To create modern sewer lines, PVC pipes and sewer fittings are widely used, which are the main components of the sewer pipeline. This applies to both internal and external communication. Sewer elements made of polymer materials make it possible to solve many difficulties that arise in the process of sewerage. Polymer materials improve the performance characteristics of utility networks and also make their construction more affordable.

Types of fittings for sewer pipes

To equip sewer systems, pipes and fittings are used from materials such as PVC (polyvinyl chloride), PE (polyethylene) and PN (polypropylene).

Unlike steel and cast iron products, which are connected by welding, installing plastic pipes is much easier, since their joining does not require special equipment. The advantages of plastic sewer fittings include:

- low weight, which facilitates their transportation and installation;

- long service life – the service life of a polymer pipeline reaches up to 50 years, which is achieved due to the material’s complete resistance to corrosion and chemically aggressive substances;

- wide temperature range - PVC plastic sewerage can be used to remove hot wastewater with temperatures up to 95 degrees;

- a wide range of fittings, different shapes and sizes of which allow you to form a sewer pipeline of any configuration.

Range of shaped products for sewer systems

PVC fittings are shaped elements used to connect individual pipes to each other, as well as to connect shut-off and control valves to the pipeline. Fittings for sewerage have dimensions corresponding to the diameter of pipes on the market.

According to the provisions of GOST No. 21.604 “Water supply and sewerage”, for laying internal sewerage it is necessary to use the following sizes of PVC pipes:

- bathtub drain pipe – diameter 40 mm (laid with a slope of 1:30);

- shower – diameter 40 mm (slope 1:48);

- toilet bowl – diameter 110 mm (slope 1:20);

- sink – diameter 40 mm (slope 1:12);

- bidet – diameter 40 mm (slope 1:20);

- sink – diameter 40 mm (slope 1:36);

- combined drain for shower, bath and sink – diameter 50 mm (slope 1:48);

- central riser – diameter 110 mm;

- bends from the central riser - 60 mm.

Large diameter pipes for external sewerage

For installation of external communications it is necessary to use pipes with a diameter of 160-200 mm. PVC sewer pipes and fittings are selected so that their sizes match each other.

The variety of connecting elements used for pipeline installation is classified according to two parameters - scope of application and connection method. According to the scope of application, the designs are divided into fittings intended for installation of internal sewerage, and products for external systems.

Depending on the connection method, sewer fittings are classified into:

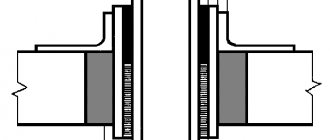

- bell-type (a rubber O-ring is installed inside the plastic structure), which ensures strong fixation of the pipe and tightness of the entire system;

- for gluing, without sealing ring.

Socket connection of sewer pipes

In terms of reliability and durability of the connection, adhesive fittings benefit, since the rubber seal during operation can lose elasticity and shrink, resulting in a gap forming between the walls of the connected structures, which causes leaks.

Compositions based on a mixture of polyvinyl chloride and tetrahydrofuran are used as glue for installing PVC sewer systems, which, after hardening, form a material with performance characteristics similar to the plastic from which the pipes themselves are made.

Proven adhesive compositions for the installation of polymer pipelines - “Tangit”, “Vinilit”, “Phoenix” and “Marx”, the current VSN 35-86 “Instructions for the installation of plastic pipes” recommends the use of “GIPC-127” adhesive.

- for permanent drainage of sewage, provided that the liquid temperature does not exceed 80 degrees;

- for short-term removal of wastewater (for no more than one minute), the temperature of which is no more than 95 degrees.

PVC sewer pipes and fittings are also allowed to be used to transport chemical waste if their pH is between 2 (acidic) and 12 (alkaline). If the sewer system will be used to drain industrial wastewater that has not been treated, it is necessary to ensure that it is resistant to the influence of chemical reagents.

Fittings for external waste drainage systems have a wide range of sizes, and different types of parts also imply certain parameters. When selecting the size of fittings for sewerage, each type of fastening is considered separately.

There are two main parameters:

- fastening diameter;

- angle of rotation.

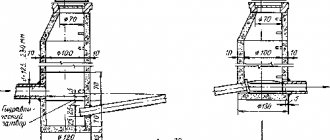

Considering in detail each type of fastening of the sewer network, we especially highlight elbows, tees, crosses and revisions.

Fittings for sewer pipes - parameters

Parameters of the internal sewerage elbow

- diameter – from 32 to 110 mm;

- angle – from 20 to 87 degrees.

The tee has three holes, which allows for parallel branching of the pipeline, as well as tilting to the side. For these purposes, the tube is equipped with holes with an inclination angle of 45, 65 and 90 degrees.

The size range of couplings and plugs is 11–50 cm, and the diameter of check valves and plugs ranges from 11 to 31.5 cm. Crosses have some similarities with tees and differ from them by one hole, each of which has a typical diameter of 5 up to 11 cm, while the angle averages 35-40 degrees.

Sewage fitting sizes

- transitions – 160x110, 200x160;

- revisions – 110–200;

- three-bell tees – 110–200 (87 degrees);

- transition tees – 110–200 (45 degrees);

- check valves – 50–160.

Correct sizing of fasteners is very important for a tight connection of sewer pipes. A part of too small a caliber simply will not fit on the pipe, and a large element will not give the network proper tightness.

Pipes made of different polymer materials are sold on the modern construction market:

- polypropylene;

- polybutylene;

- polyethylene;

- polyvinyl chloride (PVC).

Polymer sewer pipes and fittings are resistant to many aggressive environments, are easy to install, light and durable.

When installing drainage systems, fittings for sewer pipes are used without the use of special expensive equipment for gas and electric welding.

- for permanent drainage of sewage, provided that the liquid temperature does not exceed 80 degrees;

- for short-term removal of wastewater (for no more than one minute), the temperature of which is no more than 95 degrees.

PVC sewer pipes and fittings are also allowed to be used to transport chemical waste if their pH is between 2 (acidic) and 12 (alkaline). If the sewer system will be used to drain industrial wastewater that has not been treated, it is necessary to ensure that it is resistant to the influence of chemical reagents.

Read more: Insulation for sewer pipes, types and scope of application

Today, plastic pipes have almost completely replaced their metal counterparts in sewer systems. They have such operational advantages as durability, low cost, minimal weight and ease of installation, which is achieved through the use of sewer fittings, which we will discuss in this article.

You will learn what sewer fittings exist and what materials they are made from. Varieties of fittings, their standard sizes will be considered, and recommendations for installing a sewer system with your own hands will be given.

- low weight, which facilitates their transportation and installation;

- long service life - the service life of a polymer pipeline reaches 50 years, which is achieved due to the material’s complete resistance to corrosion and chemically aggressive substances;

- wide temperature range - PVC plastic sewerage can be used to remove hot wastewater with temperatures up to 95 degrees;

- a wide range of fittings, different shapes and sizes of which allow you to form a sewer pipeline of any configuration.

According to the provisions of GOST No. 21.604 “Water supply and sewerage”, for laying internal sewerage it is necessary to use the following sizes of PVC pipes:

- bathtub drain pipe - diameter 40 mm (laid with a slope of 1:30);

- shower - diameter 40 mm (slope 1:48);

- toilet - diameter 110 mm (slope 1:20);

- sink - diameter 40 mm (slope 1:12);

- bidet - diameter 40 mm (slope 1:20);

- sink - diameter 40 mm (slope 1:36);

- combined drain for shower, bath and sink - diameter 50 mm (slope 1:48);

- central riser - diameter 110 mm;

- bends from the central riser - 60 mm.

For installation of external communications it is necessary to use pipes with a diameter of 160-200 mm. PVC sewer pipes and fittings are selected so that their sizes match each other.

The building materials market is replete with a variety of products for installing a drainage system in buildings of any type:

- private houses,

- agricultural farms,

- public buildings.

The key elements of this utility line are sewerage fittings. These products are connecting parts for pipes and other system components and provide the ability to install a pipeline of any configuration.

PVC sewer pipes: types of components

Additional elements for creating pipelines are called fittings. They are used for joining pipes and connecting various equipment to the main sewer system. The products in question are used to drain sewer flows whose temperature does not exceed eighty degrees. The products can also be used for short-term transportation of wastewater with temperatures reaching ninety degrees. In the latter case, we are talking about the removal of liquids within no more than one minute. PVC products can also be used to transport chemical liquids. Their pH level can range from two to twelve.

Components for plastic sewerage are used for arranging both internal and external systems. According to the connection method, products can be mounted “under a rubber ring” or glued together without a seal.

Accessories for PVC pipes have many advantages:

- Small price. The cost of products is significantly cheaper than metal analogues.

- High variability. Many types of fittings are produced to simplify the installation of the system.

- Easy installation. The pipeline is assembled manually. To perform the procedure, you do not need to use complex equipment. The equipment is assembled according to the principle of a designer.

- Long service life. You can use polyvinyl chloride sewerage for forty years. The products are resistant to ultraviolet radiation, corrosion processes, temperature changes and aggressive environments.

- Small mass. This property greatly facilitates the process of transporting products and their installation.

Sewage systems made of polyvinyl chloride

Relatively recently, cast iron products and metal fittings were used when installing sewer systems in private and multi-storey buildings. To carry out installation work, it was necessary to use different welding methods, mainly electric welding.

Relatively recently, cast iron products and metal fittings were used when installing sewer systems in private and multi-storey buildings. To carry out installation work, it was necessary to use different welding methods, mainly electric welding.

Another fundamental feature is the fastening method. Parts can be connected in two ways:

- using an O-ring;

- by gluing.

Scheme for connecting plastic pipes with fittings

The external and internal networks are also characterized by various types of fittings for sewer pipes, each of which performs a strictly defined function. The structure of the external side of the mechanism includes the following components:

- couplings;

- audits with a cover;

- crosses;

- expansion pipes;

- reductions, etc.

Non-return valves, plugs, bends, etc. are used as specific devices for internal sewerage.

Fittings for internal sewerage

Purchase of sewer tees

sells sewer pipe tees of various configurations. Solutions for industrial, utility and business networks are on sale. The equipment is supplied in original packaging and accompanied by a set of documents.

Sewer tees of 100 mm, 160 mm, 200 mm are offered. The assortment includes various types of products.

EcoMontazh managers will help you obtain information about products. They will tell you how to insert a tee and recommend related materials. Specialists will select suitable products, fill out an application, and coordinate delivery dates.

Order a consultation

What are sewer fittings

Modern fittings for sewer pipes are mandatory elements of sewer pipelines.

- for connecting components into a single design when installing sewerage in a house or apartment;

- for connecting plumbing equipment to the main drainage line.

Modern fittings for sewer pipes are mandatory elements of sewer pipelines.

They are intended:

- for connecting components into a single design when installing sewerage in a house or apartment;

- for connecting plumbing equipment to the main drainage line.

Accessories for PVC water pipes

The creation of a water supply system is in many ways similar to the arrangement of a sewerage system. For the installation of PVC pipes, almost the same set of components is used. However, there are details that are unique to plumbing systems. These include shut-off and adjustable valves. Any system requires the installation of a shut-off valve. This element allows you to shut off the pipeline for inspection or repair work.

Valves can have different types of connections to pipes. Each part has its own installation requirements. The following types of valves are available for sale:

- straight;

- corner;

- adapters.

To select shut-off and adjustable valves, you need to take into account the type of water supply. To supply hot and cold water, parts with different requirements for tightness and resistance to temperature conditions are needed.

Types of fittings for sewerage

Fittings for PVC sewer pipes, depending on the type of sewer system, are designed:

- for installation in internal systems;

- for use in external networks.

Depending on the connection method, fittings and pipes are divided into:

- products connected “under a rubber ring”;

- elements for adhesive connection without the use of sealing rings.

To connect sewer elements using the adhesive method, fittings for PVC sewer pipes are used, which are the same for both internal and external networks:

- Clutch.

- Retraction. Can have an angle of 30°, 45°, 87° and 90°.

- Tee. Available in 45°, 67° and 90° angles.

- Revision with cover.

- Reduction (adapter).

- Stub.

- Two-plane cross. Available at 45° and 90° angles.

- Saddle for glue with a socket with an angle of 90°.

- Glue saddle with a smooth end. Angle 90°. This element is used for inserting into sewer risers.

When installing fittings for PVC pipes for sewerage, you must adhere to the following recommendations:

- You need to cut PVC products using a saw with fine teeth, since it is this tool that leaves the smallest burrs at the cut site. You can also take a piece of cable equipped with two handles for cutting;

- then you should process the resulting edge on the cut. Removing roughness and unevenness will prevent the formation of blockages and create a tight connection between the elements;

- stripping and gluing is done dry;

- When voids form in the joint area, they must be treated with glue, applying it with a brush.

Let's look at the types of fittings for internal sewerage equipped with a rubber O-ring:

- Coupling - used to connect two parallel pipes to each other; there are also inspection couplings that have an openable window for cleaning the system.

- Reduction (adapter between different diameters) - used for joining pipes whose sizes do not match, as well as for connecting cast iron products with plastic ones.

- Tee - allows you to make a parallel or inclined branch from the main pipeline; they are available with an inclination angle of 45, 65 and 90 degrees.

- Two-plane cross - makes two perpendicular branches into pipes of identical or different diameters, angles of inclination - 45 0 and 90 0.

- Single-plane cross - used for arranging two parallel branches, angles 45 0 and 90 0. With the help of crosses, drain pipes from bathtubs, sinks and plumbing fixtures are most often connected to the main riser.

- Bend - allows you to rotate the laying of two parallel pipes, angles of 30, 40 and 90 degrees.

- Compensation pipe - used during repair work to replace a damaged section of the pipeline, which is previously cut out.

- Plug - blocks the transported liquid during repairs or inspection of the pipeline.

- Aerator (sewer valve) - installed on the upper end of the sewer riser, blocks the release of sewer gases into the room through the toilet, which can occur due to air vacuum inside the riser, in which the water seal is sucked out of the siphon.

Read more: Indirect heating boiler device and principle of operation

Types of sewer fittings

For the installation of external sewerage, in addition to the same range of connecting elements as when installing the internal system, the following types of shaped structures are used:

- check valve - designed to block the reverse flow of the circulating fluid in the external pipeline; it is required to be equipped with pipes laid with a slope of less than 2 cm;

- double-joint siphon - connects two parallel pipes, forming a bend at the junction, which creates an obstacle to the reverse flow of sewer gases.

Technical requirements and dimensions of PVC connection fittings are given in the following regulatory documents:

- GOST No. 18559 - for non-pressure sewerage;

- GOST No. 52135 - for pressure systems.

The fitting sizes must be selected according to the diameter of the pipes used. The following standard sizes of shaped structures for external sewerage are available on the market:

- couplings - diameter 110-400 mm (inspection coupling up to 315 mm), length 12-33 cm;

- bends - ∅ 110-400 mm, distance between sockets 1.5-9 cm;

- tee for 450 - ∅ 110-400, length of side sockets 14-53 cm, height from the end part to the beginning of the protrusion of the socket - 14-50 cm;

- check valve - ∅ 110-250, length from 30 to 52 cm;

- two-arm siphon - ∅ 110-200 mm, length 51-82 cm.

Non-return sewer valve

PVC fittings for installation of internal sewerage have a diameter range from 50 to 200 mm. To fasten pipes to walls, plastic clamps are used, which are seated on the supporting structure using two anchors.

Installation and connection of plastic pipelines must be carried out in compliance with the following requirements:

- Cutting large PVC pipes is done using a special tool - a pipe cutter, which can be replaced with a grinder or a hacksaw. The main thing is that the cut is perpendicular to the axis of the pipe, since a tight connection cannot be made if there are gaps at the joint.

- After cutting, the edge of the pipe must be cleaned of burrs using a file and sandpaper.

- When using adhesive fittings, the joining areas must first be degreased, after which glue can be applied. The composition is applied in an even layer using a brush; excess glue when joining structures is removed with a rag.

- If fittings with a rubber seal are used, the contacting surfaces must be coated with silicone sealant before installation. which will reduce the risk of leaks. You need to install the pipe not all the way, but so that a compensation gap of 1 cm is formed. You will need to perform preliminary joining and mark the entry boundary on the pipe.

Socket connection technology for sewer pipes

If the pipes are connected using fittings correctly, the sewer pipeline will not require repairs throughout its entire service life.

PVC shaped elements according to the method of ensuring the tightness of the connection are of two types:

- With sealing rubber rings.

- Designed for connection using glue.

For installation of products equipped with rubber gaskets, the following scheme is used:

- Use a rag to clean the part from dust.

- Make sure that the rubber ring is located inside the part correctly.

- Apply it to the pipe and use a marker to mark on it the required installation depth of the shaped element.

- The inner surface of the part and the seal are lubricated with silicone sealant.

- The elements are joined, focusing on the installation depth mark.

- to connect the horizontal and vertical branches, use an elbow with an angle of 90°;

- to turn the highway at a right angle, two elbows with an angle of 45° will be required;

- for turns in one plane, bends at angles of 45° and 22.5° are intended;

Important: During installation of the system, fittings for sewer pipes are connected so that the part of the part that does not have a socket is located in the direction of downward flow. In this case, the wastewater on the way to transportation to the septic tank will not encounter obstacles in the form of a protruding wall of the connecting element. This will prevent blockages from forming.

When designing a utility network, it is recommended to minimize the number of joints. Therefore, there should be few connection points using couplings. These products are used when it is necessary to bypass an obstacle on the highway.

U-shaped products designed to remove and retain small objects and debris caught in the system. Also used to create a water seal. Manufacturers offer two types of siphons: with and without a plug.

Siphons of the first type are installed if there is free access to this part of the utility network, providing the opportunity to clean the fitting.

Used when it is necessary to insert into a sewer riser.

A product that provides a transition from a pipe of one diameter to another.

Mounted in the lower part of the riser to create a slope of a horizontal branch, used during network repairs.

Used to provide access to cleaning the system.

Sewer fittings with adhesive joints are available in cross-sections of 50 and 110 mm. To ensure the tightness of the connection, adhesives and degreasers Tangit, Gebsoplast, Griffon, etc. are used.

- for installation in internal systems;

- for use in external networks.

- products connected “under a rubber ring”;

- elements for adhesive connection without the use of sealing rings.

- You need to cut PVC products using a saw with fine teeth, since it is this tool that leaves the smallest burrs at the cut site. You can also take a piece of cable equipped with two handles for cutting;

- then you should process the resulting edge on the cut. Removing roughness and unevenness will prevent the formation of blockages and create a tight connection between the elements;

- stripping and gluing is done dry;

- When voids form in the joint area, they must be treated with glue, applying it with a brush.

Let's look at the types of fittings for internal sewerage equipped with a rubber O-ring:

- Coupling - used to connect two parallel pipes to each other; there are also inspection couplings that have an openable window for cleaning the system.

- Reduction (adapter between different diameters) - used for joining pipes whose dimensions do not match, as well as for connecting cast iron products with plastic ones.

- Tee - allows you to make a parallel or inclined branch from the main pipeline; they are available with an inclination angle of 45, 65 and 90 degrees.

- Two-plane cross - makes two perpendicular branches to pipes of identical or different diameters, angles of inclination - 45 and 90.

- Single-plane cross - used for arranging two parallel branches, angles 45 and 90. Crosses are most often used to connect drain pipes from bathtubs, sinks and plumbing fixtures to the main riser.

- Bend - allows you to rotate the laying of two parallel pipes, angles of 30, 40 and 90 degrees.

- Compensation pipe - used during repair work to replace a damaged section of the pipeline, which is previously cut out.

- Plug – blocks the transported liquid during repairs or inspection of the pipeline.

- Aerator (sewer valve) - installed on the upper end of the sewer riser, blocks the release of sewer gases into the room through the toilet, which can occur due to air vacuum inside the riser, in which the water seal is sucked out of the siphon.

- check valve - designed to block the reverse flow of the circulating fluid in the external pipeline; it is required to be equipped with pipes laid with a slope of less than 2 cm;

- double-jointed siphon - connects two parallel pipes, forming a bend at the junction, which creates an obstacle to the reverse flow of sewer gases.

Read more: Classification and marking of fittings for steel pipes

Rubber ring fittings for external sewerage

To install internal sewerage, manufacturers produce the following fittings for plastic sewer pipes “under a rubber ring”:

- Clutch. There are several varieties of it on sale - full bore repair and with stop.

- Reduction. It is used when the sizes of sewer pipes and fittings do not match and when switching from a cast iron pipe to a plastic product.

- An inspection with a lid is needed to carry out cleaning activities.

- Tee. Can have an angle of 45°, 67° or 90°.

- Two-plane cross. Available with an angle of 45° and 90°. It is used for sockets of different diameters.

- Single-plane cross. Can have an angle of 45° and 90°.

- Retraction. Available in 30°, 45° and 90° angles.

- Stub.

- Compensation pipe.

When an external sewer system is created, pipes and fittings are connected “under a rubber ring” using the following elements:

- Clutch.

- Retraction. Can have an angle of 15°, 30°, 45°, 67° and 90°.

- Double socket elbow (90°). It has rubber rings on both sides.

- Tee. Available in 45°, 67° or 90° angles.

- Three-socket tee with 90° angle.

- Reduction. It is used to switch from a pipe of one diameter to a product with a different diameter.

- Stub.

- Single-plane cross. Can have an angle of 90°.

- Revision with cover.

- Check Valve. It is installed on a pipeline laid horizontally with a slope of 2 centimeters per meter.

- Double siphon.

- Clutch. There are several varieties of it on sale - full-bore repair and with stop.

- Reduction. It is used when the sizes of sewer pipes and fittings do not match and when switching from a cast iron pipe to a plastic product. Naturally, you need to take into account the dimensions of plastic sewer pipes when choosing components.

- An inspection with a lid is needed to carry out cleaning activities.

- Tee. Can have an angle of 45°, 67° or 90°.

- Two-plane cross. Available with an angle of 45° and 90°. It is used for sockets of different diameters.

- Single-plane cross. Can have an angle of 45° and 90°.

- Retraction. Available in 30°, 45° and 90° angles.

- Stub.

- Compensation pipe.

- Clutch.

- Retraction. Can have an angle of 15°, 30°, 45°, 67° and 90°.

- Double socket elbow (90°). It has rubber rings on both sides.

- Tee. Available in 45°, 67° or 90° angles.

- Three-socket tee with 90° angle.

- Reduction. It is used to switch from a pipe of one diameter to a product with a different diameter.

- Stub.

- Single-plane cross. Can have an angle of 90°.

- Revision with cover.

- Check Valve. It is installed on a pipeline laid horizontally with a slope of 2 centimeters per meter.

- Double siphon.

Installation Tips

The simple recommendations below will help in arranging the sewer system:

- To cut PVC shaped parts for sewerage, it is better to take a saw with the smallest teeth, which minimizes the number of burrs at the cut site.

- The cut edge must be processed after cutting. This will make it possible to avoid gaps in the future and ensure that the shaped parts are connected as tightly as possible.

- Shaped parts must be cleaned and glued dry.

- If voids are found in the place where the shaped parts are connected to each other, they should be sealed using a brush.

USEFUL INFORMATION: Replacing a sewer pipe in an apartment: at whose expense, price

If the pipes and fittings were installed according to the rules, the finished sewer system will last the period guaranteed by the manufacturer.

Fittings for sewer pipes: types, sizes, installation methods

Glue method for installing fittings

- bends;

- plugs;

- saddles;

- tees;

- crosses;

- metal fittings.

When connecting pipes using the adhesive method, standard PVC products are used, which are the same for both external and internal networks.

The adhesive connection is valued for its high sealing qualities, because special glue is used in the process of working with pipes. When solidified, the substance becomes dense and hard, preventing liquid from leaving the pipeline at the junction points. Connectors for the adhesive installation method are practically no different from the analogues used in the standard circuit.

What types of fittings should be used when laying the main line?

When deciding on the types of fittings for sewerage, it is worth considering.

- Effluent parameters. Polymer fittings are vulnerable to acids. If operating conditions are not observed, they will quickly fail.

- The specifics of the highway. The parameters for laying the line are of decisive importance. The number and type of fittings used depend on them.

- Features of connected equipment. Integrated installations should not create high pressure. This will lead to the destruction of the network.

The drainage line is laid at a slope. Its absence leads to stagnation of wastewater and the appearance of an unpleasant odor.