Plasma metal cutting is a high-tech process that allows you to quickly and accurately cut metal sheets of any thickness. Thus, different types of aluminum with a thickness of up to 120 mm, cast iron up to 80 mm, copper up to 70 mm, stainless and carbon steel up to 5 cm are amenable to this procedure. Metal cutting technology consists of point heating to a high temperature and subsequent melting of the material in the required area.

A plasma jet is used as a cutter in plasma cutting of metals. Thermal, electromagnetic, chemical and gas-dynamic processes that interact with each other are responsible for the intense heating of the jet. This procedure is significantly more efficient than other methods of cutting various metals, which are difficult to use with shaped cutting methods.

The advantages of this type of metal cutting, compared to the laser method, are versatility and favorable cost.

What is plasma cutting

When cutting metal with plasma, the electric arc intensifies. This is possible due to the action of gas under pressure. The cutting element is heated to high temperatures, resulting in high-quality and fast cutting of metal.

Unlike gas cutting, its plasma counterpart does not contribute to overheating of the entire workpiece. High temperature occurs directly at the place where the metal is cut, and the remaining parts of the product do not heat up and are not deformed.

The principle of plasma cutting of metal is based on:

- delivery of the required voltage by a current source (standard voltage - 220 V, increased voltage - 380 V, for cutting metal in large enterprises);

- transmitting current to the plasma torch (torch) through cables, as a result, an electric arc lights up between the anode and cathode;

- supply of air flows through hoses by a compressor to the device;

- the action of swirlers inside the plasmatron that direct flows to the electric arc;

- the passage of vortex air flows through an electric arc and the creation of ionizing air heated to high temperatures;

- closing the working arc between the electrode and the surface being treated when the plasma torch is brought to it;

- exposure of air under high pressure and high temperature to the product being processed.

The result is a thin cut with minimal sagging.

The arc can burn in standby mode if the device is not used at a specific time. During standby mode, combustion is maintained automatically. When the torch is brought to the workpiece, the arc instantly goes into operating mode and instantly cuts the metal.

After turning off the device, it is purged to remove debris and cool the electrodes.

The electric arc is universal in its action. It is capable of not only cutting, but also welding metal products. For welding, filler wire suitable for the specific type of metal is used. It is not air that is passed through the arc, but an inert gas.

What can be cut: plasma capabilities

When talking about the capabilities of plasma, you need to understand how plasma cutting and welding works. This processing is carried out by melting the material using heat. The latter is generated by a compressed plasma arc, after which the melt is removed from the cutting zone by a plasma jet.

This technology is universal, so it is currently actively used in a number of areas. It allows you to work with most metals, as well as achieve record cutting speeds and workpiece thicknesses.

Separately, it is worth mentioning the economic component of the issue. You can work with plasma cutting without large financial costs; it is equally important that it can be done either using machines or manually.

Let's name the main areas in which automated and manual plasma cutting of metals is used.

1. Plasma cutting of pipes.

The most convenient are installations for plasma cutting of pipes, so-called pipe cutters equipped with centralizers. They differ from classic pipe cutting equipment in their high processing accuracy, which remains unattainable for gas autogenous cutting.

It is important that most of the equipment for cutting pipes using plasma allows for auxiliary operations. Among them are surface preparation, seam cleaning, chamfering and edge cutting. Precise movement of such equipment along the pipe is ensured by special drives.

2. Plasma cutting of sheet metal.

Most often, this technology is used for cutting thin sheets, since other methods do not allow such operations. It is important that for manual plasma cutting of sheet metal, fairly compact and lightweight devices with low power consumption are used.

Plasma can handle most metals, including steel, cast iron, bronze, copper, brass, titanium, aluminum and alloys of these metals. This technology has only one limitation - the thickness of the sheet, which is associated with the level of thermal conductivity. With greater thermal conductivity, the thickness of the sheet decreases, which can be cut using this method.

3. Figured plasma cutting of metal.

Such artistic processing requires the use of specialized equipment and is actively used in construction and many industries. Thanks to CNC and special programs, it is possible to produce flat parts regardless of their complexity.

Plasma makes it possible to cut complex contours on sheets no more than 100 mm thick. It is worth noting that the result does not depend on the presence of paint, corrosion, galvanization or any contaminants on the metal. When shaped using plasma, the cut area is heated to +30,000 °C, and such a high temperature allows you to melt any metals.

4. Plasma cutting of cast iron.

At the moment this is the most reliable and effective technology. The fact is that we are talking about a method that is both economical, fast and convenient, superior to cutting with an angle grinder and gas in terms of the listed characteristics. Plasma makes it possible to work with cast iron in heavy industry. This is how, for example, scrap accumulated on enterprise premises is prepared for disposal. Thanks to plasma, deep cuts are made in metal, making it possible to cope with the most labor-intensive tasks.

5. Plasma cutting of steel.

This method works great when cutting steel of various thicknesses. It is important that plasma makes it possible to cut stainless steel, which is not possible with oxygen cutting. In this case, virtually no burr formation occurs, so it is possible to reduce time costs and increase production productivity.

Plasma cutting of stainless steel compares favorably with gas cutting in a number of characteristics, such as:

- high level of security;

- the ability to produce parts of any complexity and shape;

- low level of environmental pollution;

- fast burning;

- versatility and efficiency;

- high processing speed of steel sheets of small and medium thickness;

- accuracy and high quality of cuts, which eliminates the need for final processing.

By cutting rolled steel, sheets of the required format and strips, that is, narrow strips of steel with a longitudinal section, are very quickly and accurately produced.

Plasma cutter structure

A plasma cutter is a device used to cut metal products in various ways. The unit structure includes the following elements:

- electrical power source;

- compressor;

- plasmatron;

- cable hoses.

Several devices act as power sources:

- inverter;

- transformer.

Principle of operation

Result of the plasmatron operation

The principle of operation of the plasmatron is as follows. A flow of high-temperature ionized air is created, the electrical conductivity of which is equal to the electrical conductivity of the workpiece being cut (i.e., the air ceases to be an insulator and becomes a conductor of electric current).

An electric arc is formed, which locally heats the workpiece: the metal melts and a cut appears. The plasma temperature at this moment reaches 25,000 – 30,000 °C. Particles of molten metal appearing on the surface of the workpiece being cut will be blown away from it by the air flow from the nozzle.

Technology

The technology of plasma cutting of metal can be briefly described as follows. All types of metals up to 220 mm thick can be treated with plasma.

The effect appears after the ignition of the plasma-forming gas when a spark is formed in the electric arc circuit (between the tip of the nozzle and the non-consumable electrode. The spark ignites the gas flow, and here it is ionized, turning into controlled plasma (with an extremely high exit speed of 800 and even 1500 m/s ).

Interesting: Plasma arc metal cutting technology

In the outlet hole, due to the narrowing, the flow of the plasma-forming carrier accelerates. A high-speed plasma jet allows you to obtain an outlet temperature of about 20,0000C. A narrowly directed jet of thousands of degrees literally melts the material in the targeted area of influence, heating around the treatment site is insignificant.

The plasma-arc method is used to close the treated surface into a conductive circuit. Another type of cutting (plasma jet) - works in the presence of third-party (indirect) formation of a high-temperature component in the working circuit of the plasma torch. The metal being cut is not included in the conductive circuit

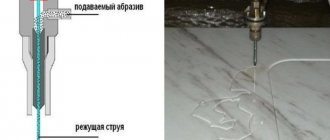

Plasma jet cutting

Plasma jet cutting of workpieces is used for processing materials that do not conduct electric current. When cutting with this method, the arc burns between the forming tip of the plasmatron and the electrode, and the object being cut does not participate in the electrical circuit. A plasma jet is used to cut the workpiece.

Plasma arc cutting

Conductive materials are subjected to plasma arc cutting. When cutting using this method, the arc burns between the workpiece being cut and the electrode, its column is combined with the plasma jet. The latter is formed due to the supply of gas, its heating and ionization. The gas blown through the nozzle compresses the arc, gives it penetrating properties and ensures intense plasma formation. The high temperature of the gas creates the highest flow rate and increases the active effect of the plasma on the melting metal. The gas blows metal droplets out of the cutting area. To activate the process, a direct current arc of direct polarity is used.

Plasma arc cutting is used for:

- production of parts with straight and shaped contours;

- cutting holes or openings in metal;

- production of blanks for welding, stamping and machining;

- processing of forging edges;

- cutting pipes, strips, rods and profiles;

- casting processing.

Types of plasma cutting

Depending on the environment, there are three types of plasma cutting:

- simple. This method involves using only air (or nitrogen) and electric current;

- with protective gas. Two types of gas are used: plasma-forming and protective, which protects the cutting area from environmental influences. As a result, the quality of the cut improves;

- with water. In this case, water performs a function similar to a shielding gas. In addition, it cools the components of the plasma torch and absorbs harmful emissions.

Plasma cutting based on these principles ensures not only high-performance production, but also completely fireproof: the materials used in the technology are not flammable.

Video

Watch videos that clearly explain how plasma cutting works:

Operating principle of air plasma cutting of metal

Air plasma cutting: what is the principle of implementation based on. The cutting plasma is a heated gas with a high electrical conductivity. It is also called ionized. Plasma is generated by a special arc element. This cutting method is commonly called plasma cutting.

A conventional arc is compressed by a plasma torch. Ionized gas is blown into it, with the help of which it can generate hot air. It is capable of processing using elevated temperatures. The metal is cut, melting at the same time.

Metal processing occurs thanks to both a plasma arc and a jet. In the first option, the metal product is directly affected, in the second - indirect. The most common and effective cutting method is direct action. For a material that does not have electrical conductivity (usually non-metallic products), the indirect influence method is used. In any of the options, the material being cut does not lose its state of aggregation and its structure is slightly subject to deformation.

Interesting: Plasma cutting of concrete - technology features

Working principle of a plasma cutter

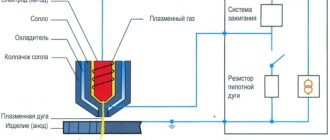

A plasma torch is a technical device that creates an electrical discharge between an electrode (cathode) and the surface of a workpiece (anode), this occurs in a gas flow that forms plasma.

The principle of operation of the device: water or gas is used for cooling, plasma-forming gas is used to produce plasma. The gas flow entering the chamber is heated to high temperatures and then ionized, thereby acquiring the properties of plasma. Plasma-forming gas and cooling gas are supplied to various channels of the plasmatron . When power is applied, a so-called auxiliary discharge is formed between the cathode and the nozzle; visually it can be seen as a small torch.

The main (working arc) is formed when the secondary discharge touches the surface being processed, which in this case acts as an anode (plus). Stabilization of the discharge can be carried out by a magnetic field, water or gas; often the stabilizing gas is also plasma-forming. After this, material can be cut, coated, welded, surfaced, or even mined by breaking up rocks.

Conventionally, the design of a plasma torch can be represented as several main elements:

- insulator;

- electrode;

- nozzle;

- mechanism for supplying plasma-forming gas;

- arc chamber.

Design and principle of operation of a plasmatron with a combined nozzle and channel

A special feature of a plasmatron using air plasma cutting is the combination of a channel and a nozzle. The air passes through the nozzle channel to the outside. The operating principle is similar; when power is supplied, an auxiliary discharge is formed between the cathode and the nozzle. The air, twisted in a spiral, stabilizes and compresses the column of the working discharge. It also prevents the electric arc from touching the walls of the nozzle channel.

Types of plasma torches

Plasmatrons can be divided into three global types

- electric arc;

- high frequency;

- combined.

Devices operating on the basis of an electric arc are equipped with one cathode, which is connected to a DC power source. For cooling, water is used, which is located in the cooling channels.

The following types of electric arc devices can be distinguished:

- with a straight arc;

- indirect arc (indirect plasma torches);

- using an electrolytic electrode;

- rotating electrodes;

- rotating arc.

Automatic: operating principle

The automatic plasma cutting machine has:

- Remote Control,

- plasma torch

- work table for workpieces.

Automatic cutting machine (China).

Photo source: ru.made-in-china.com On the control panel, preset programs are adjusted if cutting deviates from the set parameters. For quick corrections during operation and selection of optimal cutting conditions.

An electric current is passed through a sheet installed on the desktop. A primary electric arc runs between the surface of the sheet and the plasmatron. In which compressed air is heated to the state of plasma. The primary arc is hidden in a hot ionized jet, which cuts the metal.

Cutting starts from the middle or from the edge. The more often the arc is interrupted and a new spark is ignited, the shorter the resource of the nozzle and cathode becomes. A competent automatic cutting operator selects cutting modes according to the table and based on specific conditions (metal thickness, nozzle diameter). Thanks to this, you can achieve significant cost reductions. At the end of the operation, the machine will independently notify the operator, turn off and remove the plasma torch from the material.

Interesting: Plasma cutting modes

What are the disadvantages and limitations of plasma cutting?

The main disadvantage of the inverter is the inability to use it for cutting thick metal products.

The transformer is effectively used when cutting thick-walled metal that an inverter cannot handle. It can withstand fluctuations in mains voltage, but is characterized by low efficiency. Transformers are inconvenient due to their heavy weight.

A compressor is a device that supplies air to an electric arc. The mechanism contributes to the creation of vortex air flows directed towards it. The compressor ensures that the arc cathode spot is clearly located in the center of the electrode. If the process is disrupted, consequences arise in the form of:

- formation of two electric arcs at once;

- weak arc burning;

- plasma torch failure.

During the operation of a conventional non-industrial plasma cutter, only compressed air is passed through the compressor. It creates plasma and cools the electrodes. Industrial units use mixtures of gases based on oxygen, helium, nitrogen, argon, and hydrogen.

The plasma torch performs the main function of the device - cutting the product. His device includes:

- cooler;

- electrode;

- cap;

- nozzle.

The plasmatron contains a hafnium electrode that excites the electric arc. Zirconium, less often beryllium and thorium electrodes are used. Their oxides are toxic and even radioactive.

A plasma jet passes through the plasmatron nozzle, cutting the products. The quality of cutting, technology, speed of operation of the unit, width of the cut and cooling rate depend on its diameter.

The cable carries current coming from the inverter or transformer. Compressed air moves through the hoses, forming plasma in the plasma torch.

Advantages and disadvantages of cutting technology

This technology has its advantages compared to other processing methods.

High performance, easy to learn.- Plasma cutting has high precision and a variety of cut lines.

- The treated surface does not require additional grinding.

- During operation, environmental pollution is minimal.

- The hand-held equipment used is mobile, light in weight and small in size.

The disadvantages of this method include the small cut thickness, up to 100 mm. You cannot work with two devices at the same time, and also deviate from the perpendicularity of the cut.

Technological aspects of plasma cutting

A consistent study of the stages of plasma cutting of metals allows you to understand how a plasma cutter works:

- the ignition button is pressed, leading to the start of current supply from the transformer or inverter to the plasmatron;

- a pilot electric arc with a temperature of 70000C appears inside the plasmatron;

- an arc is ignited between the nozzle tip and the electrode;

- compressed air enters the chamber, which passes through the arc, heating and ionizing;

- in the nozzle the incoming air is compressed, escaping from it in a single stream at a speed of 3 m/s;

- the compressed air escaping from the nozzle heats up to 300,000C, turning into plasma;

- when the plasma comes into contact with the product, the pilot arc goes out and the cutting (working) arc lights up;

- the working arc melts the metal at the point of impact, the result is a cut;

- parts of the molten metal are blown away from the product by air currents escaping from the nozzle.

Any plasma metal cutting technology depends on the cutting speed and air flow. High speed results in a finer cut. At low speed and high amperage, the cutting width becomes larger.

With increased air flow, the cutting speed increases. The larger the nozzle diameter, the lower the speed and the wider the cut.

Plasma torch selection

To choose the right machine for plasma cutting of metal, you need to decide what characteristics the device should have. The initial data can be:

- automated or manual cutting method;

- duration of work;

- electrical energy consumption;

- metal thickness;

- metal type;

- How often are consumables replaced?

- user reviews about equipment and manufacturers.

A good option for optimal price and power is the Svarog CUN 40 B (R 34) model. This is a lightweight and compact device that is used in cutting thin sheet metals less than 0.12 cm. It is easy to operate, unpretentious in operation, and compressed air consumption is minimal.

The devices with the best energy saving indicators include the AURORA PRO AIRFORCE 60 IGBT model. It is suitable for cutting conductive material. The operating principle is based on non-contact ignition of the arc. The result of cutting is high-quality work without metal deformation.

The BRIMA CUT 120 model is suitable for cutting thick metal. The device is used for cutting non-ferrous, carbon, stainless metal and copper. The thickness of the metal can reach up to 35 mm. It has built-in arc adjustment and smoothly changes the operating parameters of the device.

Read this article on how to assemble a plasma cutter from an inverter yourself.

Read this article on how to assemble a plasma cutter from an inverter yourself.

Plasma cutting techniques

In practice, two methods of cutting metal with plasma are used:

- plasma jet;

- plasma-arc method.

Plasma jet cutting has found application in the processing of non-metallic products that are not capable of conducting electric current. With this processing method, the product is not part of the electrical circuit. The arc burns between the electrode and the tip of the plasma torch. The product is cut by a plasma jet.

The plasma-arc method is widely used. It is used for: cutting profiles, pipes;

- manufacturing products with straight contours;

- casting processing;

- forming holes in metal;

- production of welding blanks.

The arc burns between the electrode and the workpiece. The arc column is combined with the plasma jet. The jet occurs due to the gas blown through the operating compressor, which becomes very hot and ionized in the process. The gas promotes the formation of plasma, and due to its high temperature, the cutting speed of the metal being processed increases. This method involves the use of a direct current arc with straight polarity.

Manual plasma arc cutting of metals

Manual plasma cutting is carried out using portable (mobile) plasma cutting machines, consisting of:

- The main apparatus containing a transformer and a rectifier substation.

- Power cable.

- A hose package going from the apparatus to the plasma pistol. The hose package contains an air hose and a power cable.

- Plasmatron (plasma pistol) – plasma is formed in it.

There are two main methods of manual plasma cutting:

- Indirect cutting with a plasma jet. This method is mainly used for cutting non-metallic materials. In this case, the electric arc that forms the plasma lights up between the electrode and the plasmatron nozzle. The material being cut does not participate in the formation of plasma, and cutting is carried out by a plasma jet escaping from the cutter.

- Direct plasma arc cutting. This is exactly our case, since this method is used for cutting metals. It is used in both manual and mechanized plasma cutting. An electric arc lights up between the electrode and the metal being cut and combines with a high-speed air flow to form plasma. The resulting plasma jet is so powerful that it literally evaporates the metal during the cutting process.

Manual plasma-arc cutting has proven itself so well that it is now used in almost all enterprises with a metalworking shop. A large number of private owners offer on-site plasma cutting services, because... hand-held devices are very mobile; they can be carried in the hands or on a shoulder strap.

The main advantages of hand-held plasma devices:

- Mobility, portability (hand-held devices of low and medium power weigh from 10 to 25 kg).

- Availability of use (operate from 220 V, current depends on the power of the device).

- Versatility (can cut all types of metals).

- Affordable price (manual plasma cutting machines made in Russia cost from 15,000 to 70,000 rubles.

Pros and cons of plasma metal cutting

| pros | Minuses |

| Versatility of use (intended for processing any metal products, provided that a device of the correct power with the required air pressure is selected). | Small range of cutting thickness (no more than 100 mm). |

| Minimal harm to the environment. | Harm to the environment and health (a master who worked with a plasma cutter, for which nitrogen is provided as a gas, receives serious poisoning). |

| High productivity, second only to laser cutting, but superior in cost. | High price of the unit. |

| High quality of work, characterized by a small cut width and the absence of severe overheating of the entire product during plasma processing. | Complex design. |

| There is no need to warm up the entire product, which affects its quality. | Increased noise level during operation. |

| Process safety due to the absence of the need to use gas cylinders. | The maximum permissible angle of deviation from the perpendicularity of the cut is only 100-500, depending on the thickness of the product. |

Types of plasma torches

Enterprises widely use automatic and manual plasma cutting.

You can cut metal using various types of devices.

- Plasma cutters for cutting metals. This group includes air plasma and gas plasma cutters. The air plasma cutter has a simple design and is used for cutting ferrous metals. It can operate from both single-phase and three-phase networks. The gas-plasma apparatus operates on water vapor; hydrogen, argon, oxygen, and nitrogen are used to form plasma.

- Induction cutter. This is a high-frequency device operating on the principle of inductively coupled plasma with temperatures up to 6000 K and a high electron density.

- Combined devices. They are represented by a symbiosis of high frequency currents and an electric arc. The electrical discharge is compressed under the influence of a magnetic field.

- Gas devices that work by compressing the arc column with a plasma-forming gas.

- Water devices whose working fluid is steam gas. High-temperature water steam promotes accelerated combustion of carbon.

- Magnetic cutters. Such devices are ineffective and not popular. Their main advantage is that the compression of the electric arc is adjusted without loss of gas.

Depending on the type of plasmatron, you can easily process any type of steel, including metals with high thermal expansion, as well as materials that do not conduct electric current.

How does a plasma torch work?

The process of formation of a plasma arc occurs approximately as follows.

An electric discharge occurs between the nozzle and the plasmatron electrode and the so-called pilot arc is ignited. It is blown out through the nozzle and touches the metal surface being cut. A short circuit occurs between the electrode and the metal, and a real arc is created, which heats and ionizes the gas supplied to the plasma-forming chamber. The resulting plasma flow is blown out of the nozzle. The vortex gas narrows and concentrates the plasma, preventing it from touching the nozzle walls. The plasma speed ultimately reaches 2-3 km per second, and the temperature reaches 30 thousand degrees.