In our article today we will tell readers about this method of hardening metals as cryotreatment. On the pages of our website you can find a lot of information about various methods of metal processing. Such as, for example, turning or mechanical processing. But this is completely different... The main goal of cryogenic processing is to give the material increased strength by changing its internal structure. In this definition lies the main advantage of metal processing at ultra-low temperatures. Other hardening methods affect only the outer layers, while cryotreatment changes the metal completely.

How it works?

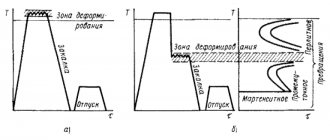

What is the essence of this method? In its most simplified form, this is slow cooling. The metal is gradually cooled to a temperature of less than 190° and maintained in this state for up to a day and a half. Then slowly warms up to room temperature. This technology was first used in the 30s of the twentieth century and has not lost its popularity since then. During cryotreatment, the metal becomes harder, more durable, wear- and shape-resistant. Tools and parts that have undergone cold treatment last longer. At each technological stage in the production of tools and parts, the metal from which they are made is compressed or stretched. As a result, residual stress accumulates in the finished product. If you do not get rid of it, the part will become deformed during subsequent use. Cryogenic treatment of metal products relieves them of internal residual stresses, thereby significantly increasing their service life.

Areas of application of cryotreatment

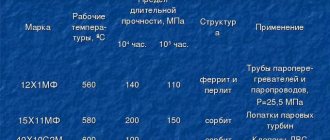

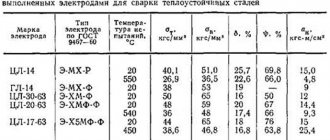

Hardening at low temperatures is most widely used in the production of metalworking tools. This is due to several factors. Firstly, such a tool must have increased wear resistance. Secondly, the tool, made from high-alloy steel, is best subject to cryo-treatment.

Cryogenic processing is also actively used in the defense industry, in particular in the production of gun barrels.

Another area of application of cryoprocessing is the production of drilling and mining rigs, pump parts and lifting mechanisms - in short, the production of mechanisms operating in an aggressive environment under increased loads.

Cryogenic processing finds its application in the most unexpected areas. For example, in the production of wind instruments. According to musicians, treated copper or brass instruments sound much better.

In the modern metallurgical industry, there are various technologies for increasing the wear resistance of parts, mechanisms and tools. Tough competitive conditions dictate their own rules: how to increase service life, increase wear resistance and at the same time reduce costs? Strong market positions will be occupied by those who can not only puzzle over these questions earlier, but also find the most correct answer.

Each of the existing metal hardening technologies has its own advantages and disadvantages. The only thing they have in common is that changes occur only in the surface layer of the metal, at best to a depth of 2-3 mm. This indicator does not allow us to talk about the maximum increase in hardening and service life as a whole.

Today in Russia there is a technology that allows improving characteristics throughout the entire volume of a product - this is cryogenic processing. The technology is a process of slowly cooling parts and tools according to a special program in a cryoprocessor to the temperature of liquid nitrogen, followed by holding for a certain time. After which a process of gradual return to room temperature occurs. The temperature control process is automated and controlled with an accuracy of one degree.

The use of unique technology allows enterprises to reduce costs by:

— increasing the wear resistance of parts, tools and mechanisms;

— reducing the number of defects;

— reducing costs for repairs and replacement of equipment and tools.

For Russia, the technology is unique and has been introduced into industry since September 2013 by research and production, part of the Group.

Together with leading scientists from Izhevsk State Technical University. M.T. Kalashnikov Scientific and Production Center "CryoTechResource" conducts research in the field of changes in metal structure at the molecular level.

It is worth noting that cryogenic processing is a one-time process that does not need to be repeated, since all the properties of materials acquired during deep cooling are maintained throughout the entire service life of the parts.

During cryogenic processing, the following main changes occur in the structure of the metal:

· Increased hardness, wear resistance and strength as a result of the transformation of retained austenite into martensite.

Cooling to low temperatures makes it possible to further transform retained austenite into martensite. Residual austenite is relatively soft, which does not give it the required wear resistance and strength properties. The strength of steel increases with increasing martensite content in the structure.

· Improved dimensional stability (dimensional stability).

Retained austenite is unstable at room temperature and begins to disintegrate over time. For most applications this is not a problem. However, where extremely fine tolerances are required, this decomposition can lead to dimensional changes as a result of differences in the crystallographic sizes of the phases. Dimensional stability can be improved by repeating low-temperature treatment cycles. This may be important where dimensional tolerances are critical. Moreover, this works not only on steels, but also on alloys of non-ferrous metals such as aluminum and titanium.

· Increasing impact strength and wear resistance of steels.

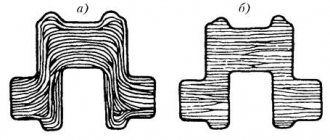

In addition to the well-known effect of transforming retained austenite into martensite with a corresponding increase in hardness, deep cryogenic treatment also affects martensite. The crystallographic and microstructural changes that occur during cryotreatment lead to the formation and more uniform distribution of carbides of alloying elements in the microstructure with a subsequent increase in impact strength and wear resistance. Finely dispersed carbides fill the boundary regions of crack formation and microvoids in the structure, creating a more coherent crystalline structure. The amount of these carbides increases with decreasing processing temperature and increasing holding time.

· Increasing service life by removing residual stresses.

All parts and tools are produced with internal arbitrary compressive and tensile stresses as a result of previous technological operations. As a result of these stresses, parts are deformed during heating during operation; in stress zones, as a rule, fatigue cracks appear over time, which negatively affects the service life of the product.

Structural changes with uniform expansion and contraction that occur during cryogenic processing contribute to the almost complete removal of internal stresses in the metal.

“The technology of cryogenic processing is extremely interesting for both small and large industrial enterprises,” says Ivan Danilov, chief technologist of SPC “CryoTechResource”. “We are talking not only about increasing service life, strength and wear resistance, but also about a fundamentally different level of processing, which will ultimately allow manufacturers not only to reduce costs, but also to become more competitive.”

The use of cryogenic processing is relevant for almost any industry where friction is present, and there is a need to increase fatigue strength and wear resistance, but the greatest effect can be achieved in the following industries:

1. Industry. The applications here are endless. Almost any equipment is subject to wear and tear, and this is what cryogenic treatment most effectively combats. In any industry: oil production equipment, machine tools, construction and road machines, drilling and mining equipment, liquid pumps, lifting mechanisms... Equipment that contains friction pairs will last longer, taking into account the use of technology.

In addition to increasing wear resistance, sometimes an important factor will be improving the operating conditions of equipment due to better heat transfer of cryogenically processed parts.

We should also highlight metalworking tools, ranging from drills of minimal diameter to huge rolling shafts. Metalworking tools are typically made from high-alloy steels with a high carbon content. It is on these steels that cryogenic treatment gives the greatest effect.

For any metalworking enterprise, tools are one of the main expense items. As a result of processing, the tool life can increase by 2-3 times (in some cases up to 6 times). But costs are reduced not only due to savings on tool costs, but also due to a significant reduction in equipment downtime for tool replacement and subsequent adjustment.

2.Defense-industrial complex. This point largely overlaps with the previous two. But it also has its own characteristics.

Cryogenic treatment can greatly increase the service life of the most important part of a firearm - the barrel. It doesn’t matter whether it’s a pistol, a tank or a ship’s gun, manufacturers are always fighting to increase their service life. In addition, the stability of thermal deformations during shooting increases, which cannot but affect accuracy. In addition to barrels, the technology can be used in the processing of precision drives and mechanisms, brackets for installing optical devices on military equipment, electronic components and much more.

3.Electronics and audio equipment.

Cryogenic treatment allows you to remove residual internal stresses in the structure of the conductor, which increases its conductivity or, in other words, reduces resistance. As a result, the electron current in the conductor becomes freer, not only along the conductor itself, but also in the areas where the conductor connects to the patch connectors.

The dielectric materials used to insulate cables also become more uniform and provide better insulation. Unlike many of the “esoteric” factors that marketers are so fond of citing, the improvements in performance of cryogenically treated cables can be easily measured. The resistance of the audio cable decreases, and special infrared detectors record a decrease in heat dissipated by the cable by 30 - 40%. For an audio cable, this indicator is very important, since it allows you to significantly increase efficiency with the same amplifier power.

4 . Transport. The use of this technology is possible for any type of transport: road, aviation, railway, river and sea.

Cryogenic treatment can significantly increase the service life of brake discs, bearings, gears and chain drives, all kinds of hinges, springs, bushings and any other parts where friction is present. Separately, it is worth mentioning the processing of engines. An engine with processed elements (or the entire engine assembly can be processed) not only has a significantly longer service life, but also increases power by several percent. It is clear that the effect is not immediately visible, but over time it becomes more and more noticeable and more pleasing to the pocket. Particularly indicative is the use of technology in motorsport, where every little thing can decide the outcome of the race.

5. Musical instruments. Most wind instruments are made of copper and brass. Cryogenic treatment has a positive effect on their structure. No serious scientific research has been conducted in this area, but the fact that the sound of the instrument improves is undeniable. The processed musical instrument was appreciated not only by individual musicians, but also by entire orchestras around the world.

Today there are already positive reviews from domestic companies processing springs, rollers for road construction equipment, metalworking milling cutters, conductors for speaker cables, and chains for chainsaws.

Cryogenic technology can not only compete with the traditional technologies used in the field of increasing wear resistance and hardening, but also significantly improve the mechanical characteristics of processed products without an undesirable increase in fragility and other side effects. At the same time, the use of cryogenic processing technology can significantly reduce costs, which will ultimately affect the efficiency of the enterprise and allow it to take a leading position in the market.

Cryogenic processing technology became a winner of the regional competition “100 Best Products of Russia” and was noted by the International Public Organization “Academy of Quality Problems” as a new service in the category “Industrial and Technical Services”.

Specialists from SPC “CryoTechResource” are ready to carry out trial processing of products free of charge, so that domestic manufacturers can independently evaluate its effectiveness and implement it in their production.