Watering is not an easy task, and running around the dacha with a bucket back and forth is tiring. That is why the best solution to this issue on a personal plot would be to build a water supply system for the summer, and the best material would be plastic pipes.

There are two types of country water supply:

- collapsible;

- stationary.

Features of planning a country water supply system

Building a water supply system on a summer cottage is always more difficult than building a water supply system for a residential building or garage. The main problem is that formally you will need to build three branches:

- Plumbing with drinking water for a country house;

- Stationary water supply system for supplying technical water to the house and to watering points in the beds;

- A temporary structure or portable system of pipes and hoses for connecting drip and shower irrigation of beds, shrubs and trees.

For each system, you can choose your own version of plastic pipes that is most suitable for the task. In addition, the price of plastic pipes for water supply in the country is of no small importance. For example, if you try to draw up a water supply diagram for a country house, it will become clear that in this case everything will take no more than 20 m of pipes with three consumer points - for the kitchen, shower and toilet.

Such a water supply system can be easily assembled with your own hands from polypropylene pipes. The whole idea of installing a water supply system in a country house will cost a maximum of $150-200, provided it is connected to a centralized water supply system or to an already built well with a pump and outlet.

If you try to assemble a water supply system for an irrigation system using the same scheme, then the costs of purchasing and assembling plastic pipes alone can increase several times. For example, for a standard dacha plot of 6 acres, the total length of the pipeline laid in the ground is at least 100 linear meters; accordingly, the price of an irrigation branch of a polypropylene water pipeline will increase by at least 2-3 times. To this scheme it is worth adding a system of hose waterers and drip irrigation, for example, for a greenhouse or beds under film.

For your information! A properly planned and constructed plastic water supply can withstand 10-15 years of operation without major repairs or maintenance.

A country irrigation system assembled from rubber hoses and steel pipes, with a higher construction cost, lasts approximately half as long, so there is no real alternative to using plastic.

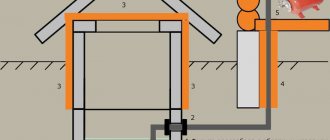

A typical design of a country plastic water supply system is shown in the diagram. As a rule, water supply to the beds was carried out in the form of several parallel pipelines with a diameter of 20 mm, which were connected in the form of a “comb” to the main pressure line with a cross-section of 40-50 mm.

To ensure the supply of irrigation water, one pressure irrigation and one supply line are sufficient to supply the house and fill the drip irrigation reservoir.

Features of the selection of plastic pipes for each segment of the water supply system

The simplest conclusion suggests itself: in order to reduce costs, for each section of the country water supply you need to use your own, most suitable brand of plastic pipes.

Four types of plastic pipes and hoses are currently used for country water supply:

- Polypropylene;

- Polyethylene;

- Silicone;

- Polyvinyl chloride.

PVC pipes have good strength characteristics and satisfactory resistance to sun and frost, but it is better not to use it for arranging above-ground water supply systems. In any case, PVC plastic pipes will require special wrapping with polyethylene foam, which protects against accidental scratches and impacts during installation and further use.

For your information! Of the entire range of plastic pipes for country water supply systems, only metal-plastic ones with an aluminum reinforcing layer are not used.

First of all, the price of metal-plastic pipes is several times higher than polymer pipelines made of polyethylene with a similar cross-section.

The metal-plastic pipeline perfectly withstands prolonged heating, high water pressure, and can serve in a summer cottage for several decades. But under one condition - the country water supply must be completely empty of water in winter, and completely filled in summer.

Thin-walled metal-plastic pipes swell when they freeze and the connecting fittings become deformed. In the summer, standing idle without water leads to intense corrosion of the aluminum sublayer; if you step on it or run over it with the wheel of a vehicle, then with a high degree of probability such a country water supply will be damaged.

Which pipes are better

The water supply system for a summer residence can be made of copper. The main advantage of copper structures is their high service life of 70 years. At the same time, copper is highly expensive. Not every person can afford such a water supply.

You can also choose polypropylene pipes for your dacha. Their service life is more than half a century. Their cost is quite affordable. A universal option for water supply in a dacha are stainless steel structures. Their service life is quite long, they can be used for cold and hot water supply systems. The downside, again, is the high cost.

Metal pipes have a long service life. However, they are rarely used when arranging a private home due to a number of disadvantages, in particular:

- Risk of corrosion;

- Risk of deposits;

- During installation you will need a welding machine;

- Insufficient level of environmental friendliness.

A worthy alternative for arranging water supply in a dacha are plastic pipes. Let's consider their advantages:

- Chemical resistance;

- Resistance to corrosion;

- Resistance to deposits;

- Service life more than half a century;

- When transporting hot water, virtually no heat is lost;

- Easy to install.

Plastic pipes are just a general name for many groups of these structures. Which system is better to choose? It all depends on your needs and operating conditions of the system. You can see the variety of these designs in the photo.

It is recommended to use PVC pipes for organizing open wiring, as they have the required rigidity and are also resistant to ultraviolet radiation. When installing them, gluing technology is used.

Polypropylene pipes are universal. They can be used to transport both cold and hot water. With their help, you can also organize a heating system and underground sewerage. Their advantages are the same as those of structures made of cross-linked polyethylene. At the same time, the price of the product is lower. Welding equipment is used during installation. It is worth keeping in mind that when organizing the transportation of hot water, structures with metal or fiberglass reinforcement are used.

Metal-plastic pipes differ in their structure: an outer and an outer polymer layer. The middle layer is made of aluminum. To organize the transportation of cold water, blue or light blue structures are used. If you need to install a hot water supply system, you should choose white structures. Let's consider the advantages of metal-plastic structures:

Corrosion resistance;

- Neat appearance;

- Ease;

- Plastic;

- Long service life;

- Easy to install.

You can also choose PVC pipes. To arrange the transportation of cold water, structures marked PVC are intended, and hot water – CPVC.

Additional recommendations

You can see the entire range of designs for the dacha in the photo. In addition, we have a video on our website with instructions on choosing the right pipes. For the installation of water supply systems, designs from Western brands are usually selected. Manufacturers from Germany, the Czech Republic, and Austria enjoy trust. When purchasing, be sure to check the product certificate.

Advantages and disadvantages of polyethylene pipes

Firstly, the cost of a linear meter of polyethylene water pipe with a diameter of 25 mm is only 30 cents; for comparison, a meter of polypropylene pipe will cost at least 1.5 dollars. Even taking into account the fact that couplings for polyethylene and polypropylene cost 2.2 dollars and 1.3 dollars respectively, the use of polyethylene pipelines will cost much less than plastic pipelines based on polypropylene.

Moreover, polyethylene, as a rule, is sold in the form of coiled sections of 20 and 100 m. Polypropylene pipes are sold in retail in ready-made pieces of 4 m and 6 m, which means that the number of couplings will be required several times more.

Secondly, polyethylene pipes have good resistance to solar ultraviolet radiation, high strength and ductility. Even at low temperatures and frozen water inside the water supply, plastic pipes do not fail.

Two grades of polyethylene pipes are produced for plumbing systems:

- LDPE is a high-pressure polymer, used for small sections of water pipelines where good flexibility and strength are required;

- HDPE is a low-pressure polymer, used for high-pressure water pipelines and highways.

For your information! Country water pipelines are built from polyethylene pipes designed for transporting drinking water.

They are easily distinguished by their blue or white longitudinal stripe on a black background. Any other brands, for example, with a yellow or orange stripe, are designed for transporting gas and liquid chemical products, so they are not even suitable for watering in a summer cottage. On the surface of the plastic pipe, the purpose, diameter, wall thickness and GOST, on the basis of which the plastic product is manufactured, must be indicated.

In addition to the brand of polyethylene and purpose, plastic pipes are distinguished by operating pressure:

- Low-pressure or L-class, the working pressure in the line is no more than 2.5 atm;

- Medium-pressure S and SL, designed for pressure from 4 to 8 atm;

- High-pressure T-class, used for water pipelines with a working pressure of more than 10 atm.

The latter are used for equipping wells and boreholes in summer cottages; class L and SL are most often used for water supply distribution throughout the territory, provided that the terrain has a difference of no more than 10 m in height for every 100 m of horizontal length.

Advantages of polypropylene pipes

Polypropylene products are modern, durable and environmentally friendly. Their main difference is the connection method, that is, soldering different parts using a special welding machine. The result is a very reliable coupling, which takes no more than 1 minute to create.

Polypropylene has an operating temperature of +75 degrees. When using such pipes under pressure conditions of 7-8 atm, their service life will be about 25 years. However, the maximum temperature at which such pipes can be operated is +95 degrees, but, accordingly, the service life will be shorter.

Metal-plastic, for example, in this case has an advantage, since its operating temperature is initially +95 degrees, and the maximum is +110 degrees.

When it comes to strength and resistance to mechanical stress, polypropylene has the advantage. In addition, it can easily withstand the freezing of water in a pipe, which cannot be said about metal-plastic.

Advantages of polypropylene pipes:

- There are no harmful substances inside that impair the quality of water.

- They do not have lime and bacterial deposits.

- With proper soldering and careful use, the products will last 50 years.

- According to test results, polypropylene elements are shock-resistant.

- Installation takes a matter of seconds, does not take much time and is carried out by soldering with a special device and fittings.

- The parts are inexpensive.

For irrigation, as a rule, pipes with a cross-section of 20-25 mm are used, although a larger diameter is allowed. A large cross-section is especially important when using a centralized water main, where there may be low pressure.

Do-it-yourself installation of a country water supply system

The main difference between a country water supply system and a home circuit is that pipe routing must be carried out taking into account the following requirements:

- Large length of water mains on the territory of the summer cottage;

- For every 5-7 m of the length of the underground water supply, it is necessary to solder in an outlet with a tap.

The water pipeline must be laid in the ground to a depth of at least 40-45 cm with a protective layer of slate scraps, fragments of plaster stone or old asbestos-cement pipes.

For your information! Laying a plastic pipe allows you to protect the pipe from accidental damage by a shovel, cutting blade of a walk-behind tractor or tractor.

Most summer residents are well aware of the effect of plastic pipes rising in the ground. Over time, due to the washing off of the top layer and heaving of the soil, the lightweight plastic pipe is gradually squeezed out to the surface, so laying protection makes it possible to combat the deformation of the water supply system.

It is clear that water supply pipes can be laid simply on the surface of the ground, but in summer cottages this installation method is used extremely limitedly for two reasons. Firstly, this interferes with the processing of the beds, and secondly, prefabricated structures made of polyethylene pipes are quite easily damaged by being caught by a tool or touched by the wheel of a walk-behind tractor.

One of the most important characteristics of a plastic water supply is its strength and rigidity, which become the main obstacle when installing an irrigation system. Rigid material can only be bent at a large radius, so compression couplings have to be used for joining and turning.

Essentially, a coupling or fitting is two parts connected into one body using threads. To splice two lines of water supply, it is enough to install the halves on the ends of the pipes, lay the seal and close the fitting with force. It is clear that this connection method is not designed for radial load, therefore, if you step on the plastic coupling, it is quite possible that the fitting will have to be disassembled and spliced in a new way.

In the same way, you can connect a flexible hose, build a turn in the line at a right angle, or make a branch into several threads of smaller diameter.

Installation of the irrigation outlet is relatively simple. To do this, install a clamp with a coupling on the pipe for installing a vertical outlet; after tightening the bolt fastening, you need to drill a hole and screw in a tap with a nozzle under the hose.

Installation of water supply at the dacha

It is most advisable to use polyethylene pipes for low-pressure irrigation with a diameter of 20.0 - 40.0 mm and a wall thickness of up to 2.0 mm. For branch branches, products with a diameter of 25.0 mm will be sufficient. Such pipes fully cope with their task and will not require replacement for a long time. They are also able to withstand mechanical loads, even such as being hit by garden equipment.

Compression fittings for connecting PE pipes

Laying your own garden water supply from polyethylene pipes is quite simple. The only tool you need to prepare is an adjustable wrench. The connection of pipe products will be carried out using compression fittings; they are the most practical and effective for dacha conditions.

The pipeline is laid in several stages:

- First, as with the installation of any other water supply system, a detailed layout diagram is drawn up, including the future irrigation system. It allows you to more accurately navigate the quantity of pipe products and compression fittings.

- There are two methods used to lay the pipeline:

- open on the ground surface. With this method, the installation and dismantling of PE pipes is greatly facilitated, but at the same time the likelihood of damage to the products increases;

- at a shallow depth in the ground. In this case, the HDPE pipe for the dacha is more protected, and dismantling it will not be difficult.

Laying PE pipes on the ground

- The second method is preferable. The main HDPE pipe at the dacha is laid in the ground. In this case, you don’t have to worry about accidental damage.

- The branches can be laid along the ground, or even better, mounted on special holders for more convenient connection to sprinkler devices.

When laying the pipeline, it is necessary to ensure a slight slope of the system in order to drain water from the pipes at the end of the season. To do this, it is enough to mount a regular valve at the lowest point of the main line.

- It is recommended to install valves at branch points. Then you can precisely control the supply of water exactly to the right places in your summer cottage.

Buried pipeline installation

- Buried pipeline laying.

- The required pipe sections must be securely connected using compression fittings.

- To connect, the ends of the products must be cleaned of dirt and it is advisable to remove the end chamfer. Unscrew the union nut of the fitting a couple of turns.

- On the pipe itself, mark the depth to which the coupling should enter the pipe.

- Applying a certain force, the fitting is inserted into the pipe and the union nut is tightened.

When tightening fittings, ensure that the nut is tightened to the recommended torque. Otherwise, if the tightening is insufficient, the tightness of the connection is not guaranteed. If you apply more force than normal, there is a possibility of damaging the pipe.

We can conclude that a self-installed country water supply system from HDPE pipes is an effective way to ensure water supply to a country house for domestic needs, as well as to organize a practical and reliable watering system for a summer cottage, while you can significantly save money and time.

Traditional methods of splicing polyethylene water pipes

If a plastic water supply system is laid on the ground surface and the water pressure exceeds 8 atm, then a more rational solution would be to use horn welding instead of fittings, or connect the pipes with a metal pipe. Both methods have been tested in practice and, according to reviews from owners of summer cottages, provide more reliable and high-quality joints of polyethylene pipes.

For your information! The services of a specialist in installing fittings and joining individual water supply lines are often more expensive than the plastic pipes themselves.

For welding, you will first need to make a device in the form of two metal sockets, with an opening angle of 15-20o. Before welding, the two ends of the plastic pipes are trimmed so that there is a mutual overlap of 40-50 mm. Usually, special scissors are used to cut polyethylene, but you can do the same job with a regular hacksaw.

The sockets are placed on the ends of the pipes. One is inserted with a cone inside the pipe, the second is put on the other end over the end. Both devices are slowly heated with a propane torch to melt the polyethylene. After 7-10 minutes. the sockets are removed, and the ends of the pipes are forcefully inserted into each other by 40-50 mm. The result is a strong and tight connection.

No less reliable and durable splicing of 25 mm polyethylene pipes can be done using a conventional metal splice 150 -200 mm long with threads at both ends. The internal diameter of the plastic pipe is 21 mm; it will not be possible to connect two threads of polyethylene water supply using a one and a half inch piece of pipe, since its outer diameter is 22 mm.

After cutting the thread, the bend can simply be screwed inside the plastic pipe. The sharp edges of the threads cut into the plastic, engage and securely fix the bend inside the pipeline. To assemble the joint, it is enough to apply rubber glue-sealant to the threads and wrap the second piece of plastic pipe. It is clear that the assembly of plastic pipes on bends can only be done sequentially, since one section of pipe has to be rotated relative to another.

End welding for the assembly of plastic water pipes in summer cottages, as it is designed for the assembly of pipelines with a wall thickness of 5 mm and above.

Materials for polypropylene water supply in a summer cottage

The reason for this popularity is the very simple and reliable soldering system of polypropylene; with a little practice, not only long pipeline branches can be made from plastic pipes, but also greenhouses, hotbeds, frames of tents and canopies.

In addition to the high price of the material, polypropylene has several significant disadvantages that you should know about before planning the construction of a water supply system at your summer cottage:

- If polypropylene pipes are filled with water, then freezing, as a rule, leads to the appearance of hidden cracks and destruction of the line;

- Under the influence of solar ultraviolet radiation, the process of secondary polymerization begins in polypropylene. Over time, the material begins to crumble and lose strength, even if the pipeline is not exposed to direct sunlight.

Some brands of polypropylene pipes can be used for street water supply. As a rule, manufacturers paint plastic in black and green colors; polypropylene for internal installation is light gray, white or beige.

For the main supply line of the pipeline, you can use a pipe measuring 32x3 mm; this will be enough to lay out the water supply and organize irrigation on 5-6 acres of a summer cottage. Branches and outlets are made with 16x2 mm pipes with the installation of taps.

Shut-off and switching valves need to be given special attention. Traditionally, for plastic water supply systems, most supplying companies suggest using polypropylene taps with a rubber mushroom that blocks the flow hole.

Such designs are usually used as shut-off valves in domestic water supply systems. They are not suitable for country water supply; even with regular maintenance, such valves and taps quickly fail. Their main advantage is ease of installation; they can be soldered into a plastic line, like a regular coupling.

A more rational solution would be to use conventional bronze valves; their service life is 10-15 years or more. The only inconvenience is that to install such a crane you will have to additionally purchase two metal-to-plastic adapters.

Methods for connecting polypropylene pipes in a summer cottage

Traditionally, to assemble a water supply system from polypropylene pipes, a special soldering iron is used, approximately the same as in the photo above. The quality of the assembly of a plastic water pipe depends on two factors - the availability of skills in performing installation operations and the characteristics of the soldering iron itself. You shouldn’t try to assemble a water pipe using homemade devices; it’s better to rent high-quality equipment for a couple of days, which can be used to solder water pipes, as they say, to perfection.

The principle of soldering is quite simple - the connecting coupling and the end of the pipe are heated on the nozzles of the soldering iron, after exposure, the parts are simply connected by hand with little effort.

The method is simple, but in the conditions of a summer cottage it is not so easy to apply, since it is not always possible to extend the electrical network to the junction of the water supply system, even with the help of a cable reel. Some parts can be soldered in a country house, but still, approximately 30% of soldering work with plastic pipes will have to be done practically in the garden beds.

If there is no electricity at your summer cottage, then the plastic water supply can be glued together with a specialized dichloroethane-based glue. The glued joint has almost the same strength as the soldered version, but working with dichloroethane requires caution, since the solvent is classified as a substance hazardous to health.

Recommendations for arranging a water supply system in a summer cottage

The classic design of a country water supply system involves wiring according to the following scheme. The entrance to the site is made of polyethylene with a diameter of 50-70 mm. The water supply must be insulated and laid in the ground at the depth of maximum soil freezing. An inspection well and a shut-off valve must be installed at the entrance. From the valve, water is directed through a PE pipe into a storage tank, from which part of the flow through a polypropylene pipe goes to the country house. Most of the water flow is redirected from the tank to the underground water supply, and then to the beds.

With this construction of a country water supply, an unlimited number of consumers can be connected to the tank, for example, a greenhouse or a car wash. Moreover, even in the absence of electricity or a pump malfunction, watering can be easily organized by gravity; a small height difference of 1-2 m will be enough for normal watering.

Organization of watering on the site

It is very important to determine the source of water on the site. It would be good if a central water supply line was laid along the street. You can simply connect to it after receiving the appropriate permission. If there is no water pipeline, then there are only two options left:

1. Summer water supply at the dacha from a well. To do this, you will need to dig a well on the site, strengthen it and ensure it is filled with water. A submersible or surface pump is used to supply water to the pipes. The same principle is used to supply water from a well. The disadvantage of this supply is the low water temperature, which the plants do not like.

Organization of watering from a well using flexible hoses

2. Water supply for irrigation from the reservoir. Water is collected into a reservoir located on the site, where it reaches a temperature suitable for irrigation, and from there it is supplied to the installed polypropylene water supply.

Read about how to solder polypropylene pipes with your own hands in a separate material.

If you are interested in learning how to organize a drainage device in a bathhouse, we talked about this in another article on the site.

A description of the different types of irrigation pumps is here.