The main working element of an autonomous water supply system is the pumping station.

This term refers to a set of components that maintain constant pressure in the pipeline.

Their large number causes a variety of causes of technical malfunctions.

For example, many users are concerned about the question: why does the pumping station often turn on? What to do? There is no definite answer to this - several factors influence the rhythm of operation of pumping equipment.

Incorrect operation of the pressure regulator

One of the reasons leading to the constant switching on of the pressure pump is incorrect operation of the pressure regulator. To make sure that it is working properly, you need to do a number of certain actions.

The first step is to check the correctness of the readings of the built-in pressure gauge, if one is included with the pumping station. This can be done using a car pump with a built-in pressure gauge.

After making sure that the pressure gauge is “honest,” begin checking the adjustment unit:

- Remove the protective cover from it.

- Pump air into the battery cylinder through the safety valve, thus creating operating pressure in the system at the minimum acceptable level.

- By turning the screw on the large spring counterclockwise, lower the pressure threshold at which the pump automatically turns on.

- Bleed the air and pump it back up, repeating the procedure several times.

The automatic relay must operate when the minimum pressure threshold specified by the manufacturer is reached in the accompanying documentation - instructions or operating instructions for the pumping station.

Failure of the equipment operating mode can also be influenced by an overestimated maximum threshold set on the relay. It should be set at 95% of the maximum permissible pressure in the autonomous water supply system.

Don’t be lazy to check the condition of the machine’s inlet. If it is clogged with dirt, the equipment will not work properly. To eliminate this reason, it is enough to clean with a stiff brush.

Equipment design

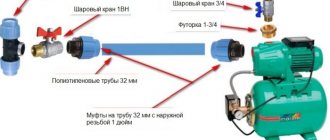

A standard water supply pumping station for a private home is a collection of individual devices that are interconnected.

To repair such equipment yourself, you must take into account all the design features, as well as be able to correctly determine the cause of the malfunction.

Pumping station design:

- submersible or surface pump pumping liquid and maintaining stable intra-system pressure;

- pipeline with a check valve that prevents the backflow of water in the event of a shutdown of the pumping equipment;

- membrane tank or hydraulic accumulator , which is a sealed container divided into parts by an elastic membrane and designed to create a small reserve of water;

- control unit installed in the area between the membrane tank and the pump, and represented by a pressure gauge and pressure switch.

Control devices allow you to correctly assess the level of intra-system pressure, control the operation of the pumping system, turning them on and off in a timely manner.

The pumping station turns on after the pressure in the system drops to 1.0-1.6 atmospheres.

The equipment turns off only when the upper pressure readings are reached.

For example, in a private one-story house, the standard upper pressure threshold is 2.6-3.0 atmospheres.

What do you know about the coolant temperature standards in the heating system? To what extent should the liquid be heated and what is its temperature at the “return” outlet, read this useful article.

How to choose shampoo for a high-pressure car wash is written on this page.

Checking the injection pump

The pumping station will often turn on even if the pump is not provided with sufficient power. The pump impeller will not be able to develop the required power. In this case, the pump will not be able to create maximum pressure in the pipeline; in order to fill the pipes with water, it will have to work almost without interruption.

A power deficiency may be the result of a malfunction of individual parts of the pump - electrical or mechanical. Malfunctions of the power supply also contribute to this problem.

The main reasons for the lack of power:

- Salinization of the pump inlet and outlet pipes: can be eliminated by mechanical cleaning or rinsing with cleaning solutions.

- Oxidation of the contact surfaces of the terminal box: they should be cleaned with fine sandpaper, having first disconnected the pump from the power source.

- Unstable voltage in the electrical network: its fluctuations are checked while the pumping station is running. This drawback can be eliminated by connecting a voltage stabilizer.

Over time, individual components of the mechanical part of the pump wear out, which leads to a decrease in the maximum possible pressure level in the system. You can check the pump's capabilities visually by disconnecting it from the outlet water supply.

A weak stream of water at the outlet of the pump indicates a high degree of wear of its parts. Most of them cannot be repaired, so you will have to replace the entire worn-out unit.

The autonomous water supply system of a private house is carried out using a pumping station. Like any equipment, it can also fail, and in order not to constantly call a specialist, you can carry out some repairs to the pumping station yourself. We will analyze the main breakdowns and their elimination.

Recommendations for choosing and installing a pumping station can be found here.

Have you decided to install a water supply system in a private house yourself? Then the next topic will be interesting for you: https://aquacomm.ru/vodosnabzenie/zagorodnyie-doma-v/avtonomnoe-vodosnabzhenie/istochniki/kak-otregulirovat-rele-davleniya-nasosnoj-stancii.html. Step-by-step setup of the pump station pressure switch with your own hands.

Background or how to buy a pumping station at half price

A long time ago, in a galaxy far, far away... But no, that's a slightly different story. In general, several years ago I once bought a pumping station for my well. I wanted, you know, civilization in my house - like everyone else: water from the tap and other delights. I don’t remember the model of the station I bought, but it gave me plenty of problems. But more on that later.

My well is located only 3 meters from the house. So I bought a pumping station, installed it underground, brought a plastic pipe from a well to it, deepening it 1 meter into the ground so that it would not freeze in winter. But during installation, I accidentally broke the thread on the pump body itself. Naturally, at this point it began to suck in air and constantly turn off.

Well, what can you do - when buying a cheap station (it cost me somewhere around 5 thousand rubles) with a plastic impeller housing, you had to prepare in advance for this outcome.

Tired of constant interruptions in water supply, I turned off the station, grabbed it and took it to the store for further repairs. There they even made me very happy - mechanical damage does not apply to warranty cases!

Of course, they took the pumping station for repairs, but they had to fork out money for the work.

While the pump was being repaired, I had to carry water from the well by hand. And so on for a whole month, while the renovation was going on. My nerves were on edge.

Finally, the station was returned from repairs. Joyful, I return home with it, install it, connect it, turn it on, and... There is no water. At all. Although everything looks intact, when turned on it starts working, but does not pump. What to do: I turn off the pumping station again and take it to the store.

It turns out that the would-be repairmen, when replacing the housing with a new connection thread, simply forgot to put the impeller back in place. It is unclear how one can forget about the main unit that actually provides water pumping.

Arriving at the store, I immediately attacked the sellers with abuse: the renovated station does not work - what kind of nonsense is this? Naturally, the sellers shrug their shoulders - what do we have to do with it? - and point to the repairmen. That’s right, it wasn’t the sellers who repaired this station for me and forgot about the impeller.

In short, they advised me to contact the store owner directly and demand a refund from him for the goods. Despite the day off, the sellers called the store owner and said that a buyer had come and was making a scandal - demanding a refund for the pumping station, which turned out to be faulty after repairs.

To be honest, I didn’t even expect that the owner would agree to return my money, so I started looking at options for what I could get instead of this station. The store owner arrived and started asking me the reason for my dissatisfaction. I explained to him that after the repair the station did not pump water, and the repair itself lasted a very long time, in turn, I myself asked the question how long I would have to sit at home without water with the purchased pump.

To my surprise, the problem was solved quickly - the owner immediately began to offer me a replacement, and at a price that was higher than the cost of the station I originally purchased. But I immediately told him that I was not going to pay extra - and there was nothing to do with it! - but he replied that no additional payment was required.

It would be a sin not to take advantage of such a generous offer, so I did not hesitate and chose the LEO LKJ-901IA pumping station - its price, if I’m not mistaken, at that time was 9,450 rubles. This is a functional and reliable model that operates fully automatically and is equipped with a contact opening function when dry running occurs.

Checking the pressure accumulator

The next step in finding the reasons for frequent pump starts is to check the serviceability of the hydraulic accumulator.

If the container is damaged, this will lead to water leakage and, as a result, to a catastrophic drop in pressure in the pipeline.

A highly stretched rubber membrane will have the same effect.

How to check the integrity of the tank? Press the valve nipple (it is located on the part of the battery filled with air). If air is released from it, the integrity of the container is not compromised. The appearance of water from the valve indicates damage to the membrane. It will have to be changed.

If the situation develops unfavorably, the only way out is to completely replace the entire battery.

What to do and how to fix the problem

Naturally, first you need to find out what is causing this problem. Let's move on from the simple.

1. Pressure in the accumulator. On the rear wall of the hydraulic tank there is a pneumatic valve, which is closed with a plastic cover.

We remove the cover; for easy unscrewing there are special recesses for fingers.

Let's check if there is any air in the hydraulic tank. We press the nipple with a match, the characteristic sound of escaping air will be heard. There is no sound, which means the tank is empty.

You can skip this procedure and immediately use the pressure gauge. According to the rules, it should be 0.2 bar below the minimum starting pressure. Read more about this here. If the indicator is less than the required level, we take a pump, I use a regular manual one. After pumping it up a little, we check the pressure.

Important point: first disconnect the pumping station from the network, open the tap (mixer) and drain the water.

How to determine the required pressure without a pressure gauge? I do this procedure by eye. When we pump air into the tank, water begins to flow from the tap. You need to pump until the pressure becomes almost the same as if the pumping station was connected to the network and raising water.

It is recommended to check the pressure once a month.

2. Membrane integrity. Again, press the match on the pneumatic valve; if water flows out of it, the bulb is definitely torn and will need urgent replacement.

To get to it, I needed to disconnect the pumping station from the suction line, and also remove the pressure hoses from the outlet located on top.

We unscrew the bolts that secure the tank lid, which also presses the membrane. We take out the torn bulb, rinse and dry the tank. We assemble in the reverse order with a new membrane.

By the way, the rupture may be due not only to the fact that the membrane has lost its qualities or worn out. This may occur due to insufficient air in the tank.

3. Check valve. To check, disconnect the pumping station from the suction line; no water should flow out of the valve.

If the valve is leaking water, do not rush to buy a new one. Remove it and carefully inspect it; it is possible that a foreign object has gotten inside and is preventing the valve from working correctly.

We have looked at the possible reasons why the pumping station often turns on. It is better not to cause breakdowns at all, to carry out maintenance on time. Let us remind you that the average service life of a pumping station is 5 years.

Other Possible Causes

You have checked the pressure switch and adjusted it. The pump of your station develops the necessary power, and the battery is as good as new - and the installation continues to turn on after a short period of time or even works without a break... Leave the station alone and start inspecting the pipeline.

The pump will turn on frequently if one of the following problems occurs:

- Fistulas have formed on the pipes or their connections have become depressurized. The presence of leaks in the network inevitably leads to a loss of pressure.

- The supply pipe is clogged and clogged with debris, as a result of which its throughput has sharply decreased.

- The water level in the source dropped and its filling slowed down.

The search for leaks in hidden sections of pipelines is carried out by step-by-step inspection of individual network segments. The pressure in each of them must be monitored by installing a pressure gauge.

The area being tested can be considered intact if, in the absence of water intake, the reading on the pressure gauge remains unchanged for 10-30 minutes.

Frequent switching on of the pumping station can also be caused by blocking the check valve with some foreign object. The blocking element can be removed by disassembling and washing the water fittings. By the way, maybe, having disassembled the check valve, you will see that it has simply worn out and lost its tightness. Since this item is a consumable item, simply replace it with a new one.

Such a simple device as a storage tank for water supply actually plays an important role in the correct operation of the autonomous system.

How and why a well is pumped with water after drilling, you will learn by reading this material.

Preservation during a break in operation

Such measures are designed to extend the life of the equipment and help maintain high performance indicators.

Conservation rules:

- disconnecting the equipment from the power supply and turning off the safety circuit breaker;

- releasing pressure in the system;

- disconnecting the suction hose and water pressure;

- checking the pressure in the hydraulic accumulator;

- draining residual water from pumping equipment.

You will learn about the reasons that force the mechanism of turning the water supply pumping station on and off frequently while watching the video.