A drainage well made of concrete rings is an engineering structure that is made when laying sewer systems for various purposes. Mainly, mines of this type are used to collect domestic wastewater, storm water and groundwater. Today it is possible to build inexpensive tanks from brick, concrete and wood. But precast concrete wells remain the most popular among private developers, government and commercial contractors.

Even modern containers made of polymer plastic could not displace time-tested reinforced concrete rings from the construction market. This is explained by the versatility and reliability of these products, which can be used in almost any soil except permafrost. Before making a final decision on the choice of material for the construction of drainage and wastewater systems on the site, you should dwell on the main operational characteristics of the reinforced concrete rings from which underground mines are made.

Advantages of prefabricated wells made of reinforced concrete products

Concrete is the strongest building material from which structures such as dams, bridges and multi-story buildings are built. This already indicates that reinforced concrete products are durable and meet all the requirements for engineering structures for various purposes. To make rings for wells, cement grade M400-M600, fine granite crushed stone and heavy quartz sand are used. The solution is poured into molds, where it hardens when exposed to vibration and pressure. Compression resistance is achieved by using a steel mesh frame and 12 mm reinforcement.

The advantages of such products are obvious:

- Long service life . If the manufacturing and assembly technology is followed, a ring shaft can successfully perform its tasks for 100 years. All that is needed to maintain the structure in working order is periodic cleaning and restoration of the integrity of the joints.

- Biological and chemical inertness . Concrete does not lose its properties from exposure to chemically active substances and organics. Rodents and insects are not interested in this material and cannot cause any damage to it.

- Ecological cleanliness . This is an important factor that is taken into account when constructing water wells. Concrete does not emit harmful substances regardless of temperature, the presence of alkali and acids in the water.

- Simplicity and high speed of assembly . If you have digging and lifting equipment, the well can be assembled within one working day. In hard-to-reach areas, the shaft assembly can be done manually.

- Monolithic structure. The integrity of the shaft is achieved by protrusions and recesses on the edges of the rings, the use of durable gasket material and steel brackets that tighten the rings together.

- The presence of steel steps embedded in the walls, making it easier to descend into the mine and perform various routine maintenance.

Today it is possible to manufacture components for drainage wells to order. Thus, the manufacturer can make a ring with ready-made technological holes of the required diameter, cast support and load-bearing plates of any configuration, which allows you to build a well hatch that best suits the design of the area.

Having mentioned the advantages of mines made of reinforced concrete, we should dwell on their disadvantages. These include significant weight and fragility of products. In addition, for the operation of special equipment, it is necessary to equip access roads and prepare the construction site.

How to make a drainage well with your own hands and connect pipes to it

Basements and ground floors of private houses located in areas with high groundwater levels are often subject to flooding, which can ultimately lead to the destruction of the foundation. A complete drainage system installed around the house will prevent this.

We will tell you how to arrange drainage and install a drainage well with your own hands. The article presented for consideration describes in detail the design of a system for collecting and draining groundwater to drain it from the foundation. Options for constructing wells are listed and installation methods are described.

For a visual understanding of complex information, it is accompanied by useful diagrams, collections of photos and video tutorials.

- How to install an inspection and collector well

Purpose and design of the drainage system

Drainage must be carried out if the house is located in a low-lying area, or the groundwater level is higher than the ground floor or basement of the building, and there is a risk of flooding. It is especially important to drain the area located on clay soils, which are prone to heaving when the lower layers freeze during the cold period.

The drainage system simultaneously performs several important functions:

- reduces groundwater pressure on the walls and floor of the house;

- prevents flooding of basements;

- drains the area adjacent to the building.

It is advisable to carry out the arrangement of drainage at the stage of digging a foundation pit for the house, so as not to disturb the landscape of the site when outbuildings have already been erected and equipped on it.

Image galleryPhoto from A drainage well is a functional component of the drainage system, which is designed to collect and drain groundwater. The installation of a drainage system along with the installation of wells should be carried out at the stage of foundation construction. The drainage system is installed before the installation of formwork for pouring the foundation. Wells installed at points where the direction of the drainage pipe changes , i.e. in the corners, serve to monitor the operation of the system. The drainage system is laid separately from the standard and storm sewer systems. It can only be connected to a storm drain in a common collector well. The construction of formwork for pouring a slab or strip type foundation is carried out after laying all types of sewer pipes and installing objects. Work on pouring the foundation and further arrangement of communications is carried out taking into account already installed systems. After insulation of the foundation and introduction into the basement space necessary communications, the pit is backfilled. The drainage well is cut 10 -15 cm above the level of the compacted fill and a hatch is installed. Purpose of drainage wells Time and place of installation Laying geotextiles at the bottom of the trench Installation of drainage wells in the corners Specifics of organizing the drainage system Construction of formwork after laying pipes Pouring the foundation, taking into account communications The final stages of drainage arrangement

To install a drainage system around the perimeter of the house, a trench is being developed. It should be located at a distance of one and a half to three meters from the foundation pit or building (if the house has already been built).

Then a closed pipeline is laid into it, and one or more drainage wells are installed in the necessary places. The number of wells and pipe channels depends on the area of the site, the depth of groundwater, and the type of soil.

The figure shows that in the absence of drainage, groundwater puts pressure directly on the base of the foundation and walls and seeps into the house. If there is a drainage system, the water goes into the outlet pipes

Some people confuse the drainage system with the stormwater system, but the difference between them is quite significant. Storm drainage is designed to drain rainwater and, as a rule, is located on the surface. The depth of the drainage pipes should be below the base of the foundation.

When arranging stormwater and drainage systems, it is possible to divert the pipes of both sewers into one collector well

You can read about how to develop a drainage system project for collecting and draining groundwater, draining and landscaping a site in another popular article on our website.

Main types of drainage wells

There are several types of wells, which differ from each other in their purpose, material of manufacture and size. The design of drainage wells of different types is almost the same.

They are a container with a closed bottom, into the shaft of which drainage sewer pipes are supplied. The well is completely immersed in the ground, and its top is covered with a hatch.

The main difference between wells is their purpose. Each type is designed to perform a specific function and is located in a specific place in the drainage system.

Characteristics of manholes

Inspection or otherwise inspection drainage wells are intended for:

- conducting routine inspections of the sewer system;

- monitoring the performance of the pipeline;

- periodic cleaning of pipes and carrying out repair work.

Inspection wells are installed in places where there is the greatest likelihood of contamination or silting of pipes. Their sizes are selected taking into account the characteristics of the sewer system. In small pipelines, as a rule, inspection wells with a diameter of 340 to 460 mm are installed.

It is advisable to equip a large drainage system with large-diameter inspection wells, equipped with all the necessary devices for carrying out routine inspections and repair work.

Large drains are equipped with drainage structures with an internal diameter of up to one and a half meters. Some containers are equipped with steps for convenient descent. An adult can easily fit into such a well to carry out work on cleaning or repairing the pipeline. Cleaning the system is carried out by flushing the pipes with a jet of water under pressure.

A type of inspection wells are rotary structures, which are located at the corner joints of pipes. They do not have to be installed on every turn; they are usually installed across the corner.

When installing rotary wells, it is necessary to take into account the design of the drainage system and install them so that all corner and cross sections of the pipeline can be brought to them.

Rotary wells are buried in the corners of the pipeline. They are installed in such a way that, if necessary, it is possible to quickly clean the sewer. Purpose of storage structures

A collector or in other words a water intake well is used to collect and accumulate water and its subsequent pumping into a reservoir or drainage ditch. It is a large container with a diameter of up to one and a half meters, into which all the pipes of the drainage system are diverted.

It is installed in places where it is impossible to install a filter well or to divert water collected by the sewer into a drain. As a rule, they are taken outside the site.

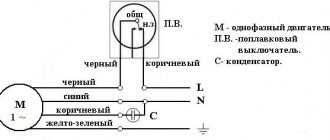

To drain accumulated water, a submersible drainage pump with a drain pipe is installed in the collector wells, which pumps the collected liquid into a natural reservoir

The water intake tank is usually equipped with an electric pump, which pumps the accumulated liquid into a reservoir or for watering a garden. Typically, an automatic system is installed in storage tanks, which, when the tank is filled to a certain level, pumps out water automatically.

Features of absorption tanks

Filter wells are used in areas with slightly moist soil, located far from natural bodies of water and not equipped with drainage systems. In this case, the amount of water to be pumped should not exceed 1 cubic meter. m per day.

The shape of the well can be round with a diameter of up to one and a half meters, or rectangular or square with an area of no more than 6 m. Typically, concrete rings or plastic containers are used to make the well.

The depth of the absorption well in the ground must be at least two meters, and the thickness of the filter layer must be at least 30 cm

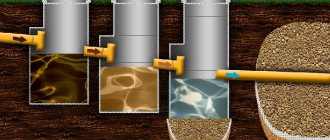

The structure of the absorption well differs from other types of drainage tanks in that it does not have a sealed bottom. Instead, a filter system is installed at the bottom of the well, which passes dirty water runoff through itself, cleans it of debris and discharges it into the deep layers of the soil.

Material for making drainage wells

Wells for arranging a drainage system can be made yourself from concrete rings, or you can buy ready-made plastic containers of the required size and install them on the site. It’s up to you to decide how to make a drainage well, but it’s worth considering that the first option is cheaper, but much more labor-intensive to manufacture, the second is simpler, but somewhat more expensive.

Image galleryPhoto from To organize all types of drainage systems, a wide range of pipes and manholes are produced from PVC, PP, HDPE polymers, etc. In the old fashioned way, drainage inspection and collector wells are still sometimes built of brick. The method does not satisfy the pace of construction and requires experience from the contractor. The construction of drainage wells from ready-made concrete rings is carried out much faster. However, their installation often requires the use of lifting equipment. Assembling a drainage well from polymer-sand elements is much easier than from concrete rings. The product is produced with parts for constructing a bottom and a hatch. Polymer products for drainage. Brick object for the drainage system. Constructing a well from concrete rings. Polymer-sand elements.

Making a well from concrete rings poses a number of problems. Due to the large weight of concrete structures, you may have to hire special equipment and invite assistants. They need to make holes for pipes, which is also quite difficult.

However, the complexity of installing a concrete well is justified by its great reliability, strength and durability. Concrete structures are practically invulnerable to any negative influences.

They can be installed in any place and even in areas standing on soils subject to hydrothermal movement and heaving during freezing, where plastic structures can be deformed.

Modern plastic containers are also very reliable, and in addition, they are convenient and easy to install, weigh little and are easy to assemble. Their body already has holes of the required diameter for connecting pipes.

Many people resort to a combined installation option in order to save money. For inspection and rotary wells, plastic tanks are purchased, and the filter and storage tanks are made of concrete rings. There is another available option - to make a well yourself from plastic pipes; how to do this is described below.

Plastic containers are available in different sizes; their bodies already have bends of the required diameter for connecting pipes. Basic principles for arranging drainage on the site

To install the drainage system, the highest point of the site is selected, and a trench is dug from it with a slope of 2 to 5 cm, two meters deep, where the pipes are laid. Rotary wells are installed in the corners, and inspection wells are installed in the places of nodal connections.

To ensure the natural flow of water through the pipes, a trench for laying a sewerage system is dug at a slope of at least 2 cm from the top point of the site

The end point of the sewer system, where all pipes laid with a slope lead, is a filter or storage well, from where forced or natural drainage of water is carried out.

For the installation of drainage sewerage, it is recommended to use special corrugated pipes with perforation, made of PVC or polyethylene. They have no technical restrictions on installation and are very easy and simple to install. Depending on the size of the outlet holes in the drainage well, you can purchase pipes with a diameter of 50 to 200 mm.

There are small slits throughout the entire area of the drainage pipe, which are necessary for water to seep out from the soil.

For the full operation of the entire sewer system, it is necessary to carry out a number of preparatory measures. Sand is poured into a 5 cm layer at the bottom of the trench and compacted thoroughly. Then the bottom and walls of the ditch are covered with geofabric, which will serve as a filter to prevent siltation of the system.

This is followed by a layer of crushed stone, approximately 10 cm on which a perforated pipe is placed, covered with another layer of crushed stone and wrapped in geofabric with an overlap. On top of this “pie” is poured a layer of earth, which was selected when digging the trench.

To ensure the full functioning of the drainage system, it is necessary to carefully prepare the base and lay the pipes in the manner shown in the photo. Manufacturing and installation of plastic wells

The installation process depends on the type of well. For viewing, rotary and storage structures it is necessary to make a concrete base. Absorption wells without a bottom require the installation of a filter system.

Image galleryPhoto from The assembly of a drainage system with the installation of polymer wells is carried out at the highest possible speed. For the construction of the system and installation of wells, all types of parts are produced that significantly facilitate and speed up installation work. The structure of polymer wells is not affected by aggressive environments, they are indifferent to the proximity of water and temperature fluctuations. well necks, we produce hatches, in the range of which you can find options that are resistant to high loads. Advantages of plastic wells. Operational connection. Operational advantages. Construction of a well neck. How to install an inspection and collector well.

If you purchased a ready-made plastic container, then you only need to install it on a pre-prepared base. The installation of both types of wells is practically the same. The difference can only be in size, number of outlet pipes, as well as in horizontal or vertical arrangement.

Inspection rooms, as a rule, have a vertical design; storage rooms can be made horizontally or vertically. In addition, collector wells are usually equipped with a drainage pump and pipes are discharged into a drainage basin.

The pipes must be connected after installing the container on a carefully prepared base, after which the pipes are sealed and the well is backfilled

Before constructing a well for collecting and discharging drainage water, dig a ditch, carry out preparatory work as described above, and lay pipes, but do not fill it up yet.

Well installation consists of the following steps:

- deepen the area where you plan to install the well, it should be 40 cm deeper than the level of the pipes;

- pour and compact a layer of sand and crushed stone;

- prepare a concrete solution (3 parts sand and 1 part cement) and fill the bottom with it;

- after the base has hardened and is completely ready (this will take about 2 days), lay a layer of geotextile;

- Place the container on a concrete base and connect it to the pipe bends;

- Cut the plastic pipe to the required size to match the depth of the well.

- Approximately at a distance of 40-50 cm from the bottom, make holes for the pipes and equip them with rubber gaskets.

- Attach the bottom to the container and seal all seams with bitumen mastic or other sealant.

Finally, mount the hatch on top, fill the structure on all sides with crushed stone and soil.

Installation of a plastic absorption structure

To install a filter well, you will need plastic containers without a bottom. Their installation is carried out in the same way as described above, with the exception of pouring a concrete base. Instead, a filter system is made at the bottom of the well that purifies the incoming water naturally.

In order for an absorption well to work productively for a long time, it must be installed correctly, as shown in the figure (+)

A layer of gravel, crushed stone or other similar material 20-30 cm thick is poured into the bottom. Pipes are brought into the upper part of the well, the structure is covered on all sides with crushed stone or gravel, the top is covered with geofabric and closed with a hatch.

Making containers from plastic pipes

If you don't have a ready-made plastic container, you can make it yourself. To do this, you will need a plastic pipe of a certain diameter (35-45 cm for inspection and rotary structures and 63-95 cm for collector and absorption structures). In addition, it is necessary to purchase a round bottom and a plastic hatch in accordance with the size of the pipe and rubber gaskets.

Manufacturing algorithm:

Installation of a homemade drainage tank is carried out according to the above described scheme.

Construction of a well from concrete rings

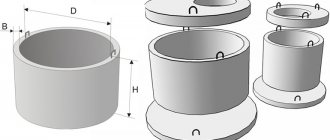

For the well, it is necessary to purchase reinforced concrete rings, which are made from moisture-resistant concrete. The dimensions and diameter of the rings are selected based on the type and purpose of the well. But it must be taken into account that their depth must be at least two meters.

Concrete rings are available in various sizes (height from 10 cm to 1 m and diameter from 70 cm to 2 m), so choosing a product will not be difficult. For a well, rings with a height of 50-60 and a diameter of 70-150 cm are usually chosen. Their weight, depending on the size, ranges from 230-900 kg.

Concrete rings are lowered one after another into a pre-dug hole and placed on top of each other.

Of course, such a weight is not impossible to lift alone, so you will have to invite one or two assistants. The structure can be installed in two ways. If the diameter of the ring allows a person to fit inside, then you can simply place it on the ground, and then begin to excavate the soil from the inside.

The ring will press with its own weight on the ground and gradually sag as soil is dug out from under it. In this way, you can install all the rings, placing them on top of each other and fastening them together with metal brackets.

The second option is to first dig a pit, the width of which should be approximately 40 cm greater than the diameter of the rings. If the soil is soft, the bottom should be covered with a 15-20 cm layer of gravel, and then concrete rings should be lowered. With this method, if an inspection or storage well is being made, it is advisable to install a lower ring with a solid bottom.

After installing the concrete rings in place, it is necessary to carefully seal all the cracks with bitumen. You can make a viewing window in the ceiling for visual inspection of the well

If there is no bottom, then you will need to make it yourself. To do this, the lower part of the well is filled with concrete mortar with reinforcement. When installing an absorption structure, the bottom of the container is equipped with a filter system, as described above.

All joints between the rings are coated with a cement-sand mixture, and then, after drying, sealed with bitumen-polymer waterproofing.

Next, from the well, according to the developed scheme, a trench is dug for drainage pipes, but do not rush to lay them, since you will first have to do another rather labor-intensive job - making holes in the concrete to connect the pipes. This can be done using a hammer drill and pobedit or diamond bits for concrete. They have different diameters, so choosing the right size is easy, but their cost is quite high.

If you don’t have a concrete crown on your farm, and you don’t want to spend money on buying one, you can resort to another cheaper method. In the place where you intend to make the branch, attach the pipe and draw a circle of the required diameter with a pencil. Drill through holes along the contour of the drawn line with a hammer drill.

Holes are drilled with a concrete drill in increments of 1-2 cm from each other, one is made in the center of the circle

Point the crowbar at the central hole and begin to break it slowly, as the hole widens, take a large hammer or sledgehammer and complete the process. Now you can bring the pipes and, putting protective rubber seals on them, insert them into the hole made. Also coat the insertion points with bitumen. Install the ceiling.

The concrete well is filled with crushed stone on all sides to a height of approximately 50 cm, and then clay is poured to the very top and compacted well. Such a clay cushion will prevent water seepage and extend the life of the well.

Conclusions and useful video on the topic

Detailed instructions for arranging a drainage system at home can be viewed in the following video:

The following video will tell you how to make a drainage well from concrete rings:

Installing drainage wells is a difficult process, but mandatory for areas with high groundwater levels. If the territory is not equipped with a full-fledged drainage system in a timely manner, then periodic flooding of the basement of the house will inevitably lead to the destruction of the foundation of the building.

We are waiting for your stories about how you built drainage on the site and installed drainage wells. You can write about your own experience, comment and discuss the article, and ask questions in the block below.

Source sovet-ingenera.com

Types of drainage wells

As a rule, the arrangement of a drainage and water disposal system is not limited to the construction of just one mine. To ensure the normal and comfortable functioning of infrastructure located in an isolated area, it is necessary to carry out a fairly large amount of work on the design and installation of underground communications.

When arranging sewer systems, the following types of drainage wells are installed:

- Auditing (inspection) They are sealed tanks that are installed on long sections of the pipeline. Designed for collecting garbage and sewage, inspecting the mine, carrying out routine and cleanup work.

- Rotary . This is an analogue of inspection wells, which is installed in places where the highway turns within 15-90°.

- Drops. Having a standard device, they are mounted on slopes to reduce the speed of movement of wastewater. A whole cascade of such structures can be installed on one site.

- Cumulative . They are the final device of the groundwater and flood water collection system. Completely sealed to prevent unplanned flooding. The collected liquid, after settling, is pumped out and used for economic purposes.

- Filtration . They are part of the drainage and sewer systems. The concreted tank rests on a thick bed of sand, gravel and crushed stone. Such a filter ensures maximum wastewater purification, which prevents contamination of the aquifer.

- Pressure . Such tanks are installed at the highest point of the area. Their task is to preventively flush the pipeline with water under pressure. The outlet pipe is equipped with a shut-off device.

The optimal option for arranging sewer systems is to use a cascade of wells of different types and sizes. This allows you to effectively drain wastewater and maintain cleanliness and optimal soil moisture.

Basic principles of drainage arrangement on the site

The drainage installation begins with choosing a location. Need to consider:

- if the terrain is uneven, the system should start from the top point and end at the bottom;

- drains are laid no closer than 1000 mm from the foundation, deeper by 500 or more millimeters;

- slope for drains with a diameter of 110 mm – 10 mm per linear meter, for a diameter of 160 mm – 5 mm/m;

- A sand and gravel filter is made around the pipes.

The drains are not completely filled with liquid; even a diameter of 110 mm has a large reserve. However, the larger the diameter, the smaller the slope can be made. According to SNiP, it is allowed to make a slope of up to 3 mm/m, but it is difficult to maintain such a level. The level is measured every 10 meters, making sure that there is no “wave”.

Correct installation of drains

The backfill is carried out with coarse sand, a layer of 15 cm. To protect it from washing out, it is wrapped in geotextiles. Two layers of fabric are laid over the trench, sand is poured in, and the first layer of fabric is wrapped. Then crushed stone is poured and wrapped in geotextiles. Crushed stone size is 16–32 mm. To remove dust, it is pre-washed with water.

After washing, the crushed stone is not dried, but placed in bags. If it doesn't work out after a week, you need to rinse it again.

On top, on the sides, the pipes are lined with crushed stone, which can be replaced with gravel. The width of the trench is three times the diameter of the pipes. Unwashed crushed stone is poured over washed crushed stone, in a fraction of 8–40 mm, in a layer of 10–20 cm, and covered with soil.

Manufacturing technology for prefabricated well elements

Despite the fact that today not only state-owned enterprises are engaged in the production of concrete products, their production is carried out on the basis of and in compliance with the requirements specified in GOST 8020-90.

The norms of the state standard precisely define such parameters as:

- material for manufacturing and its proportions;

- production technology with maximum deviations;

- dimensions of concrete rings (height, diameter, wall thickness);

- additional functions (hinges, brackets, technological and transportation holes);

- rules for acceptance and certification of products;

- product labeling;

- storage rules (where, orientation, number of tiers);

- procedure for transportation, loading and unloading;

- terms of Use;

- repair and maintenance rules;

- warranty obligations.

All parameters of the components of drainage wells are standardized. Their manufacturing technology requires minimal deviations from the specified values. Thus, the internal diameter of wall rings is 750-2500 mm. Their height can be either 900 or 180 mm with a wall thickness of 70 mm. Additional rings with similar thickness and diameter have a height in the range of 100-300 mm. The slabs that are laid on top and bottom of the shaft are made of different thicknesses depending on the conditions in which the drainage wells will be operated.

Loading and transportation of concrete products is carried out in a rigidly fixed state. In this case, the slabs can be laid in 6 tiers, and the wall rings - in 2 with a shift of half an element.

Connection of drainage pipe to well

The use of the usual concrete rings for arranging containers in the drainage and sanitation system is gradually fading into the background. Today they have been successfully replaced by plastic structures that have such improved characteristics as resistance to aggressive environments, light weight, strength and flexibility. When choosing a drainage well and drains for it, it is advisable to give preference to products of one brand, so that no problems arise during installation.

The pipes with the tank are fixed when the route turns on a span of no more than 13-15 meters, as well as in the places where the drain is attached to the filter tank.

To ensure tightness, sealing collars of the required diameter are placed on the pipes. To connect you need to follow these steps.

- The bushing and coupling should be prepared according to the diameter of the pipe.

- A coupling is inserted into the hole made with an electric drill, a high-quality sealant should be applied to it and a sleeve is inserted.

- The well is placed in a prepared shaft.

- The inside of the coupling is treated with silicone lubricant.

- The pipe is connected to the tank.

- The structure is filled with sand or soil, and each layer of 15 centimeters should be carefully compacted, controlling the verticality of the structure.

- Finally, a lid with a hatch is put on the well.

Such simple steps will allow you to install a drainage well made of PVC or HDPE with your own hands, which cannot be said about the installation of concrete structures. In this case, you cannot do without the help of specialists.

General arrangement of wells made of reinforced concrete

As a rule, all drainage wells, regardless of their purpose, are structurally the same. The difference lies in the arrangement of their base. Thus, when installing inspection, rotary and differential tanks, a durable bulk foundation is made from crushed stone.

The layer of stone should prevent the mine from subsiding under the influence of its own weight and seasonal soil movement. A more solid foundation is created for filtration type drainage wells. In addition to a solid foundation, gravel and sand are backfilled. This layer is designed to trap chemicals and organic substances. Its thickness is at least half a meter.

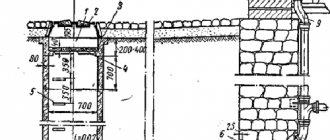

Apart from these differences, the design of a drainage well made of concrete rings is as follows:

- Base plate. It is designed to receive and distribute the weight of a prefabricated shaft made of reinforced concrete rings onto the ground. In order to prevent the well from tilting, even for the filtration tank, a plate with a hole in the middle is used. The strength of the connection with the wall ring is achieved due to the protrusion along the perimeter of the slab.

- Wall ring. This is the main element of drainage wells of any type . Depending on the characteristics of the site where construction is taking place, from 1 to 20 wall rings are used to create a shaft. It is almost impossible to make a well deeper than 20 m due to the limited capabilities of digging equipment.

- Additional ring. Used to adjust the height of a prefabricated column to the required size in cases where it is impossible or economically impractical to do this using soil excavation. While fully consistent with the wall rings in diameter and wall thickness, the additional products have a height of 10, 20 and 30 cm, which allows you to achieve an almost ideal result.

- Floor slab. This product is equal in diameter to wall rings. Designed for hermetically sealed closure of the shaft. Prevents gases from escaping from the well, people and animals falling into it, the tank clogging with debris and insects, and the penetration of rain and flood water.

- Hatch with cover. The element is a cast iron or steel ring of a special shape, which is rigidly attached to the floor slab. Lids are made in a removable or folding version. They are made of cast iron, plastic or polymer-sand mixture.

If a sewer well is installed on a roadway or in a place where vehicles can run over it, then a road slab with a high-capacity hatch is laid on top . Depending on the operating conditions, slabs are used that can withstand short-term loads of up to 3,000, 15,000, 25,000 or 50,000 kg.

Purpose, design of the drainage system

The construction structure is designed to balance water on controlled land. The system monitors excess water removal. Composition: channels, pipes (drains), sometimes drainage wells. Excess water is collected from the site and transported outside through drains. Typically, pipes are laid out along the perimeter of the serviced area with a slope in one direction. Water enters a river, lake, ditch, low places, and the soil is drained.

Causes:

- creating favorable conditions for plants;

- soil drainage for construction;

- protection of the foundation from water pressure;

- reducing the influence of heaving.

Each type has its own technique, but the principle remains the same. The basis of drainage is pipes. At first, they were asbestos-cement, ceramic. To collect water, slits and holes were made in asbestos-cement pipes. Ceramic ones were produced, 33 cm long, connected end-to-end, without compaction. Through the cracks, water could penetrate inside. The system quickly clogged, required frequent flushing, and did not last long.

Modern pipes are made of polymer and composite materials, with filter shells that allow only water to pass through. Plastic drains with a geotextile shell are popular. To increase rigidity, the surface is made corrugated. Drains made of expanded clay glass and plastic concrete have a porous surface and no holes are required.

Drainage well assembly technology

Before equipping the territory with sewage and drainage systems, a set of measures is carried out to study the soil, determine the terrain and draw up design documentation. When planning a sewer system for draining domestic wastewater, it is necessary to follow the rules for placing wells.

They should be built at such a distance from:

- wells or wells for water - 50 m;

- fruit trees - 3 m;

- vegetable garden, greenhouse, flower garden - 10 m;

- residential building - 5 m;

- reservoir of any type - 30 m.

Only after drawing up a diagram and agreeing with representatives of the SES can you begin to work. When building a shallow well of 1-2 sections without a bottom, the work can be done manually. This method involves digging and removing soil from under the rings and then installing new fragments.

However, this solution is applicable only in cases where it is planned to install 1-2 shallow drainage wells. When you have to install several such structures and dig out tens of meters of trenches, it is better to rent earth-moving and loading equipment. The invested funds will pay off in a short time and high quality of work performed.

The technology for arranging the drainage system is as follows:

- The area is marked in accordance with the project.

- An excavator is used to dig out trenches for pipes and pits for wells.

- The bottom of the open pits is cleared of tree roots and large stones. The soil is leveled and compacted.

- A cushion is being constructed for laying products in ditches and pits.

- The base plates are laid. They are carefully aligned and fixed in a given position.

- A sealant is applied to the fasteners of the base plate. This can be bitumen, cement mortar or a special sealant for concrete.

- Wall and additional rings are installed sequentially. Their joints are sealed and protected with various sheet materials. In heaving soils, the shaft elements are tightened with steel brackets.

- After adjusting the height, the well is covered with a floor slab.

The hatch and cover are installed. The opening around the shaft is filled with a mixture of gravel and sand.

Installation of the structure

If you are installing a monolithic plastic well, then it does not require preparation. The prefabricated version is assembled according to the attached diagram before installation. You can make a well from a piece of pipe of the required diameter. To assemble the structure you will need:

- plastic corrugated pipe with a diameter of 35 to 60 cm, depending on the purpose of the well;

- elements that are the lid and bottom;

- O-rings.

It is necessary to cut holes in the pipe according to the size of the drains. To connect the pipes, sealing couplings will be required. Installation takes place in several stages:

- Dig a pit for the container, the dimensions should exceed the diameter of the tank by 40 cm.

- The walls of the pit are leveled, crushed stone is poured onto the bottom. If the area has a high groundwater level, then the bottom must be concreted.

- After the concrete has hardened, lower the container and level it.

- The drainage system pipes are connected, all joints are treated with sealant.

- Backfilling is carried out with a mixture of sand and gravel, each layer is carefully compacted.

- The structure is covered with a lid, which should protrude 10-15 cm above the ground.

Installation of a manhole

Material of manufacture

Concrete rings of standard sizes or plastic elements are used to complete the structure. The parts are brought to the site and then installed in pre-prepared pits and trenches. Concrete elements are cheaper for the home owner, but it is necessary to use lifting equipment to move and install the rings. Plastic wells for drainage have an increased price, but are easy to install and seal.

Concrete parts have increased strength and do not collapse during operation; the structure can be used in frozen soil or in areas subject to seasonal swelling. Plastic tanks bend or burst when the ground moves, but reinforced structures are available. The advantage of a container made of synthetic material is the presence of couplings for connecting water supply lines. It is possible to build a combined drainage system using concrete and plastic elements in the structure.

Preparing for work

Before constructing a well installation, it is necessary to purchase suitable reinforced concrete rings that are resistant to moisture. Dimensions and cross-section depend on the purpose of the device and the functions of the ring itself.

Products are produced in different sizes. Diameter can be from 0.7 to 2.5 m, height - from 0.1 to 2.5 m: the range of options is wide.

For a drainage well, products are usually chosen with a height of half a meter and a cross-section of 0.7–1.5 m. Their weight depends on the size and can be from 200 to 900 kg.

Absorption devices are placed on a bulk filter pad. It must be made at least half a meter high from sand and gravel-crushed stone mixture. The arrangement of the pillow will be required even when the lower reinforced concrete ring is equipped with a built-in filter bottom.

Storage tanks and inspection devices are installed on the bottom slab or on a cement screed. The bottom of the pit must first be compacted. The rings are placed one on top of the other with strict adherence to the vertical. The joining areas are sealed with bitumen mastic or liquid cement. In order for the prefabricated elements to be securely fastened, they are connected from the inside with metal ties so that one edge of the plate is held on the upper ring, the other on the lower one.

Construction and operation

Correctly installing inspection systems for a dacha or private home is one thing; maintaining them in working order for a long time is quite another. If maintenance is not carried out after some time, the entire drainage system will not be effective. To avoid this, it is recommended to carry out preventive work:

- Check the connection between the drain and the ditch and the drainage drains. A lot of garbage can accumulate here. Contaminants can be very different: silt, leaves, soil particles, etc. Therefore, shafts must be provided with ladders for the necessary cleaning.

- Particular attention is paid in winter. The groundwater level becomes lower during this period. Therefore, there will be no water in the pipes and collector. In this case, the system should not be preserved for the winter, since the pipes were initially placed at a depth below the soil freezing level. Moreover, the presence of crushed stone and sand creates a layer resistant to deformation.

- If washing is necessary, it is carried out with water pressure.

- Once every 15 years, a global cleaning and flushing of the entire drainage system is performed.

- The serviceability of the pumping equipment is checked.

- It is necessary to make sure that the hatches reliably cover the container from the entry of debris from the outside.

Conclusions and useful video on the topic

The owner of a country house can independently build a drainage system that allows removing excess groundwater. There are videos that show in detail the process of designing and arranging wells and connecting pipes. The videos explain the nuances of constructing vertical wells from concrete rings, as well as methods for sealing the system. If the owner of the site is not confident in his own abilities, it is recommended to contact a company engaged in the arrangement and maintenance of drainage systems.