GOST R 9.316-2006 Unified system of protection against corrosion and aging (USZKS). Thermal diffusion zinc coatings. General requirements and control methods (as amended)

NATIONAL STANDARD OF THE RUSSIAN FEDERATION

Unified system of protection against corrosion and aging

THERMODIFUSION ZINC COATINGS

General requirements and control methods

Unified system of corrosion and aging protection. Thermodiffusion zinc coatings. General requirements and control methods

OKS 25.220.40 77.060

Date of introduction 2007-07-01

Preface

The goals and principles of standardization in the Russian Federation are established by Federal Law No. 184-FZ of December 27, 2002 “On technical regulation,” and the rules for applying national standards of the Russian Federation are GOST R 1.0-2004 “Standardization in the Russian Federation. Basic provisions"

Standard information

1 DEVELOPED AND INTRODUCED by the Technical Committee for Standardization TC 213 “Metal and other inorganic coatings” and TC 214 “Protection of products and materials from corrosion”

2 APPROVED AND ENTERED INTO EFFECT by Order of the Federal Agency for Technical Regulation and Metrology dated September 21, 2006 N 204-st

3 INSTEAD GOST R 51163-98

Information about changes to this standard is published in the “National Standards” index, and the text of changes and amendments is published in the monthly published “National Standards” information indexes. In the event of revision or cancellation of this standard, the corresponding notice will be published in the published information index “National Standards”. Relevant information, notifications and texts are also posted in the public information system - on the official website of the Federal Agency for Technical Regulation and Metrology on the Internet

An amendment was made, published in IUS No. 2, 2007

The amendment was made by the legal bureau "Code"

Introduction

Thermal diffusion galvanizing of product surfaces is intended to increase their corrosion resistance.

Thermal diffusion zinc coating is anodic in relation to ferrous metals and electrochemically protects steel from corrosion. It has strong adhesion (adhesion) to the base metal due to the mutual diffusion of iron and zinc in the surface intermetallic phases, so the coating does not peel off or chip under impacts, mechanical loads and deformations of the processed products. GOST 9.302-88 does not establish a test method for assessing the adhesion of thermal diffusion zinc coatings. The methods for testing the adhesion strength of zinc coatings established in GOST 9.302-88 are widely used and recommended for assessing the adhesion strength between different layers of thermal diffusion zinc coating, however, in some cases other tests may be more acceptable, which should be established in agreement with the consumer.

The advantage of thermal diffusion coating technology compared to galvanic coatings is not only its superior corrosion resistance, but also the fact that it does not cause irreversible hydrogen embrittlement of the metal during the application process (directly in the container). Treatment of the product before and after coating must exclude the possibility of hydrogen embrittlement. Hydrogen embrittlement in high-strength steel products must be excluded, therefore, when this requirement is specified by the consumer, the absence of hydrogen embrittlement is determined in accordance with the requirements of this standard.

Thermal diffusion zinc coating precisely follows the contours of the products; it is uniform in thickness over the entire surface, including products of complex shapes and threaded connections.

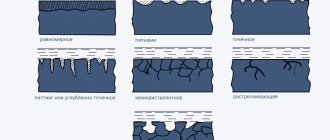

Thermal diffusion zinc coating mainly consists of an iron-zinc -phase of variable composition containing up to 10% iron.

Due to the presence of iron impurities on the surface of the coating, when exposed to high humidity or condensation, a brown coating may appear on the surface of a galvanized product, which is not a sign of the appearance of foci of corrosion of the base metal. In order to preserve decorative properties and further increase corrosion resistance, parts coated with thermal diffusion galvanizing are subjected to subsequent additional surface treatment. Additionally, post-treatment of zinc coatings is designed to slow or prevent the formation of white corrosion products on surfaces exposed to high humidity atmospheres, salt water, marine atmospheres or cycles of condensation and drying.

Appendix A (for reference). Quality control of the prepared surface

Appendix A (reference)

A.1 To control the quality of the prepared surface of the product before coating, from 2% to 5% of the total number of samples, but not less than four products, are taken from the batch. Single products and structures (brackets, consoles, supports, blocks of rigid crossbars) are subjected to complete control.

A.2 Fasteners are controlled for the necessary tolerance for coating using a standard die, nut and other devices specified in the technological documentation.

A.3 Methods for quality control of the prepared surface - according to GOST 9.402.

TYPES AND THICKNESS OF COATINGS

2.1. When choosing coatings you should consider:

purpose of fittings;

purpose of the coating (protective - for internal parts or protective and decorative - for others);

material;

operating conditions for the fittings are U1.1 and UHL(HL)1.1 according to GOST 15150.

2.2. The choice of the type and thickness of the protective and protective-decorative coating is carried out in accordance with the table.

| Main material | Type of coverage | Designation and coating thickness, microns, not less | |

| Shoe accessories | Accessories for leather goods, sewing, textile and haberdashery products and universal | ||

| Steel | Nickel bright | Nb6 or N6.b | Nb31 |

| Nb62 or N6.b2 | |||

| Nb9 or N9.b | |||

| Nb153 or N15.b3 | |||

| Nickel semi-shiny | Npb64 | Npb62.4 | |

| Npb94 | |||

| Nickel matte | H6.m | H9.m | |

| Semi-shiny nickel, followed by paint coating | Npb3/lkp | Npb.3/lkp | |

| Nickel black with nickel underlayer | N6.N.h | N6.N.ch2 | |

| N9.N.ch | |||

| Nickel black with a nickel underlayer with partial polishing of the front surface (finishing in the color of blackened silver) | N6.N.ch.mp (blackened silver color) | N6.N.ch.mp | |

| (blackened silver color2) | |||

| N9.N.ch.mp | |||

| (blackened silver color) | |||

| Nickel black with a copper underlayer, protected with colorless varnish | M6.N.ch/varnish5 | M6.N.ch/varnish5 | |

| Nickel black with an underlayer of copper with partial polishing of the front surface, protected with colorless varnish (finishing in the color of old copper) | M6.N.h.mp/varnish (old copper color) | M6.N.h.mp/lacquer5 (old copper color) | |

| Nickel polished, tinted, protected with clear varnish | Nb6.tn/lac5.6 | Nb6b.tn/lac5,6 | |

| Nickel bright, chemically or electrochemically oxidized, protected with clear varnish | Nb6.ox.tsv/varnish5.6 | Nb6.ox.tsv/varnish5.6 | |

| Nickel black with an underlayer of copper and nickel, protected with colorless varnish | M6.Nb3.N.ch/varnish5 | M6.Nb3.N.ch/varnish5 | |

| Nickel polished with partial paint coating | Nb6/lkp5 | Nb6/lkp2.5 | |

| Nb9/lkp5 | |||

| Semi-shiny nickel with partial paint coating | Npb6/lkp3 or | Npb6/lkp2.5 or N6.m/lkp2.5 | |

| N6.m/lkp3 | Npb9/lkp5 or N9.m/lkp5 | ||

| Nickel black with an underlayer of nickel and copper with partial polishing of the front surface, protected with colorless varnish (finish to match the color of old copper) | N3.M6.N.ch.mp/varnish5 | N3.M6.N.ch.mp/varnish5 | |

| (old copper color) | (old copper color) | ||

| Nickel black with a nickel underlayer, protected with colorless varnish | N6.N.ch/varnish5 | N9.N.ch/varnish5 | |

| Nickel black with a zinc sublayer, protected with colorless varnish | Ts6.N.ch/varnish5 | N6.N.ch/varnish5 | |

| Nickel polished with a sublayer of shiny copper | M3b.Nb3 | M3b.Nb6 | |

| Semi-shiny nickel with copper underlayer | M3.Npb34 or M3.N3.m4 | M3.Npb64 or M3.N6.m4 | |

| Nickel shiny with copper underlayer | — | M6.Nb3 | |

| Nickel polished, protected by colored lacquer | Nb3.tsv/varnish5,6 | Nb3.tsv/varnish5,6 | |

| Nickel matt with partial paint coating | Nb.m/LKP4.5 | Н6.м/лкп4.5 | |

| Nickel black with copper sublayer | M6.N.h | M6.N.h | |

| Titanium nitride, deposited by ion-plasma method, with a sublayer of shiny nickel | Nb6.titanium nitride, color 6 | Nb6.titanium nitride, color 6 | |

| Copper with a nickel underlayer, chemically oxidized black, with partial polishing of the front surface, protected with colorless varnish | N3.M6.ox.h.mp/lacquer5 | N3.M6.ox.h.mp/lacquer5 | |

| Shiny copper with a nickel underlayer, tinted, protected with colorless varnish | N3.M6.b.tn/lac5.6 | N3.M6.b.tn/lac5.6 | |

| Copper shiny, tinted, protected with clear varnish | Mb6.tn/lac5,6 | Mb6.tn/lac5,6 | |

| Copper shiny, protected with clear varnish | M6.b/lacquer5 | M6.b/lacquer5 | |

| Copper, chemically oxidized black, protected with clear varnish | M6.ox.h/varnish5 | M6.ox.h/varnish5 | |

| Copper, chemically oxidized black, with the front surface partially polished, protected with clear varnish (finish to match the color of old copper) | M6.ox.h.mp/varnish | M9.ox.h.mp/varnish | |

| (old copper color) | (old copper color) | ||

| Semi-shiny copper protected with clear varnish | M6.pb/lacquer4.5 | M6.pb/lacquer4.5 | |

| Copper, chemically oxidized, with partial polishing of the front surface, protected with clear varnish, with partial enamel coating (finish in the color of old copper) | M6.ox.mp/lkp5 | M6.ox.mp/lkp5 | |

| Copper, electrochemically oxidized | M6.ox. | M6.ox. | |

| Bright copper with an underlayer of shiny nickel, protected with colorless varnish | Nb3.M3.b/lac5 | Nb3.M6.b/lac5 | |

| Shiny copper, obtained from pyrophosphate or cyanide electrolytes, with a copper underlayer, tinted, protected with colorless varnish | M3.pyrophosphate.M3.b.tn/varnish5,6 | M3.pyrophosphate.M6.b.tn/varnish5,6 | |

| or M3.cyanide.M3.b.tn/varnish5,6 | or M3.cyanide.M6.b.tn/varnish5,6 | ||

| Copper with partial polishing of the front surface, protected with colorless varnish | M6.mp/lac5 | M6.mp/lac5 | |

| Made of bright copper-zinc alloy with a shiny nickel sublayer, protected with colorless varnish | Nb3.M-Ts(70)3.b/lacquer5 | Nb3.M-Ts(70)3.b/lac5 or | |

| Nb6.M-Ts(70).b/varnish5 | |||

| Made of shiny copper-zinc alloy, protected with colorless varnish | M-Ts(70)3.b/varnish5 | M-Ts(70)6.b/lacquer5 | |

| Made of copper-zinc alloy with an underlayer of copper and shiny nickel, protected with colorless varnish | M3.Nb3.M-C(70)/lacquer5 | M3.Nb3.M-C(70)/lacquer5 | |

| Made of copper-zinc alloy (brass), with an underlayer of copper and shiny nickel, tinted, protected with colorless varnish | M3.Nb3.M-Ts(70).tn/varnish5.6 | M3.Nb3.M-Ts(70).tn/varnish5.6 | |

| Made of copper-zinc alloy (brass), chemically oxidized black with partial polishing of the front surface, protected with colorless varnish | M-C(70)6.ox.h.mp/varnish | M-C(70)6.ox.h.mp/varnish | |

| Bright chrome with bright nickel sublayer | Nb6.H.b | Nb6.H.b2 | |

| Nb9.H.b | |||

| Shiny chrome with copper and nickel underlayer | M3.Nb3.H.b2 | M3.Nb3.H.b2 | |

| M3.Nbb.H.b | |||

| Shiny zinc with colorless chromate plating | Ts6.b.khr.btsv. | Ts9.b.khr.btsv. | |

| Zinc with rainbow chromate | — | Ts9.hr | |

| Zinc, chemically or electrochemically oxidized black, protected with clear varnish | Ts6.ox.h/varnish5 | Ts9.ox.h/varnish5 | |

| Shiny zinc, protected with clear varnish | Ts6.b/varnish5 | Ts9.b/lacquer5 | |

| Zinc, chemically or electrochemically oxidized black, with the front surface partially polished, protected with clear varnish (blackened silver finish) | Ts6.ox.h.mp/varnish | Ts6.ox.h.mp/varnish | |

| (blackened silver color) | (blackened silver color) | ||

| Zinc, colorless chromated, protected with clear varnish | Ts6.khr.btsv/varnish5 | Ts9.khr.btsv/varnish5 | |

| Zinc with paint coating | Ts3/lkp5 | Ts3/lkp5 | |

| Zinc, chemically oxidized black, with partial polishing of the front surface | — | Cb.ox.h.mp8 | |

| Zinc with paint coating | — | Ts6/lkp5.8 | |

| Chemical oxide black, protected with clear varnish | Chemical Ox.h/varnish5 | Chemical Ox.h/varnish5 | |

| Chemical oxide black with paint finish | Chemical Ox.ch/LKP5 | Chemical Ox.ch/LKP5 | |

| Chemical phosphating with paint coating | Chem.Phos./LKP5 | Chem.Phos./LKP5 | |

| Oxide colored, hot-processed, protected with clear varnish | Hor.Ox.color/varnish5,6 | Hor.Ox.color/varnish5,6 | |

| Oxide, hot-processed, with paint coating | Gor.Ox/LKP5 | Gor.Ox/LKP5 | |

| Oxidized, hot-processed, protected with clear varnish | Hor.Ox/varnish5 | Hor.Ox/varnish5 | |

| Paintwork | Lkp5 | Lkp5 | |

| Chemical oxide black, oil impregnated | Chem.Ox.p.prm7 | Chem.Ox.p.prm7 | |

| Oxide black, hot-processed, oil-impregnated | Hor.Ox.ch.prm7 | Chem.Ox.p.prm7 | |

| Brass | Nickel bright | Nb3 | Nb6 |

| Nickel semi-shiny | Npb34 | Npb64 | |

| Nickel polished, tinted, protected with clear varnish | Nb3.tn/lac5,6 | Nb6.tn/lac5.6 | |

| Nickel polished with partial paint coating | Nb6/lkp5 | Nb6.lkp5 | |

| Nickel black with a nickel underlayer with partial polishing of the front surface, protected with colorless varnish | N3.N.ch.mp/lac5 | N3.N.ch.mp/lac5 | |

| Nickel black with nickel underlayer | N3.N.ch. | N6.N.ch. | |

| Copper followed by partial polishing, protected with clear varnish | — | M3.mp/lac5 | |

| Copper, chemically oxidized black with partial polishing of the front surface, protected with clear varnish (finish to match the color of old copper) | M3.ox.h.mp/lac5 | M6.ox.h.mp/lacquer5 | |

| (old copper color) | (old copper color) | ||

| Nickel black, protected with clear varnish | N.p/varnish5 | N.p/varnish5 | |

| Nickel black with partial mechanical polishing of the front surface, protected with colorless varnish | N.ch.mp/lac5 | N.ch.mp/lac5 | |

| Chemical oxide, followed by diamond surface treatment, protected with varnish | Chemical Ox.alm/varnish5 | Chemical Ox.alm/varnish5 | |

| Chemical oxide black, with partial polishing of the front surface, protected by clear varnish (finish in the color of old copper) | Chem.Ox.h.mp/varnish5 | Chem.Ox.h.mp/varnish5 | |

| (old copper color) | (old copper color) | ||

| Oxide, hot-processed, with partial polishing of the front surface, protected with clear varnish (finish in the color of old bronze) | Hor.Ox.mp/lacquer5 | Hor.Ox.mp/lacquer5 | |

| (old bronze color) | (old bronze color) | ||

| Chemical oxide, black protected with clear varnish | Chemical Ox.h/varnish5 | Chemical Ox.h/varnish5 | |

| Chemical oxide colored, with partial polishing of the front surface, protected with clear varnish | Chem.Ox.tsv.mp/varnish5,6 | Chem.Ox.tsv.mp/varnish5,6 | |

| Chemical oxide colored, protected with clear varnish | Chemical Ox.color/varnish5,6 | Chemical Ox.color/varnish5,6 | |

| Oxide, obtained by chemical passivation, protected with colorless varnish | Him.Pas/varnish5 | Him.Pas/varnish5 | |

| Oxide, obtained by chemical passivation, with paint and varnish coating | Him.Pas/LKP5 | Him.Pas/LKP5 | |

| Oxide, obtained by chemical passivation on a matte surface, protected with clear varnish | mt.Khim.Pas/varnish5 | mt.Khim.Pas/varnish5 | |

| Chemical oxide with paint coating | Chem.Ox/LKP5 | Chem.Ox/LKP5 | |

| Oxide, obtained by chemical passivation on a mechanically polished surface, protected with colorless varnish | mp.Khim.Pas/varnish5 | mp.Khim.Pas/varnish5 | |

| Oxide, obtained by chemical passivation on a chemically polished surface, protected with colorless varnish | hp.Him.Pas/varnish5 | hp.Him.Pas/varnish5 | |

| Oxide, obtained by chemical passivation on an electrochemically polished surface, protected with colorless varnish | ep.Chem.Pas/varnish5 | ep.Chem.Pas/varnish5 | |

| Chemical oxide with partial surface polishing, protected with clear varnish, with partial paint coating | Chem. Okay. mp/lac5 | Chem.Ox.mp/lacquer5 | |

| Oxidized, obtained by chemical tinting, protected with clear varnish | tn/lac5,6 | tn/lac5,6 | |

| Lacquered on a chemically polished surface, protected with clear varnish | HP/varnish5 | HP/varnish5 | |

| Lacquered on an electrochemically polished surface, protected with clear varnish | ep/varnish5 | ep/varnish5 | |

| Varnish on a mechanically polished surface | mp/lac5 | mp/lac5 | |

| Paintwork on a mechanically polished surface | mp/lkp5 | mp/lac5 | |

| Paintwork | Lkp5 | Lkp5 | |

| Aluminum and its alloys | Anodic oxide transparent shiny, filled in water | An.Oksb.nv | An.Ox6.b.nv |

| Anodic-oxide transparent shiny, filled in a dye solution | An.Oxb.tsv6 | An.Ox6.b.tsv6 | |

| Anodic-oxide transparent shiny, filled in water, with partial paint coating | An.Oksb.nv/lkp5 | An.Oksb.b.nv/lkp5 | |

| Anodic-oxide transparent shiny, filled in a dye solution, with partial paint and varnish coating | An.Oxb.tsv/LKP5,6 | An.Ox6.b.nts/LKP5,6 | |

| Nickel bright | Nb6 | Nb6 | |

| Copper, chemically oxidized, with partial polishing of the front surface, protected with clear varnish (finish in the color of old copper) | — | M6.oke.mp/lac | |

| (old copper color) | |||

| Copper, shiny, protected with clear varnish | — | M6.b/lacquer5 | |

| Copper, chemically oxidized, with partial surface polishing, protected with clear varnish | M6.ox. mp/varnish | M6.ox.mp/varnish | |

| Varnish on a mechanically polished surface | mp/lac5 | mp/lac5 | |

| Anodic-oxide transparent, filled in water, followed by diamond surface treatment | An.Ox.nv.alm | An.Ox6.nv.alm | |

| Anodic-oxide, filled in a dye solution, followed by surface treatment | An.Ox.col.alm6 | An.Ox6.color.alm6 | |

| Anodic-oxide, filled in water, with partial enamel coating | An.Ox.nv/lkp5 | An.Ox6.nv/lkp5 | |

| Anodic-oxide, filled in a dye solution, with partial enamel coating | An.Ox.tsv/LKP5,6 | An.Ox6.tsv/LKP5,6 | |

| Anodic-oxide transparent shiny, obtained on a chemically polished surface, filled in water | xp.An.Ox.b.nv | xp.An.Ox6.b.nv | |

| Anodic-oxide transparent, shiny, obtained on an electrochemically polished surface, filled in a dye solution | zpAn.Ox.b.tsv6 | zp.An.Ox6.b.nv6 | |

| Anodic-oxide transparent, shiny, obtained on a chemically polished surface, filled in a dye solution | xp.An.Ox.b.tsv6 | xp.An.Ox6.b.tsv6 | |

| Anodic-oxide transparent, shiny, obtained on an electrochemically polished surface, filled in water | ep.An.Ox.b.nv | zp.An.Oks6.b.nv | |

| Anodic-oxide transparent shiny, obtained on a chemically polished surface, filled in water, with partial paint coating | xp.An.Ox.b.nv/lkp5 | HP An.Ox6.nv/lkp5 | |

| Anodic-oxide transparent shiny, obtained on an electrochemically polished surface, filled in water, with diamond processing of the front surface | ep.An.Ox.b.nv.alm | ep.An.Ox6.b.nv.alm | |

| Anodic-oxide transparent shiny, obtained on an electrochemically polished surface, filled in water, with partial paint coating | ep.An.Ox.b.nv/lkp5 | ep.An.Ox6.b.nv/lkp5 | |

| Anodic-oxide transparent shiny, obtained on a chemically polished surface, filled in a dye solution, with partial paint coating | xp.An.Ox.b.tsv/lkp5,6 | hp.An.Ox6.b.tsv/lkp5,6 | |

| Anodic-oxide transparent shiny, obtained on an electrochemically polished surface, filled in a dye solution, with partial paint coating | ep.An.Ox.b.tsv/LKP5,6 | ep.An.Oxb.b.tsv/LKP5,6 | |

| Anodic-oxide transparent shiny, obtained on a chemically polished surface, filled in a dye solution, with a partial paint coating (finish in the color of blackened silver) | xp.An.Ox.b.nv/lkp5 | xp.An.Ox6.b.nv/lkp5 | |

| (blackened silver color) | (blackened silver color) | ||

| Anodic-oxide transparent shiny, obtained on an electrochemically polished surface, filled in water, with a partial paint coating (finish in the color of blackened silver) | ep.An.Ox.b.nv/lkp5 | ep.An.Ox6.b.nv/lkp5 | |

| (blackened silver color) | (blackened silver color) | ||

| Anodic-oxide transparent, obtained on a chemically polished surface, filled in a dye solution, with partial paintwork (finishing in the color of old bronze) | xp.An.Ox.tsv/LKP5,6 | hp.An.Ox6.tsv/lkp5,6 | |

| (old bronze color) | (old bronze color) | ||

| Anodic-oxide transparent, obtained on an electrochemically polished surface, filled in a dye solution with partial paint coating (finishing in the color of old bronze) | ep.An.Ox.tsv/LKP5,6 | ep.An.Oxb.tsv/LKP5,6 | |

| (old bronze color) | (old bronze color) | ||

| Nickel black with a nickel underlayer, with partial polishing of the front surface (finish to match the color of blackened silver) | N6.N.ch.mp | N6.N.ch.mp | |

| (blackened silver color) | (blackened silver color) | ||

| Copper, chemically oxidized, with partial polishing of the front surface, protected with colorless varnish, followed by diamond surface treatment | M6.oke.mp/lac.alm | M6.ox.mp/lac.alm | |

| Zinc alloys | Semi-shiny nickel on copper-zinc alloy (brass) | M-C(70)3.N.pb64 | M-C(70)3.Npb94 |

| Nickel bright | Nb6 | Nb9 | |

| Nickel semi-shiny | Npb64 | Npb94 | |

| Nickel bright on copper-zinc alloy (brass) | M-C(70)3.Nb6 | M-C(70)3.Nb9 | |

| Bright nickel with shiny copper sublayer | M6.b.Nb6 | M6.b.Nb6 | |

| Nickel shiny with copper underlayer | — | M6.Nb3 | |

| Nickel black with an underlayer of copper and shiny copper with partial polishing of the front surface, protected with clear varnish (finish in the color of old copper) | M6.M3.b.N.ch.mp/lac5 | — | |

| (old copper color) | |||

| Nickel black with an underlayer of copper and shiny nickel | M6.Nb3.N.ch. | — | |

| Nickel black with an underlayer of copper and shiny nickel, protected with colorless varnish | M6.Nb3.N.ch/varnish5 | M6.Nb3.N.ch/varnish5 | |

| Nickel black with an underlayer of copper and shiny nickel with partial polishing of the front surface (finishing in the color of blackened silver) | M6.Nb3.N.ch.mp | M6.Nb6.N.ch.mp | |

| (blackened silver color) | (blackened silver color) | ||

| Nickel black with an underlayer of copper and shiny nickel with partial polishing of the front surface, protected with colorless varnish (finish to match the color of blackened silver) | M6.Nb3.N.ch.mp/lac5 | M6.Nb3.N.ch.mp/lac5 | |

| (blackened silver color) | (blackened silver color) | ||

| Chrome shiny | X6.b | X9.b | |

| Nickel black with partial polishing of the front surface, protected with clear varnish (finish to match the color of blackened silver) | N.ch.mp/varnish | — | |

| (blackened silver color) | |||

| Nickel shiny, tinted, on a copper-zinc alloy (brass), protected with colorless varnish | M-Ts(70)3.Nb6.tn/lac5 | M-Ts(70)3.Nb6.tn/lac5 | |

| Nickel shiny, tinted, on copper, protected with clear varnish | M6.Nb6.tn/lac5 | M6.Nb6.tn/lac5 | |

| Made of copper-zinc alloy (brass), chemically oxidized, with partial polishing of the front surface, protected with clear varnish (finish in the color of old bronze) | M-C(70)6.ox.mp/lacquer5 | M-C(70)6.ox.mp/lacquer5 | |

| (old bronze color) | (old bronze color) | ||

| Made of copper-zinc alloy (brass), shiny, protected with colorless varnish | M-Ts(70)6.b/lacquer5 | M-Ts(70)6.b/lacquer5 | |

| Made of copper-zinc alloy (brass) shiny with an underlayer of copper and shiny nickel, protected with colorless varnish | M3.Nb3.M-C(70).b/varnish5 | M3.Nb3.M-C(70).b/varnish5 | |

| Semi-shiny zinc with colorless chromating on copper-zinc alloy (brass) | M-Ts(70)3.Nb6.tn/lac5 | M-Ts(70)3.Nb6.tn/lac5 | |

| Semi-shiny zinc with iridescent chromating on copper-zinc alloy (brass) | M-Ts(70)3.Ts6.pb.hr7 | M-Ts(70)3.Ts6.pb.hr7 | |

| Semi-shiny zinc with colorless chromating, protected with clear varnish | Ts6.pb.khr.btsv/varnish5 | Ts6.pb.khr.btsv/varnish5 | |

| Semi-shiny zinc with iridescent chromating, protected by clear varnish | Ts6.pb.hr/varnish | Ts6.pb.hr/varnish | |

| Copper, electrochemically oxidized | M6.ox | M6.ox | |

| Copper, chemically oxidized, protected with clear varnish | M6.ox.h/varnish5 | M12.ox.h/varnish5 | |

| Bright chrome with bright nickel sublayer | Nb6.Hb | Nb9.Hb | |

| Nbb.Hb2 | |||

| Copper, chemically oxidized with partial polishing of the front surface, protected with clear varnish (finish to match the color of old copper) | M12.ox.h.mp/lacquer5 | M12.ox.h.mp/lacquer5 | |

| (old copper color) | (old copper color) | ||

| Copper, chemically oxidized with partial polishing of the front surface, protected with clear varnish, with partial enamel coating (finish in the color of old copper) | M6.ox.mp/lac5 | M6.ox.mp/lac5 | |

| (old copper color) | (old copper color) | ||

| Copper shiny with a copper underlayer, tinted, protected with clear varnish | M6.M6.b.tn/lac5 | M6.M6.b.tn/lac5 | |

| Oxide, chemically produced, protected with clear varnish | Chemical Ox/varnish5 | Chemical Ox/varnish5 | |

| Oxide, obtained by chemical phosphating, followed by paint and varnish coating | Chem.Phos./LKP | Chem.Phos./LKP | |

| Oxide, chemically produced, with partial polishing of the front surface, protected with colorless varnish (finish in the color of blackened silver) | Chem.Ox.mp/lacquer5 | Chem.Ox.mp/lacquer5 | |

| (blackened silver color) | (blackened silver color) | ||

| Chrome shiny | — | X9.b | |

| Copper shiny | M6.b | — | |

| Zinc bright with subsequent chromate plating | — | Ts9.B.hr7 | |

| Made of copper-zinc alloy, tinted, protected with clear varnish | M-Ts(70)9.tn/lac5 | M-Ts(70)9.tn/lac5 | |

| Copper shiny, tinted, protected with clear varnish | M6.b.tn/lac5,6 | M6.b.tn/lac5,6 | |

| Paintwork | Lkp5 | Lkp5 | |

| Plastic | Bright nickel with an underlayer of chemically produced copper, matte copper and shiny copper | Chemical M.M6.m.M3.b.Nb6 | Chemical M.M6.m.M3.b.Nb6 |

| Nickel shiny with an underlayer of chemically produced copper, matte copper and shiny copper, tinted, protected with colorless varnish | Chemical M.M6.m.M3.b.Nb6.tn/varnish5.6 | Chemical M.M6.m.M3.b.Nb6.tn/varnish5.6 | |

| Nickel black with an underlayer of chemically produced copper, matte copper, shiny copper and shiny nickel | Chemical M.M6.m.M3.b.Nb6.N.ch | Chemical M.M6.m.M3.b.Nb6.N.ch | |

| Nickel black with an underlayer of chemically produced copper, matte copper, shiny copper with partial polishing of the front surface (finish to match the color of blackened silver) | Chem.M.Mb.m.M3.b.Nbb.N.ch.mp | Chemical M.Mb.m.M3.b.Nb6.N.ch.mp | |

| (blackened silver color) | (blackened silver color) | ||

| Nickel black with an underlayer of chemically produced copper, matte copper and shiny copper | Chemical M.M6.m.M6.b.N.ch | Chemical M.M6.m.M6.b.N.ch | |

| Nickel black with an underlayer of chemically produced copper, matte copper and shiny copper with partial polishing of the front surface, protected with colorless varnish (finish to match the color of old copper) | Chem.M.M6.m.M6.b.N.ch. mp/lacquer5 (old copper color) | Chemical M.M6.m.M6.b.N.ch | |

| mp/lacquer5 (old copper color) | |||

| Nickel shiny with an underlayer of chemical nickel matte obtained by bulk processing | Chem.N.Npb3.Nb6 | Chem.N.Npb3.Nb6 | |

| Nickel black with an underlayer of chemically produced nickel, matte nickel, shiny copper, with partial polishing of the front surface, protected with colorless varnish (finish to match the color of old copper) | Chem.N.Npb3.M6.b.N.ch. | Chem.N.Npb3.Mb.6.N.ch. | |

| mp/lacquer5 (old copper color) | mp/lacquer5 (old copper color) | ||

| Bright nickel with an underlayer of chemically produced nickel, matte copper and shiny copper | Chemical N.M3.m.M6.b.Nb3 | Chemical N.M3.m.M6.b.Nb6 | |

| Nickel black with an underlayer of chemically produced nickel, matte copper, shiny copper and shiny nickel | Chemical N.M3.m.M6.b.Nb3.N.ch. | Chemical N.M6.m.M3.b.Nb6.N.ch. | |

| Nickel black with an underlayer of chemically produced nickel, matte copper, shiny copper and shiny nickel with partial polishing of the front surface (finish to match the color of blackened silver) | Chemical N.M3.m.M6.b.Nb3.N.ch.mp | Chemical N.M6.m.M3.b.Nb6.N.ch.mp | |

| (blackened silver color) | (blackened silver color) | ||

| Nickel shiny, with an underlayer of chemically produced nickel, matte copper and shiny copper, tinted, protected with colorless varnish | Chemical N.M3.m.M6.b.Nb3.tn/varnish5.6 | Chemical N.M6.m.M3.b.Nb6.tn/varnish5.6 | |

| Nickel black with an underlayer of chemically produced nickel, matte copper and shiny copper | Chem.N.M6.m.M6.b.N.ch. | Chem.N.M6.m.M6.b.N.ch. | |

| Nickel black with an underlayer of chemically produced nickel, matte copper, shiny copper, with partial polishing of the front surface, protected with colorless varnish (finish to match the color of old copper) | Chem.N.M6.m.M6.b.N.ch. | Chem.N.M6.m.M6.b.N.ch. | |

| mp/lacquer5 (old copper color) | mp/lacquer5 (old copper color) | ||

| Shiny copper with an underlayer of chemically produced copper, matte copper and shiny copper, tinted, protected with colorless varnish | Chemical M.M6.m.M6.b.tn/varnish5.6 | Chemical M.M6.m.M6.b.tn/varnish5.6 | |

| Shiny copper with an underlayer of chemically produced copper, matte copper and shiny copper, chemically oxidized, protected with colorless varnish | Chemical M.M6.m.M6.b.ox/varnish5 | Chemical M.M6.m.M6.b.ox/varnish5 | |

| Shiny copper with an underlayer of chemically produced nickel, matte copper and shiny copper, protected with colorless varnish | Chemical N.M6.m.M6.b/varnish5 | Chemical N.M6.m.M6.b/varnish5 | |

| Shiny copper with an underlayer of chemically produced nickel, matte copper and shiny copper, tinted, protected with colorless varnish | Chemical N.M6.m.M6.b.tn/varnish5.6 | Chemical N.M6.m.M6.b.tn/varnish5.6 | |

| Nickel black with an underlayer of chemically produced nickel, matte copper and shiny nickel, with partial polishing of the front surface (finish to match the color of blackened silver) | Chem.N.M6.m.Nb.6.N.ch.mp | Chem.N.M9.m.Nb.6.N.ch.mp | |

| (blackened silver color) | |||

| (blackened silver color) | |||

| Bright nickel with an underlayer of chemically produced nickel and bright copper | Chemical N.M6.b.Nb6 | Khim.N.M9.b.Nb6 | |

| Bright nickel with an underlayer of chemically produced nickel, matte nickel, tinted, protected with colorless varnish | — | Chemical N.N6.m.Nb6.tn/varnish5.6 | |

| Nickel black with an underlayer of chemically produced nickel, bright copper and bright nickel | Chem.N.Mb.6.Nb.6.N.ch. | Chem.N.Mb.9.Nb.6.N.ch. | |

| Shiny nickel with an underlayer of chemically produced nickel and matte nickel | — | Chem.N.N9.m.Nb6 | |

| Nickel black with an underlayer of chemically produced nickel, shiny copper, with partial polishing of the front surface, protected with colorless varnish | — | Chemical N.M12.b.N.ch.mp/lacquer5 | |

| Shiny copper with an underlayer of chemically produced nickel, tinted, protected with colorless varnish | — | Khim.N.M12.b.tn/varnish5,6 | |

| Shiny copper with an underlayer of chemically produced nickel, protected with colorless varnish | — | Khim.N.M12.b/varnish5 | |

| Nickel black with an underlayer of chemically produced nickel, shiny copper and shiny nickel, with partial polishing of the front surface, protected with colorless varnish | — | Chemical N.M9.b.N6.b.N.ch.mp/varnish5 | |

| Bright nickel with an underlayer of chemically produced nickel, matte copper, shiny copper and shiny nickel, oxidized, protected with colorless varnish | — | Chemical N.M6.m.M3.b.N6.b.ox/varnish5 | |

| Nickel black with an underlayer of chemically produced nickel and shiny copper | — | Chem.N.M9.b.N.ch. | |

| Nickel shiny with an underlayer of chemically produced nickel, matte copper, tinted, protected with colorless varnish | — | Chemical N.M6.m.Nb6.tn/varnish5.6 | |

| Nickel black with an underlayer of matte copper, shiny copper and shiny nickel | M6.m.M3.b.Nb6.N.ch9 | M6.m.M3.b.Nb6.N.ch9 | |

| Nickel black with an underlayer of matte copper, shiny copper and shiny nickel with partial polishing of the front surface (finishing in the color of blackened silver) | Mb.m.M3.b.Nb6.N.ch.mp9 | M6.m.M3.b.Nb6.N.ch.mp9 | |

| (blackened silver color) | |||

| (blackened silver color) | |||

| Nickel shiny with an underlayer of matte copper and shiny copper | M6.m.M3.b.Nb69 | M6.m.M3.6.Nb69 | |

| Shiny copper with an underlayer of matte copper, chemically oxidized, protected with colorless varnish | M6.m.M6.b.ox/varnish5.9 | M6.m.M6.b.ox/varnish5.9 | |

| Shiny copper with an underlayer of matte copper, chemically oxidized with partial polishing of the front surface, protected with colorless varnish (finish to match the color of old copper) | M6.m.M6.b.ox.mp/lacquer5.9 | M6.m.M6.b.ox.mp/lacquer5.9 | |

| (old copper color) | |||

| (old copper color) | |||

| Shiny copper with an underlayer of matte copper, protected with colorless varnish | M6.m.M6.b/varnish5.9 | M6.m.M6.b/varnish5.9 | |

| Nickel black with an underlayer of matte copper and shiny copper, protected with colorless varnish | M6.m.M6b.N.h/varnish5.9 | M6.m.M6b.N.h/varnish5.9 | |

| Nickel black with an underlayer of matte copper and shiny copper, protected with colorless varnish (finish in the color of old copper) | M6.m.M6.b.N.ch.mp/varnish5.9 | M6.m.M6.b.N.ch.mp/varnish5.9 | |

| (old copper color) | |||

| (old copper color) | |||

| Nickel shiny with an underlayer of matte copper and shiny copper, tinted, protected with colorless varnish | M6.m.M3.b.Nb6.tn/varnish5.9 | Mb.m.M3.b.Nb6.tn/lac5.9 | |

________

1 Used to cover keys for suitcases and business briefcases.

2 Used to cover accessories for wallets, school bags and backpacks, as well as provided that the roughness parameter ( Ra

) on the front surface before coating is not more than 0.16 microns.

3 Used for fittings manufactured by order of the USSR Ministry of Defense.

4 Used by agreement with the consumer.

5 The brand of paint and varnish coating and the regulatory and technical documentation for it are indicated.

6 Instead of the designation “color” and after the designation “tn” the color of the coating is indicated.

7 Used for internal parts, as well as upon customer request.

8 Used for buttons.

9 The electrically conductive sublayer is not regulated.

2.3. Technological processes for producing metallic and non-metallic inorganic coatings in accordance with GOST 9.305.

2.4. Designation of coatings according to GOST 9.306.

2.5. Maximum thickness of metal coatings according to GOST 9.303.