Without running water and sewerage, no home can be considered cozy and comfortable to live in. But water supply and drainage is needed not only for the home, greenhouse, garden, orchard; industrial buildings also require pipe laying. Therefore, today great importance is paid to the quality of the routes laid.

Polypropylene pipes meet all the parameters required when laying a pipeline underground.

Steel and cast iron pipes have long been no longer the best options; they are susceptible to corrosion and are easily destroyed under the influence of various external conditions, although they are characterized by mechanical strength. Nowadays, laying a pipeline in the ground has strict requirements, including:

- simplicity and reliability;

- resistance to mechanical stress;

- chemical inertness;

- simple operation;

- no need for frequent repairs or replacement of damaged elements.

These requirements are met by polypropylene pipes, which are used in various fields, maintaining operability and efficiency under all conditions.

Material selection

For the construction of underground sewer pipe systems, a variety of materials are currently available. Not so long ago, the main material for sewer pipes was cast iron. Today, cast iron pipes have been almost completely replaced by polymer pipes. In addition to the cost and weight of pipes, the main advantage compared to metal products is their longer service life. In addition, polymer pipes do not require the use of special equipment for installation.

A polymer pipeline, in addition to the listed advantages of low weight, has several more significant advantages:

- There is no corrosion on the surface;

- The surface inside the pipes is very smooth, so masses cannot accumulate;

- Plastic is a dielectric, this is especially important since modern homes have a large number of electrical appliances;

- Resistance to aggressive chemically active substances in the composition;

- Plastic pipes do not emit toxic emissions hazardous to health;

- Very low cost of the product compared to metal pipes;

- Possibility of various configurations of the waste line. However, without understanding and knowledge about the sewerage system, it is impossible to correctly take advantage of all the advantages of plastic products.

- The installation of sewerage in the ground is impossible without the listed advantages of polymer pipes, because they have a direct impact on the overall duration of use and quality of the pipeline.

Types of sewer pipes and their features

The process of laying external sewerage looks quite simple. The pipes are laid in a dug trench, connected to the system located inside the house, as well as to the collector, and then covered with earth.

Before drawing up an external sewerage project, you need to decide on the type of pipes. The dimensions of the trench, slope, etc. depend on the diameter, cross-section and material of these elements.

Pipes that are used to create external sewage systems are distinguished by many parameters, such as diameter and cross-sectional configuration, as well as material. Today, sewer systems are made of:

- cast iron; ceramics; concrete; asbestos cement; plastic; fiberglass.

Cast iron pipes weigh quite a lot, their internal surface is not very smooth, and installation is very complicated, so this type of sewage system is used extremely rarely in private plots.

Ceramic elements are easier to install, but they can be easily damaged if handled carelessly. Concrete structures of large weight are also difficult to install, so they are rarely used for external sewerage in a private house. Inexpensive and lightweight asbestos cement structures have been popular in the past, but they are somewhat fragile, and the smoothness of their internal surface leaves much to be desired.

Plastic pipes for external sewer systems are usually orange in color to distinguish them from elements for internal systems.

These are lightweight, durable and easy-to-install pipes. The undisputed leader in the sewer systems market is plastic. Pipes made of PVC, PP, PVP have all the characteristics necessary for external sewerage: light weight; significant strength; resistance to chemicals; ease of installation; smooth inner surface; ability to withstand very low temperatures, etc. Fiberglass is also very good for sewerage , which is a composition of polyester resins reinforced with special fiberglass.

However, such structures weigh significantly more and are much more expensive. To create a sewer system on a personal plot, round plastic pipes are most often used, the diameter of which is usually 110 mm. When laying pipes using the puncture method, for example, under the road surface, as well as in other places with high loads, it is recommended to use double-layer pipes with a corrugated outer surface. Please note! Pipes made of polyvinyl chloride (PVP) can withstand heating only up to 40 degrees, while polypropylene (PP) structures can withstand temperatures up to 80 degrees. High-strength polyethylene (HDP), which is used in the production of sewer pipes, occupies an average position in terms of heat resistance.

Pipeline laying rules

The installation and laying of a sewage pipeline in an individual residential area or land plot is carried out according to special rules from 1985. According to this document, in addition to technical requirements, other standards for the correct installation of sewer pipes in the ground were announced.

According to these regulations, the depth of laying the sewer system must be equal to the freezing depth of at least 50 centimeters. The distance is calculated from the bottom of the pipes if the pipeline is installed on the ground.

The laying of a sewer line in the ground is carried out in compliance with the following requirements:

- To prevent erosion by groundwater, which is especially important in seasons with precipitation, the location of the future sewer system must be well compacted and compacted;

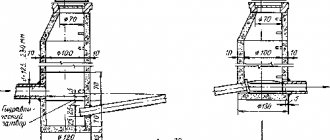

- Technologically correct pipe laying involves constructing a special well in the place where there is a bend or a sharp turn. This technological well serves for repair needs, with its help the replacement of faulty elements and preventive maintenance are carried out.

There is also another important recommendation for laying sewer pipes in the ground, thanks to which you can get additional benefits in the form of convenience to the system elements if they fail. To do this, you need to sprinkle the bottom with a sand “cushion” of 15 - 20 centimeters. The same size should be applied over the pipes.

Selecting polymer pipes for home piping

The functional purpose of the pipeline dictates the conditions when choosing the type of pipe, diameter and material used in manufacturing. The materials traditionally used for laying pipelines are giving way to polymers, which are not inferior in strength and tightness, but are much lighter and have a relatively low cost. A pipeline made of polymer structures will have a higher throughput, and the selection of components and fittings will not be difficult and will not require significant costs.

Polyethylene pipes are recommended for laying underground pipelines, since the source material is resistant to temperature changes and soil pressure. For household water supply systems, it is advisable to purchase a model of low-pressure polyethylene pipes PN10, which can withstand constant pressure up to ten atmospheres. Low density PN6 grade is not recommended for underground pipelines. Installation of a polyethylene pipeline can be carried out without special tools.

Taking into account the relatively high thermal expansion of polyethylene, the pipeline design provides for L- or U-shaped bends.

For home plumbing and sewerage, you can use pipes made of different polymers

Polypropylene pipes are stiffer and stronger than polyethylene pipes. They are also easy to install; the lack of flexibility is made up for by installing adapters and angles. Besides. They are easy to connect with elements made of other materials.

For home water supply up to 15 m in length, pipes with a diameter of 20 mm are selected, for a length of up to 30 m - 25 mm, for a longer length - 32 mm. (The calculation is based on the average water speed in the system, not exceeding 2 m/s). To supply hot water, you will need polypropylene pipes with a reinforcing layer of aluminum foil or fiberglass (PN20 or PN25). When laying a pipeline from polymer materials, it is advisable to select all its elements from one manufacturer. They should not have any irregularities or roughness.

Work order

Digging a trench

The very initial stage of arranging a sewerage system in the ground can be called the procedure of excavating a trench itself. Depending on the scope of work, you can use heavy special equipment such as an excavator. However, if the volume is small, then you can do it yourself. The main thing that is necessary is to comply with the dimensions of the drainage pit in accordance with the documentation requirements. Compliance with its dimensions is mandatory for any method of excavating a trench.

Laying

According to accepted requirements, waste pipes are recommended with an outer diameter of 110 mm. If the pipes to be laid are oversized, then the width of the trench will increase.

If the developer needs to lay a sewer system according to all the rules, then the following should be taken into account:

- Laying a pipeline in the ground involves installation from a supporting foundation;

- In cases where the residential building does not have a hole, you will have to hollow it out and run a pipeline to it;

- If the construction project initially provides for an outlet hole in the foundation, all that remains is to simply join the component parts of the plastic pipes.

Sewer insulation

The wastewater that passes over the surface of the pipes most often has a normal temperature no lower than room temperature, especially if the system is properly designed, the liquid is not retained, but immediately enters the waste pit. However, sometimes you have to deal with frozen drains. This carries a high risk of pipe destruction and deformation due to the expansion of frozen water. That is why, in order to avoid such a development of events, it is necessary to carry out additional insulation of the external pipeline.

There are three ways to prevent possible sewer freezing:

- maintaining the depth of soil freezing in winter;

- insulation of pipes in the ground using insulation materials (foamed polyethylene, polyurethane foam, mineral wool and others);

- insulation using a heating cable in the design.

Laying pipes

The technology for laying sewer pipes in a trench is no different:

First, the internal sockets are cleaned and the O-rings are checked. Laying pipes begins from the foundation of the building.

If a sewer pipe outlet is laid in the foundation of the house, then the part to be laid is put on it with a socket. The smooth end of the pipe is coated with silicone. Then the pipe connection takes place without problems.

If there is no outlet in the foundation, then either a hole is cut in the foundation, or the pipes are laid under it; the pipe is laid with a slope. SNiP specifies the standard slope: per 1 meter - 2 cm. Then the liquid through the pipes will flow smoothly and silently; the pipe from the building to the collector does not always run perfectly straight.

There are often twists and turns. For this purpose, bends are used at an angle from 15 to 90 degrees. If the length of the sewer line is 15 meters, then an inspection is installed above the elbow; the pipes are connected to each other until they stop.

They are joined manually. You should ensure that the bell is perfectly clean. And to make joining easier, you should use silicone grease; if it is not possible to make a trench of greater depth, and the pipes fall within the freezing level, then the pipes should be insulated with stenoflex.

Laying a water pipeline in the ground from HDPE

In accordance with the type of system, pressure or non-pressure material is selected for laying polyethylene pipes in the prepared trench. Thanks to the first type of pipe, it is possible to continuously maintain a given pressure; a product without pressure cannot boast of this. Pressure - perfect for water supply, the other - for the sewer network.

By following the correct sequence of actions, it is possible to quickly and efficiently complete the work of laying HDPE pipes in the ground.

It’s worth starting with a schematic indication of where and how the pipes will be placed on the site. To draw up a plan, it is not necessary to have an engineering degree; it is enough to understand the key features of the soil and the existing territory.

For proper installation, it is recommended to use special technical documents for the area. Often, they already describe existing communications and land reclamation areas, if they are located nearby. Guided by the specified documentation, you can schematically establish the location of the future pipes.

Pay attention to several parameters: territorial area in order to determine the correctness of branches and incoming components, as well as the softness and flowability of the soil, which will affect the correct selection of the raw material base.

The sponsor of the article is the production and trading company “NEFTEPROMKOMPLEKT”. The company sells products for the oil and gas industry; one of the best products is heat-shrinkable cuffs Tial M.

It is also important to know the designation of HDPE products, since there are many varieties of them. It has been noticed that for laying networks underground it is worth using PN10. The material fully meets all standards for drinking water resources. HDPE is designed to withstand continuous pressure up to 10 atmospheres. They are endowed with high strength. With the arrangement of sewerage, the situation is simpler: the use of standard products without special features is allowed.

When laying a water supply system in a dacha, pay attention to the recommended immersion depth of the structure - 1.6 m. This is due to soil freezing rates, which reaches 1.4 m. Which means that by digging a hole that is shallower in depth, there is a risk of major damage to the pipes .

The soil below a level of 1.6 m always contains positive temperatures. If it is not possible to immerse the pipe to the specified depth, it is worth considering carrying out auxiliary work related to insulation of the system. It is not advisable to immerse the product below the fixed line, since the HDPE will not cope with physical pressure and will burst.

Technology of external water supply from polyethylene pipes

When arranging external water supply networks, it is worth taking into account special points such as:

- increased linear expansion rate, which is 15 times more than that of metal pipes;

- great sound effect;

- low fire resistance;

- reduced adhesion to other construction materials.

Due to their physical properties, polyethylene pipes exhibit greater plasticity, which helps to avoid disintegration under increased linear load and deformation of the water supply system.

In order to compensate for linear expansions for plastic water pipes, couplings are used during its assembly. The factory product is produced with a length reserve of up to 10 mm. Planning of this reserve is associated with the calculation of the occurrence of a technological joint, compensated by the expansion of pipes.

Which pipe to use for underground sewerage

The market offers us pipes for underground sewerage of various diameters, materials and connection options. To make an informed choice, you need to consider:

- temperature and chemical aggressiveness of wastewater;

- volumes of discharges during periods of maximum load;

- minimum temperatures of the climatic zone;

- depth and angle of sewer installation;

- soil type.

External sewer pipes must meet numerous requirements : to be durable, reliable, wear- and frost-resistant. Properly selected sewer pipes for specific conditions will ensure effective waste disposal for many years.

The use of welding when installing polypropylene pipes

Welding acts as the main means of connecting elements when laying a pipeline. Obtaining permanent connections that eliminate changes to the design is extremely convenient for trench installation. A polypropylene pipeline can be laid using the route method, which involves preliminary welding of sections to a size that allows transportation. The final connection is made on site.

Pipes with a diameter of 25 mm are welded within nine to ten seconds, 32 mm - two to three seconds longer. The soldering iron heats up to 260-270º C. You need to carefully monitor both the heating temperature and time. If the heating is insufficient, it will not be possible to achieve the required joint strength. Overheating manifests itself in blackening of the plastic, which means that the area is damaged and should be removed.

When connecting polypropylene elements by welding, they are pre-cleaned. To avoid the appearance of gaps at the joint, the depth of the fitting is pre-marked at the end of the pipe. Upon completion of welding, the resulting melts are allowed to cool, since hasty removal will deform the pipe.

Diameter

When choosing the diameter of a sewer pipe, it is necessary to take into account the external and internal dimensions, since the wall thickness can vary significantly.

For domestic external sewerage, the standard 110 mm is applicable . This diameter is enough to service a country house. When combining several houses or an entire village into one sewer network, the diameter must increase in accordance with the calculations for the project.

All the time we were talking about pipes with a round cross-section, which are used in the vast majority of cases, because wastewater moves through them as quickly as possible. However, this is far from the only option. Ellipse-shaped pipes are sometimes used : they are necessary when the soil creates strong pressure on the pipes or when the load of wastewater on them is too high. When the sewerage system is not located too deep (up to 1 m), pipes with a semicircular and rectangular cross-section can be used. It is also worth noting that if the sewer system is not deep enough, it must be insulated to avoid pipe rupture during the cold season.

Possible problems when laying polymer pipes

Laying polymer pipes using the trench method seems to be the best choice when constructing a pipeline. If you need to carry out work in an area where the soil is too hard and laying a trench is difficult, you should, if possible, wait for weather conditions with high humidity. A similar effect can be achieved by moistening the soil at the installation site.

In loose soil, the puncture method is used for underground pipe laying.

Laying a pipeline in loose soil is accompanied by constant soil shedding. This can lead to deformations in the system and its failure to operate. Therefore, it is customary to strengthen loose soils using, among other things, special geotextiles. Another way out of this situation is to use the puncture method. Then a pipe made of polymer materials will be placed inside a steel pipe previously laid as a protective casing.

Good to know! The trenchless installation method has to be resorted to when some large object gets in the way of the pipeline. In this case, polymer structures can be additionally insulated with a steel casing.