Materials used in the production of sewer pipes

Before connecting sewer pipes, you should select the material from which the parts will be made. The following materials are used in production:

- PVC.

- Cast iron.

- Steel.

- Asbestos cement.

- Concrete.

- Ceramics.

- Corrugation.

Only products of the first two material options are used everywhere. If the sewer system is located on the territory of an industrial facility or is an external network of a house, then corrugated pipes can be used.

Cast iron products are installed when an external sewer system is being installed. Such pipes are not afraid of corrosion, which is their main advantage. However, due to its too heavy weight, it is not practical to use cast iron for the installation of internal sewage systems. Therefore, such installation is often carried out from PVC.

Plastic pipes - instead of outdated materials

The products we are interested in include pipes for water supply and wastewater disposal made from polypropylene, polyvinyl chloride, polyethylene and polybutylene. These thermoplastic materials are capable of softening when heated to high temperatures, and upon subsequent cooling, completely restore their structure and physical properties. In recent years, wastewater disposal systems have been created with the help of such products. They are confidently displacing outdated types of sewer pipes and connections from the market:

- Made of concrete. Such pipe products are now used only for arranging local sewer systems in country houses. Concrete structures are heavy and very difficult to transport and install.

- Made from asbestos cement. These pipes are described as having increased resistance to chemical and thermal influences, as well as corrosion, affordable cost and low weight. But their throughput is quite low, and when installing asbestos-cement networks, there is a high probability of pipe breakage and deformation due to their excessive fragility.

- Made of cast iron. These products have many operational advantages. For this reason, they have always been actively used to build sewer networks. But cast iron pipes also have a lot of disadvantages, ranging from heavy weight to their tendency to quickly clog.

Advantages of polymers

As noted earlier, polymers are most often used in the pipe production process. The main advantage of this material lies in its ability to soften. That is, under the influence of high temperatures, the polymer becomes soft. As soon as cooling occurs, it returns to its original state. Other advantages of polymers are worth noting:

- Resistance to corrosive processes.

- There is no need to insulate the pipe that will be laid in the ground.

- Resistant to aggressive environments and chemicals.

- Smooth inner surface to prevent clogging.

- Low weight.

- The ability to arrange engineering communications of almost any complexity due to convenient installation.

- Long service life.

example

The only disadvantage of polymer is considered to be limited throughput. However, this unpleasant moment can be eliminated by selecting a pipe with a larger diameter.

Fittings play an important role in connections. With the help of these connectors, the system is sealed and does not allow unpleasant odors to enter.

Connection with fittings

To connect system parts to each other, you can use several types of fittings. Connectors differ in the following characteristics:

- Purpose of the product (connecting or intermediate)

- Fitting design (swivel, tee, extension)

- Shape (T or L-shaped, straight).

samples

When the above classification is used when choosing a material, selecting specific models will become much easier. In addition, it is worth purchasing rubber gaskets, which are placed in the joint when installing the fitting.

Actions to be taken before starting work

Installation of an engineering system and, in particular, connection of parts requires the following actions:

- Drawing a drawing in which it is necessary to take into account all the objects that need to be connected.

- Selecting connection points for the riser and outlet pipes. It is in these places that the fittings are installed.

It is important to remember that pipes with a diameter of 50 and 110 millimeters are used for sewerage. Using the first option, sewer connections are made for household appliances, shower stalls and washbasins.

Experts do not recommend purchasing large quantities of material, since plastic sewer pipes are connected very easily, and it is almost impossible to spoil polymer products.

To increase the service life of communications, you should pay attention to simple rules:

- Compliance with the installation parameters of the inclination of parts. This will allow water to be removed from the system at maximum speed. The slope is calculated taking into account that for each meter of pipe the decrease was no more than 2-3 centimeters.

- Installation of the sewer system on your own should begin from the plumbing or household appliances in the direction of the main riser. Thus, the passage of liquid is not complicated by joints.

You may also like: Replacing sewer pipes in an apartment - what you need to consider, video review!

Features of installation of plastic sewer pipes

Plastic is one of the cheapest materials used to make consumables for sewerage equipment. When laying communications in a private house or apartment, price can become the determining parameter in the choice of pipes.

In addition to being cheap, plastic has other advantages:

- light weight, which simplifies the delivery of pipes and fittings and installation of the pipeline;

- the ability to choose the type of plastic and connection method suitable for a particular case;

- the smoothness of the walls and the chemical inertness of the polymers, due to which no build-up is formed on the inner surface and the throughput of the pipeline does not decrease during operation of the sewage system;

- compatibility with other materials - you can not only assemble a sewer entirely from plastic, but also replace part of the old pipeline with polymers, since there are special connecting elements for combining plastic with pipes made of metal alloys;

However, the installation of a sewer pipeline made of polymer products has its own characteristics:

- plastic is afraid of ultraviolet radiation, so plastic sewers must be hidden from direct sunlight;

- despite the elasticity characteristic of polymers, most pipes cannot be bent; to change the direction it is necessary to use bend fittings;

- sewerage consumables are made from polymers that have different limits of high-temperature exposure: polypropylene (80º), polyethylene (50º) and polyvinyl chloride (40º), the pipe material should be selected based on the maximum temperature of the wastewater;

- for internal and external sewerage, pipes are made with different strength indicators, which for convenience are painted in different colors: gray for internal or apartment pipelines, orange for external ones;

- when laying a deeply buried pipeline in regions with a deep level of soil freezing (more than 2 m), pipes with a corrugated outer surface are used;

- indoors, thin-walled corrugated pipes are used to connect household and plumbing appliances;

- Since the operation of the sewerage network requires a slope of 1-3%, allowing wastewater to move by gravity, sewerage in an apartment is assembled from the riser to the devices, in a private house - from the outlet pipe to the devices, and on the street from the outlet pipe to the collection or discharge point drains;

- network elements are fixed to the walls with fastening increments of 8-10 pipe diameters to prevent sagging and deformation of the pipeline;

- Even entire units made of polymer products are lightweight, so it is convenient to assemble large parts of the drainage network and connect them to each other once assembled.

We recommend that you read: How to choose glue for high-quality joining of PVC pipes?

Regardless of the pipe material, the pairing of pipe circuit elements is always carried out in such a way as to minimize the number of obstacles in the path of wastewater.

Note! Making right angles is not allowed; if you need to rotate the pipeline 90 degrees, assemble a unit from 30- or 45-degree elbows. The network parts themselves are joined so that a thin pipe or pipe fits into a wider one, and not vice versa, so that the contents of the drain do not cling to an obstacle, forming a blockage.

Detachable connection options

The detachable connection can be flange or coupling. The first option is best suited for PVC. To improve the tightness, you can use rubber gaskets and cast iron fasteners. The sequence of work on how to connect sewer pipes looks like this:

- The pipe is cut to the required length. At this stage, it is important to cut smoothly, and there is no need to chamfer.

- The loose flange is put on the cut site.

- A gasket is installed that extends from the cut point to a distance of at least 10 centimeters.

- A flange is placed on the gasket and secured with flanges on the branch parts.

- Fastening elements are secured.

Using couplings, you can understand how to connect sewer plastic pipes during repairs, as well as when installing the system under or without pressure. In order for the work to be completed efficiently, the following list of actions should be observed:

- The ends of the parts that will be connected to each other are cut at an angle of 90 degrees.

- The coupling should be applied so that its central part is located at the joint.

- A mark is drawn on both parts that corresponds to the placement of the coupling.

- The ends of the parts, as well as the inside of the coupling, are treated with a special lubricant.

- One pipe is inserted as deep as possible into the coupling.

- The installation is carried out so that the axis is single.

- The coupling is inserted into the second part up to the mark made earlier.

Using this method, the system can be easily disassembled if necessary. When installing couplings, attention should be paid to the tightness of the connection points.

Dismantling an old pipe

The cast iron pipeline must be dismantled very carefully to prevent chips or cracks.

We recommend that you familiarize yourself with: Sewer adapters for installing pipes made of different materials

In the past, joints were often sealed using cement and tow, so it may take a lot of effort to release the joints.

It is necessary to disconnect the pipes by twisting, and in no case by rocking. If you are not sure that the socket of a cast iron pipe can be released without damage, it is better to carefully cut it with a grinder.

It is important! You should not try to break off a cut cast iron pipe. Most likely the break will be uneven and you will have to cut again. It is better to work with the grinder a little longer and cut the cast iron product completely.

One-piece installation methods

Connecting sewer plastic pipes in permanent ways can be:

- In the bell. This option involves a socket connection of sewer pipes with a smooth pipe end. It is important to remember that surfaces must be cleaned and degreased. In addition, the smooth end should be chamfered. Next, the connection is coated with silicone, and during installation it is important to ensure that the longitudinal axis coincides. The smooth end is inserted into the socket. The part should not move to a distance exceeding the mounting mark.

- Welding . If the socket welding option is used, then the outer surface of the smooth end of one part and the part of the socket inside the second are melted by a welding machine. When butt welding is used, moderate pressure melts the connecting ends, as well as the joint. This method can be used in situations where it is necessary to connect sewer pipes of different diameters.

- Gluing . Connecting sewer pipes using this method implies the presence of a special adhesive composition that is used to coat the connecting ends of the pipes. The choice of adhesive depends on the material used to produce the parts.

Construction of houses

146 votes

+

Vote for!

—

Vote against!

Sooner or later, everyone has to deal with the need to install pipes. Depending on the pipe material you chose, the installation technology itself will depend. In this article we will talk about which connection is better to choose - welded, threaded or socket - when working with pipes made of various materials.

Content:

- Types of sewer pipes and connections

- Sewer pipe connection angle video

- Preparatory work

- Connection of metal sewer pipes video

- Cast iron pipe connection

- Joining of steel pipes

- Connection of plastic sewer pipes

- Mounting on coupling video

- Welding installation

- Socket installation

Types of sewer pipes and connections

If previously sewer pipes were made mainly of metal, today on the market you can find not only steel cast-iron pipes, but also ceramic or plastic ones.

Ceramic sewer pipes are produced with a diameter of 150-600 mm and are more often used when installing external sewerage. The main advantage of such pipes is the resistance of ceramics to aggressive groundwater. In domestic construction, the use of ceramic pipes is extremely rare. As for the connection of ceramic sewer pipes, it is similar to the connection of cast iron pipes.

The most commonly used plastic pipes today are made from polypropylene, high- and low-density polyethylene, and polyvinyl chloride. Such pipes are characterized by ease of installation, lightness, and also mechanical strength and resistance to corrosion. There are plastic pipes for external and internal installation and they differ not only in diameter, but also in color. The former are painted orange, the latter – gray.

And finally, the traditional material for making sewer pipes is cast iron. Such pipes have excellent mechanical strength and corrosion resistance.

There are also steel sewer pipes on the market, but they are rarely used when laying sewers, as they are susceptible to the harmful effects of corrosion and are not resistant to aggressive groundwater.

As for the method of connecting pipes, it can be done by welding or gluing. If you plan to create a collapsible sewage system, then the pipes can be connected using threads using fittings or flanges. In this case, flange connections are used on large-diameter pipes, since it will simply be inconvenient to connect them using threads. Which of these types of connections is most suitable for PVC pipes or cast iron pipes, as well as how these pipes are connected, we will describe below.

Sewer pipe connection angle

When arranging a sewer system in a house with your own hands, you must remember that for normal operation, the pipes must be laid at a slight angle. In general, the slope should not be less than “0.02”, which means that with a total length of the water pipe of one meter, the height difference at the ends of the pipe should be two centimeters.

Moreover, if the volume of wastewater is small, then the slope indicator should be greater and amount to “0.03”.

In general, the connection angle of sewer pipes can be calculated independently using the formula:

Or simply use ready-made solutions.

Preparatory work

Before proceeding directly to connecting sewer pipes, it is necessary to carry out some preparatory work:

- Make sure that you have purchased the entire range of related products and when installing pipes you will not suddenly find out that there is not enough special glue or, for example, heat-resistant gloves.

- Mark the location of communications, prepare the area for work and create a pipe placement plan.

- Carefully checking the pipe placement plan, mark the blanks and begin cutting the material. To avoid wasting material, it is recommended to cut from larger to smaller sizes.

- To make joining pipes convenient, the cut points must be cleared of burrs, wiped clean of dirt, and degreased with a special compound.

- If metal pipes are to be installed, then external or internal threads are applied to them.

Connection of metal sewer pipes

The connection of metal sewer pipes can be carried out in one of two ways: welding installation and socket installation. In this case, installation in a socket is usually carried out when connecting cast iron pipes, while welding is mainly used when connecting steel pipes.

Cast iron pipe connection

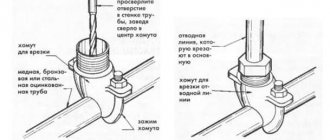

As mentioned above, the connection of cast iron sewer pipes is carried out using sockets. This installation is carried out according to the following scheme:

- We insert the cast iron pipe (the side without the socket) into the already installed socket.

- We take flax tow and use it to seal the gap between the installed tail part of the pipe and the inner edges of the socket. To do this, take a special wooden spatula and, striking it with a hammer, hammer the first wound layer of tow into the socket. At the same time, be sure to ensure that when clogging, the tow does not get inside the pipe, as this can lead to the formation of blockages. By the end, 2/3 of the socket should be filled with sealant.

- The remaining third of the socket will need to be filled with sealant without impregnation.

- Afterwards, the socket is filled with cement mortar prepared in a proportion of 9 volumes of cement to 1 volume of water. The solution must also be thoroughly compacted in the socket, and then covered with a damp cloth. This is done so that cracks do not form on the cement when it dries. In addition to cement mortar, you can also use asbestos-cement mixture, bitumen mastic or silicone sealant.

This method is used to connect cast iron pipes to each other, but there are also situations when it is necessary to connect a cast iron pipe with a plastic one. In this case, it is recommended to use special adapters and couplings. They are suitable for connecting sewer pipes of different diameters, as well as from different materials.

In order to efficiently carry out the transition from a cast iron pipe to a plastic one, it is necessary to evenly apply silicone sealant to the clean and dry inner surface of the socket of the cast iron pipe. We also apply it to the adapter itself, after which we insert the adapter into the socket. The connection will become completely sealed immediately after the silicone sealant polymerizes.

Connection of metal sewer pipes video:

Joining of steel pipes

Welding is used to connect steel pipes. And here the main thing is to do everything professionally and taking into account all the nuances of the process. However, even after spending money on a welding machine and properly welding steel pipes, we end up with a rather unreliable structure. Since the steel pipes themselves are not entirely ideal for sewerage, and the welding seam, compared to the rest of the metal, will be more susceptible to corrosion. That is, just by putting the sewer system into operation, we already know that it has weak points that over time can cause water leaks.

Of course, in addition to welding, steel pipes can be connected using detachable threaded connections. Thus, the American fitting is the most popular of these connectors and consists of two ends that are connected to each other by a union nut.

Connection of sewer plastic pipes

When connecting sewer plastic pipes, it can be done in one of three ways: with a threaded coupling, with welding, and with a socket. Each of the technologies requires the use of certain skills and equipment, so we will look at each of them in more detail.

Coupling mounting

First you need to decide on the type of coupling for the plastic pipe. However, before proceeding directly to the description of the installation process on the coupling, it should be noted that this method of joining sewer pipes is allowed only if their diameter does not exceed 63 mm. In the same case, if the diameter of the pipes allows installation on a coupling, you can get a completely collapsible water drainage system.

The process of connecting pipes using a compression or threaded coupling is quite simple. It is enough to simply disassemble the fastening element, put a lock nut and an O-ring on the pipe. Next, you need to insert the pipe into the coupling fitting and screw a lock nut onto the thread of the coupling end, which will secure the connection point.

Threaded installation is considered the fastest way to connect sewer pipes, since the system can be operated immediately after tightening the locknut. However, you need to understand that fast does not mean reliable. Also in the case of threaded couplings, the threaded pair may unwind over time and water will begin to leak at the joint.

Welding installation

Depending on the material from which the sewer pipes are made, cold welding technology, or as it is also called gluing, is practiced, as well as diffusion welding technology. Cold welding is used when installing polypropylene pipes, and diffusion welding is used when connecting PVC pipes. In this case, both welding methods are used when fixing a pipe in a socket or when installing it in a coupling.

Installation of polypropylene pipes by welding is carried out as follows:

1. Cut the end of the pipe and measure the depth of the pipe in the coupling. Trimming and marking the depth must necessarily precede welding, since otherwise you significantly risk the quality of the installation, and therefore the reliability of the entire system.

2. Using a special soldering iron, heat the coupling and pipe. To do this, both products must be put on the nozzle and heated to 260 degrees.

3. The heated parts are removed from the guides, after which the pipe is pressed into the coupling at the marked depth.

With this option for installing polypropylene pipes, the system is considered ready for use immediately after the seams have cooled to room temperature.

The connection of PVC sewer pipes is carried out as follows:

1. We cut the end and mark the immersion depth.

2. Apply special glue to the inside of the coupling and the outer part of the pipe, and then insert the pipe into the coupling to the marked depth. We turn it a little around the axis. Note that when choosing glue, it is better to give preference to the product that is recommended by the manufacturers of fittings and pipes themselves.

Socket installation

Installation in a socket can only be carried out if we are talking about connecting pipes that will subsequently become part of non-pressure networks. Also, the pipes themselves for installation in a socket must have a special thickening at the end.

The socket connection is carried out as follows:

1. A pipe is installed on the supporting surface. The bell is installed in the direction opposite to the flow movement.

2. Insert the O-ring into the socket of the receiving pipe.

3. When the sealing ring is installed, insert the smooth end of the second pipe.

4. After assembling the connection, it is necessary to fix the second pipe on the supporting surface.