Cuffs for sewer pipes are parts that ensure the tightness of the connection (flexible - much more reliable than traditional caulking with a cement lock device). They are cylindrical (less often ellipsoidal and other shapes) products with thick walls, made of rubber, PVC, polyurethane, silicone, paronite. Cuffs are used mainly for joining cast iron and plastic pipes, connecting plumbing equipment to the sewer network (ready-made fittings for modern systems go on sale already equipped with O-rings).

What are seals?

Sealants for sewer pipes are cuffs made of elastic materials. They perform different functions:

- eliminating leaks, sealing connections;

- transition from the production of plumbing fixtures to the sewer pipeline;

- sealing external connections.

The main consumer of sealing collars is cast iron sewerage. A cuff for a cast iron sewer pipe is most often used for areas where lines are connected from other materials. Most connections require a good seal. It provides a transition from cast iron to plastic, or seals the connection of homogeneous pipes of different sizes. The technology for installing cast iron pipelines provides for different assembly methods. They depend on the design of the connecting elements.

However, sealant for plastic sewer pipes is used much more often. This happens because the share of plastic pipelines in the total composition of networks significantly exceeds the number of cast iron lines. Almost all modern systems are assembled from plastic elements.

There are transitional cuffs for sewerage, the dimensions of which exactly correspond to the diameter of certain elements of plumbing and sewerage. Typically, these are transitional elements specially manufactured for certain areas:

- connecting the toilet outlet to a cast iron tee;

- attaching corrugations from the sink to plastic pipes;

- connecting the washing machine drain hose to the sewer;

- connection of dishwashers, etc.

In addition, there are cuffs that seal socketless joints. They are a piece of polymer tube that works on the principle of heat shrinkage.

Advantage of using

There are different options for sealing joints when assembling a sewerage pipeline, but when working with plastic pipes, sealing collars are most often used. What is the advantage of this option?

- Availability. Prices for sealing cuffs are low.

- Profitability. A properly installed seal can provide a high level of sealing, and it also lasts a long time.

- Maintainability. If necessary, a connection sealed with a rubber O-ring can be easily disassembled, and the seal itself can be easily replaced.

Materials

The cuff of the sewer adapter must be elastic and resilient. Requirements for the material used in the manufacture of seals:

- ability to work with corrosive or aggressive chemical compounds;

- strength;

- reliability;

- ability to withstand pressure and sudden temperature fluctuations.

Rubber meets these requirements to a greater extent. During manufacturing, rubber, polyurethane, and silicone are mixed into the raw materials. This is done in order to increase durability and resistance to detergents or cleaning compounds. Additives increase the durability of rubber and reduce the tendency to self-residual vulcanization.

The sealing of cast iron sewer transitions is done using a hemp rope impregnated with resin. It is tightly packed into the gap of the socket, after which the remaining gap is filled with plumbing sulfur or cement mortar. This sealing method does not require the use of finished parts, but is used only when installing long lines. To attach any plastic element to the cast iron socket, a special cuff for cast iron sewerage is used.

Definition and purpose of a sewer cuff

Interpipe space seal

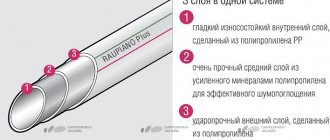

Various materials are used for production. Products in the form of corrugated pipes and rings are intended for use in production and residential buildings. Elastic polyurethane, silicone and rubber elements are used to seal joints of plastic pipes, fittings, and various types of adapters, giving them strength and eliminating leaks.

Parts are classified according to purpose:

- Rod ones have a seat between the rod and the inner surface of the cylinder. Ensure tightness during forward and reciprocating movement of the rod.

- Pistons are used to prevent the working medium from entering the gaps between the piston and the hydraulic cylinder. The advantage of using them is maintaining the freedom of movement of moving elements.

- Universal ones can work in any conditions.

Depending on the type of connection, the cuffs can be sealing, ensuring reliable tightness, or transitional, allowing you to easily connect elements of different diameters.

Types and sizes

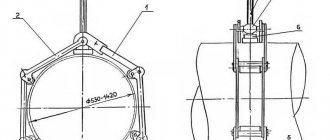

Sealing elements are made in two types:

- internal. Performs simultaneously the functions of an adapter and sealant;

- external. Used to seal joints of socketless pipes.

The size of the rubber seal for the sewer exactly corresponds to the inner diameter of the socket and the outer diameter of the attached element (corrugation, washing machine or dishwasher hose, toilet outlet, etc.). The outer surface of the adapters is made corrugated to make it easier to insert the part into the socket. The ribs of the corrugated section rest more tightly against the walls of the socket, providing reliable protection against leaks.

The most common diameter of internal sewerage pipes is 50 mm. This size is most often found on internal systems made of plastic, and in older houses you can still find internal wiring made of cast iron. However, even in modern apartment buildings there are cast iron sewer risers. tees, also made of cast iron, go from them to the apartment. The connection of the plastic horizontal wiring is ensured by a cuff on a 50 cast iron sewer pipe. It has the shape of a rubber plug with a 50 mm hole.

External cuffs are used when assembling street parts of drainage systems. They are put on the connection area and heated. Due to the high temperature, the material shrinks and tightly grips the connecting node. They do not require great sizing accuracy, but an overly large cuff may not be able to reduce size on a large scale. It is recommended to choose elements that fit freely onto the pipe, but do not exceed its diameter too much.

Also read: Longitudinal sewer profile: what is it, why is it needed, construction

Properties

High-quality seals used to seal pipeline joints must have the following properties:

- elasticity, that is, the ability to restore shape after mechanical impact;

- ability to withstand exposure to fairly high temperatures and various detergents;

- long service life.

These properties are met by rubber cuffs, as well as seals made of silicone or rubber.

Advice! Modern manufacturers make cuffs from rubber with polymer additives. As a result, the products are more rigid. This property makes installation difficult, but polymer cuffs last much longer.

Installation

Installing the sealing elements is not very difficult. First, the cuff is inserted into the socket, being careful not to distort it. Some craftsmen try to hammer in tightly fitting parts. This should not be done. It is better to apply any type of lubricant to the rubber (regular shampoo or liquid soap will do) so that the plug fits easily into the socket. The same procedure is performed with the hose if the central hole is too tight.

When installing a cuff in a cast iron pipe, you must carefully monitor the condition of the socket. Perhaps there are thin cracks there that will split apart under pressure and the bell will break. This element will have to be changed. Accuracy and avoidance of unnecessary haste will help to avoid this.

How to choose and install the sealing collar in the sewer?

Stores sell cuffs of different sizes, configurations, and colors. Most apartments have a plastic pipeline installed; it has a standard diameter of 40 or 50 mm. To connect the drain, you should buy a 45 or 90 degree tee with a diameter of 50 mm, insert it into the pipe without removing the thin O-ring. It happens that the tee is manufactured according to other standards and does not fit into the main pipe. To do this, remove the sealing ring, lubricate it with plumbing sealant in its place, also treat the outer edge of the plastic tee and insert it with a force of several centimeters. If you don’t have sealant on hand, a soap solution will serve as a substitute. There is another option: to do this, take a 40 mm tee and connect it through a 50 * 40 mm cuff; such a joint will be more reliable.

It is more convenient to put the seal on the tee, and only then insert it into the sewer pipe.

For drainage, reductions of 50*25 mm and 50*20 mm are produced, where 20 and 25 mm are the diameter of the internal hole. The most suitable option is 50*20 mm, it allows you to insert the hose most tightly. But this size is difficult to find in stores; they usually offer 50*25 mm and even 50*32 mm. It is not recommended to buy the latter even after much persuasion from the sales consultant - the seal does not wrap around the hose at all, which makes its stay in the sewer useless.

The procedure for connecting the SMA to the drain is shown in the video:

Important! If the diameter of the tee is 40 mm, then the seal for the drain should be 40*25 mm or 40*20 mm.

Tips for attaching adapters

Difficulties in installing the toilet are explained by the fact that the length of the cuff is shorter than necessary. This means that before choosing a seal, you need to calculate the distance between the plumbing outlet and the sewer drain.

When purchasing a corrugated product, you can follow this rule - the length of the sleeve should be greater than the diameter of the coupling by a third of its length. The use of seals of this type will require the installation of additional fasteners, which will maintain the straight appearance of the structure. If this is not done, large bends and sharp corners may lead to blockages in the system.

In addition to the configuration and length, the effectiveness of the functioning of devices is affected by the thickness of their walls - the thicker it is, the longer the service life will be. If the coupling begins to leak, the part must be replaced; if there is no visible damage, you can tighten the fasteners and strengthen the fit of the sink to the riser.

Toilet cuffs: classification

There are many options for bathroom cuffs on sale, but all of them are made of either plastic or rubber. The plastic cuff is more modern, suitable for joints with polymer sewer pipes.

The second option is more flexible, which means it is more suitable for joints with cast iron pipes. The color of manufactured plastic and rubber products is standardized - white, gray and beige.

Conical cuffs are often produced on a rubber basis . They are quite elastic and, due to the changing diameter, allow you to connect the toilet to a hole of non-standard diameter.

We can say that the conical cuff is a universal option for those bathrooms whose installation is planned in apartments of old construction. This option is often called a glass cuff , which is characteristic due to its shape.

The eccentric variety is used quite often. It represents a connection standard because it is universal for all types of toilets. It has a cylindrical shape, where both ends of the cylinder are offset from each other. We talked about versatility, since such an eccentric makes no difference in connecting to a bathroom with an oblique or direct outlet.

The practice of operating such a connection indicates 100% tightness of the inclusion of the bathroom in the pipeline.

Another option is the corrugated variety . It is used where using an eccentric cannot get out of the situation. This is rare, but sometimes the purchased bathroom may have an unusual shape, which does not allow the use of established connection standards.

A distinctive feature of the corrugated variety is the ability to bend at an angle of 90 degrees or more, which allows us to install the bathroom in the place we need.

Installation instructions for various types of cuffs

The principle of using various adapters is the same, but the process of their installation has a number of features due to the characteristics of the products.

Installing the rubber seal

The rubber element is placed in the socket of a metal pipe, thereby sealing the joint between the drain and the toilet. In addition, the part protects the plumbing product from damage during replacement and installation.

To create a tight connection between the device and the pipe with a rubber cuff, a sealant is applied along the entire joint, forming a waterproof sealed ring after curing.

Rules for using the eccentric

When there is a slight displacement of the axes of the toilet and wastewater drain, curved couplings are used - eccentrics. A height difference of more than 5 cm will require a change in the location of the pipes. If communications are installed at floor level or close to it, it is better to choose devices with an oblique type of outlet.

The drain hole must be free of dirt and rust.

Work algorithm:

- Preparing the drain hole, which is cleaned of old deposits.

- Installation of the adapter. It must be inserted with the wide end onto the sewer outlet pipe and the joint must be secured with sealant. If the product parameters are selected correctly, the drain outlet can be lubricated only with soap.

- Connecting a sealing part to the outlet of a sanitary product, which is also performed using a sealing agent.

- Check the water tightness of the connection by draining the water.

- Fastening the device with bolts.

Since the eccentric coupling can be selected incorrectly, it is recommended to purchase a part with a flexible corrugated center. If necessary, it needs to be moved or pulled out a little, while maintaining the functional characteristics of the product. The eccentric is equipped with a threaded connection, which allows the use of several seals.

Installing a corrugated cuff

The versatility of corrugated adapters is explained by the ability to change shape and length. Such products can be mounted at any angle, moving the sink to a suitable location. The most popular models include products with a diameter of fixing ends of 110/90 mm and 110/80 mm. The disadvantage of the devices is the thin material of the walls, which can be damaged if used carelessly.

The corrugated model is used for temporary connection of plumbing fixtures during repairs, in the presence of a large displacement of the axis of the input and output of system elements, as well as during work on installing the product at a distance of up to 1.5 m from the riser.

The principle of connecting the adapter is similar to the fixation scheme for other types of couplings. It is not recommended to stretch the sleeve to its maximum length, as it will quickly lose flexibility and fail. As an option, you can use a combined cuff, the design of which includes rigid parts.

Selecting an adapter taking into account different editions

- Vertical release. It is rarely found on the shelves of domestic stores, since the vertical supply of sewerage to the bathroom is almost never used anywhere or by anyone. This supply consists of a hole in the floor for connecting an eccentric. The pipes are located under the floor. Installation involves complete masking of the connection point.

- Horizontal release. Unlike the previous one, it occurs more often. If we look at the toilet from the side, we will see a horizontal outlet directed towards the wall. When choosing this option, you should think about the sewer system at the time of building the house, since the inlet hole should be located opposite the horizontal outlet. If there is a slight displacement of the pipes relative to each other, then select an eccentric for the toilet that matches the color, because it allows you to connect such connections. Do not forget about the conical version, which is suitable if the holes coincide in the planes, but differ in diameter.

- Oblique release. Models with such a tap are common. The oblique outlet is determined by the inclination of the outlet at 45 degrees. The corrugated version is suitable for connection, as it allows you to achieve any connection angle, as well as extend the connection contour to the desired values.