What is the mechanism of a pumping station

To understand why the pumping station does not turn off, you need to familiarize yourself with the elements of which it consists:

- Directly pumping equipment. It is divided into submersible and surface devices. They branch into different types according to performance and are capable of operating in several modes.

- Hydraulic pressure accumulator. Presented in the form of a container, which is divided into two parts using fairly flexible rubber. When the pump is turned on, this container is filled with water and the rubber is stretched. When the mechanism is turned off, everything returns to its original position, and the collected liquid helps maintain a stable pressure in the pipeline.

- Control node. It includes a pressure gauge; it measures the pressure available in the system. Thanks to the presence of auxiliary elements in the installation, the maximum and minimum pressure values are set. When the highest level is reached, the pump receives a command to operate, and when it reaches the lowest level, it is turned off.

Factory settings

The relay is available with preset pressure values:

Lower indicator

is 1.5 bar. As soon as the pressure in the system drops to this level, the contacts are closed and the well or submersible pump is turned on.

Upper indicator

according to standard settings it is 2.5-3 bar. The maximum value is 5 bar - it is indicated on the sensor scale. When the set value is reached, the contacts are broken and the pump is turned off.

The difference between the upper and lower values is called the differential. It can be adjusted

.

Water pressure is provided through air injection. A certain amount of air is pumped into a tank that has a rubber container (bulb) with a car nipple. The air presses on the water, which fills the bulb, thereby ensuring proper operation of the station.

Why does the pumping station need to be turned off?

It is noted that one of the most common problems is that the pumping station does not turn off. The essence of combining all the parts that make up the station is that they regulate its periodic shutdown and timely operation.

Thanks to this, the service life of the pumping station increases significantly, and the number of wear parts is reduced. Some types of this equipment have an electric motor and are therefore completely unsuitable for continuous operation.

If you notice that your pumping station is working without a break, you need to stop the device and try to find out the root of the problem.

The most common cause of station malfunctions

Most often, the pumping station does not turn off precisely because of breakdowns in the coordination of the control unit. In the main part of the main components of the pumping station, the degree of pressure is coordinated using two springs, large and small, which are located on the relay. The task of the large spiral is to regulate the lower pressure threshold, and the small one regulates the difference between the maximum and minimum values. It is also worth noting that during use of the pumping station control unit, it may become clogged, which significantly impairs its functioning.

Since there is a hole in the middle of the relay, during operation, and especially if all the pumped water is heavily contaminated, it can become clogged. Therefore, before starting to coordinate the main assembly, it is recommended to review the available relay parts and, if there is a need, carefully clean the input hole.

It is important to note that the relay must be adjusted very carefully. If you apply excessive force, you can permanently break the device. To make it easier to fix existing problems, the above assembly should be partially disassembled. To perform these steps, it is recommended:

- disconnect the station from the electrical network;

- liquid is drained from the battery tank;

- an ordinary pump from a car is connected to the inlet valve of the accumulator, always with a pressure gauge;

- the pressure required for the operation of the station is created in the accumulator tank;

- remove the cover that blocks the passage to the control unit that controls the relay - as a result, access to the springs will be gained;

- to increase the minimum pressure, you must turn the adjusting screw clockwise, and to decrease it, turn it counterclockwise;

- To adjust the difference between the lowest and highest pressure readings, this can be done by turning the adjustment screw.

It should be noted that the maximum pressure at which the station must be turned off must be at least 95%.

Additional reasons

There are several other less common reasons why the pumping station does not turn off for a long time:

- Water leakage is observed. To fix this, you need to find the damaged area and solder it.

- Failure in the electric relay unit. During operation, contacts may become dirty, oxidize, and sometimes even burn. This causes the pump to turn on and off frequently. To eliminate the malfunction, it is recommended to turn off the power to the device and thoroughly clean all contacts.

- And also the pumping station often turns on due to unstable voltage in the network. In this situation, it is advisable to purchase a power stabilizer.

In addition to the above options, constant operation of the device can be caused by air leaks in the inlet pipe. This will cause the pump to never turn off.

There is also an emergency drain valve at the pressure source. When a critical point is observed, it is activated to eliminate the breakdown of the device.

Occasionally, the pump may stop functioning or run continuously as a result of exposure to temperature, excessive heat or cold. This happens with devices that are not used constantly.

Regarding the cost of repairing a station, it should be emphasized that in the event of a serious breakdown (engine combustion), it will be cheaper to purchase new equipment. This is especially true for situations where the pump was purchased for 5–6 thousand rubles. If the equipment is still expensive, then it is better to change the engine rather than spend huge sums on purchasing a station. Other parts are less expensive:

- prices for a pressure gauge vary in the range of 200–500 rubles;

- a check valve costs from 100 to 500 rubles;

- The battery can be bought for approximately 750 rubles.

As a result, I would like to note that a station breakdown can be caused by a huge number of different reasons. But the most common problem is incorrect regulation of the automatic unit of the device. Provided that it is installed well, all operating rules are followed and simply handled with care, the station will last a long time.

Each of the above problems can be easily fixed with your own hands, but it is advisable to seek help from specialists in order to prevent the situation from worsening. It is better to pay a little money for repairs than to install a new station.

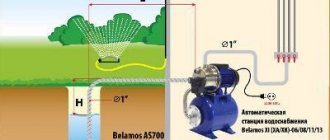

Equipment design

A pumping station makes it possible to pump water from a well into a house. This is a collection of several devices combined into a single system. At the moment, the most popular are deep-well pumps from the manufacturers Gilex and Pedrollo. They have proven themselves to be very high quality products. But even devices from these companies can fail. You need to be able to determine the cause of equipment failure, and also take into account all the design differences of each specific model. This is necessary for self-repair. Design of an autonomous pumping station:

- Centrifugal pump. It can be either surface or submersible. He pumps the liquid into the water supply. The same pressure is maintained at all times.

- Check valve. Prevents fluid from going back into the well if the pumping equipment is turned off.

- Storage tank. Necessary for storing a small amount of water in case the pump fails.

- Control block. This element regulates pressure. Installed between the storage tank and the pump. Has a built-in pressure gauge.

The hydraulic system includes additional control devices. With their help you can regulate internal pressure. They allow complete control of the entire system. The pump is turned on and off thanks to the control unit.

The equipment automatically starts working when the intra-system pressure drops to 1 atmosphere. Switches off at the maximum permissible pressure. The standard limit is 2-3 atmospheres. Thus, the pump itself turns on and off automatically.

Construction of a pumping equipment complex

In order to understand what malfunctions can occur in a complex of pumping equipment when organizing pumping water supply, and how to correct them, you need to know the composition of the devices and the order of their operation.

You may be interested in information about how the Aquarius pump works

Pumping stations consist of the following components:

- pumping equipment itself . Depending on the characteristics of the water supply source, pumps can be submersible or surface pumps. They can have different operating modes and power;

- hydraulic pressure accumulator . This unit is a container that is divided into two parts by a partition made of flexible but durable rubber. When the pumping device operates, the container is filled with water and the rubber partition is stretched. When the pump stops operating, the partition tends to return to its original position and returns the water accumulated in the container to the pipes, maintaining the pressure in the water supply pipelines at a constant level;

- control unit . This unit consists of a pressure gauge that measures the pressure in the system. Mechanical parts in the control unit set the minimum and maximum pressure values. When the minimum indicators are reached, the unit gives a command to turn on the pump, and when the maximum indicators are reached, the pumping equipment is turned off.

Briefly about what a pressure switch is.

Such a device in a pumping station is a switch capable of closing and opening a circuit in accordance with the set pressure.

When the water pressure drops to the lower limit, the electrical circuit is closed, the pumping station begins to operate and pump water. When the upper limit is reached, the circuit opens and the pumping station is turned off.

Troubleshooting the pumping station

One of the common malfunctions of a pumping station is its constant operation. The essence of combining a pump, a pressure accumulator and a control unit into a single complex is that the pumping device operates periodically, when the minimum set pressure indicators are reached.

This mode of operation can significantly extend the service life of pumping equipment and protects its components from excessive wear. Some pumps cannot operate continuously at all - this is due to the specific characteristics of the electric motors.

If the pump included in the station does not turn off and starts working constantly, it is necessary to stop the equipment and try to find out the cause of the malfunction. The constant operation of the pumping station “for wear and tear” can be caused by various factors. Let's take a closer look at them.

Incorrect pumping station adjustment

Perhaps the most common cause of malfunction of the pumping station may be incorrect adjustment of the control unit.

In most control units in pumping stations, the minimum and maximum pressure levels in the system are adjusted using two springs: large and small, located directly on the relay:

- a large spring is intended to set the lower pressure threshold in the system;

- a small spring is responsible for the difference between the minimum and maximum values.

In addition, during operation, the control unit of the pumping station may become clogged, which negatively affects its operation. So, there is an inlet hole in the relay housing. During operation, especially if the pumped water is significantly contaminated, it may become dirty. So before you begin adjusting the control unit, simply inspect the components of the control relay and, if necessary, carefully clean the inlet hole.

Adjustment of the control relay must be approached with caution. This is a rather “thin” device and forceful interference with its operation can lead to additional damage.

In order to be able to adjust the automation unit of the pumping station, it must be partially disassembled. To adjust the device, perform the following steps:

- disconnect the pumping equipment station from the electrical network;

- drain all water from the pressure accumulator tank;

- connect a household or regular automobile pump with a pressure gauge to the inlet valve of the pressure accumulator;

- create working pressure in the hydraulic accumulator tank;

- remove the cover that blocks access to the control unit of the monitoring relay - you will gain access to the springs.

The minimum pressure in the system (once reached, the pumping equipment is turned on) is set by a large spring. Turn the adjusting screw clockwise if you want to increase the minimum threshold and counterclockwise if you want to lower the threshold.

Having adjusted the minimum threshold, proceed to set the difference between the minimum and maximum pressure. This indicator is determined by turning the adjusting screw of the small spring of the control relay. Turn the screw clockwise if you want to increase the upper threshold and counterclockwise if you want to lower the upper threshold.

Please note that the maximum pressure value at which the pumping device should turn off must be 95 percent of the maximum permissible pressure in the system

Operating principle

The device consists of a brass body with fittings for connecting to the water supply network, spring valves and an electric relay. On the outside, the elements are covered with a plastic cover. The operating diagram of the RDM 5 pressure switch is as follows:

- The manufacturer sets the device to the lowest pressure limit of 1.4 Bar, the highest - 2.8 Bar. When the pressure in the accumulator is less than the lower limit, the relay contacts are closed and the pump pumps water into the intermediate membrane tank.

- When the pressure has risen to the upper limit (2.8 Bar), the spring valve is activated and opens the relay contacts. The water supply stops.

- When water supply appears in the house, the hydraulic accumulator begins to empty, the pressure decreases, and when the lower threshold of 1.4 Bar is reached, the relay contacts close again and the pump resumes its operation.

As a rule, the RDM 5 device is equipped with ready-made pumping stations, consisting of a pump, a water accumulator tank and the control relay itself. The station is configured at the factory and is completely ready for operation; all that remains is to connect it to the pipe and the electrical network. But finished products are not suitable for everyone for the following reasons:

- the hydraulic accumulator capacity is insufficient;

- the pressure of the standard pump is small to ensure water supply to the required height;

- a deep-well pump is used that is lowered into the well.

In the above cases, the automatic water supply system will have to be assembled from separate elements, and the pressure switch will have to be configured accordingly, coordinating its operation with the storage tank. Before purchasing and connecting a device, it is recommended to study its technical characteristics:

- pressure control range in the water supply system - from 1 to 4.6 bar;

- ambient temperature range - from 0 to +40 °C;

- minimum pressure drop - 1 bar;

- supply voltage - 220 V;

- diameter of fittings - DN 15, connection - G ¼''.

If some of the technical characteristics of the RDM 5 relay do not suit you, then you will have to look for another regulator. But practice shows that the parameters of this device meet the requirements of the overwhelming number of autonomous water supply systems.

Other reasons for the constant operation of the pumping station

In addition to the incorrect operation of the control unit of the pumping equipment station, other reasons may be the reason for the device not turning off.

Hidden water leak. As a result of this malfunction, the pumping equipment will, under the influence of the control unit, constantly maintain the specified water pressure in the system. To fix this problem, you need to identify the leak and seal it. However, keep in mind that leaks can occur anywhere in the plumbing system.

In addition to adjustment problems, problems may arise in the electric relay unit. During operation, contact contamination, oxidation, or even burning of the surface may occur. To eliminate this problem, the device is de-energized and the contact surface is thoroughly cleaned.

Problems with constant switching on of pumps can also arise due to unstable voltage in the network. Measure the voltage on your power grid while the device is running and, if necessary, include a transformer or power stabilizer in your system.

Constant operation of pumping equipment can also be caused by air leaks in the inlet pipe of the device.

The pressure accumulator may have an emergency release valve. When a certain critical pressure level is reached, it is triggered to prevent equipment damage. Sometimes the settings of this valve can be lost, and then it releases pressure at low values. This deficiency is corrected by adjusting or replacing the valve.

As you can see, problems in the operation of a pumping equipment complex can be caused by a variety of reasons. The main factor influencing the unstable operation of the pumping station is incorrect adjustment of the equipment automation unit. This flaw can be corrected by almost anyone with minimal technological skills.

To learn more about the procedure for correcting deficiencies in the operation of pumping equipment stations, watch the training video.

How to adjust the device?

Setting up the pressure switch is carried out after installing the internal and external water supply network of the house and connecting it to the electrical network.

Connections of external and internal pipelines must be verified by tests so that subsequent leaks do not interfere with the adjustment process. Due to leaky joints, the pressure before or after the pump will spontaneously decrease, which will also affect the operation of the relay.

Before setting, you should determine the required pressure value. To supply water to all water collection points located on different floors, it is necessary to ensure the necessary pressure in the accumulator. The forces of the tank membrane must be sufficient to push the entire volume of water to the required height and overcome all local resistance. At home, this pressure value is most often determined experimentally.

The calculation is simple: 1 m of lift height is equal to 10 m of horizontal section and corresponds to a pressure of 0.1 Bar. The farthest branch of the water supply is taken into account. Having approximately determined the required pressure, it is necessary to create such pressure from the air chamber of the accumulator. To do this, remove the plastic cap from the spool valve (usually located at the end of the reservoir) and pump up the air chamber with a regular car pump, monitoring the pressure with a pressure gauge.

- Without connecting the internal water supply pipe, check how the relay works together with the pump at the factory settings. At the same time, check the tightness of the external pipeline.

- Remove the plastic relay cover covering the adjustment screws.

- The large screw adjusts the upper limit (pump shutdown), the small screw adjusts the pressure drop. Adjust the lower limit so that its value is 0.2 bar more than what you pumped into the accumulator.

- To reach the exact values, you will have to adjust it several times, opening the faucet taps and releasing water from the battery. At the same time, record the pressure gauge readings when turning the pump off and on and adjust them with the adjusting screws.

As a result of the settings, the difference between the lower and upper limit should not be less than 1 Bar. Practice shows that the optimal pressure drop is about 1.5 Bar, then the pump will not turn on too often. After completing the adjustment, do not rush to put the cover back in place; monitor the operation of the system for 1 day. Minor adjustments may be needed.

Monitoring the pressure in the system allows you to avoid failures in the operation of the station and failure. Therefore, maximum attention should be paid to the correct configuration and adjustment of the relay.