Choosing a seam for the roof and the main type of fastening

The installation of a seam roof begins with the choice of fastening - the seam. The folds can be standing or lying, but they differ in that with the help of horizontal folds you can effectively connect all the elements that are in the same position. Standing elements can be used to connect the roof along the entire length of the slope.

Rebates are characterized by different types of joints produced, which can be single and special double . In the first case, there is one classic bend; a double bend is distinguished by its ability to ensure maximum tightness. Such folds are used in those areas of the roof where there is a danger of moisture accumulation due to leakage, which is typical for gutters.

Standard tool for repairing standing seam roofs.

Since we are dealing with metal, we have the appropriate tools to carry out the necessary repairs to a seam roof. And so we designate the list of the most popular, which is basically similar when installing this coating:

- I think the most interesting one is chalazen, since during repairs there is a lot of manual labor - folding, bending, joining the seams of adjacent sheets of overlaps, it is difficult to imagine the full implementation of the work without it.

- Scissors with different cutting angles are especially needed when working on junctions and valleys.

- Bending pliers are useful for separating a folded seam (single or double), the so-called panel patterns are fastened together quite firmly. The metal in the connection area is wrapped between each other one to two times; this is not an easy job, especially when you need to save the sheet for later reassembly.

- In order to secure the folded picture back, we need two roofing frames, with the help of which a folded seam is created. As an alternative, there is an electric seamer.

The photo above shows all the other tools, such as a truncated mallet, large pelican scissors, a square, a roofing hammer, equipment for hemming in a cornice unit, a tape measure, etc.

.

Possible reasons for the appearance of seam roof repairs.

If we talk about the possible causes of problems with repairs, then we can divide them into two large groups:

- Metal fatigue, that is, due to the natural aging processes of the metal coating.

- Errors in the technological execution of work when installing a seam roof by roofers, tinsmiths, carpenters - the so-called human factor.

- Natural reasons for roof repairs are the appearance of rusty areas of metal destruction, especially in the nodes of a seam roof, such as the junction of a horizontal carpet of metal covering with a vertical one. For example, connections to a wall, a hatch, a chimney, a dormer window, a parapet (apron), a valley and a ventilated ridge.

It is quite difficult to diagnose a violation of the tightness of the coating in such areas; the metal is twisted into complex shapes and bends; a thorough inspection must be carried out, preferably during daylight hours.

Having made the necessary notes with a marker in the proposed repair areas, we calculate the required amount of material and timing for its correction.

Also, natural problems that arise during the operation of a seam roof are wear and tear on the rafter system. Deformation and destruction of this roof structure lead to sheets of seam panels coming out of the seam joints.

Roofing pie

The seam roofing pie is characterized by a special multi-component system, which, in addition to the roofing itself, consists of various other elements. This includes sheathing, insulation, and high-quality waterproofing. Hence the name of the roofing pie - it consists of a large number of layers . If the pie is arranged correctly, a large number of different problems can be avoided. This is an ideal opportunity to prevent the appearance of icicles, the accumulation of condensation and heat loss.

A competent ventilation system is of great importance in the process of designing and arranging a roof. It removes excess moisture from the entire roofing pie. To drain water through the membranes into the equipped ventilation, it is worth leaving several holes in the roof during the installation process . Wooden sheathing will cope with this process perfectly.

Do-it-yourself semi-automatic seaming machines

To speed up the process of installing a seam roof, you can use semi-automatic tools - they allow you to perform a high-quality connection of roofing panels in a shorter period of time than when using manual tools. Semi-automatic seaming machines are supplied in a kit that includes two devices necessary for alternate installation of the joint. In order for the seam roofing clamp to be connected, all you have to do is pull the machine behind you.

A semi-automatic machine for standing seam roofing has many advantages compared to manual tools:

- High speed;

- Good quality of the connecting seam along the entire length of the joint;

- Possibility of processing metal sheets of different thicknesses;

- Complete safety for the polymer layer located on the surface of the panels;

- Possibility of quick and high-quality installation of metal sheets on large roof areas.

What is a clamp and why is it needed?

In the process of installing seam roofing, fastening devices such as clamps are used. Essentially, this is a special device that is designed for fastening roofing sheets . You don’t have to use nails, which can disrupt the integrity and complete tightness of the coating.

The use of a clamp greatly simplifies the process of installing the roof covering and ensures the overall durability of the system. Finishing the roof with similar elements makes it aesthetically pleasing and as airtight as possible.

Which manual folding machine is best?

Work related to the construction of buildings and installation of roofing is carried out using modern equipment.

Manual folding machine

For this purpose, machines are used to create seams. This can be a homemade machine, made with your own hands, or a factory analogue, for example, the SFP 700 folding machine.

Why do you need a manual folding machine?

To create a seam roof, sheet or rolled metal is used. The edges of such a roof are connected by means of a special seam - a fold. Forming a waterproof seam seam is possible using a device such as a seam rolling machine lc 12r or SFP 700.

The main purpose of such a unit is to provide mechanical bending of sheet metal for roofing in order to create seams. Renting a folding machine is relevant if the volume of work being carried out is not large.

When using the SFP 700 device, all types of roofing can be made in the form of rolls, rather than separately laid sheets. Using the SFP 700 model machine, it is possible to significantly reduce the time required to complete work by several times, increase labor productivity and reduce the number of transverse roof seams to a minimum.

Renting a folding machine allows you to create double or even triple locks at the joints of the roof, and the finished panels will be equipped with rolled stiffeners. These elements will significantly increase the strength of the entire structure and improve the appearance of the roof.

The machine is needed to form a waterproof seam on a sheet of metal

Renting a folding machine is also relevant in cases where it is necessary to create a roofing picture of a rectangular, wedge-shaped or trapezoidal shape. In addition, the manual unit SFP 700 can be used to create:

The manual machine SFP 700 is intended for the production of various profiles on the edges of workpieces or sheets of galvanized steel. Materials with a polymer or paint coating can also be used.

The only significant drawback of the presented machine is the high cost and large dimensions of some models. However, a unit such as SFP 700 and its analogues differ:

Device Features

The manual machine model SFP 700 has modules such as a forming device, a bed and an electric drive. The frame is presented in the form of a welded metal structure on which the shafts are placed.

Steel rollers pull the metal strip along the machine

They ensure the formation of an even weld seam. The forming device pulls the metal strip along the machine. In this way, stiffening ribs and double-seam components necessary for interlocking roofing elements are created.

Sheathing for standing seam roofing

The fastening of the seam roof is carried out strictly in advance

installed sheathing. This will help prevent sagging of the steel sheets, but only if the required pitch range is fully observed.

The following materials are used as lathing:

These elements are attached strictly from below and upward, that is, from the eaves to the roof ridge. If you are installing metal sheathing or loose wood sheathing, you should use a high-quality anti-condensation film before installing it along the rafters. When using a special continuous sheathing or other completely continuous base, a special vapor diffusion film will need to be laid over the entire flooring.

The sheathing pitch is 20 centimeters ; it is allowed to use a pitch in the range of 20-40 centimeters.

The material provides the following advantages:

Where the installation of roof assemblies is carried out - valleys, roofing eaves, as well as connections and abutments to various protruding elements of the structure, a second sheathing profile element is mounted . This gives increased strength and rigidity to the installed panels.

The design of the sheathing is made smooth; the presence of recesses and various protrusions is unacceptable. Roofing ribs and standard ridges are mounted straight, and the lowest board is also straight.

If the sheathing is made of wood, preference should be given to wood species such as aspen, spruce, fir, and pine. The humidity of the boards should not be more than 12% . To give the wood strength and durability, the material should be impregnated with special antiseptics.

You can significantly increase the service life of wooden sheathing by coating it with drying oil. A structural vapor diffusion film is laid on the finished sheathing. Its durability, as well as the quality of the entire roof as a whole, depends on the proper arrangement of the sheathing. Even a relatively small deflection of the sheets can weaken the density of the mounted folds.

If an insulated roof is installed, high-quality ventilation must be provided. In this situation, a counter-lattice is first installed, a special hydro-windproof membrane is mounted under it, and only then the lathing itself

For installation and repair

Installation or repair of a seam roof cannot be done without a full set of special tools. We wrote a separate review about the cost of seam roofing, and about the types of seam roofing too. The quality of work, the tightness of connections, the durability of the coating - all these parameters directly depend on the availability of appropriate devices and on the qualifications of the specialists who use seam roofing tools in their work.

The composition of the kit largely depends on the type of roof and the method of joining the edges, but in any case you have to connect some sections manually, using all the necessary devices. Let's look at the most common of them:

Roofing mallet

A roofing mallet is an essential tool for a roofer and comes in many different shapes:

- small

- big

- with beveled handle

- fail-safe

They are made of plastic or wood and are used for manually forming a fold according to the appropriate template. There are a lot of offers on sale from different manufacturers; the user can choose the most convenient and suitable type of tool for him.

Roofing scissors

Scissors are an important tool for standing seam roofing, used in all cases of designing the final sections of the canvas, connecting with transversely directed patterns and in other cases. There are different types of metal scissors:

- pelicans

- perforated

- die-cut

- curly

- scoring

- checkpoints

In addition, there are universal scissors that can perform any of the specialized operations. A special feature of the professional tool is the ability to “cover” the cut with a layer of zinc, tightening the protective layer and joining it together. The cut edge is protected from contact with moisture, which is important for the safety of the fabric.

Roofing pliers

Another name for roofing mites is khapa. They are necessary for most operations and are available in different types:

- envelope

- frame

- edge

- “parrots” (used to open seams during repair work)

- big small

There are models designed to perform special types of connections:

- straight pliers are used to form seam joints

- curved pliers are used for finishing shaped elements, making ridges or edging bends

It is almost impossible to provide a complete list of tick species. This is a universal and multifunctional tool for standing seam roofing, which can be purchased in specialized stores. They are produced by various companies; the choice is very large and can satisfy any request.

Mandrels for forming folds

A mandrel is a specialized tool designed to form a fold by hand joining. There are many types of mandrels, differing in the size and shape of the support bar. Each type can provide only one type of connection, hence the variety of shapes and sizes.

During operation, the mandrel is applied to the side of the seam and, with hammer blows, the fold is bent along the edge of the support bar, making an even and uniform bend along the entire length of the joint.

For different types of folds or seam shapes, there are straight and radius types of mandrels, high or low, designed to form the primary or secondary bend of the joint. The prices for mandrels are quite high. Not every master can afford to have a large set of such devices, especially if he does not do roofing work at a professional level.

Roofing frames, manual sheet benders

Roof frames are used in sets of two types - primary and secondary frames. The primary ones create the first fold of the fold, and the secondary ones provide completion and sealing of the connection. They work on the principle of reverse pliers - the working jaws converge when the handles are pulled apart.

In addition to double frames for rebates, there are frames for cornices, which are used when decorating the lower overhang of the roofing sheet. High-quality frames are expensive, so it is advisable to purchase them only for regular use in work mode.

Seam roof slope - optimal and minimal

In the process of installing a seam roof, it is important to observe the slope of the roof. It can be optimal or minimal. The choice is made based on the architectural and planning features of the building.

The optimal slope is on average 10-15 degrees of inclination.

Builders move ordinary living quarters to the higher part, and utility rooms and bathrooms to the lower part. The optimal roof slope can be steeper, then the angle of inclination can be 20-30 degrees.

As for the minimum slope of a seam roof, they are recommended for certain categories of roofing coverings. The design features of such a roof make it possible to cover roofs of any size without any problems, as long as they are flat.

Principles of machine assembly

The first and most important thing is to assemble a reliable support with an ideal horizon.

Relative to it and directly to it, the stationary part of the machine is attached - this is a support beam, a metal corner with a bolted connection. A strip of metal is laid between the beam and the table - this creates a groove for pinching the edge. It is important to firmly attach the beam to the support so that during bending it does not rotate along with the traverse from the applied force. The traverse is a lever with a minimum arm of 1:10 - the same angle as the beam, but fixed to a moving axis. The next important step is to center the yoke's axis of rotation. This factor affects the quality of the resulting fold.

What a finished manual folding machine looks like and some design features can be seen in this video:

You can discuss various concepts for assembling machine tools and share your own experience in the comments.

Seam roof waterproofing

When installing the roof, it is important to pay special attention to the connecting seams.

This is one of the most important indicators, which has a direct impact on ensuring the sealing of the roof and seams. If you use a special covering equipped with a self-locking fold, as well as a double standing fold, you can ensure a high level of tightness.

It is equally important to use a high-quality fastening element, that is, nails, screws and a clamp for a seam roof, made of high-quality galvanized steel.

They play an important role in providing a seal, the longer they will maintain their quality, preventing leaks.

Proper installation of hydro- and thermal protection under the roof completely reduces the risk of rapid wear of the roof covering. High levels of tightness will remain for decades.

Types of seam connections

Fastening scheme

The advantages of this method of arranging sheet coverings include:

- ease of laying sheet material with relatively low weight;

- relatively low cost of sheet steel blanks;

- high quality and reliability of connecting seams.

All of the above advantages make it possible to use this coating forming technique in the repair of buildings of any profile, as well as in the manufacture of roofs in newly built houses. This method is especially popular in low-rise (private) construction.

Let us note in passing that when installing a base under a seam covering, a classic “roofing pie” is prepared, which includes elements of hydro-, steam- and thermal insulation. At the same time, the roofing material itself, cut and laid in the form of strips of rolled steel, has a decorative polymer coating that sets its color scheme.

Sheet connection diagram

Steel blanks are laid on the roof sheathing in pre-measured longitudinal strips, which may not always be solid. For high-quality joining of individual strips of flooring, a special type of connection is used - the so-called “lying” seam, which has a flat shape and is hardly noticeable against the background of the coating.

Types of seams

Please note that the longitudinal edges of the workpieces are joined using the standing seam method (see figure), forming a complex convex shape. Please also note that in addition to the standard single connection, locks with more complex double rebates can be used.

Installation of seam roofing - instructions

The construction of a structure from a professional point of view must be carried out with careful observance of certain conditions, as well as the sequence of actions established by professionals.

Do-it-yourself seam roofing:

Tools and materials

When you have decided on the length of the machine and the installation method, you can move from theory to practice. To assemble a simple folding machine with your own hands, you need to prepare the material base, as well as collect a minimum set of tools for assembling components and metrological verifications:

- welded profile or any other material for assembling the frame and clamping arm;

- metal corner - the thicker the section, the more reliable;

- traverse axis - two short metal rods or hinges;

- parts for mounting bolted connections;

- tools: drill, grinder;

- measuring instruments: corner, level, tape measure.

This list can be continued endlessly, but you can’t do without these tools. So, the last question remains to be answered: where to start assembling your folding machine?

Installation of snow guards

The work of installing the roof involves the installation of special

fencing. These are a kind of snow retainers that are able to solve a huge number of different problems.

By means of fences you can reduce the flow of snow from the roof. This will completely prevent the possibility of damage to health and property. It is possible to protect growing plantings near the building.

Fences seriously improve working conditions during work related to roof maintenance. Snow guards effectively prevent possible damage to the gutter.

It is important to carry out such roof fencing in full compliance with the requirements officially recorded in SNiP 21-01-9. The documents indicate that fences must be present on roofs with a slope angle of 12 degrees and with a total eaves height of 10 meters .

Snow guards for standing seam roofing should not only be reliable and durable, but also attractive in their external characteristics. It is advisable to ensure that the design is fully consistent with the overall style of the house. For this purpose, special profile pipes or similar materials are used. All parts of the fence should be painted with a special polymer paint on a special powder base.

Types of seam connections and methods of their installation

A seam joint is a permanent, but not rigid, butt joint of thin metal sheets. Let's talk about their types and methods of use.

A seam joint is a permanent, but not rigid, butt joint of thin metal sheets. The word “rebate” comes from the German “Falz” and is translated as “groove, groove”.

This type of connection is most widespread in the roofing industry. The fact is that when joining metal sheets, one has to solve issues related to their thermal expansion.

Changing geometric dimensions due to temperature changes does not allow for a rigid, hermetically sealed connection. At the junction site, tension occurs in the material, leading to significant deformation. That is why the best connection method is a seam connection.

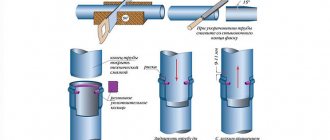

When folding, two roofing elements are connected, the edges of which are pre-processed so that when they are brought together, a fixing seam can be obtained (Fig. 1).

Seam seams come in three types:

Structurally, seams are divided into two groups:

Types of bending machines

Although everything is quite simple and unambiguous in the classification of bending equipment, not every machine is suitable for creating a seam connection. The known tool base is divided into three large categories:

- machines for rolling rods: reinforcement, wire;

- pipe bending machines for processing the contours of hollow welded and rolled profiles;

- machines designed to work with sheet and roll materials.

These three groups, in turn, can be divided into manual and automatic devices with hydraulic or mechanical traction. In addition, there are segmental and rolling mechanisms - the first are designed for bending large parts (rolled or sheet steel, fittings), and the second are for processing piece products of a simple configuration.

To create a folded edge, machines of the third group are used - these are manual or mechanized devices designed to work with rolled metal edges of various thicknesses. The advantages of folding machines are difficult to overestimate: a seam created by mechanization is much more reliable than a seam created by hand. In addition, the duration of work is significantly reduced, as is the effort expended. To assemble a high-quality machine, you will have to spend some time, which will still pay off in high productivity.

Reclining fold

When connecting the end edges of roofing sheets running across the slope, a recumbent type of fold is used (Fig. 2), and for the side edges that are directed parallel to the roof slope, a standing type is used.

Recumbent folds are considered not entirely reliable, so they are used less and less. In addition, rolled roofing material can be cut along the entire length of the slope, eliminating the need for cross connections. But, since this type of fold has not completely outlived its usefulness, let’s consider its design features.

The rebated edge of the recumbent type is produced as follows (Fig. 3):

a) lay the canvas on the edge of the marking table, upholstered at the ends with a corner. Then a line is drawn along the bend line of the roofing sheet. The width of the bend depends on the thickness of the sheet - the thinner the sheet, the smaller the bend;

b) use a wooden mallet or rubber hammer to make a neat bend;

c) be sure to ensure the perpendicularity of the bend;

d) then the sheet is turned over with the fold up and they begin to “pile” it onto the sheet with the same mallet. The second workpiece is performed in a similar way;

e) the edges of the two canvases are connected into a lock, which is pressed with a mallet;

f) using a hammer and a metal block, cut the top sheet so as not to jam the seam seam.

Standing seam

Single

This type of fold has the simplest design. It is used on roofs with a large slope (at least 10°).

Installation procedure for a single standing seam:

1) From the side of the smaller edge, press the scraper tightly against the high edge. Adjust the height of the scraper until it matches the smaller edge. Bend the high edge toward the surface of the scraper with a mallet. Remove the comb bender.

2) close the low fold of the fold with a high one.

3) press the seam using a hammer and a comb bender, which is pressed tightly against the back side of the seam joint (Fig. 4).

Double

Bending machines also make the work much easier, with the help of which you can quickly and easily bend an edge to give it the required profile. Double standing seam is the most commonly used method for joining two adjacent roofing sheets. Seam roofing is one of the most common types of roofing.

The production of this seam connection begins with the creation of an angular standing seam, after which it is bent down 90°. To compensate for temperature deformations, a gap of 3 to 5 mm wide is left at the base of the folded structure.

Since in order to obtain a double profile it is necessary to increase the number of working operations, the time for installing the roof covering also increases accordingly. But these inconveniences are fully compensated by the reliability of a thoroughly closed seam - because it ensures the hermetic integrity of your roof during precipitation.

However, even such a strong joint will not save you from stagnant water on the roof, so the use of a double standing seam is permissible only on roofs with a slope of 10° or higher. It is believed that a special sealant can help the matter - a tape that is inserted into the fold before it is pressed with a seaming machine.

Rack and pinion

The slatted fold is essentially reminiscent of a double vertical fold, but, unlike it, it has a wider joining edge due to the use of a wooden block.

Electrical equipment, light, lighting

0 votes

+

Vote for!

—

Vote against!

The construction of buildings and work related to the creation of roofs require not only great physical effort from workers, but also the use of modern equipment, because creating roof seams is not an easy task. Roll forming equipment, including a self-made folding machine, can solve these problems. Let's take a closer look at this machine, its structure and principle of operation, and also try to assemble the structure ourselves.

Purpose of folding machine

Seam roofing is a roof covering that is formed from sheet or rolled metal by connecting the edges of the metal with a special seam called a seam. The use of seam seams ensures absolute waterproofness of the finished coating, because during its formation there are no through holes in the roofing material. Rebates are classified by compaction level and orientation. In the first situation, double and single connections are distinguished, in the second - standing, recumbent and corner.

Creating a waterproof double standing seam is possible manually using special equipment or in a modern way - an electromechanical seaming seaming machine. The main purpose of seam-rolling machines is to mechanize roofing work on the roof, which is made of steel.

Unlike the usual method of carrying out roofing work, when using a seam-rolling machine, the roof is obtained in the form of a roll, rather than individual sheets. The length of such a roll of steel is from the ridge to the cornice. Thus, if you have such a machine, you will be able to take advantage of all the advantages of modern construction technologies, for example, reduce the time of construction work by two to three times, increase labor productivity, and also reduce the number of transverse seams to a minimum.

Having small dimensions, folding machines allow them to be used directly on construction sites. Such construction equipment is capable of making a double and triple seam lock and achieving ideal geometry, which is problematic with the manual method of seam work. The panels are immediately produced with rolled stiffening ribs, which increase strength and improve the appearance of the roof. However, if the roof slope is large, the machine cannot be used.

Using folding machines, roofing patterns are formed that have standard rectangular, wedge-shaped and trapezoidal shapes. This equipment is used to create such products as roofing, air ducts, chimneys, flashings, slopes, beacons, drainpipe systems, C-shaped slats, W-shaped profiles, channels, angles, I-beams, elements of snap joints, various fastening seam connections ( corner, lying, standing, snap seam), stiffeners (trapezoid, semicircle), decorative bends of the roof. The most common type of joining the edges of sheets is considered to be a single folded fold.

Folding machines help produce different profiles along the edges of a workpiece or sheet of galvanized steel, including polymer-coated material. The raw material for folding machines is sheet or coiled metal made of thin-sheet low-carbon steel, stainless and galvanized, with a polymer and paint coating (plastisol, pural, polyester) and without coating, made of aluminum, copper and zinc-titanium.

Advantages of folding machines

Folding rolling equipment began its history in the distant sixties in Western countries, and today such machines are extremely popular. In the modern domestic market, equipment is mainly represented by foreign companies and is distinguished by high quality, high labor productivity and ease of operation. Among the shortcomings, the only things that stand out are the huge price of folding machines by Russian standards and their large size.

Folding rolling equipment has a lot of advantages and advantages over other similar installations:

- adaptability to the conditions of Russian construction sites;

- no damage to the material coating;

- high quality of manufactured panel paintings due to precise design and optimization of the configuration of profiling rollers;

- achieving straightness of the panels at the output;

- the presence of manual stepwise readjustment to the required width of the workpiece;

- Possibility of equipping with a manual cross-cutting knife;

- the possibility of additional installation of rollers, which are used for rolling stiffeners and arched paintings;

- ensuring high-quality rolled metal with polymer coating.

Design of folding mechanism

A folding machine is a mechanism that is designed for profile processing of the edges of sheet or coil metal for further creation of folded joints. Simply put, the device bends one of the edges of the steel to a certain configuration to make their connection. The use of this equipment contributes to the production of workpieces, the reliability and quality of which far exceeds the quality of analogues obtained through manual processing.

The seam-rolling roofing machine itself consists of a forming device, a bed and an electric drive. The bed is a welded metal structure on which six pairs of shafts are placed, which act as a forming device. Serves as a forming device for pulling a metal strip along the machine and forming stiffening ribs and the constituent elements of a double fold at its edges for a double locking connection. If you change the width of the metal strips, you can reconfigure the device to a new size.

The electric drive consists of an electric motor, a chain drive and a worm gearbox. An additional roller unwinding device can be installed on the folding machine, which is designed for mounting, unwinding and feeding rolled metal that weighs up to 1 ton. In addition, the machine can be equipped with crimping devices for connecting sheets into a single roofing sheet, which are profiled on the machine.

The movable device of the machine consists of 2 movable rods, which are rigidly connected to each other by a pressing square. The horizontal shelf of this square is made in the form of a wedge, under which a longitudinal strip is placed for crimping the edge of the roofing sheet into the longitudinal recess of the square. The guides for the rods are brackets and passages at the ends of the horizontal shelf. The movable device of the folding machine is held by springs in the upper position, in which a sheet can be inserted into the machine and removed after the edge bending process.

The profiling device is located on a steel tubular frame. The rollers are made of high quality special steel with a special finish that guarantees effective protection against the effects of corrosion. There are two types of crimping devices available - automatic and manual. The folding machine is equipped with four piano-type wheels, two of which have brakes to greatly facilitate transportation.

This design of a seam-rolling machine allows you to change equipment to work with metal that has different thicknesses, and to correct the bend of the edge when using a sealing tape when installing a seam roof. Additional equipment is considered possible to carry out roof installation with greater speed and simplify the procedure. This is facilitated by the installation of a control system, a circular saw for metal and a transverse manual circular knife.

The operation of a folding machine is characterized by such technical characteristics as the speed of profiling and the permissible thickness of sheet metal at the input. Different modifications of machines are capable of producing several types of seam joints, so it is recommended to order the required set of rolling rollers in advance.

Operating principle of folding machine

Before you make a folding machine, you should know how it works. The operating principle of the folding machine is based on roll technology, which makes it possible to produce roofing panels along the entire length of the slope and avoid unnecessary horizontal connections. Iron in rolls for roofing is much cheaper than sheet iron; it is convenient to lift it onto the roof and make pictures directly there. A roll of metal strip is placed on an unwinding device.

After pressing the “Start” button, which is located on the push-button panel, the electric motor is turned on, which transmits rotation through a chain transmission and gearbox to the shafts of the forming device. The end of the metal strip is fed along the machine guides to the 1st pair of forming rollers. The rollers grab the metal strip and pull it across the entire surface of the forming device. When a certain length of the formed sheet is reached, the folding machine is turned off by pressing the “Stop” button. To pull the molded sheets back, the design has a reverse.

After this, installers only need to connect the two parts. In addition to similar roofing work, lying seams made using seam benders are used to make sealed air ducts or drainpipes. Transportation of the machine is permitted in any position that does not allow mechanical damage to the controls and structure. Periodically, it is advisable to carry out preventative adjustments and lubricate working parts (chain, pressure shaft screw, chain tensioner, pressure shaft guides, gears).

Using a folding machine at home

Since the price of folding machines is quite high, it is customary to assemble the structure yourself at home. A homemade folding machine is installed on a workbench in such a way that the horizontal shelf of the square is placed in the same plane as the working surface of the machine. To bend the edges of a recumbent fold, a standard sheet must be laid on the machine so that the edge of its narrow side is flush against the stops. As a result of pressing the pedal, a small depression appears on the sheet. Using a staple, you need to turn the bending angle, bending the edge of the sheet to a given angle.

After bending the edges for the fold, you should release the pedal: the movable device rushes upward under the action of springs. The bending angle is simultaneously retracted to its original position. The sheet jumps off when the movable device is lifted from the pressing square. Then the sheet is turned over 180 degrees, and the fold edge is folded on the other side of the sheet in the same way. It is customary to assemble double paintings from single paintings made in this way. Assembly is done manually or using a folding machine.

A small manual folding machine is used to fold edges along the short side of a sheet. On the frame, which is made of angles, a clamping angle with a plate that is welded at the bottom is fixed. The clamping angle is raised and lowered with a pedal. A sheet of roofing steel is laid on the machine table and the short side is inserted under the clamping angle with the edge of the sheet extending outward to the width of the rebate to the stop pins that are on the bending bar.

By pressing the pedal with his foot, the roofer clamps the edge of the sheet with a corner and, then rotating the bending bar, bends the edges for a lying seam. The sheets prepared in this way are connected in pairs into patterns on a roller drive machine. In the center of the machine there are two rollers, one above the other, mounted on two shafts. The rollers are driven by an electric motor through a belt drive and gears. The roofer interconnects two sheets with bent edges and pushes them between the rollers that compact the rebated seam. Then the edges are folded back for a standing seam.

Corner seam joints are used when making roofing elements such as umbrellas and caps for chimneys, as well as when creating household equipment. They begin to connect two sheets with a simple corner fold, bending the edges at 90 degrees, and lay one of them on the plane of the sheet. Then a sheet is placed on the machine with the edge bent upward, which is inserted into the gap that is formed after the edge of the other sheet is turned up. The resulting ridge, after compaction, is dumped onto the surface of the first sheet.

To connect two sheets with a combined corner fold, the edge of the sheet that was moved from the machine is bent by 30° and a break is made in it. Then the sheet is turned over, and the resulting break is dumped onto the surface and the edge is bent, forming a double recumbent bend. The sheet with a double bend is then installed on the machine and the edge of the other sheet, which is previously bent, is inserted into the slot of the second bend. The vertical edge is finally folded on the bend of the first sheet onto the plane of the second sheet and compacted on a metal support on both sides. The width of the edges in sheets that are connected by corner folds depends on the level of sheet thickness.

We will analyze the sequence of operations when creating a double corner fold using the example of inserting a bottom into a rectangular box. Edges are drawn to the bottom according to the dimensions of the box to form folds and the corners are cut off. Along the dotted lines, after this, all the edges are bent at the bottom in one direction; narrow bends are made on the edges to the outer sides. The corners of the box are cut and the bottom is inserted into it. Place the bottom flaps on the sides of the box, using a mallet and a metal stop. Next, lay the box on the workbench, sequentially align all the edges of the single fold. The edges are finally edged onto the side walls of the box and then sealed.

When manufacturing various roofing elements and household equipment, owners have to connect parts not only using angular straight seams, but also curved seams, which are usually used to connect angled and round pipes. The design of a curved rebate is the same as a straight one. With a curved seam joint, an additional operation is flanging, which consists of expanding the folded edge due to thinning its thickness.

Without which installation is impossible: tools and equipment for seam roofing

The arrangement of a seam roof has its own characteristic features. The technology of joining metal sheets requires certain knowledge and skills, and the covering material requires significant, but very careful influence. Every craftsman who deals with folding professionally has his own tools, without which it is difficult, and sometimes simply impossible, to perform installation work first-class and quickly. Today we’ll talk about the necessary tools and mechanisms for this work, a general idea of which every developer should have, at least in order to determine the level of qualifications of the hired workers.

Minimum set of manual roofing tools

Good seam roofing roofers have in their arsenal several dozen different tools, the presence of which makes it possible to solve all sorts of problems. Hand tools are vital for installing horizontal seams and individual roofing elements, such as exposed pipes, vents, ridge sections, etc.

A basic set of manual roofing tools is as follows:

- Wedge-shaped or rectangular mallet;

- Scissors that allow you to cut metal both straight and at an angle;

- Seam hammer with short handle;

- Roofing mandrel required for bending sheet metal;

- Pliers that allow you to separate double folds (haps);

- Set of pliers;

- Rebated chalazen.

Tools and equipment for seam roofing

A good specialist has more than forty different tools in stock that are used when installing seam roofing. The standard roofer's kit includes:

When installing a seam roof, in addition to experience and skill, you will need a set of simple and easy-to-use tools, which determine the speed and quality of the work.

Video: hammer and mandrel

However, standard tools are still secondary, although necessary. Their role in creating a seam roof is not as great as that of those used for stamping panels and forming bending units - a seam machine and a seam rolling machine. Therefore, let us dwell in more detail on this equipment.

Video: tool for forming envelopes “Heron” when making junctions

DIY installation

For a standard connection of panels, you need to purchase a machine for rolling seams. Don’t bother replacing it with handy means, this may disrupt the technology and affect the quality of the entire roof. If there is no opportunity or desire to acquire a machine, a self-latching seam roof with edges on which a special lock has already been formed is used. This type of sheet simplifies installation and speeds up work several times. The lock consists of a locking tooth that is covered by a hook when one metal strip is placed over another. All that remains is to latch the system, which takes literally a few seconds.

Tools for work

To install a seam roof, you will need the following tools:

Fastening is done to a metal or wooden sheathing, continuous or in increments of no more than 40 cm. A waterproofing layer must be provided. Standard dimensions of sheets for installation of seam roofing:

Self-locking technology makes seam roofing generally more expensive, but ease of installation and guaranteed quality of connections lead to real savings in roof construction.

Current: copper roofing

Stainless steel is not always chosen as the coating material. Copper seam roofing has a long service life and durability due to the properties of this metal. At first it stands out with a characteristic shine, then it becomes covered with patina and acquires a noble shade. Copper does not deteriorate for hundreds of years; such a roof with a seam joint will become truly durable.

Fastening features: clamps

Regardless of the metal of manufacture, the rebate is divided into the following types:

Using clamps, panels of both types are installed: self-latching and using tools. A clamp in a seam connection allows you to attach metal panels to the sheathing completely unnoticeably. It comes in two types: movable and fixed. The first is used for sheets longer than 8 m, and the second for short sheets (up to 8 m). Direct fastening is done using a self-tapping screw with a press washer. The most reliable is the standing double seam. It is made by double bending the edges, thanks to which it differs in appearance: a characteristic convex longitudinal joint is obtained.

Installation features

The first and all subsequent panels are positioned with the bottom lock towards the next installation. The work is carried out from the bottom up, the distance between the longitudinal joints is 40 cm. There is no fundamental rule on which side to start installation from: left to right or right to left. The main thing is to respect the location of the lower lock. For metal sheathing, use self-tapping screws 4.8x20 mm, for wooden sheathing, 4.8x35 mm. If the sheathing is solid, fastening is carried out at a distance of at least 40 cm; if the sheathing is sparse, the fastening is done in each row. In places where sheets adjoin pipes and walls, a wall profile is used.

Machines for creating seam roofing

Seam rolling (bending, folding) machine is the main technical equipment for arranging seam roofing. He rolls metal roll or sheet material, transforming it into panels with specially curved edges - paintings.

Modern folding machines are small in size and weight, i.e. they are mobile, so they can be installed on the roof to speed up installation work and protect the finished panels from deformation during lifting.

The seam rolling machine for making roofing panels can be installed directly on the roof to simplify and speed up the work

Working with a folding machine requires certain qualifications, and it is quite expensive, so such equipment is only found among professionals. The fact that the roofers you hire have their own machine most likely means that they specialize in the manufacture of seam roofs and have sufficient experience in such work.

A high-quality and beautiful seam roof can only be created with extensive experience and special equipment, which only professionals have

A good roofing machine costs from 1 to 4 million rubles. depending on the model, productivity and additional functions - the presence of strip width control, an unwinder, a length counter, the ability to produce double folds, etc. Therefore, this equipment is often rented for the period of work. Folding machines from the German company Schlebach (Germany) are considered the most reliable and high-quality.

The main task of the seam rolling machine is to form a key joint and close the longitudinal seam using the molding method

Manufacturing of seam panels

Let's look at the production of paintings using the example of a modern mid-price rolling folding machine Schlebach Mini-Prof-Plus with standard equipment:

The Mini-Prof-Plus is a compact unit weighing 315kg, making it well suited for rooftop applications. In addition, the equipment with telescopic scissors allows the production of panels even when installed on an inclined plane. The quality of the rental is guaranteed by 7 pairs of rollers made of special steel, which make it possible to work with metal that has a protective polymer coating, and at the same time do not leave scratches or dents on it.

The Mini-Prof-Plus folding machine has a length controller, which makes it possible to roll roofing panels with centimeter precision, and manual cutting immediately before profiling

Operating principle of Mini-Prof-Plus:

At the exit from the machine, rolled or sheet iron is transformed into finished products with double seam

Video: making roofing pictures

For the production of self-latching seam panels, the SFP3 machine is used - inexpensive, silent and well-proven equipment, which can be used by two teams in several shifts at the same time.

The SFP3 machine makes it possible to produce panels with click-seam and perforations along the edges and ensures the loading of two teams at once

The paintings processed on this machine have ready-made strips with perforations for quick fastening of the canvases to the frame and stiffening ribs, thanks to which the strength of the roofing is significantly increased. SFP3 and similar models are convenient to use for arranging pitched roofs with an angle of inclination greater than 15°.

Click-seam roofing panels have a unique lock, the use of which does not require special tools during installation, which simplifies and speeds up roofing work without losing the quality and beauty of the seam structure

Video: roofing machine SFP3

To make roofing pictures when building a house with your own hands, you can use a sheet bender. It can be purchased at a price of 150 thousand rubles. for a simple manual model up to 5 million rubles. for a fully functional automatic machine with program control.

Purchasing a manual sheet bending machine can be quite justified if small-scale production of roofing panels is necessary.

You can make a sheet bending machine yourself. This will significantly facilitate and reduce the cost of manufacturing roofing panels when constructing a roof yourself. The process of assembling the sheet bender will be discussed in more detail below.

Production technology

The seam-rolling machine is indispensable both for arranging the seam roof itself and for the production of auxiliary roofing accessories. This includes elements of the drainage system, front and end roof overhangs, and it is also used to make galvanized ventilation ducts.

Types of folds

A seam connection is a twist between two adjacent sheets of metal, and in order to arrange this twist, you need to bend the fold along the edge of the sheet, and it is precisely to bend this fold that you need a seam rolling machine.

There are 2 folded joints - these are single and double folds, plus folds can be standing or lying.

The level of tightness depends on the choice of connection.

- A single fold is considered the basis, here one sheet is simply bent at 90º, and on the second sheet a kind of hook is made and after joining this hook is crimped;

- A double fold can be called an analogue of a single fold, only the twisting is done in 2 turns. To wrap the metal this way, the size of the hook in the workpiece must be smaller, on average about 5-7 mm, and the height of the workpiece must be, on the contrary, larger.

As for the recumbent connection options, they are exactly the same as the standing ones, only turned to one side.

Nowadays, L-shaped roofing seams are quite common; there is no practical benefit from such a connection, it is no better or worse than a double bend, but many believe that the roof looks much more impressive this way.

The L-shaped rebate looks especially good on rounded radii.

When selecting equipment, keep in mind that there are machines for arranging recumbent folds, standing folds and universal units that can be adjusted as necessary to any type of bend.

General information about machines

The main advantage of a seam roof is that the covering is monolithic, without any fastening or connecting holes. But the roofing metal itself is quite thin and making blanks in production and then transporting them to the site is inconvenient and often unrealistic.

A small folding machine makes a big difference. With such equipment, you can make blanks directly on site; moreover, there are models that can be installed directly on the roof.

There is one more important nuance: to bend the edges of sheets, you need a folding machine, and to make a double fold and crimp the connection, bringing it to the final result, a folding machine is used.

The seam settling machine significantly reduces the time of roof installation.

Often, the thickness of metal for roofing works ranges from 0.5-1 mm, with a maximum of 1.2 mm. But a good machine for standing seam roofing is designed to work with metal from 0.3 to 1.5 mm.

Such equipment is already closer to professional, and it can be used to make not only roofing paintings, but also to bend blanks for various kinds of drainage or ventilation pipes, plus make valley gutters and ridge caps.

By the way, the blank for a seam roof (a strip of roofing metal with curved seams) is called “Picture” among professionals.

The very principle of operation of the unit is simple: any folding machine has a number of crimping shaped rollers, which actually bend the edges of the sheet. Crimping rollers are installed in pairs on crimping shafts.

A manual folding machine is well suited for amateur use.

The number of such crimping shafts may be different, but no matter how many there are, they are driven by a gearbox, and the gearbox itself rotates thanks to an electric motor. There is, of course, manually operated equipment, but the productivity there is very low and such devices are rare.

Folding machines

The second most important type of equipment needed to create a seam roof is seam seaming machines. They are divided into several categories.

Hand tools

Manual folding machines are often called frames or haps. They form a double standing seam in two steps. The work, of course, is labor-intensive, but the manual mechanism has one undeniable advantage - it can be used on highly sloping roofs and in hard-to-reach places where an automated device will not fit. Therefore, in addition to modern equipment, a serious team of roofers must have a folding handbrake.

The manual folding mechanism allows you to obtain a high-quality seam in hard-to-reach areas of the roof where the use of electrical devices is impossible

Video: Manual tool for closing double standing seam

Semi-automatic folding machines

Semi-automatic folding machines are installed at the beginning of the future seam and pulled with a cable, leaving behind a double folded connection. The use of semi-automatic machines ensures high installation speed compared to the manual method, as well as careful treatment of the protective polymer layer of the metal. Semi-automatic folding machines are most effective when laying long paintings.

Semi-automatic seaming devices are most effective when creating double seam seams on long panels

Video: operation of a semi-automatic folding device

Automatic folding devices

Electric designs for rolling seam seams are based on modern technologies that minimize the human factor when creating seam seams and greatly increase labor productivity. The mechanism of use is very simple - the device is installed in the proper place and turned on. The machine, moving in a given direction, itself connects the workpieces with a double fold. The result of their use is a durable and perfectly flat seam roof in record time.

Electric seaming machines, with virtually no human intervention, join roofing panels with a double standing seam, creating a high-quality seam in one pass.

Video: Wuko folding machine

Unfortunately, in the domestic market the choice of automatic electric folding machines is limited. The products of the famous German company Schlebach are represented by only three models:

The first one costs 337 thousand rubles, and the rest - about half a million. The folding mechanisms of the Austrian brand Wuko are not much cheaper - the only Wuko 1006 series can be purchased for 210 thousand rubles. Naturally, such perfect technical equipment can only be found among real professionals.

Reliability, longevity, quality and the undeniable attractiveness of standing seam roofing is a union of advanced technologies and installation skills, which is based on the knowledge, experience, tools and equipment necessary to perform such work. That is why their high cost is fully justified, which more than pays for itself in the further operation of the seam roof due to the absence of the need for special care and repairs.

Source

Folding machines: for large and small areas

For the production and installation of seam roofing, a mobile roofing machine is required. It is produced for renting paintings and closing double folds:

For example, such machines are produced in Russia, although such Western analogues as Wuko lock'n'rolle are also in demand.

To work with the roof of an ordinary private country house, it also makes sense to use modern equipment, which significantly improves the final quality of the roof. But for some reason, most teams still work the old fashioned way, using a traditional mallet and hammer.

It’s better to rent the necessary tools for a few days, and then the seams on the roof will be perfectly smooth and reliable. Moreover, the machine is usually capable of producing seam roofing from any roofing metal, be it copper, steel or aluminum.

So, let's take a closer look at what this tool is. Today, folding machines on the Russian market are provided by seven major manufacturers. This indicates the possibility of a good choice.

For example, an electric folding machine joins and closes profiled panels with a double standing seam. Moreover, she does this in one pass, quickly moving along the seam directly on the roof.

Advice: when choosing such a tool for yourself, it is better to give preference to a domestic one, since it is designed to withstand possibly careless handling during operation, and therefore has a more durable body and protection from moisture penetration.

Keep in mind that European folding machines are usually designed for a fold height of 25 mm, and American equipment is designed for 38 mm. Therefore, it is necessary to calculate in advance the compatibility of various equipment.

The fact is that for some machines you can adjust the height of the legs, while for others you will have to separately order such legs for 38 mm (and this is an additional cost). By the way, for small manual machines the issue of rebate height is not important.

Mobile equipment is installed directly on the roof and solid panels are made for double standing seams. Here it is important to purchase a really high-quality machine.

Otherwise, installers manage to cut the panels lengthwise into several parts, and then join these parts with rivets, which is absolutely wrong. This results in roofs made from expensive materials such as zinc or copper, but with big problems in terms of airtightness.

Here is an example of how such a machine works:

Mechanical folding machines are cheaper, but you will also work slower with them. There is also always a human factor - the risk of simply not pressing the fold.

The set of Mobiprof machines includes two machines for joining panels with a double standing seam. With a slight movement, you need to move the first machine in order to make L-shaped folds, and then the second machine to form the folded lock itself.

These machines have a special adjustment for the degree of clamping of the fold, which is very important for working with different types of metal. In this case, the seams are closed quite quickly, almost the same as with electromechanical machines.

The Wuko lock'n'rolle device is used to close rebates and double standing seam panels. It is convenient for them to work in any direction, but they will have to hold the machine itself with both hands, like a plane. Among the advantages we can name low price and weight.

Separately, we note such a seam-rolling machine as the Wuko 1006. It is small and light, and, perhaps, the only one that can be used for installing roofs of complex shapes, which have many junctions and transitions. The machine itself covers single and double L-shaped standing seams well.

It differs in its design from other models in that it has a special closing mechanism - a special hammer, which seems to tap the fold (while all other models press this fold with rollers). This is noticeable in his work: such a machine moves slowly, sometimes leaving marks on the metal. But it works great on any type of joint.

Let us note separately that quite a lot of folding machines were originally designed to work with expensive ductile metals. They are not suitable for rolling high-hardness galvanized steel.

There is also special equipment for making seam roofing on radius rafters. These are car models that differ from each other in terms of the minimum roof radius. Therefore, if you buy the wrong machine, you will also have to arm yourself with hand-held roofing tools to finish off the seams.

Look what all these cars look like: