Basic properties of copper wire

To create wire, pure grades of copper are usually used - M3, M2, M1, M0 and higher (that is, grades with a copper content of more than 99%).

Production is carried out in a factory manner, and various ores or recyclable materials are used as feedstock. Based on their structure, there are two main types of wire: soft and hard. The soft one is suitable for engineering applications, while the hard one is often used for decorative purposes.

Properties

- Low material resistivity (P-value is 0.0175). Thanks to this, electric current easily passes through the metal, and the conductor does not heat up.

- Quite high density of copper wire (about 9 g per 1 cubic centimeter). Because of this, the material is light in weight and has a dense structure.

- Corrosion resistance. Thanks to this, the material does not rust or deteriorate during storage.

Where can I get copper wire at home? The wire is part of electric motors and electricity transformers. Therefore, it can be found in any electrical appliances - TVs, hair dryers, irons, vacuum cleaners and so on.

Copper wire is also very often used as a conductor of electrical current, so it can be found in wires and cables. Please note that cable copper is usually covered with a special protective sheath, which is difficult to remove manually. Whereas on transformers and electric motors the winding is in its pure form (insulation in this case is not required for technical reasons).

Method of treatment with copper coins

It must be remembered that coppers are only held on the body by the sore spot. Therefore, everything that accepts metal as a deliverer is subject to treatment.

For heart disease, one disc is placed under the center of the left collarbone. The point is found by the pain caused by sharp pressure with a finger when moving along the collarbone. Another disc is placed on the back between the spine and the obtuse (upper) angle of the scapula. It is advisable to hold the coin at this point more often for those people who are concerned about the behavior of their heart. While here, the disc simultaneously stabilizes blood pressure.

Copper coin - treatment

Frequent, boring headaches (on one side or the other) can be cured by wearing a hat with copper coins sewn into the lining (using a bandage). The cap is placed on the sore side; if the crown of the head hurts, it is placed on the forehead.

Ear disease is removed by two coppers: one is placed on the tragus, the other on the behind-the-ear bone. Moreover, this way they restore hearing and cure tinnitus.

If the veins are swollen and nodes appear on them, coins are placed near them (they cannot be used directly on the veins and nodes). They will remove inflammation, the veins will take their original places.

For glaucoma and eye cataracts, the disc is placed on the groove directed to the temple (not to be confused with the temporal fossa) and secured with an adhesive plaster. The coin is held until it comes off on its own. If a black circle forms under it, you should be happy - it did a good job. By the way, you can check the result by reading. As a rule, the text appears much better after treatment.

A serious problem is intestinal disease, which is constantly abnormal in every second person. Cases have been recorded when discs installed on the abdomen of patients without a patch “moved” themselves to diseased areas (pancreas, liver) and “clung” to the skin so that there was no need to hold them. They effectively fight colitis, gastritis, cholecystitis.

There is a known method of treating the intestines by American healers, who place the patient on a copper sheet, which has a detrimental effect even on cancer with metastases.

By the way, if your eyes begin to itch and become cloudy, then you need to start treating the original source, located inside the abdomen. Physiologist Mechnikov said that eye diseases are caused by faulty intestines. Therefore, you need to clean it with coins.

For hemorrhoids, one piece of copper is placed edgewise to the anus, the other is placed between the buttocks (touching the discs is not allowed). The coins will not fall, because the inflammation will grab onto them on its own, like a magic wand.

A formidable male disease - prostate adenoma - can also be treated with copper disks. One is applied to the anus, the other a little higher. The duration of wearing them is determined by the severity of the disease and can be several months.

With tracheitis, bronchitis, and asthma, discs will definitely help: they are placed (in large quantities) in the projection of the indicated systems and organs. If the metal is applied on time, then pneumonia will subside quickly and will not become chronic.

Injuries, bruises, and fractures can be restored effectively with metal. It relieves swelling, makes bones heal faster, removes and straightens unsightly seams.

Metal therapy can treat the most serious kidney diseases. She successfully corrects surgeons’ mistakes and actively fights the effects of radiation. It is surprising that copper is able to “reach” inflammation at any depth. It gets rid of women's diseases quite quickly. The main thing is not to be lazy and place coins on your lower abdomen at night. Metal saved many women's breasts from surgery. He restored a huge number of nasopharynxes, which are extremely necessary to keep in order, because Americans consider nasal mucus to be the cause of many diseases, even cancer. Copper is bactericidal, therefore it combats infectious arthritis of the joints.

Areas of application

- Copper wire for winding various transformers and energy generators. For such purposes, wire of small or medium diameter with a high specific copper content (more than 99.5%) is usually used. Thanks to this, electric current passes through the conductor freely and without delay, which improves the technical and operational characteristics of transformers and generators.

- Creation of cables and conductors of electric current. Copper wire is also widely used to create conductors, since copper conducts electric current very well and heats up slightly during operation.

- For needlework and creating frame structures for decorative purposes. You can make various decorative items - rings, frame products in the form of animals, wicker toys, and so on. Copper craft wire of grades M3 and higher has become widespread in this area. The specific copper content in this case is not too important.

The wire is also used for welding copper and brass products. You need to select the grade of copper depending on the composition of the original parts that will be welded. If the original parts and the welding wire have different compositions, then the quality of the weld will not be very high, which can lead to cracking and damage to the material.

Where is it used?

This depends on the type of metal; M1 wire can be used for grounding. It is distinguished not only by excellent electrical conductivity, but also by excellent conductivity of heat. This product will bend without any problems. Based on M1 wire, various wires are made for air and sea transport, for cryogenic equipment. But electrical round wire is needed to obtain:

- winding of electric motors;

- cords;

- cables and wires.

The welding wire discussed in detail above is used as a connection for semiconductor elements, during annealing and processing of silicon crystals. In addition to these applications, copper wire is needed for:

- crusher posts;

- obtaining rivets, nails and other accessories;

- creation of building structures and printing machines;

- production of light industry equipment;

- production of costume jewelry and decorative goods;

- creating chains, rings, bracelets, beads;

- some medical interventions (externally only!).

Resistance calculation

Electrical resistance is of particular importance in situations where the wire is used as a winding for transformers and generators. After all, if the resistance is too high, then in the event of an emergency, the winding may ignite, which can lead to catastrophic consequences.

Resistance formula

To accurately calculate resistance, use the following formula: R = (P x L)/S. It deciphers like this:

- R is the total resistance. We need to find this parameter as a result of calculations (units of measurement - Ohm).

- P is the resistivity of the material. This indicator is a physical constant, and it depends on the type of chemical element. For copper the constant P will be equal to 0.0175 (units - (Ohm x mm x mm)/m).

- L is the total length in meters. The larger it is, the higher the resistance of the conductor will be.

- S is the cross-sectional area in square millimeters. This parameter also affects the final resistance - the smaller it is, the higher the resistance will be.

Please note that the parameter S is usually indicated in the technical documentation, but instead of the cross-sectional area, sometimes only the cross-sectional diameter of the wire is indicated. In this case, it is necessary to calculate the area using the formula: S = (Pi xdxd)/4. This formula is deciphered as follows:

- Pi is a mathematical constant that is approximately equal to 3.14.

- d is the cross-sectional diameter of the conductor in millimeters.

As a result, the resistance of copper wire is measured using two formulas: R = (P x L)/S = (4 x P x L)/(Pi xdxd).

Examples of problems

Let's try to solve a few simple problems:

- Task 1. Determine the resistance of a wire whose length is 100 meters and cross-sectional area is 5 square millimeters. In our problem, the area parameter is known, so we will use the first formula R = (P x L)/S. Let's substitute our values: R = (0.0175 x 100)/5 = 0.35 Ohm.

- Task 2. Determine the resistance of a wire whose length is 500 meters and cross-sectional diameter is 2 millimeters. In this problem the diameter is known, so we will use the second formula R = (4 x P x L)/(Pi xdxd). Let's substitute our values: R = (4 x 0.0175 x 500)/(3.14 x 2 x 2) = 2.78 Ohm.

What affects the resistance of a copper wire

The electrical impedance of a copper cable depends on several factors:

- Specific resistance;

- Wire cross-sectional area;

- Wire lengths;

- External temperature.

The last point can be neglected in conditions of domestic use of the cable. A noticeable change in impedance occurs at temperatures above 100°C.

Resistance dependence

Resistivity in the SI system is denoted by the letter ρ. It is defined as the resistance value of a conductor having a cross-section of 1 m2 and a length of 1 m, measured in Ohm ∙ m2. This dimension is inconvenient in electrical calculations, so the unit of measurement Ohm ∙ mm2 is often used.

Important! This parameter is a characteristic of the substance - copper. It does not depend on the shape or cross-sectional area

The purity of the copper, the presence of impurities, the method of making the wire, and the temperature of the conductor are factors that affect the resistivity.

The dependence of the parameter on temperature is described by the following formula: ρt= ρ20. Here ρ20 is the resistivity of copper at 20°C, α is an empirically found coefficient, from 0°C to 100°C for copper it has a value equal to 0.004 °C-1, t is the temperature of the conductor.

Below is a table of ρ values for different metals at a temperature of 20°C.

Resistivity table

According to the table, copper has a low resistivity, lower only for silver. This ensures good conductivity of the metal.

The thicker the wire, the lower its resistance. The dependence of R of the conductor on the cross-section is called “inversely proportional”.

Important! As the cross-sectional area of the cable increases, it is easier for electrons to pass through the crystal lattice. Therefore, with increasing load and increasing current density, the cross-sectional area should be increased

An increase in the length of a copper cable entails an increase in its resistance. Impedance is directly proportional to the length of the wire. The longer the conductor, the more atoms there are in the path of free electrons.

conclusions

The last element that affects the resistance of copper is the temperature of the environment. The higher it is, the greater the amplitude of movement of the atoms of the crystal lattice. Thus, they create an additional obstacle for electrons participating in directed movement.

Important! If you lower the temperature to absolute zero, which has a value of 0° K or -273°C, then the opposite effect will be observed - the phenomenon of superconductivity. In this state the substance has zero resistance

Temperature correlation

Wire drawing

For production at factories, a special casting technology is used, which makes it possible to obtain copper wire with a cross-sectional diameter of about 20-30 millimeters. This figure is quite high, since such a thick wire has a lot of disadvantages - high specific gravity, high resistivity of the material, and so on.

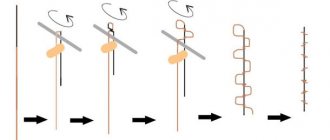

Therefore, after casting, drawing is also used. This technology allows you to reduce the diameter of the product to the required parameters (from 1-2 micrometers with ultra-fine drawing to 10 millimeters with coarse drawing). The drawing technology itself is quite simple: thick wire is passed through special holes (dies), the diameter of which is less than the diameter of the original wire.

Technology

Drawing requires special drawing machines, as well as adherence to a certain procedure.

- Immediately before drawing, the original wire must undergo an etching procedure. For this, a solution of hydrochloric acid is usually used, which is heated to low temperatures (40-50 degrees Celsius). After etching, it is also recommended to anneal the metal workpiece - this will make the metal fine-grained, which will allow for better drawing. After annealing, it is necessary to neutralize the remaining etching acid and rinse. Pickling and annealing can significantly increase the service life of drawing machines - if this is not done, the drawing holes-dies will quickly become clogged with scale, which will slow down the production process.

- Now you can proceed directly to drawing. To do this, the ends of the original wire are sharpened using forging tools, and then the wire is inserted into special die holes. After this, the engine of the drawing machine is started. To obtain thin or ultra-fine wire of small cross-section, it is successively passed through several dies.

- At the last stage of processing, the wire becomes quite rigid and springy. To get rid of this drawback, final annealing of the material occurs in the last compartment of the drawing machine. At the end, drying is carried out in special cabinet compartments - after this, winding is carried out on reels. Drawing is completed - the wire spools can now be placed in a warehouse and delivered to the customer using vehicles.

Automation

The drawing procedure is semi-automated - the operator only prepares and threads the initial wire, and the machine itself performs the drawing itself in automatic mode (although the operator can control the procedure parameters using the control panel).

In some cases, special lubricants can be applied before drawing - these can be fatty oils, emulsion inhibitors, solutions of alkaline salts, and so on. The purpose of applying a lubricant is to reduce friction during drawing - this allows you to obtain a thinner and more uniform wire + by applying a lubricant, the risk of ruptures is minimized.

CONTROL METHODS

3 1 Inspection of the surface of wire and rods is carried out without the use of magnifying devices. Surface quality control is carried out with a given probability of 97.5% (acceptance level of defects is 2.5%)

3 2 Determination of the dimensions of wire and rods is carried out in accordance with GOST 26877 with a micrometer in accordance with GOST 6507 or other devices that provide the necessary accuracy. If disagreements arise, sizing is carried out in accordance with GOST 6507 Dimensions are checked with a given probability of 97.5% (acceptance level of defects is 2.5% )

3 3 The curvature of the rods is determined according to GOST 26877

3 4 To analyze the chemical composition, one sample is cut from each selected skein (coil, drum, core), rod. Selection and preparation of samples to determine the chemical composition are carried out according to GOST 24231

The chemical composition of wire and rods is determined according to GOST 13938 1 - GOST 13938 12, GOST 13938 13, GOST 1652 1 - GOST 1652 13, GOST 1953 1 - GOST 1953 15, GOST 6689 1 - GOST

6689 22, GOST 9716 1 - GOST 9716 3, GOST 23859 0 - GOST 23859 11, GOST 25086 or other methods that provide the necessary accuracy of determination

If disagreements arise in assessing the chemical composition of wire and rods, the analysis is carried out according to GOST 13938 1 - GOST 13938 12, GOST 13938 13, GOST 1652 1 - GOST 1652 13, GOST 1953 1 - GOST 1953 15, GOST 6689 1 - GOST 6689 23, GOST

9716 1 — GOST 9716 3, GOST 23859 0 — GOST 23859 11, GOST

25086

3 5 For tensile testing, two samples are cut from each selected skein (coil, drum, core). Sampling for tensile testing is carried out according to GOST 10446

3 6 Sampling for bend testing is carried out from both ends of each controlled coil (coil, drum, core) or from two sections at a distance of at least 5 m from each other. Bend testing of wire is carried out in accordance with GOST 1579 3 7 Bend testing of rods is carried out around the mandrel with a radius of curvature equal to the diameter of the rod

3 8 To check a bar for a fracture, both ends of the bar are cut on one or both sides, after which it is broken. The cut must be made in such a way that the fracture passes through the central part of the bar. The width of the fracture must be at least 60% of the diameter. 3 9 Determination of the presence of residual stresses in wire and brass rods are carried out according to GOST 2060

3 10 The quality of winding is checked by external inspection

4. TRANSPORTATION AND STORAGE

4 1 Transport marking - according to GOST 14192

4 2 Wire and rods are transported by all types of transport in covered vehicles in accordance with the rules for the transportation of goods in force for this type of transport, by rail - small or low-tonnage shipments

4 3 Wire and rods must be stored indoors on racks or pallets and must be protected from mechanical damage, moisture and active chemicals

Subject to the specified storage conditions, the consumer properties of wire and rods do not change during storage.

APPENDIX 1 Recommended

Remelting

Waste or deformed copper wire can be melted down in special industrial furnaces. After remelting, copper must also go through several stages of purification to rid the material of various impurities. In factories this happens as follows:

- Scrap copper metal is cleaned from the windings and placed in special vats where the material is heated.

- To increase the temperature, oxygen is injected.

- As a result of this operation, the temperature rises sharply, which leads to complete melting of the copper and burnout of all major impurities.

- After this, special hoods are turned on, which leads to rotation of the vat of metal - due to this, the copper is separated from the refractory debris.

- Now the copper is poured into molds and, after cooling slightly, placed in water baths to form solid ingots.

- After this, the copper is placed in special electrolysis baths - this allows you to get rid of various metal impurities (gold, silver, aluminum, tellurium and other elements).

- Then small plates are formed, which are then sent for remelting - at the end, a thick wire is formed from molten copper by casting (after cooling, its diameter can be reduced using drawing in the standard way).

Please note that in factories, copper goes through several stages of purification - which is why melting copper at home makes little sense. Yes, theoretically, you can heat copper at home to the required temperatures, followed by melting the metal. However, at home it is practically very difficult to clean without special equipment.

Basic provisions of GOST

Basic physical properties and quantities in the form of technical parameters, chemical composition, testing methods and geometric dimensions are determined by GOST R-53803-2010. All copper wire rod after 2010 is produced in Russia in accordance with this GOST.

The standard defines the nominal standard sizes of sections adopted today in Russia. This is wire and copper rod with a thickness of 8 to 23 mm. Tolerances for a wire of 8-14 mm can be of the order of 0.4 mm, and for a rod with a cross-section from 15 to 23 mm - 0.6 mm.

Existing standards divide copper wire rod into types, the marking of which indicates the method by which it was manufactured. The methods determine the purity of the metal, on which its price directly depends. Thus, the KMB marking means oxygen-free wire rod. But it also contains subspecies Moo with 99.99% Cu, M1 - 99.9%, M4 - 99.0%, where the numbers indicate the Cu content as a percentage. Moo is a cathode electrolytic grade that is completely devoid of oxygen and has the highest electrical conductivity with the lowest possible resistance. and the cost of a kilogram of such copper is the highest. But the KMor marking informs that this copper wire rod is made from refined waste and copper scrap, that is, this wire rod contains copper of different grades.

Explanation of markings

The “M” in front of the metal purity index simply means “copper.” Two “zeros” (00) – high purity. One zero (0) is just blank. With numbers 1,2,3 – technically clean. The last element of the markings is usually a letter index, indicating the method in which the metal was cast: K - cathode. U – cathode remelted. Oxygen-free copper is designated by the letter B, deoxidized copper by P, and deoxidized copper by introducing phosphorus into the melt will be marked accordingly by the letter F.

In total, about 20 grades of this metal are produced in Russia, intended for use in various industries.

An intermediate position between these grades is occupied by copper rod marked KM.

The GOST adopted in 2010 allows for the production of copper wire rod of other nominal sizes, if such was the customer’s requirement.

There is also a list of chemical elements that are strictly regulated by GOST according to their maximum values in the composition of copper for industry. These are bismuth, arsenic, sulfur, antimony, lead, tellurium, selenium, silver, iron and oxygen. Their share in the total mass of a copper ingot or wire rod should not exceed values from 0.001 to 0.005%. The most harmful to the quality of copper is the content of bismuth and lead in it, since these substances make copper brittle with even slight heating. Therefore, the mass percentage of these elements should not exceed 0.001%. The presence of sulfur and oxygen in copper improves its ability to be cut, but sulfur at the same time impairs the ductility of this metal.

The content of substances such as phosphorus, cobalt, silicon, nickel, manganese, chromium, tin, zinc and aluminum is not regulated by GOST.

There may be dents, scratches, gouges and scratches on the surface of the drawn wire, but if their dimensions do not exceed 0.2 mm, the material is suitable for production. An exception is made only for high-precision technologies.

Product requirements

But in some cases additional requirements are put forward:

For finished products, twisting and unwinding tests are provided.

- Wire with a cross-section of 16 mm or more must withstand 3 cycles of twisting and unwinding. With a cross section from 13 to 16 mm – 5 cycles. And with a cross section from 8 to 13 - 10.

- The elongation of the wire rod at break must be at least 35%.

- The value of temporary resistance in megapascals must be expressed as a number of at least 160.

Additional tests may be carried out at the request of the client. So, these may be tests for hydrogen embrittlement for grades KMB and for helix elongation - such a test may be required for grades KM and KMor.

Although quite standard and even high-quality copper can fall into the “copper scrap” category. This can happen when:

- The percentage of metal oxidation in the coil exceeded the weight measurement method of 0.01.

- The presence of mechanical defects in the form of tears, notches and dents, if cleaning could not eliminate these defects.

- Exceeding the shelf life of the coil of wire rod for more than 3 months (after the expiration of this period, a comprehensive check of all parameters of the coil is required, and if at least one of them does not comply, even refined copper with a purity of 99.99% can be considered scrap). Therefore, the production of high-purity cathode electrolytic copper grades is always done for a specific customer and in the case of only 100% prepayment, with a warning about the possible consequences of failure to pick up the ordered wire rod on time.

Copper wire welding

Used for welding products and sheets based on copper or brass alloys. Copper wire in this case is used as a substrate from which the weld will be formed. Let's consider the critical points of the main welding methods:

Gas welding

For gas welding of copper, it is recommended to use boron-based flux solutions to quickly remove oxides in order to improve the quality of the weld and minimize the formation of air bubbles inside the weld.

It is necessary to monitor gas consumption depending on the thickness of the alloy. If the thickness of the object is less than 1 cm, then the gas consumption will be 150-160 l/hour. If the thickness of the object is more than 1 cm, then the consumption will be about 200-250 liters.

Welding is recommended to be done with quick but precise movements. Melting should be done like this: first the filler wire is melted - then the edges of the copper objects are melted.

Semi-automatic welding

Semi-automatic welding is recommended to be done in a flux environment to minimize the risk of air bubbles. The optimal wire for welding is M2, although grades M1 and M3 can also be used.

For semi-automatic welding, it is recommended to use a voltage of 30 volts and a current of 300 amperes. Welding is recommended to be done with transverse movements, but without sudden vibrations. Otherwise, air bubbles and harmful oxides may form, which will adversely affect the quality of the weld.

Argon arc welding

This welding method is optimal. By using argon, the risk of formation of oxides and air bubbles is reduced, which makes the seam smooth and solid. For welding, you need to use electrodes based on tungsten alloys. Electrodes on a different base are quickly destroyed and can contaminate the seam. For welding, it is recommended to use reverse polarity current. If the copper product has a large and medium thickness, then a slight heating must be performed before welding. When working with thin products, preheating may not be necessary.

Production of copper rod

Copper wire rod is produced using the technology of drawing metal through rolling rollers on special mills, where they make profiled material (wire) of different thicknesses from the wire rod.

When passing through the rollers, the copper rod, which is transformed into wire under their influence, is subjected to strong heating using eddy induction currents or in a gas flame. After passing through the rollers, the hot wire is placed into coils using devices called coilers. At the same time, the material is cooled. In slow-running coilers and on thin wire, such cooling occurs naturally; when quickly winding the finished product, forced air flow is used.

Because of the preheating during the drawing phase, the process is called hot rolling.

Transportation and storage

Rules for storing copper wire are regulated by GOST standards. Basic Rules:

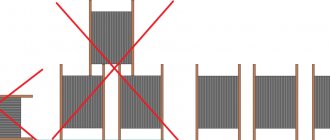

- The optimal method of storage and transportation is the use of frame bays. For transportation, the coils must be packed in a special film. It will protect the material from adverse environmental conditions. In most cases, coils can be stored in a fold without packaging.

- The wire must be stored in special warehouses. The basic requirements for storage are low humidity, dry ventilation, minimal risk of prolonged wetting of the material (short-term wetting due to carelessness is allowed), and so on.

- Different grades of copper should be stored separately in the warehouse. If the wire becomes tangled during transportation, untangling is necessary. When unraveling, under no circumstances should the material be allowed to twist in a figure eight pattern.

Types of copper wire

The technical characteristics and properties of copper wire are determined by the requirements of GOST and TU. According to current standards, there are seven types of it:

- Soft (0.02–16.0 mm) - MM.

- Hard (0.02–16.0 mm) - MT.

- For communication lines (2.0–4.0) - MS.

- For enameling (0.0125–2.8), hard - MFC.

- For enameling (0.0125–2.8), soft - MME.

- Made of oxygen-free alloy (0.02–16.0), hard - MTB.

- Made of oxygen-free alloy (0.02–16.0), soft - MMB.

How to distinguish copper from brass and bronze

The first metal is a Cu-Zn alloy. The zinc content varies in the range of 4 – 45%. When an alloy is characterized by a high addition of a major impurity, it is easy to distinguish it from pure metal by color. The color of copper is pink-red, brass is lighter, but scrap brass may have a dirty surface. The more zinc in the alloy, the more its color shifts from red to yellow. Therefore, visual perception is unacceptable for high-copper brasses, where the presence of impurities is at the level of 10%. In this case, there are 3 options left for how to distinguish copper from brass without using a tool:

- By sound. It is advisable to have an ear for music here. When struck against metal, soft copper sounds muffled, while brass sounds loud. The method works well for massive, oversized products - pipes, for example.

- Along the fold. The ductility of copper allows the metal to be easily bent. Harder brass is not as malleable.

- By weight. The density of Cu9 g/cc is higher than that of Zn (7.1). The resulting characteristic value for brass is on average 8.6 g/cc. The difference is small, but if you have accurate scales, it is possible to distinguish metals.

Visual difference between copper and bronze and brass

A good identifier of copper, relative to brass, is shavings. In pure metal it is spiral-shaped. On the contrary, the brass shavings are straight and needle-shaped.

A more complex approach involves the use of chemicals, namely hydrochloric acid. Chemically inert copper does not react in solution, whereas when brass is immersed, a white coating forms on the surface of the metal. This is zinc chloride, the result of the reaction of this metal with an acid.

Video – copper and brass:

Methods for determining copper and brass yourself at home

Copper is a metal that, due to its characteristics, is suitable for making decorative items. Copper is also a component of metal alloys used for the same purpose. The most popular alloy is brass, which contains copper, as well as tin and zinc. Many people wonder how to distinguish copper from brass, because outwardly they are practically indistinguishable.

Brass is characterized by the following composition: copper accounts for 70%, and zinc - 30%. As for the last component, 50% of the brass alloy is made from recycled zinc. Technical brass contains up to 50% of this zinc, and up to 4% of the alloy composition can be lead.

Product made of brass