Reasons for jerking

Manifestations also vary. This is when the water from the tap comes out in jerks or when there is a surge in the pressure created by the pump when sucking liquid from a well or well.

Most often, this situation occurs because:

- An air lock has formed in the pipeline. As a result, the pumping station works to push it through, and periodically this succeeds, but as soon as the pressure breaks through, the pressure drops, and the pump is forced to pump up pressure in the system again.

- The pressure switch has failed. The pressure gauge shows correctly, but the pump does not turn on and off in a timely manner. This is due to an underestimated upper limit or an overestimated lower threshold.

- The system has depressurized. This could be a hole in the pipeline, an insufficiently tight connection, poor-quality shut-off valves, or damage to the working chamber of the pump, as well as failure of its mechanical components.

In each case, repairs must be made. A preliminary audit is carried out in order to identify the true cause. If there are no visible consequences, you have to go through the entire chain from the well to the consumer.

Individual water supply for a country house is not only a big plus, but also for some owners of water intake structures it is a “headache”. Since well owners often have the problem of “no water in the well,” as a result of which all repair activities fall entirely on the owner’s shoulders. Of course, it’s good when the well has a guarantee certificate and all work to restore the source of water supply will be carried out by the drilling company that equipped it (well or well). But, if the well is quite old and the water from it begins to flow in spurts, the owner will have to decide what exactly to do, either try to restore the water supply himself and identify the reasons why this is happening, or seek help from a specialized drilling company that deals with professional repair and cleaning of wells.

Now let's look specifically at why water from the well began to flow in spurts . There are several reasons for this: equipment breakdown, the aquifer has dried up, or there is not enough water. We will not consider the breakdown of well equipment in this article, but you can familiarize yourself with similar articles on our website, such as: “Repair of a well pump”, “Repair of a hydraulic accumulator”, “Replacing the membrane in a hydraulic accumulator”, “Repair and cleaning of a well” and other.

Order services and get information!

What prompted me to write this article: “ What to do if water comes out of a well in spurts? ". This is a phone call from one of our clients who wanted to find out why the water from the well was flowing intermittently. Note that as a result of a conversation with the owner, it turned out that the well was drilled into the first aquifer, and its depth is about 9 meters. I hope that this article will help other owners of water intake structures (wells or wells) to determine for themselves why such an unpleasant situation arises with a water intake structure or water supply system.

But, if you need the help of professionals, then you can always order repairs and cleaning of the well and water supply system in a country house in Nizhny Novgorod Burovaya . We carry out comprehensive work aimed at restoring the source of water supply on a turnkey basis. Our company also drills wells in the Nizhny Novgorod region with subsequent high-quality construction. You can find out all the detailed information on ordering services and costs by calling the company. Thank you for trusting us with your work and your water intake structure!

The most common problems associated with a well and the presence of water in it, such as:

- Reducing water in a well or well (periodic, frequent or constant);

- Drying of the well (meaning the water has completely dried up or the water is quickly running out);

- The supply of water to the water supply system occurs in spurts.

Note that such troubles may be associated with the result of incorrect drilling and installation of a water well. Therefore, to drill a water supply source and equip a well, it is necessary to call only a competent drilling contractor who can not only drill and equip a well, but also document his work (contract, estimate, guarantee, documents for the water supply source, etc.).

If the water level in a well or well drops

All year round, water has been steadily flowing into your home from a well and have you never noticed a lack of water before? And now you are faced with an unpleasant situation when there is periodically no water in the well, or it quickly runs out? Why did this happen? Let's take a closer look at the reasons for this situation and how to eliminate it. The main prerequisite for the emergence of such a situation with a well or well for water can be:

- Natural conditions for changing geology where the water intake structure (well or well) is located. Those. The reason for this phenomenon may be a displacement of the bottom of the formation from which you take water.

- Changes in aquifers by season. This usually happens on hot summer days, causing the aquifer to dry out for a while.

- Defects that were made during the construction of a well or well.

- Silting of filters if the water supply source has not been used for a long time.

The reason for changes in the water level in a well or well can be other factors, such as:

- Drilling work was carried out in close proximity to your well or well;

- Connecting another well to the aquifer, i.e. your neighbors drilled a well into the same aquifer from which you draw water, resulting in interruptions in water supply.

- In this case, you need to wait and not use the well for 30 days so that the water level returns to its normal state, but if this does not happen, then you will have to think about deepening the well.

Note that deepening (drilling) a well should be done only after a thorough determination of the cause of the situation.

It will be important to deepen a well or well only in a few cases, such as:

- If you are not satisfied with the water level, but its quality is completely satisfactory;

- If drilling and construction of a new well is not suitable for you due to lack of space on the site;

- If no horizontal displacements were detected.

If the water is completely gone

As a rule, this situation happens if the well has been in operation for quite a long time. Or the well was drilled into the first aquifer, the so-called perched water, so the volume of water in it can vary - dry up and be restored. Also, if the aquifer is used by several water intake structures or the horizon is completely dry, as a result, the water supply may completely stop. In this case, in order to solve a similar problem with water, it is necessary to deepen (drill) the well into another aquifer, and drill a new deep well (artesian). Of course, everything depends on your financial capabilities.

The flow of water from the well is jerky

If the water pressure in the water supply system from the well periodically changes, this occurs due to a change in the pressure force in the communication, i.e. The pressure has dropped, and therefore the water stops flowing. In this situation, it is necessary to calculate where exactly the pressure fluctuation occurs in the water intake structure: at the level of installation of pumping equipment or at one water supply point.

To fully understand where exactly the change in pressure occurs, you need to use the method of elimination. First, check all the points in the house, i.e. open the taps. If the water comes in spurts at all points, then the problem lies in the pipe that is connected to the house. In this case, air can penetrate into the pipe along with the incoming water, resulting in the formation of an air lock that does not allow water to flow with constant pressure.

The most common reasons why the pressure in the water supply system at home changes and water flows in spurts are:

- The tightness in the water supply system is insufficient. It is necessary to check the operation of all communications in each individual area, starting from the hydraulic tank, well pump to all pipes.

- Failure of pumping equipment; the check valve of a well pump often fails.

- Various debris getting into the pump. In this case, when the pump is turned on, the pressure quickly rises and the pump switches off. After the pressure drops again, the unit turns on. As a result of this reason, water enters the house in spurts. what to do in this case: replace the filter and clean the well pump.

- The depth at which the well pump is installed is incorrectly selected or the amount of water in the well is insufficient.

- The membrane in the accumulator has broken. In this case, it is necessary to replace the membrane in the hydraulic tank or buy a new one. The pump may also be dirty and need to be cleaned.

- It also happens that air comes out of the hydraulic tank due to natural reasons. In this case, you need to pump it up with a regular bicycle pump. After such an event, the pressure in the water supply system normalizes and the water pressure becomes constant.

From all that has been written above, it is worth adding that drilling and installation of a water well should be carried out only by qualified employees of the drilling company. Since drillers will be able to accurately calculate the well’s flow rate, its productivity and service life, and will also select the necessary equipment for the full operation of the autonomous water supply system as a whole. We also note that it is best to order the drilling of a deep well, and not to drill into the first aquifer (upper water).

Useful articles on our website:

- Drilling private wells in the Nizhny Novgorod region;

- What to do if the membrane in the accumulator breaks?;

- When repairs are more expensive than drilling a new well

VN:F [1.9.22_1171]

please wait...

Rating: 0.0/ 10 (0 votes cast)

VN:F [1.9.22_1171]

Rating: 0 (from 0 votes)

Share this article with friends and colleagues

Troubleshooting

Having made sure that there are no gusts on the route, and all connections are sealed, we can conclude that water from the well comes in jerks due to the breakdown of one of the units:

- Pressure switch. The correctness of the pressure gauge readings is checked, which must be replaced if necessary. To do this, you need to use another instrument, for example, a car tire pressure gauge. Instructions on how to configure the relay.

- Hydraulic tank. Damage may be to both the body and the diaphragm or bulb, depending on the type of structure. If, after pressing the nipple to bleed air, splashes fly from the exhaust pipe, then this is exactly the problem. The bulb or diaphragm must be replaced with a new one.

- Pump. Damage to the housing and depressurization of the working chamber are visible to the naked eye. But if the reason is the wear of mechanical components (shaft, bearings, wheels, blades), then you will have to disassemble the device and carefully inspect every detail. Dirt, silt, sand, clay are removed.

- Filter. Clogging of the coarse filtration unit can also lead to unstable operation of the pumping station. The mesh needs to be cleaned and replaced if necessary. The electrical part of the system is checked separately.

Voltage surges, breakdown of the control unit and other electrical problems can cause jerks in the operation of the pumping station. It is not recommended to carry out repairs on your own without specialized skills. It is worth contacting the service center.

Solving the main problems with filling a water source

Before deciding what to do if there is little water in the well, you need to determine the exact cause of this phenomenon. An individual approach to the problem will help to reliably eliminate it.

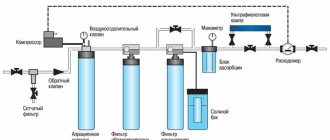

If the well produces little water and quickly empties, flushing is carried out first. To carry out washing you will need:

Food acids (for example, citric acid) are necessary for flushing the well

- special reagents (food acids or gum);

- water hammer device;

- compressor.

It is best to entrust the washing (gelling) of a water source to professionals. The use of household reagents will help in case of minor blockages, but sometimes they make the situation even worse. Water hammer is also a risky procedure; it can damage the casing.

If the reason that the well begins to produce little water is clogging or siltation, in addition to flushing, pumping is carried out. For flushing, water is supplied to the well or borehole under high pressure. To do this, you can use a fire water cannon. Pumping involves forcing the well to work continuously for up to 10 hours. Flushing and pumping ensure complete cleaning of the well from a variety of clogging objects. As soon as this happens, water will begin to circulate freely in the well.

The flushing procedure will clean the well for a short period of time, which is no more than two years. Then the bottom of the springs will gradually silt up again. You will have to repeat the procedure or drill a new well.

If a new source silts up within the first year of service, this is a serious reason for panic. It makes no sense to iron such a well. It is necessary to resolve the problem with representatives of the company that carried out the drilling.

Often only one section of the well becomes clogged, the coarse or fine filter. In this case, the filter will need to be replaced.

Another reason why the spring produces little water is its rare use. As a result, soil will accumulate in the place where the water was collected. The space for liquid will become less and less. To fix the problem, you need to start actively using the source. You will also have to wash it, but it is better to entrust it to professionals.

How to protect the station from breakdowns

In order to never puzzle over why water flows unevenly through the pipes, it is enough to initially assemble the system correctly.

If the problem is already evident, then after the repair you need to check whether everything was done correctly at the stage of arranging the source. Thus, pipes and hoses should not be kinked or deformed, which leads to a decrease in throughput.

The system includes a check valve that prevents the reverse flow of liquid through the pipeline. Check whether the pump power is selected correctly. To do this, the calculation takes into account the depth of water in a well or well, the distance of the source from the house, and the number of consumers. The flow rate of the source cannot be less than the productivity specified in the technical passport for the pumping station.

Any leaky connection can cause air leaks, which causes interruptions in the water supply. And attempts to save money by excluding any of the nodes from the system always leads to the fact that it works inefficiently. But all this can be corrected if you select all the components correctly and install them in the right sequence. The procedure is simple if you approach the issue with due care.

How to eliminate cavitation

Static and dynamic water level in the well

To begin with, let us remember that the choice of pump for a well directly depends on its diameter. For a well with a diameter of 10 cm, a submersible pump is purchased, and for a smaller diameter, a plunger or circular type of pump is needed. You also need to know that the water storage tank is located at a distance from the pump of at least five diameters of the pipe leading from the well to the tank.

When air appears in the water pumped from the well, the following actions must be taken. First of all, you should try to increase the diameter of the suction pipe.

The formation of air bubbles and voids in the water flow depends on the number of turns in the pipe, which extends from the well and goes to the water container. It is best if there is a minimum number of turns on it, which should be located in the same plane. It is especially important to avoid bending the pipe at 90 degrees.

It will be useful to read:

Since it is quite difficult or almost impossible to completely get rid of pipe turns, it is best if they have an inclination angle of 30 to 45 degrees. This solution allows to reduce vortex processes, and also increases the diameter of the suction pipe and helps reduce cavitation. In addition, if there are bends of small diameter, then it is better to replace them with a slightly larger size. It is also advisable to replace rigid pipes with flexible ones.

To eliminate strong cavitation, which causes irreversible consequences and, accordingly, destruction, it is worth removing the check valve, installing a gate valve, and replacing the suction part of the pipe with a pipe with a smooth surface, which helps reduce pressure. The main part of a gate valve is a piece of steel plate, which, using a rod with a drive, completely cuts off the flow of water. To facilitate work with this type of valve, the drive is made electrical, mechanical or pneumatic. Of course, a manual drive is also available, but using it requires some physical strength.

Since the formation of bubbles and air voids can be overcome by high pressure, which is much higher than atmospheric pressure, it is possible to increase the pressure of the suction force of the pumping station by additionally connecting a booster pump, increasing the water level in the tank and lowering the level of the pump. To lower the level of the pump, dig a small pit, the width and length of which will allow you to install a pumping station or pump, and to leave room for convenient maintenance.

The bottom of the pit must be leveled, compacted, and in addition, it can be covered with a small layer of crushed stone or sand. This is necessary so that the soil does not stick to the soles of shoes and to the metal bases of the pump.

Design Features

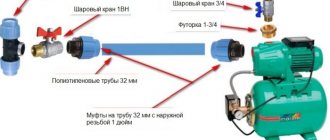

When the site is located far from the main water supply, the owners of their cottage are faced with a choice - install a conventional pump in the well or equip a well. If the question concerns a country house, then a small volume of water may be enough, but for a permanent year-round residence of a family of 3-5 people this will not be enough. Then you will need an installation that includes:

- The submersible or surface electric pump itself. This is the main structural unit that is responsible for lifting fluid from the downhole to the surface. Water pipes are connected to it - its edge fits into one of the holes in the five-pin fitting.

- Hydraulic accumulator. It is also called a storage tank. This is a metal reservoir that is divided by a membrane bulb or diaphragm. On one side there is an air valve in which 1.5 atmospheres are maintained, on the second side water is pumped in. And the more liquid, the higher the air pressure.

- Check valve. He is responsible for ensuring that the water that gets into the pump does not go back down into the face when it is turned off.

- Control block. It is also called automatic, it consists of a relay and a pressure gauge. These two devices monitor the fluid level in the hydraulic tank and the pressure in the system.

- Electrical power supply.

Work technology

Technology for pumping a well.

To carry out high-quality pumping of the well, it is necessary to prepare the following equipment:

- vibration pump;

- centrifugal pump;

- drill;

- timer switch (if possible);

- pipe for draining water.

The question of how to pump a well can be divided into 2 points:

- what equipment to use to carry out the work;

- what pump modes to use.

Most experts recommend starting pumping using vibration installations of the “Kid” type. Firstly, they pump out water with a high content of solid particles well. Secondly, at the initial stage, when the filtration cone has not yet fully formed, a slight vibration coming from the unit into the ground makes solid particles more mobile, which allows the cone to form faster.

But you should not use vibration equipment for more than 1-2 days, because after some time the opposite effect from its operation will be observed - compaction of the filtration cone. Therefore, if after 2 days the well continues to become sandy, then it is better to switch to pumping water using cheap centrifugal equipment of the “Aquarius” type.

Scheme of drilling a well for sand.

To properly pump a well, you must follow the basic rule: do not expose the well filters from water, that is, during pumping it is forbidden to remove all the water. This is due to the fact that water makes solid particles more mobile and does not allow them to stick together. If the liquid disappears, the pores will begin to clog, which will lead to a decrease in flow rate.

To properly pump a well from sand, you need to adhere to the following method:

- Lower the pump into the well and begin pumping out water, carefully monitoring its flow. As soon as air bubbles appear, the pump turns off.

- After some time, the column of water that has again formed in the well is measured.

- The initial volume is calculated: the volume of water (the height of the column multiplied by the diameter of the well) is divided by the time it enters the well. The resulting value is correlated with the pump performance. If the productivity is higher, then the time at which the pump can operate without completely pumping out the water is calculated. This will allow the pump time switch to be programmed as required.

- To do without a timer, you can drill holes in the pipe running from the pump to the surface in such a way that the volume of water flowing through them returns back to the well, thereby compensating for the excess power of the equipment.

Pumping is carried out until the water in the well is completely clean. Shaking must be done immediately after drilling, because otherwise formation clogging may occur. This will lead to the need for additional chemical and physical cleaning methods to carry out declaying. And this will entail unnecessary time and money costs.

Design and operating features

We list the tasks that can be solved with the help of a water station for the home that works without malfunctions:

- Make full automation of water supply. You no longer need to manually turn the pump on and off, check the pressure and water level.

- Determine and adjust the required fluid pressure. Make it permanent, independent of the height of the building, weather conditions and other indicators.

- Stock up on clean drinking water in case of a power outage.

- Now the water supply will be completely separate from the main line, which means there will be no interruptions during accidents on the line.

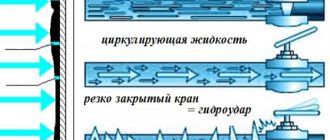

- Extend the life of equipment by minimizing the risk of water hammer - they can quickly lead to malfunctions of the water pumping station.

Depending on your capabilities and needs, you can either buy a ready-made installation or make it yourself. In the first case, the owner receives a device with a guarantee for at least a year, as well as operating instructions. In the second - small savings, but an increased risk of breakdowns. However, sometimes this is advisable, for example, when the well depth is very large, it is better to replace the surface structure with a submersible pump.

The design of the system is such that all the elements presented above are connected to each other using a multi-outlet fitting. During installation, we recommend leaving an additional outlet, which can be closed with a plug, for unforeseen situations. The hydraulic tank will be connected on one side - to the pump, on the other - to the water pipe, which will be discharged into the house if the structure is built outside its walls. It is often also possible to install the system in the basement. This makes it easier to repair an automatic water supply station with a hydraulic accumulator and regular maintenance, and also eliminates the need to insulate the elements. One caveat is noise during operation; sound insulation will be required.

The pump hums, but does not spin:

The reasons for this pumping station malfunction are as follows:

- It happens that the pump spent the winter somewhere in a barn, and in the spring they took it out and tried to start it. But it begins to hum... Due to the fact that the pump was left without water and without movement for a long time, the pump impeller “glued” to the housing. You need to manually rotate the impeller from the back side, and then plug it into the network;

- the capacitor has failed (located in the branded engine box);

- It is necessary to check the voltage in the electrical network, perhaps it is simply too low.

That's all (or almost all) that can be said about malfunctions of the pumping station for water supply systems at home and about repairing the pumping station with your own hands.

pumping station malfunctions

2013-2017 Copyright © Use of site materials is permitted with reference to vodoprovod-doma.ru

Operating principle of the equipment

If you plan to repair the device yourself, then you need to know not only what it consists of, but also how it works. In fact, this is easy to figure out.

There is a pump, it has its own individual technical characteristics (power, suction depth, speed of pumping working fluid - volume per unit of time, etc.). It requires electrical power and a hose to operate. All other details only improve the pumping process.

The principle of operation of a home pumping station and spare parts that may malfunction is as follows:

- The water does not enter the tap in transit, but first fills the accumulator. Its task, as is already clear from the name, is to accumulate moisture. To do this, the membrane bulb is filled and stretched, absorbing as much of the working medium as the maximum volume stated by the manufacturer. The effect on the membrane is such that the air in the adjacent chamber begins to compress and the pressure increases. When it reaches certain atmospheres (the values need to be adjusted or use the factory limits of 1.4 and 2.8 bar), the relay is activated. It opens the electrical circuit and, as a result, the electric pump turns off - the hydraulic tank is full.

- Then users turn on the faucet, shower, start the washing machine or dishwasher, and begin watering the garden. At the same time, the shut-off valve opens, the air strongly presses on the membrane, as a result, water comes out with a stable strong pressure. And when the air chamber becomes less than 1.4 bar (or another value set by the user), the relay closes the circuit and the pump turns on.

Common problems and breakdowns

Since the pumping station consists of several components, a breakdown may be associated with one or more of them, for example:

- the pump is clogged with dirt;

- the pump motor is broken;

- the settings of the pressure switch are lost;

- the integrity of the rubber membrane in the hydraulic tank is damaged;

- there are cracks in the hydraulic tank housing, etc.

As a result, the pumping station either works unsatisfactorily or stops functioning altogether. Sometimes it’s not the station at all, but a breakdown of, say, water pipes. To determine the cause of the problems, you should consider how the most common breakdowns occur during the operation of the equipment. For example, when figuring out why the equipment turns on but does not turn off, you need to take into account the operating features of the pressure switch.

“Dry running”, i.e. operation without water supply, idle, is very dangerous for almost all models of surface pumps. The parts wear out a lot, and the motor winding may burn out.

When troubleshooting a pumping station, you need to remember that dry running is strictly not recommended for almost all models of surface pumps. Before you turn on the pump to check its operation, you should make sure that it is filled with water. If this is not the case, the device must be filled through a special filling hole.

The pump works, but no water flows

If the pump turns on, and you can see (hear) that it is working, but no water flows into the container, you need to figure out where exactly this water goes. The first thing to check is the check valve. If it went bad, the water simply poured back out. If there is water in the intake hose, then the check valve is not to blame; you need to look for another reason.

If the hose is empty, it should be removed and the check valve inspected. It may happen that the pumping station does not pump water at all due to simple clogging of the valve holes. It is enough to rinse the device for it to start working correctly again. Sometimes you need to replace the spring or the entire valve. Of course, after replacing a part or repairing, you should check the operation of individual components of the pumping station, and only then carry out the final assembly and startup of the device.

Causes of problems: the pumping station is leaking or not working

The most common errors that lead to breakdowns are:

- Initial purchase of low-quality equipment. For example, it is worth paying attention to the width of the metal gasket of the hydraulic tank near the inlet valve. And also on welds and membrane quality, on pump power.

- Equipment incompatibility. You can avoid this if you buy complete units at once.

- Incorrect installation. If installation does not require special skills, then it is better to entrust commissioning work to a specialist.

- Poor filtration. The entire system should be provided with a good mechanical coarse filter so that the equipment is not damaged by soil particles. You can order filtration equipment on the “Water of the Fatherland” website.

- Mechanical damage.

- Poor insulation from cold and moisture, direct sunlight, and other climatic factors. It is best to install the equipment in a special pavilion.

In fact, the main reason is the lack of regular inspection. Most problems can be eliminated at the onset of development, when the first symptoms are visible. Then it is more efficient, cheaper, and faster.

How to repair a pumping station: types of faults

Failure of the pump and auxiliary equipment is typical, therefore the set of problems is usually the same for all unit owners. It is better to know in advance about possible defects in order to prevent their occurrence or react quickly.

The pump does not turn off, the pressure does not increase

In this situation, the device works “idle”, that is, electricity and time are wasted, but the result is not achieved. This significantly increases wear on parts. Here are the possible reasons and their solution:

- Insufficient water in the well. If power allows, you can immerse the equipment deeper into the face.

- Clogged pipes. The pumping station will need to be cleaned, but it is better to start with the mains. But after this, it is imperative to install coarse filters. Catchers will protect against the penetration of contaminants. You can order filtration equipment on the website.

- A broken check valve - it stops coping with its main task, that is, it does not prevent the liquid from draining back into the face when the pump is not working. It can be repaired, but is often easier to replace.

- The filter itself is clogged. The reasons and solutions are the same as for clogged pipes. In fact, any element can become clogged. Often this is also the check valve of the pumping station, and since it is quite easy to clean it (just disassemble and wash), we will not make this a separate problem.

- The contacts on the relay are oxidized, which is why the circuit does not open. They just need to be cleaned, or less often, the sensor needs to be replaced.

- The impeller of the pump has naturally worn out and needs to be replaced with a new one.

- Insufficient voltage in the electrical network. The solution may be to install a stabilizer in the circuit.

The electric pump turns on too often

Perhaps the reason is as follows:

- For high flow rates, the volume of the hydraulic tank is not large enough. You can replace it or install a second, additional hydraulic accumulator.

- The relay settings are incorrect. It is necessary to tighten the springs so that the switching occurs at a pressure of 1.4 bar.

- The check valve is broken and the water is drained back into the well, so it has to be constantly pumped up.

- A torn membrane is one of the most difficult faults, since most likely the entire hydraulic tank will have to be replaced. In addition, there are additional symptoms - the pumping station is leaking (drops form near the nipple), and the pressure in the tap becomes less.

Air in water

This can be detected not by small bubbles in the flow, because this is the norm, but because the liquid comes out in jerks and not evenly. Most likely, the reason is simple - the water level in the well has decreased somewhat, so you need to lower the hose from the pump a little. But it may be that some connections in the pipeline have lost their tightness. Then air gets into the cracks. It is necessary to go over all joints with sealant.

Why does a well pump pump water in jerks?

The water supply system is one of the main elements of a comfortable and modern home. Water supply based on a well is an almost obligatory element of any cottage, house or even summer house.

Well arrangement diagram

Of course, as soon as the water supply begins to fail, all residents of the household will notice it, since you can only last a few hours without water. And this period depends on how many residents live in the house. Therefore, they rarely save on the equipment of utility networks, especially well pumps (repairing a pump is an adventure worthy of the strong in spirit and strong in body: since the pump must be taken out of the well, and after repair, lowered back). But even the highest quality and most reliable mechanism can fail over time. One of the main and most common problems associated with well pumps is that it either completely stops supplying water, or does so intermittently. The article will discuss the reasons why a well pump pumps water in jerks. We will also provide possible solutions. Determining the problem yourself and eliminating it in a timely manner will allow you to save your money. However, it is better to entrust this work to professionals.

How to repair a water pumping station with your own hands

The first thing you need to do is find the fault. Visually inspect all components for mechanical damage. Once you have seen the source of the problem, disassemble the system, freeing the part. First, of course, you should disconnect the electric pump from the power supply so that there is no situation where it runs “dry”, because this can cause it to burn out.

Then there are two ways to proceed:

- Replacing a spare part. The components are not very expensive. The most expensive is the hydraulic tank, and it does not break down very often if a high-quality model was initially purchased. When purchasing spare parts, pay attention to the compliance with the technical specifications and the original brand. Replacement is carried out according to a simple scheme: dismantling, checking and cleaning connections, installing a new spare part.

- Repair. Sometimes this is worthwhile, but other times it is a waste of time. Based on your capabilities and the complexity of the breakdown.

Floor-standing dispenser AquaPro 6207CH (cooling/heating/room temp.)

Wall-mounted dispenser AquaPro 3207CH (cooling/heating)

Aeration column AS-0844 VO-90

Pumping stations for the home - design and some types of repairs

There are things you can do yourself, for example:

- clean the check valve and the entire system and pipes;

- clean the coarse filter;

- configure the relay;

- install an additional storage tank;

- dismantle the old structure, etc.

But other repair jobs require specialized knowledge and experience. So we recommend contacting specialists when the issue concerns hydraulic tank failure.

Replacing the hydraulic accumulator bulb

The membrane is the most sensitive place in a water reservoir, since it is the one that is directly exposed every day. When it is broken, the first symptoms appear - the water pressure in the tap decreases, and it is supplied in jerks, with air masses. The main criterion by which the presence of a breakdown is determined is the pressure in the valve, it should be 1.5 atmospheres. Otherwise, replace:

- The first step is dismantling.

- Then the water is drained.

- The flange is unscrewed.

- The membrane is pulled out.

- Rust is removed from the inside, if any, and the tank is dried.

- A new bulb is installed and the system is assembled in the reverse order.

- Test runs are being done to check for leaks.

Video on repair of pumping stations

Detailed information on the repair of pumping stations is presented here:

Interesting practical experience in repairing the Pedrollo pumping station is contained in the following video:

This video clearly demonstrates the disassembly of the station pump and the process of replacing the seal:

However, before performing this procedure, experienced craftsmen recommend inspecting the shaft located underneath. If the metal is excessively worn, the new seal will quickly deteriorate. It is necessary to either restore the shaft (if possible) or completely replace the engine.

A number of problems with the pumping station can be eliminated yourself. If complex breakdowns occur, you will have to contact specialists. With proper care, the number of breakdowns can be significantly reduced.

Did you like the article? Share it

Recommendations for installation and operation

- Entrust the work to specialists.

- Use filters.

- Set the settings in accordance with the instructions for use and technical characteristics of the device.

- Give preference to either metal pipes or PVC pipes, but with rigid reinforcement.

- The hoses must not be twisted.

Air in a water well: causes and methods of combating

An autonomous water supply system from a well in a country house or on a summer cottage can solve many problems. Firstly, to make staying in nature comfortable, and secondly, to grow a rich harvest, since regular watering will no longer be a problem. Having many advantages, the pumping station requires not only proper installation and equipping with a filtration system, but also regular washing and preventive procedures. A common phenomenon: the supply of water from a source along with air.

Reasons for the appearance of air in a water well

If the pressure becomes too low, there is air in the system

As a rule, the problem of air getting into the water is faced by households who use small volumes of water from a source or when using pumping equipment seasonally. The causes of this phenomenon may be the following problems in the system:

- The air suction at the water suction point has failed. The problem will not be solved until the pipeline is completely replaced with all the necessary parts. It’s easy to make sure that it’s working properly – just pump the water in the pipeline, for example, in the bathroom.

- Breakdown of the pumping equipment itself due to irregular or poor quality maintenance. Air bubbles are formed as a result of a weak gland seal. The solution to the problem is to disassemble the working unit of the station and fix the damage.

- Insufficient filling level of the well during large pumping. Drilling a new well, purchasing a less powerful pump, reducing the volume of water used can solve the problem. However, when drilling a new well, it is important not to reach the same aquifer, where the likelihood of airing the system again is very high.

Cavitation and its elimination

As practice shows, cavitation is the most common problem faced by owners of household plots with an autonomous water supply system.

The cause of cavitation is incorrectly selected pumping equipment. Water devices are selected taking into account the diameter of the well. For sizes less than 100 mm, plunger or circular models are suitable, 100 mm and more - submersible.

Cavitation is a violation of the density of the water column, in other words, the filling of the pipeline with air bubbles. Formed in areas with reduced pressure at a critical level. The phenomenon is accompanied by the formation of voids in the pipeline, bubble formations formed as a result of the interaction of gases and vapors released by well water.

It is not always possible to determine the faulty area yourself, since special equipment is required. It is also worth adding that this area may be unstable. If measures are not taken, the consequences will hit the pocket hard - dynamic effects on flow and vibration will lead to breakdown of pumping equipment.

To reduce the likelihood of a problem developing, you need to choose the right water pumps, taking into account the volumes of water consumed and the technical characteristics of the well.

To get rid of such an unpleasant phenomenon as the appearance of air in water, you need to consider the main ways to solve the problem:

- Replace the small diameter pipe with a larger diameter pipe.

- Install pumping equipment closer to the storage tank. When transporting the pump, it is important to take into account the established standards: the interval between the container and the pump must be no less than 5 diameters of the suction pipe.

- Replace the valve with a gate type and remove the check valve. To reduce the pressure in the pipeline, the pipe is replaced with a smooth one.

- There should not be many turns in the suction pipe. To solve the problem, you need to replace small radius bends with large ones or simply reduce them. At the design stage of an autonomous water supply system, it is recommended to place all outlets in the same plane and use flexible pipes rather than rigid ones.