Sewer outlets: types, sizes, installation methods

29.10.2018

A sewer outlet is a type of fitting designed to rotate a pipeline at an angle from 15 to 90 degrees. There are several types of such components, which differ in characteristics and recommendations for use.

- Internal and external - for assembling the external system, orange elements are intended, which are easy to detect in the ground. Indoor pipe bends are usually neutral in color.

- Regular and special - shaped products are used to combine smooth and corrugated highways.

- Manufacturing technology - all types of sewer pipe bends can be divided into cold-formed and welded.

Definition and purpose of sewer outlet

Plastic single-socket outlet

A manifold bend is a pipe element bent at a certain angle. The second name for the fitting is corner, elbow. The main function of the product is to change the direction of the sewer flow towards the central riser or septic tank from the entrance from the wall of the house and in its other areas. As a rule, the outlet has the same cross-section as the sewer pipe.

Plugs and tees are used as additional fittings when installing sewer systems. The first helps to limit the movement of water flow. The second allows you to branch the collector if the system is being laid for two or three buildings at the same time, or if storm and fecal wastewater from two different systems will flow into a common receiver.

Plastic sewer bends 110, sizes and types

Let's look at plastic sewer bends 110 - sizes and types, what they are and what characteristics they have - more details in this article!

A modern sewerage system is a complex engineering structure, the main part of which is occupied by pipelines. When creating a system, different types and sizes of pipes are used, but they are all sold in the form of straight sections. If it is necessary to change the direction or connect one pipeline line to another, special fittings are needed that have a certain shape and size. There are a large number of similar elements. The most common are plastic sewer bends 110, the dimensions of which are optimal for most pipelines. Let's take a closer look at this issue.

Material of manufacture

The market offers shaped products made from the following materials:

- Steel. It is used extremely rarely in everyday life when installing sewer systems. This is due to the metal’s susceptibility to corrosion and the complexity of installation work. To construct a steel channel, welding must be used. During the operation, the thin coating layer of steel pipes is damaged, which leads to faster wear. To extend the service life of the steel collector, galvanized metal is used.

- Cast iron. Durable material with impressive weight. Working with cast iron is just as inconvenient as working with steel. Pipeline installation is carried out using electric welding equipment, soldering or other labor-intensive methods. Shaped cast iron elements are not equipped with seals. Metal is prone to corrosion, especially when installing the external part of the sewer system. A silt build-up quickly forms on the inner walls of a cast iron outlet.

- Ceramics. Such a drainage channel is characterized by a long service life, high flow rate due to smooth internal walls and ease of installation. However, the cost, as well as the weight of the ceramic outlet, are high for a private craftsman.

- Low-density polyethylene (HDPE). The shaped elements are black and are used only when installing external sewerage. HDPE is not used in private construction. Its main purpose is the construction of industrial and central city highways. Installation of polyethylene tubes is carried out by soldering or using special couplings. Low-density polyethylene is inert to aggressive inclusions and does not respond to temperature changes.

- Polyvinyl chloride (PVC). The optimal outlet material for private construction. All PVC sewerage elements are installed in a socket. This greatly simplifies the construction process. For interior work, gray bends are used, for exterior work - brown. PVC is not afraid of aggressive environments and has low thermal conductivity. The outer part of the sewer system is less likely to freeze in the ground than a cast iron or steel network.

- Polypropylene. Bends made from this material are suitable for installation inside a building, since PP is afraid of ultraviolet radiation. The shaped elements are equipped with sockets for simplified installation. Polypropylene pipes can carry liquids up to 95 degrees. The material is not afraid of this.

Steel

Ceramics

Cast iron

There are no bends for asbestos-cement pipes, so metal sewer half-branches are used in such a pipeline.

When constructing a collector, it is important to use all elements from the same material. If it is necessary to combine several different parts, special adapters are used. Most often these are bends for corrugated pipes.

Without exception, all shaped elements are produced strictly in accordance with GOST. Otherwise, the process of installation and further operation of the system will cause difficulties.

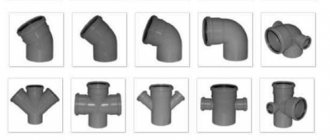

Types of bends

Regardless of the name of the manufacturer producing PVC sewer outlets, all these products comply with accepted construction standards (GOST). This makes it easier to design sewer systems, purchase the necessary materials and install them into a single system.

There are a couple of different models of corner elements, which differ in price and some design features.

- Polyethylene . They are made of dark-colored material and are connected end-to-end or using couplings. In the first case, the ends of the pipe and the outlet are heated using special equipment and joined together until the plastic completely hardens. The couplings are already equipped at the factory with a special spiral, which is heated using a welding machine for a hermetically sealed connection.

- PVC bends . The most common type. They are connected by placing a socket on a smooth pipe. Advantages: no need to use different power tools and increased speed of installation of the sewer system as a whole. Structural elements intended for indoor use are painted gray. There is another sewer outlet - in a private house (at a time when the room is not heated or the pipes are installed outside) the parts are brown. (See also the article Pipes for internal sewerage: highlights.)

Note! It is forbidden to combine these two varieties into one system. It is necessary to use bends of the same type. Otherwise, high-quality and long-term operation of the sewer system is not guaranteed. It is extremely rare that it is necessary to include special adapters in the circuit.

- Polypropylene . In addition, they have sockets and smooth ends for joining each other. These products are only used in conjunction with pipes made of similar material. The main purpose is to drain groundwater and wastewater. They are capable of passing water flow at a speed of 4 to seven meters/s.

- Bends for corrugated pipes . These elements are joined by means of couplings and are equipped with sealing rings on each side. At the point of inflection, the outer part of the product has a reduced diameter. Scope of application: joining pipes made of different materials using sealing collars.

- Wavin taps . Special, separately patented system. On the outside of the corrugated element there is an unusual triangular indentation that acts as a lock. For the manufacture of these products, excellent material is used that can withstand great pressure. Guaranteed service life - 50 years.

- Magnum taps . There are models with a bend angle of 45 and 90 degrees. A special feature is the absence of rounding, which can lead to clogging during the operation of the system. Connecting elements of a similar design are actually not used when creating sewer systems.

Types of bends

Double socket fitting

In addition to classifying bends according to the material of manufacture, they are divided into types according to the degree of bending angle. You can purchase drainage elements of 15, 30, 45, 67 and 87 degrees. In this case, bends with any bend can be connected to each other, but it is not recommended to make too sharp turns of the collector. In such areas, blockages are more likely to occur.

In addition to the bending angle, bends are divided into single-socket and double-socket.

Both types change the direction of liquid (air, gas) in the system, but differ in the complexity of installation. A single-socket outlet, as a rule, has a smaller bending angle.

Types and sizes

Cast iron pipelines are still found in older houses. The elbows used in such systems are also made of cast iron. They are heavy, difficult to install and require highly qualified plumbers. Today they are practically not used, although such elements are still on sale.

Modern sewer outlets are made from different types of plastic:

- PVC;

- polypropylene;

- low or medium pressure polyethylene.

All pipes, regardless of material, are fully compatible with each other. This means that the dimensions of PVC sewerage outlets are no different from the parameters of shaped elements made of polypropylene or polyethylene. This is convenient for installation or repair work. The most common pipelines with a diameter of 50 mm (internal sewerage laid to the toilet) and 110 mm (toilet tee and the rest of the system, including the riser). Sometimes the markings indicate a diameter of 100 mm. It must be borne in mind that these are the same pipes with a diameter of 110 mm.

There are different types of sewer twins. They are shaped elements, the difference between which is their diameter and angle of inclination. The most common types of bends for sewer pipes 110 by angle: 15°;

- 15°;

- 30°;

- 45°;

- 67°;

- 87°.

The types of tees for sewerage are very diverse. They can be divided according to the following characteristics:

- diameter;

- number of taps;

- bend angle;

- functional purpose.

The diameter of the fittings corresponds to the dimensions of the main pipelines. The most common tees for sewer pipes are 110, the types of which correspond to all possible functional tasks. At the same time, larger elements can be used for the outer part of the sewer:

- 125 mm;

- 150 mm;

- 160 mm;

- 200 mm;

- 250 mm;

- 300 mm, etc.

According to the angle of inclination of the bends:

- straight;

- inclined (at 45°).

It must be taken into account that straight bends have an angle of 87°, not 90°. This is done for the convenience of cleaning pipes with a plumbing cable, so that the direction is better set.

Based on the number of branches, there are the following types of tees for sewerage 110:

- with one outlet;

- with two;

- three;

- with four branches (cross).

According to the functions they perform, tees are divided into:

- connecting. Used to connect plumbing fixtures, or to connect another sewer branch;

- revisions. The outlet has a sealed lid. They are usually installed on risers. Used to perform system audits and remove blockages;

- cleaning These are tees with a 45° pipe angle. They are usually installed on horizontal sections of the system. The slope of the outlet is directed in the opposite direction from the riser, which makes it easier to insert a plumbing cable or hose for hydrodynamic cleaning.

Inspections and cleanings are normally closed with a threaded cap or plug, eliminating the possibility of leaks. They belong to service fittings, although they participate in the process of transporting wastewater along with any other elements of the system. At the same time, the working holes of these elements can be used to connect other pipelines. This need most often arises when using oblique tees if a new plumbing fixture is installed in the room.

Parameters, dimensions, weight

For the installation of a sewer collector, you can purchase bends of any diameter. The table shows common parameters of shaped elements.

| Diameter (mm) | Length (mm) | Weight (kg) depending on material of manufacture |

| 15 | 28 | 0,04 |

| 20 | 29 | 0,06 |

| 25 | 38 | 0,11 |

| 32 | 48 | 0,19 |

| 40 | 57-60 | 0,26-0,5 |

| 50 | 75 | 0,5-1 |

| 65 | 100 | 1-1,7 |

| 80 | 120 | 1,4-2,8 |

| 100 | 150 | 2,2-5 |

| 125 | 190 | 3,8-6,2 |

| 150 | 225 | 6,1-13,3 |

| 200 | 300 | 14,9-39 |

| 250 | 375 | 23-46,7 |

Selection order

You can buy shaped parts in online stores and in any shopping centers that sell building materials.

What basic rules must be followed:

- request product certificates from the seller;

- choose products from trusted suppliers;

- purchase pipes and fittings produced by one manufacturer - deviations of millimeters in diameter will significantly complicate installation;

- gray pipes and fittings are intended for use inside heated premises, shades of brown in color indicate the possibility of use outside buildings or underground;

- PVC products are not intended for installation in places exposed to sunlight - the plastic will collapse;

- PVC outlets and polypropylene products have smooth internal walls, which facilitates silent removal of wastewater and reduces the likelihood of sediment accumulation;

- cast iron pipes are chosen only for repairing old networks - their price is much higher, they are heavier and more difficult to install;

- if living space allows, it is preferable to use a sewer half-outlet, reducing the likelihood of blockages and reducing possible noise during the movement of drains;

- revisions are installed at turning points;

- for risers, plastic outlets of at least 110 mm in size are purchased, and drains are purchased depending on the connected sources of dirty water;

- When purchasing, pay attention to the side where the exits are directed; they can be left or right.

It is better to make underground communications made of cast iron or corrugated plastic, therefore, purchase fittings from the same material. This will help prevent possible leaks in the future.

Recommendations for selection

The shaped element for sewerage is selected according to the following criteria:

- Material of manufacture. It is desirable that it completely matches the type of pipes used to lay the collector.

- Internal section of products. It must correspond to the diameter of the pipes: if the collector has a cross-section of 110 mm, the outlet for sewer pipes is taken with a diameter of 110 mm, no more and no less.

- Availability of rubber seals. They greatly facilitate the sewer installation process.

- Product compliance with GOST. As a rule, there is a corresponding marking on the outside of the product.

- Bend angle. It is important to correctly calculate the line configuration in order to avoid errors when arranging its direction.

- The presence of a flat, smooth inner surface of the product. Otherwise, in the future, wastewater with large inclusions will provoke the formation of growths on the walls of the collector.

As a rule, when installing domestic sewerage in a private house or apartment, plastic shaped elements are used.

Purpose of the product

PVC bends for internal sewerage are needed to arrange the rotation of sewer pipes at a certain angle and are used for installing unclean water drainage systems in administrative and residential buildings.

Plastic connecting elements have a smooth interior, which greatly reduces the risk of clogging during operation, and virtually do not make noise when liquid flows through them.

In addition, their production uses material that is resistant to warm water (up to 95 degrees Celsius) and chemical detergents.

Dimensions of sewer plastic outlets: 110 and 50 mm (the diameter of the internal hole is measured).

As for angles, the standard values are:

- 30 degrees;

- 45 degrees;

- 87 degrees.

Advice! By combining a sewer outlet and a half-outlet with different bending angles, it is possible to achieve a pipe rotation of 30, 45, 60, 75 and 90 degrees. But it is advisable to avoid excessively sharp bends so that blockages do not occur.

There is another option: a branch with a diameter of 110 mm with access to pipes of a smaller diameter. They are used for various non-standard configurations.

Installation rules

Example of installation of riser branches

The tap installation technique consists of several stages.

- Cut the pipe in the place where the outlet will be attached to it. It is important to ensure that the tap is made strictly perpendicular to the central axis. Otherwise, the tube segment will not fit into the outlet socket tightly and all the way around the entire circumference.

- The cut edge on the inside and outside of the pipe is sanded to remove burrs. This is important because if they are present, clogs will form in the pipe from fibrous deposits that can cling to uneven surfaces. Then a small chamfer is made along the outer edge with an angle of 15 degrees.

- A groove with the same angle is also formed on the outer edge of the outlet in order to subsequently insert the edge of the element into the next pipe.

The edges of the collector parts are treated with sealant and joined together in the direction of the pipeline. When connecting to a socket, a small compensation gap of 10 mm must be left. It is not recommended to deepen parts of the collector beyond this mark.

Short description

Plastic bends for sewer pipes produced by our plant have the following dimensions:

- outer diameter – from 110 to 400 mm;

- rotation angle – 15° – 30° – 45° – 67° – 87°;

- wall thickness - depending on the standard size.

Note: A rotation angle of 87° is usually taken to be 90°.

Guaranteed shelf life is 2 years. The products are painted orange. The product has a socket on one side with a groove for an O-ring. The other side of the part is smooth, with a chamfer already removed. The presence of a socket makes installation simple and easy.

offers plastic elbows in St. Petersburg at a very competitive price. Products that comply with the EN 1401-1 standard will last you at least 50 years.

Source

Sealing joints

During the installation of bends, it is necessary to ensure that all joints are properly sealed, otherwise the collector will leak. In most cases, all plastic elements are already equipped with rubber seals. They are located inside the bell. If they are not there, the rubber ring is inserted all the way before joining the elbow to the tube.

Special plumbing sealants help enhance the sealing effect. They are pre-applied to the rubber seal around the entire circumference. When choosing a sealant, it is better to give preference to neutral rather than acidic. The former are more reliable, although they are more expensive. Acidic compounds are prohibited from being used when installing cast iron or steel collectors. Otherwise, the acid will corrode the metal.

Independent installation of bends

As mentioned earlier, PVC bends are the most widely used. This is due to their low cost and ease of installation.

Docking is done using special seals. Quite often they are already inserted into the internal space of the bell. In another case, the rubber ring supplied with the corner element is placed in a special recess in front of the connection.

There is an alternative method - using glue. This type of docking is less common and more complex. For adhesive joints, rubber seals are not necessary.

From time to time it becomes necessary to join pipes made of different materials. In this case, it is necessary to use sealing collars and plumbing sealants. Such a connection will be reliable and will not allow leaks during operation.

Sealing joints

The reliability of its operation depends on the tightness of the corner connections of the sewer system. You should pay increased attention to this, especially at a time when installation is done with your own hands. (See also the article Connecting the toilet to the sewer: highlights.)

It is even more scrupulous to seal joints when laying pipes underground, which often happens during the construction of private houses. The cost of repairing leaks can be very large.

It is recommended to seal connections between bends and pipes using special sealants.

These substances contain many components and are divided into two main types:

- acidic (inexpensive compounds);

- neutral (more expensive).

Note! Acid sealants cannot be used when installing iron and cast iron pipes. Before purchasing, pay attention to the composition indicated on the packaging.

In addition, if you are joining PVC bends with rubber seals, additional treatment of the ring with sealant will only add reliability to the connection.

The use of one or another sealing compound is mandatory for processing connections of the sewer system with cast iron pipes. This material, by definition, cannot be completely smooth and therefore requires the use of current compositions. The best solution is liquid silicone.

Additional methods for sealing pipe joints and bends

In addition to using sealant, it is possible to use alternative methods.

| View | Description |

| Epoxy adhesive | Very reliable and durable connection. But after the composition has completely hardened, it will be impossible to disassemble the pipes without destroying them. |

| Hemp or resin strand | Used for joining PVC bends with pipes made of other materials. In this case, the end is wrapped with the selected material approximately two-thirds of the length, inserted into the socket and filled with cement or asbestos-cement mixture. The method is reliable and time-tested. |

| Technical sulfur | This method was used in 95% of cases quite recently. At the moment, it can be used to connect sewer systems of different materials to each other. |

| Bitumen mastic | More suitable for joining ceramic outlets with similar pipes, but can be used for sealing joints of external sewerage systems made of PVC pipes. |

| Sealing tape | Least reliable method. Suitable as a temporary measure until the damaged unit is replaced. |

Repairing leaks

Well, at a time when the sewer system is operated without accidents. But if leaks occur, you should not despair.

The instructions in this section will help you quickly resolve the problem.

- Leaks at junctions with old pipes. In this case, a liquid sealing compound will help: sealant or a mixture of cement and glue. In addition, epoxy glue or raw rubber, or, in extreme cases, plasticine, will do.

- Hole. Treated with a peg treated with sealant or a splint (clamp). An emergency option is to use a rubber bandage.

- Longitudinal crack. Sealed with epoxy glue or cloth impregnated with silicone. For metal pipes it is possible to use cold welding.

- The edge of the outlet is chipped. In this case, only replacing the damaged element will help.

Sewer plastic pipes diameters, prices

Every owner wants everything in his household to work, nothing to break, and to be easy to maintain and install. And sewerage is no exception. It needs to require as little attention as possible - it’s very inconvenient if it gets clogged, but it’s no less unpleasant to clean it

If you want to have a trouble-free drainage system, pay attention to plastic sewer pipes. They are gradually replacing cast iron ones, and all because they cost less, are easier to install, have a wide range - different diameters and lengths, almost no deposits form on their smooth walls, and even have a service life of about 50 years

This whole bouquet of properties determines their popularity.

Plastic sewer pipes are made from various polymers and their compositions

Types of plastic sewer pipes

Products made from different types of polymers are sold under the general name “plastic”:

- polyethylene (PE): high pressure (HDPE) - for internal sewerage distribution,

- low pressure (LHP) - can be laid outside, in trenches (have greater strength),

And a number of other thermoplastics and their combinations, but they are rare - people prefer to use already known materials.

The material of plastic sewer pipes is selected depending on the application. For example, polypropylene is more suitable for installing sewerage inside a house or apartment. It has a higher operating temperature range - it normally tolerates environments up to 70°C, and for a short time - up to 95°C. If you have various household appliances that discharge waste hot water into the sewer, this will not be superfluous. PVC pipes, which have lower prices, are more appropriate when laying external sewers - here the drains are usually already mixed, so the temperatures are lower and PVC can withstand them without harm (working up to +40°C, short-term increase to 60°C).

Materials

Few people know that there are several types of sewer outlets. Different options differ from each other not only in cost, but also in design features, as well as operating characteristics. Let's get to know them better.

Polyethylene

Such sewer outlets are produced from raw materials with a characteristic black color. It is connected end-to-end or using a special coupling. In the first case, the end parts of the pipe and the outlet are heated with a special device, after which they are joined to each other until the material is completely dry. As for couplings, already during the production process they are equipped with a special spiral-shaped part, which is heated by a welding machine in order to completely seal the joint.

Polyvinyl chloride

Such sewer outlets are considered to be the most common. Such parts are connected in the following way: the pipe is put on a pipe with a perfectly smooth surface. The main advantage of these types of bends is that there is no need to use any power tools to work with them. Composite structural elements designed for use inside a living space are painted gray.

Polypropylene

Polypropylene sewer outlets are also equipped with sockets and ends with smooth surfaces. These components are designed for correct and precise joining.

Similar types of bends are used only in conjunction with pipes made from exactly the same raw materials. The main purpose of polypropylene parts is to drain groundwater/wastewater. It is worth noting that these elements can pass water flow at a speed of 4-7 m/sec.

Cast iron

Cast iron sewer outlets are also found in stores. Such parts are considered obsolete and are not used as often. They are distinguished by their impressive weight. In addition, they are quite difficult to install, since there are no special sealing rings. It should also be taken into account that their inner part has a slightly rough surface, which over time can become covered with sediments and growths.

Steel

To design sewer systems, sewer outlets made of galvanized and stainless steel are often used.

- Galvanized options boast good strength characteristics. However, these types of bends are susceptible to corrosion (in this they are inferior to popular plastic parts). Usually, when welding stainless steel parts, the protective coating of the material is damaged, which is why traces of rust often appear in the area where the seam is located.

- As for stainless steel, it should be noted that it is more resistant to corrosion. In addition, such sewer outlets are considered stronger, more durable and durable than the same plastic options.

Read with this

- Features of using PVC sewer pipes with a diameter of 50 mm

- Plastic sewer bends 110, sizes and types

- Disadvantages of polypropylene pipes in home heating

- Rules for laying sewer pipes

- Effective methods of thermal insulation of sewer pipes

- How to lay sewer pipes in the ground

- Sewage check valve

- Do-it-yourself installation and replacement of sewer pipes in an apartment

- Which pipes for heated floors to choose: characteristics and installation methods

- Which rehau pipes are best for heating and water supply?

What are the types of shaped elements for sewerage?

When choosing pipes and fittings for sewerage, the construction market offers a wide range of products that can be divided into several categories. Depending on the location of the highway, there are:

- Elements for installation of internal sewerage.

They are installed inside residential premises and serve to drain wastewater from toilets, bathtubs, sinks, washing machines and dishwashers. Products in this category for us are painted in grayish colors. - Parts for external sewerage. Elements, designed according to their physical characteristics to operate in harsh conditions of the outdoor environment, serve to drain wastewater from residential premises into the general sewer system or settling tanks. To make it easier to detect their location underground, they are painted orange.

Rice. 2 Cast iron pipes and fittings

According to production for personal use, the following elements are distinguished:

Cast iron. Morally obsolete products that currently have no practical application in the household.

Cast iron sewer pipes are enormously heavy, difficult to install due to the lack of integrated sealing rings, and have an internal rough surface that becomes covered with growths over time. Although pipes have a long service life of about 70 years when used inside buildings, in the ground they rust and become unusable much more quickly. Therefore, when laying, their external waterproofing is required.

Steel. A virtually unused type of sewer pipe in everyday life due to its low corrosion resistance, complex installation involving welding and thin walls.

In industry and utilities, zinc-coated steel is used to increase corrosion resistance.

Fig.3 Installation of sewerage system outlets

Asbestos cement. A good choice of options for sewer pipes compared to the previous 2 versions; pressure and non-pressure types can be used. Unlike metal ones, asbestos-cement products are lighter, do not corrode, have smooth internal walls and the highest service life. The tightness of the connection is achieved through the use of rubber sealing rings of the CAM system; the disadvantages include fragility and the lack of bends for turning the line (half bends made of metal are used).

Ceramics. The clay pipeline is easy to install thanks to integrated rubber rings and swivel fittings, has smooth internal walls coated with glaze, the highest service life and better resistance to harsh chemicals.

The disadvantages of ceramics include the extremely high cost.

Rice. 4 Properties of polypropylene (PP)

Plastic. An absolute favorite among all types of sewer pipelines in everyday life, which are made from the following plastic materials:

Polyethylene (HDPE). The scope of implementation of polyethylene pipelines does not affect personal sewerage systems; they are used in industry and public utilities. When installing such lines, pipes are connected end-to-end by welding or using external couplings welded on top and sealing the butt joint.

Cellophane has a dark color and is resistant to corrosive action and harsh chemicals.

Polypropylene (PPR). Polypropylene strips are easy to install using rubber ring sockets, have smooth internal walls, are lightweight, have superior corrosion resistance and have a long service life. In some cases (inserting tees into a line), pipes can be connected using external couplings that have an O-ring on each side.

Polyvinyl chloride (PVC). PVC sewer lines are the favorite among all types for personal use, they have a socket connection with an O-ring, and a wide range of bends with different angles are used to configure the direction.

Unlike polypropylene, they are used for installing not only internal, but also external sewerage.

Rice. 5 Properties of polyvinyl chloride

Based on their design, sewer fittings that allow the sewer line to perform its functions are distinguished into the following types:

Bend - the element is used to configure the direction of the strip at angles of 15, 30, 45, 67, 87 degrees.

In plastic sewer systems, tees or crosses are additionally used to connect pipes with a diameter of 50 mm.

Coupling - designed for an external sealed connection of joints of pipes of similar diameter using double-sided rubber sealing rings.

Tee - allows you to connect two lanes into a single highway.

Cross - designed to connect pipes at an angle of 90 degrees.

Reduction - used for joining two pipes of different diameters.

Revision - a fitting for plastic pipes provides access to the line from the inside during cleaning work.

Compensation pipe - the element is designed to perform auxiliary functions when performing engineering work in strips (inserting tees).

Rice.

6 Types of fittings for internal sewerage

Nuances of operation

Tee bend

After commissioning, the sewerage system requires careful treatment and periodic maintenance.

The rules of use are easy to follow:

- It is not allowed to knock on pipes and bends or place foreign objects on them;

- It is prohibited to store containers with flammable substances near pipelines;

- Polypropylene and PVC sewer parts must not be exposed to open fire, for example, for defrosting;

- it is allowed to hide pipelines with easily removable structures;

- During interruptions in use, water seals of plumbing fixtures are filled with water at least once every 25 days;

- It is prohibited to clean plastic pipelines with metal brushes and brushes;

- the angles of inclination of pipes and bends cannot be changed;

- after disassembling the system, change the rubber O-rings;

- when replacing parts, it is allowed to use only similar types - for example, you cannot install a plastic part instead of a cast iron one;

- It is allowed as a temporary measure in case of accidents to place a rubber cuff on the damaged pipe.

Types of plastic sewer pipes and their sizes

Plastic sewer pipes are made from the following materials:

- high and low pressure polyethylene;

- polyvinyl chloride;

- polypropylene.

The material for the drain depends on the area of application.

Polypropylene elements are more suitable for internal networks. They are able to withstand temperatures up to +70°C. In some cases, it can be tolerated for a short time up to +95°C. Pipes made of this material are suitable for systems that receive waste water from various household appliances.

Cheap PVC products are used when installing an external channel in which mixed wastewater moves. Their temperature is lower than in the internal network. Their operating indicator is +40…+60°С. Parts are divided into corrugated and smooth. Corrugated parts are used not only for installing siphons. Pipes with a ribbed outer wall, but a smooth surface inside, are characterized by increased strength.

Types of plastic sewer pipes.

Such parts withstand compression well and are suitable for a system that runs deep underground. The diameter of the products can be 110-1200 mm. The large size is designed for increased loads. These elements are used in the maintenance of apartment buildings, social buildings and cottages.

PVC bends for external sewerage

| Standard size, mm | Dimensions, mm | ||

| Dn | α, deg | Z1 | Z2 |

| 110 | 15 | 9 | 15 |

| 160 | 15 | 13 | 19 |

| 200 | 15 | 15 | 25 |

| 250 | 15 | 28 | 34 |

| 315 | 15 | 35 | 42 |

| 400 | 15 | 34 | 53 |

| 110 | 30 | 17 | 22 |

| 160 | 30 | 24 | 30 |

| 200 | 30 | 30 | 38 |

| 250 | 30 | 46 | 50 |

| 315 | 30 | 59 | 62 |

| 400 | 30 | 64 | 83 |

| 110 | 45 | 25 | 29 |

| 160 | 45 | 36 | 42 |

| 200 | 45 | 46 | 54 |

| 250 | 45 | 66 | 69 |

| 315 | 45 | 84 | 86 |

| 400 | 45 | 96 | 110 |

| 500 | 45 | 114 | 137 |

| 110 | 67 | 41 | 47 |

| 160 | 67 | 59 | 65 |

| 110 | 87 | 59 | 65 |

| 160 | 87 | 83 | 89 |

| 200 | 87 | 105 | 113 |

| 250 | 87 | 141 | 143 |

| 315 | 87 | 178 | 180 |

| 400 | 87 | 211 | 229 |

| 500 | 87 | 390 | 410 |

In pipelines of external non-pressure sewerage, the change in direction of fluid flow must be smooth, which is the purpose of this shaped part. manufactures sewerage outlets from uPVC (unplasticized polyvinyl chloride). The products comply with the European standard and are distinguished by good strength properties, wear resistance and long service life.

Installation of fittings

Sewage installation

There are a number of useful tips that will help you install fittings perfectly and correctly:

Before joining with fittings, you need to cut PVC pipes with an alloy hacksaw with a fine-toothed blade.

Thanks to this, there are no protruding pieces of formation left on the edge of the pipe at the cut site.

After the pipe is cut, it is worth processing the cut area, removing burrs and roughness. This will help to fit the fitting as tightly as possible, and during operation of the system there will be no blockages or leaks at the joints.

The cut PVC elements should be cleaned only after the product becomes dry (that is, remove water if there is any on the pipe or fitting).

If voids have formed in the area where the pipes and fittings are connected, they should be treated with glue using a brush.

Then the installation, carried out correctly, will help preserve the sewer system so that it can be used for many decades.