- Depth of laying pipes for water supply

- Standards for laying pipes

- Requirements for laying pipes in the ground

- Which pipe is better for underground water supply?

- Features of choosing water pipes for laying in the ground

- errors when laying in the ground

Most pipelines for a private home or cottage are laid underground, which increases the load on the system. Therefore, it is very important to choose the right pipes for water supply in the ground. Let's consider the features of the pipeline and the nuances of choice for maximum operational efficiency.

Depth of laying pipes for water supply

In order to correctly lay HDPE pipes for water supply, it is necessary to take into account many factors, since any deviation can lead to a malfunction of the entire system. It is very important to determine the burial depth, since the material and structural features will depend on this.

The most optimal choice is a pipe of the HDPE PN10 type, for the manufacture of which high-quality polyethylene is used. This material has the following features:

- resistance to corrosion;

- withstands pressure up to 10 atmospheres, which allows you to bend pipes to obtain the required shape;

- withstands temperature changes.

The depth should be more than one and a half meters from the surface. This placement prevents damage to the line due to pressure on the soil.

Note! To avoid freezing, it is recommended to bury pipes to a depth of 1.5 to 2 meters. If laid incorrectly, the pipeline may freeze, which will prevent the supply of water to the house and further residence in it.

Before laying the pipeline, it is necessary to study the soil map to analyze the depth of freezing and the characteristics of the ground.

Polyethylene water pipes

The modified plastic from which polyethylene pipes are produced ranks first among all types of plastics in terms of its quality characteristics. Therefore, polyethylene pipes are the strongest and most reliable.

Classified according to the following criteria:

- coolant temperature, that is, they are used for installing hot (cross-linked polyethylene) or cold water supply (low-pressure polyethylene HDPE);

- ability to withstand a certain pressure: there are pressure, medium-pressure and non-pressure;

- connection method: using fittings or welding.

Advantages of polyethylene pipes:

HDPE pipeline in a bay

- Designed for underground installation, they are highly resistant to chemicals and corrosion.

- Polyethylene is a very plastic material that can stretch under heavy loads. Therefore, pipes made of this material are highly resistant to hydraulic shocks.

- Long service life - up to 50 years.

- Relatively low cost.

- Polyethylene pipes have high thermal insulation characteristics.

- The relatively light weight of polyethylene products greatly facilitates their installation.

- The large length of the pipes (they are produced in coils) ensures ease of assembly, since the number of connections is reduced.

It is necessary to point out one drawback of these pipelines. They are somewhat affected by ultraviolet rays. It is for this reason that they are used mainly for installing underground or internal water supply systems.

This is important: Polyethylene pipes do not lose their strength even at very low temperatures. Therefore, when water freezes in them, the integrity of the material will not be compromised.

Standards for laying pipes

The performance of the system depends on the correct installation of work in accordance with technical standards. Do not think that the deeper the pipe is buried, the better the pipeline will work. It is important to comply with all requirements and standards that are established in this area.

Burying the pipe too deeply will increase the cost of digging the trench and also complicate sewer maintenance. Serious problems in this case can arise when the soil is washed away, which puts too much pressure on the pipes, which can be damaged.

The underground pipeline is laid in accordance with SNiP 2.04.03. -85°C. The standard does not specify clear parameters for the depth of laying pipes, but contains provisions that define compliance criteria.

First of all, it is necessary to be guided by climatic conditions, the level of soil freezing, and the experience of specialists involved in installation in a given region. It is also recommended to study the operating data of the equipment.

If there is no exact information about the laying, then the depth should be 0.5 meters greater than the freezing level. The distance from the pipe to the soil surface must be at least 0.7 meters.

Important! It is imperative to take into account the characteristics of the soil: clay and its mixtures freeze less, unlike sand and sandy loam.

Installation of water pipes in a private house

Having chosen the most economical option for purchasing pipes for equipping the water supply system of a private house with your own hands, we begin to connect them. The sequence of operations is as follows:

- Using special scissors, the products are cut at right angles into pieces of the required length.

- The welding depth is marked on the resulting sections. The welding area is cleaned of dust, dirt and grease stains.

- Having installed nozzles of the required diameter on the welding machine, turn it on, heating it to 260 degrees.

- The pipe sections intended for welding are put on the nozzles, avoiding rotational movements. After five to seven seconds, the pipe sections are carefully removed.

- The connection of the prepared sections is made with a quick and precise movement, without rotation. They cuddle for a few seconds.

The connection is made, but you need to give it time to cool before installation begins.

Requirements for laying pipes in the ground

There are certain requirements, compliance with which will allow installation to be carried out correctly without causing problems during operation. It is preferable to choose reinforced pipes, as they are more reliable and can withstand increased loads. It is also important to carefully insulate the system to avoid leakage and freezing.

Compliance with all requirements allows you to minimize heat loss and extend the service life of the structure. The pipeline does not need to be rigidly fixed, since the pipes will expand when transporting hot water.

In some cases, it is necessary to use additional elements for insulation and insulation. The latter is especially true for areas with harsh winters. The following options can be used as insulation:

- using a case;

- use of foam concrete;

- use of mats for insulation;

- installation of heating cable;

- increase in pressure in the pipeline.

Other requirements may be imposed on the arrangement of the system, depending on climatic conditions and soil characteristics. For more correct installation, it is recommended to consult a specialist.

Technology for laying external systems in the ground

Laying pipes in an underground (closed) way is a traditional method for installing cold water supply and sewerage pipelines in the private sector. When arranging drainage, low-pressure polyethylene pipes are also used, but of a larger diameter: they are laid at a slight angle towards the septic tank.

We recommend that you read: How to select, install and correctly use the Mayevsky valve

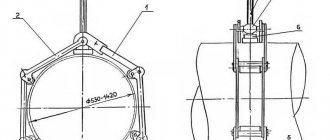

The preparatory stage when laying pipes in the ground includes marking and digging trenches corresponding to a pre-made pipeline layout diagram. The location of future pipes from the house to the well or septic tank is marked on the site, after which excavation work begins using special equipment.

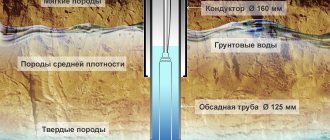

Before starting work, it is necessary to determine the properties of the soil and the depth of the aquifer, since closely located groundwater can push the pipeline out during the spring melting of snow.

Another important point before starting excavation work is the depth of soil freezing in winter. The impact of low temperatures on the pipeline is undesirable , because Pipes can burst in cold weather. The recommended depth for digging trenches is 1.4-1.6 meters. It is not recommended to bury sewer pipes deeper, because... this increases the labor intensity of work in case of repair and dismantling. If you have to lay pipes closer than 1.4 meters to the ground surface, you need to take care of insulation.

Rules for installation work

The sequence of all work on laying HDPE pipes underground looks like this:

- At the site, preliminary marking of trenches is carried out using pegs and twine, which are installed and stretched along the perimeter of future communications.

- The soil is excavated using earth-moving equipment or manually (if the length of the engineering system is relatively short).

- The bottom of the trenches is compacted manually or using a vibrating plate.

- A layer of sand or fine-grained gravel is placed at the bottom of the ditch.

- The pipeline is installed using one of the available methods.

- The trench is covered with earth.

Important! The layer of soil lying on top of HDPE pipes should not be thicker than 30 cm. Compacting the soil manually or using vibration equipment directly above the pipeline is prohibited.

To properly lay HDPE pipes, you must adhere to the following requirements:

- the depth of the pipeline must be at least 20 cm greater than the depth of soil freezing;

- the trench must be at least 40 cm wider than the diameter of the pipe;

- the thickness of the sand or gravel cushion at the bottom of the ditch is at least 15-20 cm;

- the initial coating of the pipe after laying is at least 15-30 cm, after which the trench can be buried with the soil removed during excavation.

We recommend that you read: Choosing a machine for high-quality welding of polyethylene pipes

Important! Depending on the chosen method of connecting pipes, it is necessary to provide the possibility of placing equipment in the trench. For example, if a butt welding machine is used, then the trench must be made in accordance with the dimensions of the equipment.

Possible difficulties

Obstacles to laying pipes underground can be associated with several factors:

- soil characteristics - too hard or, conversely, soft, wet, swampy and unstable soil;

- the presence of a telephone or power cable located close underground, underground technical structures (wells, hatches, neighbors’ septic tanks).

If the land plot is too loose, swampy or hard and rocky, then digging a trench to a safe depth for pipes will not be possible. In this case, it is necessary to use additional methods of insulating the pipeline and strengthening the soil.

Step-by-step instructions for doing the installation yourself

When the excavation work is completed and the trenches are prepared, it is necessary to carefully place the pipes in them. They can be connected to each other in two ways:

- butt welding;

- electrofusion welding.

The first method is used to connect large diameter pipes, for example, when installing a sewer system. To do this, you need a special device that heats the ends of the pipes to the required temperature.

Electrofusion welding involves the use of a special connecting element that is placed over the pipes. Due to the presence in the structure of the product of a metal element that conducts current, the pipe is heated to the melting temperature and forms an inextricable connection of molten polyethylene.

Attention! If you are installing a cold water supply pipeline and using pipes with a diameter of up to 63 cm, then compression fittings are also suitable for connecting them, which allow you to quickly fix the joint, achieving a high tightness of the connection.

Depending on the connection method you have chosen, the installation algorithm may look like this:

- Pipes located in the trench are centered relative to each other.

- The surface of the products at the joints is cleaned and degreased.

- An element for electrofusion welding is put on the pipe in advance and aligned symmetrically between the connected pipes.

- Using a generating apparatus, a current is supplied to the coupling, leading to the melting of the plastic.

We recommend that you read: How to make a box for heating pipes with your own hands?

In this way, all pipe sections in the trench are soldered.

Which pipe is better for underground water supply?

In order to understand the question of which pipes are best for water supply, you need to pay attention to the material of manufacture. This indicator affects the installation depth, service life and reliability of the structure.

There are a huge variety of different models and copies on store shelves, so the choice is quite difficult.

Let's look at each type separately:

- steel:

this type of pipeline is considered the most common, but recently its use has been declining. They can be used both in a private house and in an apartment building. Steel pipes are quite cheap and durable, but their installation is very difficult. They are perfect for plumbing repairs. - copper:

such products have an attractive appearance, which is an excellent advantage for outdoor installation, but not for underground installation. Copper structures are absolutely safe for human health and do not emit toxins. The service life of such products is quite long. A significant disadvantage is the high price. - metal-plastic:

this is the most common option, which is used both in private homes and in multi-apartment buildings. They are quite durable and reliable, the cost is reasonable. - plastic:

Such pipes can be of two types: polyethylene (HDPE), polypropylene (PVC). The products are extremely easy to install, reliable and durable. The most common use is polyethylene. You can carry out the installation yourself without special skills.

The last option is the most optimal, since it does not complicate installation and does not require special financial costs. When choosing a suitable material, you should rely on the characteristics of water supply, climatic conditions, diameter of the product and other features.

Metal-plastic pipes

These products are three-layer pipes, the inner and outer walls of which are made of plastic, and the inner layer located between them is made of aluminum. This soft metal allows the pipes to bend and strengthens the structure, making it more resistant to mechanical stress.

They have all the advantages of plastic pipes:

- light weight;

- inertness to impurities contained in water;

- durability;

- smooth inner surface;

- ease of assembly.

A metal-plastic water supply system is assembled on threaded fittings, which become the weakest point of the system. Over time, they weaken and leak, which, however, can be easily fixed by tightening them. But serious temperature changes can seriously damage the system.

Fittings for assembling metal-plastic pipes are the most expensive Source ssf32.ru

Features of choosing water pipes for laying in the ground

In order to decide on the choice of pipe for underground water supply, it is important to pay attention not only to the material of manufacture, but also to the following factors:

- Features of the land. The determining factors here will be the degree of freezing and climatic conditions. For warmer climates, you can use any pipes, but for cold climates, you need to choose ones that are denser and more frost-resistant.

- Pipeline operating time. In some cases, it will be used during the summer, then the pipes can not be placed too deep.

- Pipe elasticity indicator - some materials are susceptible to high pressure and may be subject to deformation.

- Distribution of groundwater that can affect the pipeline and deform it.

- The degree of load on the soil.

Note! Before choosing a suitable pipe, it is important to draw up an installation diagram.

Most of the listed criteria are suitable for polyethylene pipes, that is, HDPE. This type of product has the following features:

- rust resistance, which eliminates the need for insulation;

- minimum weight;

- easy installation and transportation;

- does not have an adverse effect on water quality.

HDPE products are more durable than PVC pipes and have an affordable price. They do not allow condensation to form and do not burst when frozen.

The disadvantages of such products are susceptibility to sunlight and temperature restrictions. These disadvantages do not have a significant impact on operation, so pipes are often used.

You can read more detailed information and get exact specifications here: https://plastdv.ru/stati/pochemu-truba-pnd-luchshij-vybor-dlya-vodoprovoda.

Selection of pipes depending on the soil

As for sandy and clayey soil, they are quite light and loose and are not capable of exerting any pressure on any pipeline. Metal-plastic and plastic pipes can be laid in such soil. The main thing is that the pipe for the water supply in the ground is of the required diameter and with the required wall thickness.

Methods for underground pipe laying

If you need to install a water supply system with a sufficiently large diameter, it is best to use corrugated pipes.

If the soil is rocky, then in this case the requirements for the water supply are much greater. Remember that this type of soil is quite rare. Taking into account rocky soil, it is necessary to use exclusively steel water supply, since plastic will not be able to withstand strong enough and powerful pressure.

Relationship between characteristics

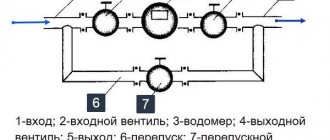

Dimensional characteristics are interrelated. For example, if the pressure in the incoming pipeline increases, then, with a constant cross-section, the pressure in the hydraulic system will become higher, and troubles may begin: connecting fittings will leak, the water supply will become noisy.

How does the length of the water pipe affect the diameter of the pipes?

Standard sizes of pipelines, their diameters are measured in inches. 1 inch is equal to 25.4 mm. The inch is indicated in the literature and on diagrams by the double apostrophe icon - “””. In domestic water supply systems, both houses and apartments use 0.5-inch or 3/4-inch calibers. They are designated as 1/2″ or 3/4″.

Table of pipe diameters for water supply.

The required diameter of the pipe elements is directly proportional to their total length. The diameter of the water supply pipes in the apartment does not exceed 20 mm.

The same section is used in a country private house with a small length, up to 10 m. If the length of the water supply in the building reaches 30 m, you need to take a pipe in a 25 mm crossbar; if the length is longer, then you should choose 32 mm.

The number of connections, turns and water points also affects the recommended diameter upwards. If you incorrectly select the capacity of pipelines for a sufficient number of consumption points, this can lead to the fact that, for example, opening a tap in one room will lead to a decrease in pressure and loss of water in another.

In a private house, the number of water points is greater than in a city apartment. The simultaneous use of most of them can even lead to the inoperability of household appliances, a washing machine or a dishwasher.

When designing and installing the system, it is better to use pipes with a spare cross-section, especially in a private house in the absence of a central water supply. Water risers have a larger diameter than the outlets going from the riser to the points of consumption.

Why does the diameter of the pipes determine the throughput of the water supply system?

According to the laws of hydrodynamics, the same amount of water passes through any section per unit time. With constant pressure and changing cross-sections in pipes, too small a cross-sectional size will lead to constantly high pressure in the system, which will reduce its reliability and can lead to breakdowns. It is inconvenient to use taps with increased pressure in the network.

To correctly calculate the water supply, it is necessary to take into account the throughput of the pipes. It must correspond to the number of consumption points, the amount of water consumed by a particular plumbing fixture. The water tap consumes no more than 5 liters of water per minute.

The table determines the pipe capacity.

When calculating the diameter of pipelines, you need to take into account:

- overall length;

- number of branches;

- number of joints and turns;

- water pressure created by a well pump

For a private country house, there is no point in making precise calculations using complex formulas and computer programs. This calculation is enough.

The water tap consumes no more than 5 liters of water per minute.

Up to 30 l/min can flow through a 25 mm pipe; with a diameter of 32 mm, the throughput increases to 50 l/min. For 10 water points, a 1-inch inlet pipe is sufficient. For greater accuracy, you can refer to the Shevelev tables. Another general rule: larger diameter - lower pressure.

The material from which the pipes are made affects the choice of their dimensional characteristics. To supply water to a home, pipes made of polymers can be used: plastic, PVC, metal-plastic, polyethylene. It is possible to create a water supply system made of steel, stainless steel or copper.