occurs due to the release of hydrogen dissolved in the steel.

Selection of structural steel by its marking

Structural metals are marked according to a complex system that includes many designations. Let's take a closer look at it.

Carbon steel of ordinary quality is standardly designated by a combination of the letters “St” and numbers from 0 to 6 - they reflect the grade number. Then there is a description of the degree of deoxidation: in calm steels - “sp”, semi-quiet steels - “ps” and boiling steels “kp”. Moreover, in structural steel grade 0, the degree of deoxidation is not indicated, but the phosphorus content in it is reflected (no more than 0.07%) , sulfur (no more than 0.06%) and carbon (no more than 0.23%). Grades from 1 to 6 can be semi-calm, and from 1 to 4 – boiling. The share of C, Mn, Si, S, P is strictly prescribed in them.

According to GOST 1050–88, the marking of high-quality carbon steels includes a two-digit number indicating the concentration of carbon in it (in hundredths of a percent): 0, 8, 10, 20, ... 60. From this designation it is obvious that, for example, steel 20 contains 0.20% carbon.

Carbon structural steels can also be calm, semi-calm and boiling, but the former is not preceded by an index. Thus, you can find designations for semi-quiet metals: 08 ps, 10 ps, 20 ps, and boiling metals: 08 kp, 10 kp, 20 kp.

The cast macrostructure of carbon steels is designated by the capital letter “L” (steel 60 L).

Determines the marking of alloyed structural steels according to GOST 4532–71. So, it must contain an alphanumeric designation reflecting the chemical composition of the material:

- aluminum – Yu;

- boron – P;

- vanadium – F;

- tungsten - B;

- cobalt – K;

- silicon – C;

- manganese – G;

- copper – D;

- molybdenum – M;

- nickel – N;

- niobium – B;

- titanium - T;

- chrome - X.

The number after the letter indicates the approximate proportion of alloying components in the alloy. If it is not there, then the material contains no more than 1% of such substances.

The number located at the very beginning of the marking indicates the amount of carbon in the alloyed material (in hundredths of a percent). Thus, the entry “30ХН3А” means that this alloy contains about 0.30% C, about 1% Cr and 3% Ni. The capital "A" at the end of the entry reflects the high quality of the steel. Particularly high-quality steels (which are obtained, for example, by electroslag remelting) are marked with the letter Ш - 30ХГС-Ш.

Some groups of structural steels contain additional symbols at the beginning of the marking. So, automatic ones begin with the letter “A”, construction ones – with “S”, bearing ones – with “Ш” (ШХ15).

Automatic steels are characterized by increased concentrations of calcium, selenium, sulfur, tellurium and phosphorus. According to GOST 1414–75, the increased content of certain substances should be indicated by the corresponding letter: calcium - “C”, selenium - “E”, sulfur - “A”, lead - “C”. A two-digit number before the letters A, AC or AC indicates the carbon concentration (in hundredths of a percent). For example, automatic steels with a high calcium content - ATs20, ..., ATs30KhN; selenium – A35E, A40XE; sulfur – A11, A20,…, A40; lead - AS14, AS40, ..., AS45G2.

Low-alloy structural steels are designated by the letter “C” and a number reflecting the yield strength (megapascal), for example, C235, C285, ..., C590. At the end of the entry there may be a capital “D” - indicating an increase in anti-corrosion properties, a “K” - reflecting a special chemical composition, or a “T” - indicating an increase in the strength of the material due to heat treatment.

The requirements that the consumer puts forward for the properties of structural steel (chemical, physical or mechanical) are met due to the specific composition of the alloy, the selection of thermal treatment methods and surface hardening methods, as well as the quality of metallurgical processing. Such material can be presented on the market in the form of rolled products, pipes, etc.

The cost of structural steel products mainly depends on the composition of the alloy and the size of the part.