The installation of a sewerage system and a well is a prerequisite in private and multi-storey buildings. Such structures are subject to certain requirements, so they must fully comply with sanitary and hygienic standards. In addition, when installing a well treatment system for a country house, any person expects that the structure will last for decades, serving faithfully.

Therefore, the optimal solution when performing such work would be to install a concrete ring. This product is made of strong and durable material that can last almost forever, provided that the ring is correctly selected and the installation is carried out in compliance with all requirements. Therefore, it makes sense to consider the features of concrete rings, understand the size range and installation methods.

What types of rings are there? Types and purpose

Well rings are round reinforced concrete structures used for arranging utility lines buried below ground level. Depending on the structure being constructed, the following types of rings are used:

- Sewage and water intake.

- Products for laying underground cable electrical networks.

- Collectors.

- Gas pipelines and water intakes.

In addition, there are the following varieties on the market:

- Rings with flat and locking ends.

- Repair.

- Additional ones.

- Supporting.

Regardless of the type and purpose, the products are made of heavy concrete, grade 200-500 , and reinforced.

Types of concrete rings for a well

The production of all reinforced concrete building structures is strictly regulated by the relevant GOSTs.

These standards also establish the size of concrete rings for a well, and any deviations from the specified standards are unacceptable. They can differ in two main parameters: the diameter of the rings for the well and its height. All other operational and technical characteristics, such as strength, density, resistance to mechanical loads, must not be lower than the indicators defined by GOST.

Today there are several main types of reinforced concrete rings. Therefore, before choosing one or another option, you should carefully familiarize yourself with the main types of these products, as well as their scope.

All concrete rings are divided by area of use:

- Sewer.

- Collector.

- Water intakes.

- Protective, designed for laying underground communications: electrical cables, gas and water pipes.

According to their design and technological properties, reinforced concrete rings are:

- With a smooth end.

- With a locking end. Along the perimeter of their end part there is a special recess-lock, which simplifies installation and increases the tightness of the joints.

- Designed to create a supporting base.

- Additional elements.

Production technology

Rings for wells are made from hard concrete, which is poured into the formwork. It is necessary to clarify that the reinforcement is first made from steel wire with a diameter of 8-12 mm . Two vertical rods are installed at opposite ends of the structure, which act as lugs for lifting the ring.

The mold is compacted using vibration to prevent the formation of voids. The formwork is removed one day after pouring the concrete. After this, the finished products are stored in open areas. The ring's tempering strength ( 50% of the specified value ) is achieved in approximately 7 days . Full concrete strength is achieved after 28 days .

Making your own mold

Rings for a septic tank, photos of which you can see in the article, are sometimes made using self-made molds. To do this, you can select barrels of the appropriate diameter, as well as pipes or air ducts. If there are no cylindrical shapes of the required diameter, then you can use separate steel sheets, which are connected to each other by door and window awnings. The connecting elements are fixed to the metal form by rivets or welding. As practice shows, it will be simpler and easier to make such products using plastic molds that are sold in stores.

Advantages and disadvantages of reinforced concrete rings

It's no secret that any building material has its strengths and weaknesses. This feature also applies to finished products. Concrete rings seem ideal, but even they are not without some drawbacks.

The undeniable advantages of reinforced concrete rings include the following:

- High quality at an affordable price.

- Wide range of sizes.

- The ability to quickly install a water supply and sewerage system.

- High tightness: tight fit of the seams prevents groundwater from entering the structure.

- Long service life: reinforced concrete is neutral to any environment, so it can last at least 100 years .

- Structural rigidity: wells made of concrete rings can be installed even on unstable soil.

Obvious disadvantages include the following:

- Dimensions and weight: it is impossible to install a concrete ring without the use of construction equipment, which somewhat increases the cost of installation.

- Lack of mobility: it is very difficult to move such a well.

You can see that there are more positive features, which explains the steadily growing popularity of concrete rings.

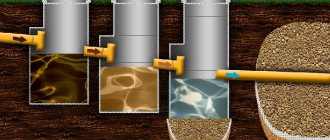

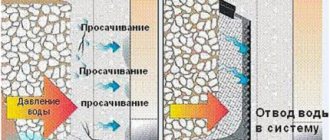

Sealing joints and backfilling

The rings for the septic tank must be sealed; the seams between them are usually sealed with cement mortar or an “Aquabarrier” type mixture. From the outside, it is possible to carry out coating waterproofing, and for reliability it is recommended to use weld-on sealants. The seams must be sealed on both sides. Sometimes the design is reinforced with plastic liners, which are cylinders of the required volume. They are placed inside a previously constructed well. If you provide reliable waterproofing, the liquid from the septic tank will not get into the ground. This extends the life of the structure and eliminates unpleasant odors.

Backfilling should be carried out upon completion of installation work. The soil removed from the pit must be mixed with sand and distributed around the structures, simultaneously compacting the backfill. Each tank is fitted with a lid, which looks like a concrete slab with a hole. It is provided for the hatch. The seams need to be sealed according to the scheme described above, at this point we can assume that the installation of the septic tank is completed, its service life will depend on how well the installation was carried out, as well as waterproofing work.

Marking according to GOST. How to read symbols correctly

Each reinforced concrete ring has a marking that determines the scope of application of the product. The symbols correspond to GOST standards, it looks like this:

- KLK - products intended for the arrangement of drains and urban storm sewers.

- KVG - rings used for installation of gas pipelines and water wells.

- KO is a support ring that forms the foundation of the well.

- KS - wall models installed in limited spaces.

- KFK – drainage systems and collector networks.

In addition, the ring markings also contain numerical designations.

Decryption example:

KS-7-9 . This means a wall ring with a wall thickness of 70 and a height of 900 mm .

Coding of reinforced concrete rings

But, regardless of their purpose and design features, they are all made from heavy types of reinforced concrete with strength grades from M-200 to M-500. The sizes of reinforced concrete rings for a well can be very different and are selected individually, depending on the diameter of the well. According to production standards, each cast ring must have a certain marking established by GOST requirements. Thanks to these markings, you can accurately select the required model of reinforced concrete product.

The encoding of reinforced concrete rings is as follows:

- KLK – for installation of city storm sewers.

- KVG is the most common version of rings intended for the construction of water wells and caissons.

- KO – support or foundation ring. Used as a basis for the subsequent installation of other elements.

- KFK - used for the construction of drainage systems, or sewer drain collectors.

But the main indicators on the basis of which rings are selected are their sizes. Depending on the diameter and height, the mass of the reinforced concrete product also changes. The table below shows the dimensions of the well ring: its height, diameter, volume, and weight. The outer diameter is designated as D-large, and the inner diameter as d-small. The minimum diameter of such reinforced concrete elements, as can be seen from the table, is 70 cm, and the largest is 200 cm.

Standard sizes of reinforced concrete rings

Concrete rings are available in a very diverse range of sizes. Standard product sizes look like this:

- Height: 10-100 cm .

- Wall thickness: 70-120 mm .

- Inner diameter: 70-200 cm .

- Specific gravity: 46-2,300 kg .

Thanks to these standard sizes, choosing rings for arranging an individual water supply system is not difficult.

| Name | Diameter D, mm | Diameter d, mm | Height h, mm | Thickness, mm | Concrete volume, cubic meters | Weight, tons |

| K-10-10 | 1160 | 1000 | 990 | 80 | 0.27 | 0.68 |

| K-10-5 | 1160 | 1000 | 490 | 80 | 0.14 | 0.35 |

| K-12-10 | 1410 | 1250 | 990 | 80 | 0.33 | 0.82 |

| K-12-5 | 1410 | 1250 | 490 | 80 | 0.17 | 0.42 |

| K-15-10 | 1680 | 1500 | 990 | 90 | 0.44 | 1.1 |

| K-15-5 | 1680 | 1500 | 490 | 90 | 0.22 | 0.55 |

| K-20-5 | 2200 | 2000 | 490 | 100 | 0.33 | 0.82 |

| K-7-1.5 | 840 | 700 | 145 | 70 | 0.024 | 0.06 |

| K-7-10 | 840 | 700 | 990 | 70 | 0.17 | 0.42 |

| K-7-5 | 840 | 700 | 495 | 70 | 0.084 | 0.21 |

| KS 7.6 | 840 | 700 | 590 | 70 | 0.3 | 0.25 |

| KS10.18a | 1160 | 1000 | 1790 | 80 | 0.46 | 1.15 |

| KS10.3 | 1160 | 1000 | 290 | 80 | 0.08 | 0.2 |

| KS10.6 | 1160 | 1000 | 590 | 80 | 0.16 | 0.4 |

| KS10.9 | 1160 | 1000 | 890 | 80 | 0.24 | 0.6 |

| KS10.9a | 1160 | 1000 | 890 | 80 | 0.22 | 0.55 |

| KS13.6 | 1410 | 1250 | 590 | 80 | 0.2 | 0.5 |

| KS13.9a | 1410 | 1250 | 890 | 80 | 0.28 | 0.7 |

| KS13.9b | 1410 | 1250 | 890 | 80 | 0.24 | 0.6 |

| KS15.18 | 1680 | 1500 | 1790 | 90 | 0.804 | 2.01 |

| KS15.18a | 1680 | 1500 | 1790 | 90 | 0.75 | 1.88 |

| KS15.18b | 1680 | 1500 | 1790 | 90 | 0.72 | 1.8 |

| KS15.6 | 1680 | 1500 | 590 | 90 | 0.265 | 0.66 |

| KS15.6b | 1680 | 1500 | 590 | 90 | 0.22 | 0.55 |

| KS15.9 | 1680 | 1500 | 890 | 90 | 0.4 | 1 |

| KS15.9a | 1680 | 1500 | 890 | 90 | 0.35 | 0.88 |

| KS15.9b | 1680 | 1500 | 890 | 90 | 0.32 | 0.8 |

| KS20.12a | 2200 | 2000 | 1190 | 100 | 0.67 | 1.68 |

| KS20.12b | 2200 | 2000 | 1190 | 100 | 0.64 | 1.6 |

| KS20.18b | 2200 | 2000 | 1790 | 100 | 1.02 | 2.55 |

| KS20.6 | 2200 | 2000 | 590 | 100 | 0.39 | 0.98 |

| KS20.6b | 2200 | 2000 | 590 | 100 | 0.3 | 0.75 |

| KS20.9 | 2200 | 2000 | 890 | 100 | 0.59 | 1.48 |

| KS20.9b | 2200 | 2000 | 890 | 100 | 0.44 | 1.10 |

| KS25.12a | 2700 | 2500 | 1190 | 100 | 0.87 | 2.18 |

| KS25.12b | 2700 | 2500 | 1190 | 100 | 0.76 | 1.90 |

| KS25.6 | 2700 | 2500 | 590 | 100 | 0.48 | 1.2 |

| KS7.3 | 840 | 700 | 290 | 70 | 0.05 | 0.13 |

| KS7.9 | 840 | 700 | 890 | 70 | 0.15 | 0.38 |

| KTs12.9 | 1410 | 1250 | 290 | 80 | 0.30 | 0.75 |

| KTs25.12 | 2700 | 2500 | 1190 | 100 | 0.97 | 2.42 |

| PK-7S | 870 | 650-670 | 360 | 100-110 | 0.036 | 0.09 |

Manufacturing stages

Rings for a septic tank, which can be installed only after the concrete has completely hardened, are manufactured using a certain technology. The solution is laid in a 25-centimeter layer, and then compacted with a metal rod. After pouring, the spacers can be removed to half the height of the mold. At the final stage, the surface of the solution is leveled. For maximum compaction of the composition, you can use a vibration installation. The solution is poured, and the mold is dismantled after 4 days.

What else is needed? Additional items

It should be noted that installing rings alone will not solve the problem of a high-quality water supply system. In order for the well to meet the requirements, the installation of additional elements will be required. This is not a mandatory condition, but compliance with this rule will help prevent contamination of the system with wastewater, increase its service life, and give the structure a complete look.

For this purpose:

- Bottom slabs provide a reliable foundation.

- Floor slabs - thanks to a narrow hole on top of such a slab, a ring of small diameter is installed, closed with a regular manhole cover.

- Additional rings are products of standard diameter, but smaller thickness. Such elements help raise the height of the well to the desired level.

The use of such products ensures maximum tightness of the well and prevents pipes from freezing in winter.

Covers for wells

| Name | Diameter Dн, mm | Diameter Din, mm | Thickness H, mm | Concrete volume, cubic meters | Weight, tons |

| 1PP 15 | 1680 | 700 | 150 | 0.333 | 0.69 |

| 1PP 20 | 2200 | 700 | 160 | 0.608 | 1.37 |

| 1PP 25 | 2700 | 700 | 180 | 1.031 | 2.45 |

| 1PP 25-2 | 2700 | 700 | 180 | 1.031 | 2.4 |

| 1PP 8 | 1000 | 580 | 170 | 0.134 | 0.33 |

| 1PP15-1 | 1680 | 700 | 150 | 0.27 | 0.68 |

| 1PP15-2 | 1680 | 700 | 150 | 0.27 | 0.68 |

| 1PP20-1 | 2200 | 700 | 160 | 0.51 | 1.38 |

| 1PP20-2 | 2200 | 700 | 160 | 0.51 | 1.38 |

| 2PP 15 | 1680 | 700 | 150 | 0.333 | 0.69 |

| 2PP 20 | 2200 | 1000 | 160 | 0.608 | 1.2 |

| 2PP 20-2 | 2200 | 1000 | 160 | 0.45 | 1.2 |

| 2PP 25 | 2700 | 700 | 180 | 1.031 | 2.4 |

| 2PP 25-2 | 2700 | 700 | 180 | 1.031 | 2.31 |

| 2PP 8 | 1000 | 800 | 170 | 0.134 | 0.33 |

| 2PP15-1 | 1680 | 700 | 150 | 0.27 | 0.68 |

| 2PP15-2 | 1680 | 700 | 150 | 0.27 | 0.68 |

| 2PP20-1 | 2200 | 1000 | 160 | 0.45 | 1.2 |

| 3PP 15 | 1680 | 1000 | 150 | 0.333 | 0.54 |

| 3PP 15-1 | 1680 | 1000 | 150 | 0.21 | 0.53 |

| 3PP 15-2 | 1680 | 1000 | 150 | 0.21 | 0.53 |

| 3PP 20 | 2200 | 700 | 160 | 0.608 | 1.34 |

| 4PP 20-2 | 2200 | 700 | 160 | 0.608 | 1.28 |

| KCP1.20N | 2200 | 700 | 160 | 0.51 | 1.28 |

| KCP1.25N | 2700 | 700 | 180 | 0.92 | 2.31 |

| KCP2.25 | 2700 | 700 | 180 | 0.96 | 2.40 |

| PVG-15 | 1720 | 700 | 140 | 0.27 | 0.68 |

| PVG-20 | 2240 | 700 | 160 | 0.57 | 1.43 |

| PVG-25 | 2740 | 700 | 180 | 0.99 | 2.48 |

| PVK-8 | 1000 | 400 | 170 | 0.06 | 0.15 |

| PK-10 | 1200 | 700 | 120 | 0.09 | 0.225 |

| PC-12 | 1450 | 700 | 140 | 0.18 | 0.45 |

| PK-15 | 1720 | 700 | 140 | 0.27 | 0.68 |

| PC-15-10 | 1720 | 1000 | 140 | 0.21 | 0.52 |

| PK-20 | 2240 | 700 | 160 | 0.54 | 1.35 |

| PK-20-10 | 2240 | 1000 | 160 | 0.5 | 1.25 |

| PK-25 | 2740 | 700 | 180 | 0.96 | 2.4 |

| PK-25-15 | 2740 | 1500 | 180 | 0.74 | 1.85 |

| PKB8 | 1000 | 400 | 170 | 0.06 | 0.15 |

| PKM8 | 1000 | 580 | 170 | 0.08 | 0.19 |

| PP 10 | 1160 | 700 | 150 | 0.159 | 0.25 |

| PP 13 | 1410 | 700 | 150 | 0.234 | 0.44 |

| PP10-1 | 1160 | 700 | 150 | 0.1 | 0.25 |

| PP10-2 | 1160 | 700 | 150 | 0.1 | 0.25 |

| PP13-1 | 1410 | 700 | 150 | 0.18 | 0.45 |

| PP13-2 | 1410 | 700 | 150 | 0.18 | 0.45 |

Bottom plates

| Name | Diameter D, mm | Thickness h, mm | Concrete volume, cubic meters | Weight, tons |

| Mon 7 | 840 | 100 | 0.12 | 0.09 |

| PN10 | 1500 | 100 | 0.18 | 0.45 |

| PN15 | 2000 | 120 | 0.38 | 0.95 |

| PN20 | 2500 | 120 | 0.59 | 1.48 |

| PN25 | 3000 | 140 | 0.98 | 2.45 |

Support rings

| Name | Diameter D, mm | Diameter d, mm | Thickness H, mm | Concrete volume, cubic meters | Weight, tons |

| K-1 | 840 | 700 | 180 | 0.053 | 0.13 |

| KO1 | 900 | 600 | 100 | 0.045 | 84 |

| KO4 | 840 | 580 | 40 | 0.02 | 40 |

| KO6 | 840 | 580 | 70 | 0.02 | 0.05 |

Rings with caps

| Name | Diameter D, mm | Height H, mm | Diameter d, mm | Thickness B, mm | Concrete volume, cubic meters | Weight, kg |

| PC 10 | 1160 | 890 | 1000 | 80 | 0.36 | 780 |

| PC 15 | 1680 | 890 | 1520 | 80 | 0.61 | 1400 |

Compound

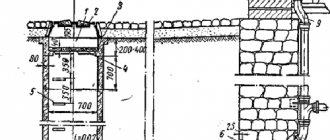

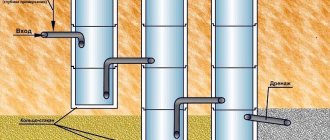

The rings should be located according to the diagram, they should be connected to each other as tightly as possible and secured with cement mortar. If soil movements are quite frequent in the area, then staples or metal plates can be used to additionally secure the elements. After completing the installation of the rings, you can begin connecting the pipes, but it should be taken into account that when laying the system it is necessary to use elements with a bend that resemble a water seal. This will prevent the unpleasant smell of sewage from entering the house.

Installation process

In order for the well to meet the established requirements, the installation of the structure must be carried out in accordance with all the rules. Here you need to follow the well-known procedure:

- Selecting a location

Water wells and drainage systems are not located close to residential buildings. The average distance from the house is about 5 meters . There should be no groundwater in the chosen location, otherwise you will have to incur additional costs for sealing. In addition, special equipment must be freely accessible to the installation site. - Pit

To dig a pit, it is better to hire equipment: the depth of the hole should be equal to the height of two rings. Digging such a pit by hand will be very problematic. A drainage cushion made of layers of sand and crushed stone, at least 50 cm .

- Rings

For the lower tier, a ring with a solid bottom is ideal; if the product is through, the bottom slab is laid first. The elements are installed on top of each other using a truck crane, the joint is covered with mortar. If the well is mounted on moving soil, the joint can be reinforced with metal staples.

After installing the rings, communications are brought to the well, the necessary connections are made, the foundation pit is filled, the rings are covered with a top slab, and sewer hatches are installed.

Excavation work: pit preparation

Whatever the size of the concrete rings, the pit will be quite large, since the filter well and cleaning chambers must fit into it. The ideal option would be to use special equipment for digging, as this will save effort and time. In the absence of it, you will have to do everything manually. Untreated wastewater should not enter the soil; this indicates that a concrete foundation must be erected at the site where the settling tanks are installed. A 50-centimeter concrete pad can be used as drainage.

Recommendations for choosing and determining the size of a septic tank based on the calculated volume

Having determined the filling volumes of the treatment station, we adjust the dimensions of the septic tank taking into account safety factors and geometric parameters of the structure.

Capacity adjustment

If we plan to clean the container less than twice a year, then add a reserve (+20%) for sediment:

Voс=Vак*1.2, (3)

If necessary, you will need a reserve volume (+20%) if you plan to receive guests often and for a long time. Then the final formula for calculating the active total volume of all chambers or modules (from the bottom to the lower edges of the outlet pipes):

Vc=Voc*1.2 or Vc=Vac*1.2*1.2=Vac*1.44, (4)

The volumetric characteristics of a treatment plant that is planned to be operated seasonally can, on the contrary, be reduced by 20%.

Accounting for geometric parameters

When selecting working tanks of a given capacity, it should be taken into account that the specific geometric dimensions of the septic tank may have functional significance. So, if there is a clear predominance of height over dimensions in plan, then the lower part of the container is excluded from the process (volume necrosis), since through ducts are created between the inlet and outlet pipes. Consequently, wastewater does not have time to settle, partially flowing into the next chamber, which negatively affects the final result of cleaning at the outlet of the equipment. On the other hand, shallow tanks that are too elongated have a small headroom for settling and sediment accumulation.

Taking into account the indicated properties of the liquid medium, the active zone, even in the smallest sewer installation, is recommended with a minimum depth of 1.3 m with a surface area of 1.8 m2.

General information

Types of networks

A sewer network is a communication with different branches, which consists of different pipes and represents one whole.

This system is necessary for transporting wastewater from users to specialized containers in which water is processed and purified.

There are two types of sewer networks:

- Internal;

- Outdoor.

Pipes and treatment systems that are located on the street refer to the external type of sewer networks. And the pipes that are located inside houses are classified as internal.

In such communications, wastewater is transported both under pressure and by gravity.

Therefore, all sewerage pipelines are divided into:

- Non-pressure;

- Pressure.

Gravity pipelines of sewerage systems are installed at an angle to ensure the movement of wastewater to the final point. For the installation of free-flow sewerage, polyethylene pipes are used.

Pressure sewer networks operate according to this principle: the pump builds up pressure and, under its action, wastewater is discharged. For pressure pipelines, pipes of good strength are used, this is necessary so that they can cope with pressure.

Also, sewer systems, depending on the purpose, are divided into the following types:

- Storm sewers (discharging melt and rain water);

- Production;

- Economic and household.

- Storm drainage is needed to remove rain and melt water.

Household sewerage is divided into two types:

- Autonomous (local);

- Central (main).

The central type of sewer system removes sewage from houses in a city area or populated area, and an autonomous sewer system serves only one house (in isolated cases, several houses).

The method of installing external sewers is divided into:

- Separate;

- General alloy;

- Semi-separated.

External sewer networks

There are several types of sewer networks that are laid externally.

Trace. This design is installed from a point to a specialized tank. Tracing is also installed in an apartment building (observing all building rules and regulations). Pipes are laid only vertically. The distance from the outer wall of the building to the communications must be at least three meters. Trace installation is carried out only when there are connections to the central sewerage network.

External sewerage consists of pipes, wells and collectors.

Sewage network located on the street. This system consists of a complex system of wells and pipes. It is done on the streets of the city. Through street sewer networks, wastewater moves to the central sewerage system, and then to treatment systems.

Collectors. These devices are designed to collect sewage and redirect it if necessary. Sewage is redirected from collector to collector, which is located near the sewerage basin or on its territory. The work of the collector is to transport wastewater by gravity or under pressure.

Treatment buildings are the final destinations for sewage. These facilities concentrate and purify wastewater. After the water is purified, it is discharged into reservoirs and then used for economic purposes.

The laying of sewer networks takes place in different ways because it depends on specific cases.

Making rings at home

Making concrete rings yourself at home will be useful if a person needs at least a dozen rings for construction purposes. If you need fewer of them, it is recommended to purchase ready-made products.

The technology for producing a concrete ring at home will be as follows:

- Stiffening ribs are welded to the ends of a durable steel casting mold, which consists of two rings, and connecting plates or unnecessary door panels are attached along the entire length. Before concreting, the plates or canvases are pulled together in half rings into a single structure.

- To raise and lower the rings using a crane, four mounting loops are installed in the mold and their curved ends are deepened into the concrete.

- The production of a concrete mixture begins with mixing a solution consisting of three components: 3 parts sand, 1 part cement and 1 part crushed stone. Water is added in small portions until the concrete mixture reaches a uniform thick consistency. The working consistency should be such that it is evenly distributed inside the mold.

Reference! You don’t have to prepare the concrete yourself, but use high-quality cement, the grade of which is not lower than 500.

- Fine aggregate (crushed stone “seed” with a fraction of 5–10 mm and washed sand) is added to the finished concrete mixture. It will give the concrete strength and a uniform structure.

- Concrete is poured into molds gradually in small portions. It is best to use a platform vibrator, which will remove air bubbles and voids. This equipment will increase the strength of concrete. If you don’t have it in your arsenal, you can use a regular hammer drill. To do this, it is necessary to sequentially press the body of the switched-on tool into different places on the outer part of the mold. As a result of these actions, vibration will be transmitted through the metal to concrete, and it will begin to settle and compact.

Attention! In the cold season, when the temperature drops below 5ºC, it is necessary to use electric heating of the mold. Otherwise, the concrete structure will turn out to be of poor quality and filled with voids.

- After the concrete has hardened in the mold, the outer part of the formwork is first removed. To do this, remove the bolts and tap the walls of the mold with a hammer. It will be easier to remove the inner part if you supply two additional square pipes, which can be knocked out to remove the inner shape.

Concrete ring volume

The volume of sewer well rings is approached as when calculating the volume of a cylinder - by multiplying the height of the product by the cross-sectional area. The last indicator is calculated using the formula:

S=πD²/4=3.14D²/4.

For example, for a ring of grade KS 10-9, where the diameter is 1 m, the height is 0.9 m:

S=3.14x1²/4=0.785 m² is the cross-sectional area.

V=SxH, where H is the height of the ring. It turns out: V = 0.785x0.9 = 0.7 m³ - this is the volume of the KS 10-9 ring.

Design and preparatory stage

When drawing up a sewerage project correctly, you need to find out:

- is it possible to connect the building to centralized networks;

- how waste will be disposed of in an autonomous system;

- what volume of wastewater will be produced daily;

- whether the private house will be in constant use;

- to what depth the soil freezes, and what is the groundwater level in the area.

Sewerage and water supply projects are developed jointly. An integrated approach allows you to avoid mistakes and make sewerage as efficient as possible. The document states:

- General data containing the name of regulations and the composition of the project. This section contains an explanatory note for the installation of water supply and sewerage systems.

- Explication of premises - contains a plan of all floors indicating wet areas and instructions for their waterproofing.

- Calculation of water consumption and wastewater disposal. The section provides the relevant standards and makes calculations taking into account a specific building - apartment or country house.

- Plumbing plan - contains the exact location of plumbing fixtures.

- Sewerage diagram - it shows the routes for laying pipes, indicating their sizes and the location of the risers.

- A specification that identifies the required equipment, fasteners, pipes and fittings.

The preparatory stage before sewerage consists of the following steps:

- Decide on the number of plumbing fixtures and their location.

- Provide the possibility of installing additional equipment that will require installing a sewer drain. To do this, it is necessary to install a closable outlet with a plug.

- After calculating all the parameters, cut the pipes, taking into account the parameters of the fittings. For plastic products, you can use a hacksaw. The cut must be made at a right angle. After the procedure, the edges should be cleaned with a knife or sandpaper.

- The installation of the sewer pipeline must be carried out at a slope, for which special brackets are used.