Properties

Caprolon is chemically resistant to various substances, many solvents, dilute acids, but it dissolves in concentrated sulfuric acid, concentrated formic acid and fluorinated alcohols.

Caprolon is harmless to living tissues and slowly dissolves in the human body. It is able to absorb water, reaching a maximum humidity of 12%, but large swelling does not occur. Caprolon has a low coefficient of friction, which allows it to be used in the manufacture of rubbing parts.

Application

Its strength is realized in the manufacture of cutting boards for the meat industry from caprolon.

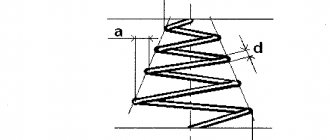

The wear resistance of caprolon is used in the manufacture of augers for removing ash and dust, which are distinguished by their abrasiveness. Caprolon is also used to make screws for other purposes, for example in agriculture for feeding feed.

Caprolon is used to make mushroom shaft bearings for ships and bearings for various pumps. Caprolon bearings are characterized by corrosion resistance, wear resistance, low friction coefficient and self-lubricating effect.

Caprolon is used for the manufacture of gears, sprockets, impellers and pump blades, various housings, conveyor belt rollers, etc.

For a long time, polymer materials have been widely used in various industries, medicine, pharmacology and for household purposes. Due to their good mechanical and electrical insulating properties, resistance to aggressive environments and durability, polymers have established themselves as universal materials. They successfully replace “traditional” structural materials (steel, bronze, etc.) and are used for the manufacture of electrical insulation, protective coatings, etc.

For domestic purposes, polymers are used as decorative and finishing materials and for various crafts. However, despite the large assortment, many polymers have similar properties, so we often face the problem of choosing the material most suitable for specific purposes and tasks. As an example, consider the differences between fluoroplastic and caprolon (polyamide PA-6). These materials practically do not differ in appearance and technical characteristics, which complicates the choice of which is better: caprolon or fluoroplastic . To understand this issue, let’s compare these materials and determine their advantages and disadvantages.

Fluoroplastic-4: properties and scope

Fluoroplastic is produced by polymerization of fluorine-containing ethylene derivatives. As a result, a semi-finished powder product is obtained for the manufacture of various parts and integral structures. At the first stage of production, a melt is prepared from polymer powder with the addition of catalysts, hardeners and various additives. Then finished products are produced using the injection or extrusion method. The industry mainly produces fluoroplastic in the form of sheets, blocks and rods. This polymer lends itself well to any type of mechanical processing, which makes it possible to obtain not only simple-shaped products, but also complex three-dimensional structures.

Caprolon: properties and scope

Caprolon or polyamide PA-6 refers to heat-resistant polymeric materials obtained from chemical compounds containing amide groups. Caprolon is produced by polymerization of the feedstock in the presence of catalysts, stabilizers and other additives. As a result, a pale yellow or white powder is obtained, from which a melt is then prepared for the manufacture of polymer products using the injection or extrusion method. Caprolon is produced in the form of sheets and rods of various diameters. This material lends itself quite well to machining, welding and gluing, which makes it possible to manufacture parts and finished products of various shapes from it.

Caprolon has the following physical and mechanical properties:

- Resistance to wear and abrasion;

- Atmospheric and moisture resistance;

- Good insulator;

- Good mechanical strength;

- Can be machined;

- Resistant to chemicals.

Caprolon is widely used in mechanical engineering, light industry, construction, medicine and for household purposes. Pipe fittings, insulating gaskets, and also anti-corrosion and other types of protective coatings are made from it.

WHAT IS BETTER: PTFE OR CAPROLON

For a long time, polymer materials have been widely used in various industries, medicine, pharmacology and for household purposes. Due to their good mechanical and electrical insulating properties, resistance to aggressive environments and durability, polymers have established themselves as universal materials. They successfully replace “traditional” structural materials (steel, bronze, etc.) and are used for the manufacture of electrical insulation, protective coatings, etc.

For domestic purposes, polymers are used as decorative and finishing materials and for various crafts.

However, despite the large assortment, many polymers have similar properties, so we often face the problem of choosing the material most suitable for specific purposes and tasks. As an example, consider the differences between fluoroplastic and caprolon (polyamide PA-6). These materials practically do not differ in appearance and technical characteristics, which complicates the choice of which is better: caprolon or fluoroplastic . To understand this issue, let’s compare these materials and determine their advantages and disadvantages.

Caprolon or fluoroplastic – which is better in the end?

To compare caprolon and fluoroplastic and choose which is better, we will use a table that shows the main technical characteristics of these materials:

| Indicator name | Indicator value | |

| Ftoroplast-4 | Kaprolon PA-6 | |

| Color | from light yellow to white | white or yellowish |

| Release form | rods, sheets, blocks | rods, blocks |

| Density of material, kg/m3. | 2100 – 2200 | 1150 – 1160 |

| Operating temperature range, °C | –269 … +260 | – 30 … +110 |

| Thermal conductivity coefficient, W/m°C | 0,25 | 0,3 |

| Water absorption,% | 0,0 | 1,5 – 2 |

| Tensile strength, MPa | 20 – 30 | 80 – 90 |

| Ultimate compressive strength, MPa | 12 – 15 | 100 – 110 |

| Elongation at break, % | 350 | 600 |

| Brinell hardness, MPa | 30 – 40 | 160 – 180 |

| Electric strength, kV/mm | 50 | 30 – 35 |

| Dielectric constant at 1 MHz frequency | 0,002 | 3,3 |

| Dielectric loss tangent at a frequency of 1 MHz | 0,2 – 03 | — |

| Coefficient of sliding friction on steel in lubricant | 0,02 | 0,06 – 0,08 |

| Coefficient of sliding friction on steel without lubrication | 0,2 | 0,2 – 0,3 |

| Abrasion resistance | high | very high |

Paronite or cardboard?

For installation in the engine system, it is better to use paronite . It is not corroded by synthetics, while cardboard is corroded by water if it is not tightened tightly. In addition, paronite can always be tightened, and cardboard only needs to be replaced.

Compared to cardboard, paronite is a more preferable option.

Gaskets made from cardboard are not used in the gas system and water supply system due to their “low” technical characteristics.

Differences

As can be seen from the table, caprolon or fluoroplastic have practically no differences in appearance , but in physical and mechanical properties they have quite significant differences. Therefore, when choosing a polymer, you should pay attention to the following criteria:

- Mechanical strength and hardness;

- Electrical insulating properties;

- Resistance to abrasion and wear;

- The magnitude of the sliding friction coefficient.

In terms of strength characteristics, caprolon is stronger than fluoroplastic , but is somewhat inferior to it in hardness and workability. Caprolon is more resistant to abrasion and wear and works better under long-term loads. The electrical insulating properties of the materials differ slightly.

It is also worth paying attention to the cost of materials. The price of caprolon is from 250 rubles. for 1 kg, and fluoroplastic - from 500 rubles. Thus, when comparing caprolon and fluoroplastic and choosing which material is better, we start from the following criteria: for working in difficult conditions and mechanisms with increased wear of parts, it is preferable to use caprolon, and in conditions of exposure to chemically aggressive environments and elevated temperatures, fluoroplastic performs better.

With regard to fluoroplastic and polyurethane, the question of which is better is not entirely correct. The first type of material has an extensive history of use, but today it is widely replaced by modern composites. To understand the topic in more detail, let’s consider the structure and properties of these polymers from the point of view of industrial use.

Comparison with fluoroplastic

Caprolon is one of many polymers used to replace metals. Of all analogues, it is most often compared with fluoroplastic and polyurethane. Technical characteristics of fluoroplastic and polyamide in comparison:

Read also: Battery for screwdriver battery repair

- Thermal resistance is better with fluoroplastic. It can withstand temperatures up to 200 °C.

- Both materials are slightly susceptible to chemical corrosion. The difference is that fluoroplastic parts are more often used in diluted acids, and caprolon parts are used in alkalis.

- The specific density of caprolon is significantly less than that of fluoroplastic. They can be distinguished by their weight. Fluoroplastic is almost twice as heavy. In places where the weight of the product plays an important role, polyamide-6 is more often used.

- In terms of compressive strength and deformation upon impact, fluoroplastic is superior to caprolon.

Fluoroplastic is a soft and flowable polymer, not suitable for use under high loads. The service life of fluoroplastic is higher than that of polyamide-6, and in terms of strength characteristics, fluoroplastic has better performance. However, caprolon is more affordable, and this often determines the choice of manufacturers in its favor. More information about fluoroplastic F4 can be found here.

Polyurethane is used to replace rubber, traditional plastics, and sometimes metals. It is indispensable in the manufacture of various gaskets and seals.

Thanks to the use of new polymer materials, manufacturers of various types of mechanisms have the opportunity to significantly lighten and reduce the cost of structures. This brings significant economic benefits and often increases the service life of products.

Products made from this material have high wear and chemical resistance.

Caprolon according to TU 2224-036-00203803-2012 is supplied both in plates and rods.

Caprolon according to TU 2224-001-78534599-2006 is supplied already trimmed, which significantly reduces the time spent on its processing.

Oil-filled caprolon has a slip rate 2.5 times higher than conventional polyamide 6, while maintaining excellent mechanical, thermal and electrical properties.

Graphite-filled caprolon has a friction coefficient 2-3 times lower compared to polyamide 6 and is superior in wear resistance to other grades of caprolon.

Kaprolon is the Russian trade name for one of the most common polyamides - polycaproamide. Let's consider the characteristics of caprolon and its analogues, as well as the types and cost of the material.

Caprolon is a relatively new material, the widespread use of which began only in the mid-1980s. It has unique properties, is characterized by high strength and wear resistance. High-quality caprolon can be outdoors for many years without deterioration in physical and mechanical characteristics, and does not require special protection from ultraviolet radiation and environmental influences. Caprolon is resistant to various chemicals, solvents, alcohols, ethers, diluted acids, while it dissolves in concentrated sulfuric and formic acids and fluorinated alcohols. An important property of this material is its low coefficient of friction, which allows it to be used in the manufacture of rubbing parts, such as bearings. But this is far from the only option for using caprolon in industry.

Features and properties of fluoroplastic

This is a category of fluoropolymers obtained by repeated polymerization of low molecular weight tetrafluoroethylene with the addition of various modifiers to provide certain properties. Polymer materials with a high fluorine content are used in various industries, including electronics, mechanical engineering, energy, nuclear and chemical industries. They are also used in the manufacture of sealing rings, guides, sliding supports and other products. Beneficial features:

- resistance to chemically aggressive reagents;

- low friction coefficients;

- non-flammability;

- resistance to temperature changes;

- no toxic emissions when heated.

Flaws:

- difficult to glue;

- high melting point;

- intensive wear and low creep when operating under load;

- irreversible deformations due to mechanical stress;

- significant recrystallization and deformation under load at both elevated and low temperatures.

Material "caprolon" and its application

Caprolon is often used instead of metals, and it is 6-7 times lighter than steel, which means that products made from it are very light in weight with great strength. As already mentioned, caprolon is used in the manufacture of bearings. The latter are resistant to corrosion, characterized by wear resistance, low friction coefficient and self-lubricating effect. In addition, caprolon is used for the manufacture of gears, impellers and pump blades, various housings, and conveyor belt rollers. Cutting boards for the meat industry are also often made of caprolon.

This is interesting.

Caprolon halves the wear of the product due to friction, increasing the service life of parts by 1.5 times. At the same time, the labor intensity of the manufacturing process for products made from caprolon is 35% less, and their cost is almost half lower compared to analogues made from steel and bronze.

Comparative characteristics of caprolon and its analogues

Various additives change the characteristics of caprolon. In addition, one should take into account the fact that caprolon can be manufactured using extrusion or casting methods, and this also affects its properties.

- Extruded polyamide 6 is a durable material with high toughness and reduced wear resistance. It is widely known as "nylon".

- Polyamide 6, made by casting, is the most common type of caprolon in Russia. It has anti-friction properties and is easy to process. The material is harmless to humans and can be used in the food industry.

- Polyamide 6 injection molded with the addition of solid lubricant provides increased sliding performance, which allows it to be used in the manufacture of various parts of units where the use of permanent lubrication is necessary.

- Molded polyamide 6, containing polyethylene, has good sliding characteristics - 3 times higher than that of conventional caprolon.

- Polyamide 6 extruded with the addition of glass fiber is one of the toughest and most durable varieties of caprolon. It is used in the manufacture of parts designed for heavy loads and high temperatures.

- Polyamide 66 extruded unfilled is used in the manufacture of parts that must withstand heating up to 100 o C.

- Polyamide 66 extruded with the addition of 30% glass fiber is characterized by heat resistance and low moisture absorption.

- Polyamides 11 and 12 are mainly used in the food industry, as they have very low water absorption characteristics.

- Polyamide 46 is the most heat-resistant type of caprolon. It melts only at 259 o C.

Read also: What are left-handed and right-handed threads

Many buyers are interested in the question: “Caprolon or fluoroplastic - which is better?” In fact, the difference between these materials is very small. However, caprolon is a little stronger; unlike fluoroplastic, it cannot be cut with a knife.

By the way…

In different countries, caprolon is produced under various brand names - zaytel, armamid, tecast, technamid, tecamid.

Sheet caprolon

The most popular product made from this material. This is a kind of blank, a semi-finished product that is used to create various kinds of parts - liners, bushings, rings, flanges and other elements. The material is typically shipped in sheets measuring 1000x1000 mm and has a thickness of 6 to 250 mm, although these may vary. It should be stored in low humidity areas.

When working with the material, it is important to follow safety precautions. Sheet caprolon is smooth, elastic and slippery, so it is not recommended to strike a loose sheet with a hammer or sledgehammer. You should wear gloves when working with this material: sharp edges can cut your hands. Sheet caprolon is easily processed on metalworking machines, but when working with it, some features should be taken into account. Thus, during mechanical processing it is necessary to ensure heat removal, since caprolon has a relatively low melting point. During complex processing, the material may crack, so it is better to divide the process into several simple steps. It is also important to know under what conditions the sheet caprolon was stored in the warehouse before sale. If he has been in a very cold room for a long time, he needs to be kept in a warm place for about 5 days.

To work with caprolon, you can use carbon steel tools. For long-term machining, it is better to use tools with tungsten carbide tips or a diamond cutting edge.

Price for caprolon

Caprolon is sold by weight, although the cost of one kilogram largely depends on the configuration of the product. The cost of caprolon ranges from 250 to 400 rubles per kilogram. As mentioned above, this material is supplied in sheets and slabs, but you can also buy rod caprolon and block caprolon, as well as various blanks from this material.

Where to buy caprolon?

There are a lot of companies selling caprolon and other polymeric materials, but usually buyers are most interested in the question of where to buy caprolon inexpensively, while receiving not only a high-quality product, but also good service.

This can be done in, which has existed since 2005 and actively cooperates with the best manufacturers in Russia and foreign countries. MetPromStar works not only in Moscow, but also in the regions - you can receive a paid order at a warehouse in the capital, and at the warehouses of well-known transport companies in other regions of the country. Shipping terminals are located in Abakan, Arkhangelsk, Astrakhan, Barnaul, Belgorod, Bryansk, Vladimir, Volgograd, Voronezh, Yekaterinburg, Izhevsk, Irkutsk, Kaluga, Krasnodar, Kursk, Lipetsk, Murmansk, Novosibirsk, Orel, Penza, Pskov, Ryazan, Samara, St. Petersburg, Saratov, Smolensk, Tambov, Tver, Tula, Tyumen, Ulyanovsk, Ufa, Khabarovsk, Chelyabinsk, Yaroslavl and many other cities. Logistics schemes have been worked out for a long time, and the buyer will receive his goods on time.

MetPromStar offers each client an individual approach, develops flexible payment schemes and discounts, and takes into account all customer wishes. The company's employees are always ready to help in choosing the right product and answer any question. Convenience, reasonable prices and a wide range of quality products were highly appreciated by many large partners of the company, including many federal enterprises, factories, retail chains and holdings. The list of regular clients includes Aeroflot, KiN, Promsvyazbank, Russian Space Systems and many others.

Read also: Vision drawing program

Synthetic polymer materials have long been used in many industries as a complete replacement for bulky and heavy steel parts, or to replace lower quality and resistant parts made from other materials. In addition to the best physical and technical characteristics, polymer materials have a significantly lower price, which is an important factor for many manufacturing enterprises and private consumers. There are quite a large number of different materials based on polymer compounds, for example, fluoroplastic, caprolon, textolite. Which one is better? The question is quite complex and ambiguous, so today we will compare caprolon and fluoroplastic - the two most popular and popular materials.

First, let's look at fluoroplastic. This name comes from a combination of two words: fluorine and plastic. Fluoroplastic received this designation, in fact, due to the fact that it is a plastic containing fluorine. It is precisely due to the high content of fluorine in its chemical composition that this material is able to exhibit high resistance to many aggressive environments, low and high temperatures and pressure. In addition, there are other properties of fluoroplastic that affect its demand. For example, it is a dielectric and is not afraid of radiation exposure. Fluoroplastic is resistant to corrosion. It is very hydrophobic, that is, it does not react to water at all, and when ignited, fluoroplastic tends to fade, that is, it does not support combustion.

If we talk about caprolone, then this material is obtained from caprolactam by polymerizing it with anions at fairly low temperatures. It is worth immediately noting that the material used to make nylon is the same material that is used to create high-strength nylon threads. Caprolon has incredibly high strength and resistance to various aggressive working conditions. Among other things, the properties of caprolon allow it to exhibit excellent wear resistance and cope very well with temperature changes. With all this, caprolon is light in weight, which is almost 7 times less in relation to steel. A special distinctive feature of caprolon can be considered its ability to self-lubricate during friction.