Grundfos Sololift pumping units are designed for forced pumping of wastewater from places located below the level of the public sewer system. Maintenance and repair of Sololift does not require the involvement of specialists. Most of the work, including installation and connection of equipment, can be done independently.

Pumping unit Sololift

What is a sololift and why is it needed?

From a design point of view, sololifts are pumps equipped with special grinders. They are most often installed in private households where there are problems with the sewer system riser located in an inconvenient location or with insufficient slope.

Application area:

- connecting a washing machine and dishwasher at a considerable distance from the sewer riser;

- installation of plumbing fixtures, including toilets, below the sewer level;

- moving the bathroom to another part of the room.

Forced sewerage promotes the most convenient drainage and allows you to install plumbing fixtures in the basement of a country house.

The variety and compactness of sololifts allow them to be installed in almost any place

The dimensions of such equipment are not too large, so the unit can easily be installed behind or inside a plumbing fixture, and thanks to the rounded shape of the bottom of the housing, waste does not linger inside the device. The forced drain installed in the home sewer system has high power levels, due to which wastewater is effectively discharged to a maximum of 90–100 meters in a horizontal position and approximately seven meters vertically.

Installation and connection rules

The installation and connection of toilet pumps and forced drainage from different manufacturers follows very similar rules. But before installation, you should read the instructions for a specific product - there may be special features.

Sewage pump for shower - with installation under the tray

Connection

The installation location must be chosen in such a way that the pump can be reached. It does not require special maintenance, but there is a need for cleaning from time to time. If a dishwasher and washing machine are connected to the pump, it is better to regularly check whether the sewage system is clogged with grease, dirt, and salt deposits. If necessary, cleaning with mild detergents is possible. It is better not to use aggressive chemical compounds, as they can damage the plastic and rubber parts of the installation.

If the sewer inlet is higher than necessary

General rules:

- An individual sewer installation must be grounded. Therefore, the outlet must be three-wire with a working ground.

- For safety, there must be a circuit breaker and an RCD on the power supply line.

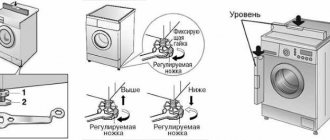

- During installation, the block is fixed to the floor. To reduce the noise level, it is advisable to install it on a vibration-damping base (rubber gasket). It is not advisable to press the housing against the wall so as not to transmit vibration from the pump. These measures are needed to reduce noise levels. A sewer pump can be installed in the kitchen to remove waste from the sink or dishwasher.

- The exhaust pipeline is made of rigid plumbing pipes. There are two recommended options - plastic sewer pipes and copper pipes. Fittings are recommended to be rigid and one-piece.

- Pipelines must be fixedly fixed (to walls, floor, etc.).

In general, installing and connecting a sewer pump for a kitchen or toilet is not a very difficult undertaking. But provided that you already have some idea about working with plumbing. In this case, you can do everything yourself.

Features of the outlet pipeline

Compact plumbing pumps for the toilet can pump wastewater not only vertically, but can also lift it upward. If there is a vertical section in its lower part, it is advisable to provide for the possibility of draining - if you have to clear the pipeline from a blockage, it is better if the drains are drained in a certain place and do not start pouring out during work.

The height of the vertical section of the outlet pipeline is determined taking into account the minimum slope of the horizontal section. Each manufacturer (sometimes each model) has its own minimum slope, but in most cases it is 1-4% (1-4 cm per 1 meter).

Rules for installing a sewage pump

Be careful. The description of sewage pumps indicates the maximum lifting height of wastewater and the maximum horizontal transportation distance. For example: 8 m up, and 80 m horizontally. But this does not mean that by lifting the pipe 4 meters up, it will be possible to transport another 80 meters horizontally. In this case - after a four-meter rise - the length of the horizontal section will be no more than 40 meters. Simply lifting 1 meter upward “takes away” about 10 meters of horizontal transportation. This is important and worth remembering.

Design and principle of operation

The pumping unit, designed for forced pumping of wastewater when plumbing equipment is located lower than the level of the general house sewer system, has a fairly simple diagram:

- storage tank body;

- submersible pump;

- check valve device;

- receiving filter system;

- cutting and grinding mechanism;

- carbon filter.

The sololift consists of 6 main elements, including a cutting and grinding mechanism

The principle of operation is not too complicated and consists in drawing liquid through a filter receiving system into the storage tank of the pumping device. An impeller-shaped cutting mechanism located on the inlet part of the device quickly crushes all inclusions entering the sololift, represented by feces, paper and personal hygiene products. At the next stage, all wastewater moves inside the outlet pipe, and a special shut-off valve in the form of a valve prevents the backflow of all the discharged liquid.

Thanks to the presence of a carbon filter installed on the top of the device, unpleasant sewer odors do not leak into the room. A hydrodynamic thermal relay controls the degree of filling, and a plastic check valve system with adapters moves through pressure pipes during the filling process. An automatic start float sensor detects the filling level of the sewerage installation, and the pump is driven by a relay signal.

Advantages and disadvantages of use

Advantages of sololift:

- a powerful electric drive with a cutting device that can handle toilet paper and personal hygiene items;

- smooth, impenetrable body;

- small station sizes;

- the device operates automatically;

- the presence of a carbon filter on the housing lid eliminates the appearance of unpleasant odors in the room;

- ease of maintenance and repair.

One of the disadvantages is the high sensitivity of the electric pump to sudden voltage changes. Not all models have the ability to pump large volumes of water (bathroom, etc.).

Choosing a sololift for sewerage

Before you start choosing a sololift model, you should decide on the number of all connected plumbing fixtures and the total amount of waste water discharged. If there is a need to connect several plumbing fixtures at once, then it is advisable to give preference to models with an additional pipe. Particular attention is paid to the installation location of the system and the power indicators of the sololift.

The choice of sololift depends on the type and number of connected devices

- Sololift + WC - connection of one toilet;

- Sololift + WC-1 - connection of a toilet and sink;

- Sololift + WC-3 - connection of a toilet, sink, shower and bidet;

- Sololift + CWC-3 - connection of a wall-mounted toilet, sink and shower;

- Sololift + C-3 - connection of a washing machine and kitchen sink;

- Sololift + D-3 - connecting a shower stall and sink.

Sololift+ is used to equip an additional bathroom, toilet and any utility room on the ground floor of the house, a bathroom in a summer cottage and an additional bathroom in guest houses. The model is ideal for installation in a bathroom used by elderly or disabled people.

The most significant selection parameters:

- number of connection points;

- maximum height for vertical pumping;

- maximum horizontal pumping distance;

- performance;

- power consumption;

- permissible temperature of the pumped liquid;

- dimensions;

- weight;

- price;

- possibility of self-installation.

When choosing sewage pumping equipment, it is recommended to give preference to reliable and durable devices produced only by trusted European manufacturers, which include Grundfos, Lowara, SFA, DAB and WILO.

Expensive products from SFA and Grundfos are industry leaders with a developed service network, producing models with a long warranty period.

The internal part should be made only of durable and corrosion-resistant materials, including high-strength plastic.

Other models fall into the category of technically simpler devices, but they also cope quite well with their basic functions. It is important to remember that the presence of additional chopping knives in the pump design and increased power directly affect the noise level of the device during operation.

Classification and types

There is no single classification of forced sewer installations, but they can be divided according to several parameters:

- Presence of a chopper. It is needed if the sewer pump is connected to the toilet.

- Performance. This is the volume of wastewater that can be pumped per unit time. There are installations with low productivity and even very solid ones. The choice depends on the number and type of connected devices.

- The temperature of the pumped medium is from 40°C to 90°C. Everything is clear here - drains from a dishwasher, washing machine, and bathtubs require sewer pumping stations capable of pumping wastewater at high temperatures.

- Duration of work. There are installations that can only be turned on for a short time (they are installed on one or two devices), and there are more “long-lasting” ones (can be used to drain the wastewater of an entire house). This is usually indicated in the specifications as the duration of operation. The percentage may be 50%. This means that the installation works for 30 seconds and rests for 30 seconds. The operation/cooling interval can be specified in seconds or minutes.

A sewer pump can be installed in the kitchen to remove waste from the sink and/or dishwasher.

When choosing a pump for forced sewerage, it is worth remembering that they are not designed to connect a bathtub. Bathrooms contain too much water, pumping out which will cause the pump to overheat and block. As a result, it will take a long time to drain the water from the bathroom. There are only a few models of forced sewerage that will cope with this task - SFA Saniplus Silence and Sololift C3. These sewer pumps do a great job of discharging large amounts of warm water.

Other companies propose to make an intermediate pit for forced pumping of drainage from the bathroom into which to drain the water. From it, pump it into the sewer using any suitable device. Taking into account the fact that the pit must be below the drainage level, this method is not always acceptable. And, despite the high cost of SFA Saniplus Silence and Sololift C3, it is often more profitable to install it than to carry out a huge amount of excavation work.

To prevent the tank from overfilling there is an additional alarm device. In some companies it simply beeps when the container is full, in others it also turns off the device connected through it (washing machine or dishwasher).

Rules of operation and maintenance

Maintenance of all sololift models involves systematic cleaning of the equipment and the filter system installed inside it. For this purpose, special detergent compositions are used.

Sequence of cleaning pumping equipment:

- Disconnect devices from the electrical network.

- Remove the top cover of the device.

- Pour detergent into the reservoir.

- Turn on the pump and drain the liquid.

- Pump the unit with running water.

- Close the unit cover.

The electrical power must be turned off when cleaning the filter, which is removed, washed and installed in its original place.

Some models are equipped with a magnetic float switch installed at different levels. During maintenance, such a float must be removed.

Technical features and functionality of Sololift sewage pumps

The Danish company Grundfos is a manufacturer of a whole series of powerful and reliable sewerage installations. An extensive line of pumps allows consumers to take an individual approach to organizing a system for draining liquid from a bathroom or toilet. Despite similar external characteristics, each model has its own power level and set of specific functions.

The device has the form of a sealed case made of high-strength plastic. A pump is attached to it, designed to pump out liquid. The equipment starts automatically as soon as the water in the tank reaches a certain level. The manufacturer produces two series of pumps: Sololift+ and Sololift 2.

Models common to both series:

- WC-1;

- WC-3;

- CWC-3.

They differ in the number of features and functions, as well as technical characteristics. There are other modifications of installations.

Technical parameters and characteristics of Sololift pumps

The main advantages of Grundfos Sololift pumping stations are ease of installation and ease of maintenance

Some pump options are equipped with an impeller with sharp cutting edges. This part is used to shred large waste that clogs drain pipes. The size of the station inlet is 10 cm. This area is convenient for connecting a pipe with a cross-section of 110 mm. The minimum lift height of the water jet is 5 m.

The structures consist of the following components:

- storage tank;

- submersible pump;

- reverse valve;

- receiving filtration system;

- cutting mechanism in the form of an impeller;

- carbon filter.

Operating temperature of most models: from 0 to 45°C. An exception is the modification of the Sololift C-3 installation, which can withstand temperatures up to 90°C.

The scope of application of Grundfos products extends to the following objects:

- baths;

- toilets (wall-hung and floor-mounted);

- showers;

- baths.

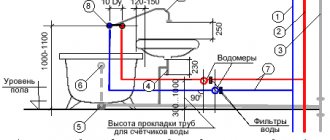

Connection diagram for the Salolift pumping unit

The kitchen sololift ensures the operation of washing machines and dishwashers. The average pressure level for most models is 9.9 m. The efficiency is 4.5 m³/h.

The accompanying equipment of pumping units provides additional advantages:

- built-in overheating protection;

- cord 120 cm long, allowing you to move the installation area;

- additional degree of purification due to the carbon filter.

Helpful advice! When choosing a pump for your home, it is very important to pay attention to its characteristics. Buying the optimal model will eliminate overpaying for unnecessary features.

Operating voltage of the equipment is 220-240 W. The thermal hydrodynamic relay controls the degree of filling. Check valves with flexible adapters are driven by pressure pipes as they fill. This principle of operation eliminates the possibility of liquid overflow and unpleasant odors entering the living space. The equipment is equipped with reliable and powerful engines. The material for the manufacture of the crankcase and shaft was stainless steel, so they are protected from corrosion.

It is better to install the Sololift 2 WC-1 pump at a distance of 15 cm from the toilet

Design features of Sololift WC-1 models

The compact dimensions of Sololift WC-1 do not require a large amount of free space for installation. They fit easily into rooms with limited space. The Sololift+ series pump is equipped with a chopper and a powerful motor. These parts ensure uninterrupted operation of the unit.

The grinder helps clear blockages in pipes that can be caused by:

- plenty of toilet paper;

- hygiene items that got into the pipeline;

- accumulations of fecal matter.

If for some reason the system fails, the equipment notifies you of the failure using an audible signal. This way, the problem will not go unnoticed. Internal parts are located within easy reach, so the process of maintenance and repair of the Sololift Plus pump is not difficult. There is no need to dismantle all connecting chains. Therefore, repairs do not require much time.

The weight of the unit is 7.3 kg (both models). The capacity of the storage tank is 9 liters. To install the Sololift on the floor, screws or dowels are used. Holes are provided in the design specifically for them. Nozzles and adapters of the required size are used as a fastening element between the sewerage system and the equipment. The adapter in the discharge line can be installed both horizontally and vertically. The return valve is also located here.

Sololift2 WC-1 – sewage pumping unit with a built-in mechanism for grinding large particles

Experts recommend installing the pump directly behind the toilet. This is done so that no more than 15 cm remains between the plumbing fixture and the injection unit. After making sure that the pump is correctly connected and securely fixed, you can begin to operate it.

The Sololift 2 WC-1 modification installation has similar characteristics, but some indicators have been improved. These include the size of the body, which has become more compact, as well as increased motor power and functionality of the cutting elements.

Technical characteristics of Sololift WC-3 models

This modification of the device has the same advantages as the previous model. There is only one significant difference between them. In this case, the design is equipped with 3 additional pipes. The improved model is designed not only for the toilet, but also for the bidet, shower stall and sink.

Important! If a shower is connected to the system, the pipeline is laid with a slope of 1%. The installation instructions for Sololift 2 WC-3 allow the installation of a toilet and 3 other water consumption points. However, not a single modification allows you to connect several toilets to the system, since for proper operation of the sewerage system you will need an inlet hole larger than 10 cm.

The Sololift WC-3 pump can be used for a bidet, shower or sink

The total weight of the structure is 7.3 kg (both models). The volume of the storage tank is 9 liters. Moreover, the model is designed specifically for connection to toilets with a tank capable of holding from 4 to 9 liters. liquids.

The modification of Sololift 2 WC-3 contains a hydraulic vortex system designed to effectively combat blockages in the sewer system. The strength characteristics of the material from which the cutting element is made have increased in comparison with the similar Sololift+ model. The unit is fully insured against leaks.

Related article:

Sewage slope per 1 meter: SNiP and regulatory parameters of the system

Requirements for the installation of the drainage system pipeline, common mistakes. Formulas for calculating the angle of inclination.

Overview of the capabilities and characteristics of Sololift CWC-3 pumps

The size of this modification has been significantly reduced. The design includes a part for crushing blockages. This type of pump is designed to be installed on a sink, toilet or bidet. The optimal place to install the equipment is a niche in the wall, since the compact dimensions of the unit allow it to be placed in a limited area. It is very important not to block the lid, so as not to complicate the process of maintenance and repair of the Sololift.

Thanks to the rounded shape of the bottom, the possibility of sediment accumulation is eliminated. When a system or equipment problem occurs, the pump triggers an audible notification. The design provides protection that prevents engine overheating, and also has a self-restart function. The weight of both models is 7.1 kg. The capacity of the storage tank is the same as in similar models of the same series.

Connecting the Salolift sewage pump

The same modification in the Sololift 2 series is characterized by a wall-mounted type of placement. Like all models in this line, the CWC-3 pump is not capable of pumping hot liquid. The maximum temperature limit is 50°C. The package includes 3 additional pipes, their sizes: 32, 40 and 50 mm.

Brief overview of other pump modifications in the Sololift 2 and Sololift+ series

There are two more models in the Sololift+ pump line, the capabilities of which are fundamentally different from those described earlier. Modification D-3 is not designed for pumping waste liquid that contains large elements. The kit does not include a cutting impeller, so connecting the pump to the toilet is not allowed.

The case has a sealed design with a round bottom shape characteristic of most models. Installation does not require the use of special tools. All you need is a screwdriver and fasteners (screws). If necessary, the pump can be easily removed. The weight of the structure is 4.3 kg. The reservoir can hold no more than 2 liters.

Model C-3 from the same series is radically different from other devices. This unit can pump wastewater that has a high temperature. The maximum limit is 90°C and only for 30 minutes. Pump weight – 6.6 kg. There is no cutting mechanism included in its configuration. The equipment is designed to be connected to sinks, washing machines and dishwashers.

The Sololift+ D-3 pump does not include a cutting impeller

Important ! It is not allowed to connect more than three water consumption points at the same time.

The model is equipped with a float switch. This magnetic element can be installed at different levels. When maintenance is carried out, the float is removed. The pump is equipped with an alarm system. Its tank holds 5.7 liters.

The updated Sololift 2 line also has the C-3 model. This unit with a rounded bottom is self-cleaning, so dirt does not accumulate. The device can pump hot water (up to 90°C) for an unlimited period of time. Since all the pumps of the new model range have powerful motors, the manufacturer has provided two fasteners in the designs. Thanks to this, the equipment does not tip over during operation. Pump weight – 6.6 kg.

Advantages of the model:

- float type switch;

- two-level descent system;

- possibility of separate drainage.

A niche in the wall is the optimal place to install the Sololift CWC-3 pump

Pumping unit D-2 is designed for pumping gray wastewater that does not contain large particles. This type of equipment is lightweight - only 4.3 kg. The maximum temperature of the wastewater is 50°C.