Manufacturing of bent channel

Published on July 20, 2013 Category: Mechanics |

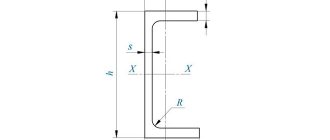

2 comments The production of double sequential “V”-shaped flexible bent channel on sheet bending machines (press brakes) from rectangular sheet blanks is one of the most widely used technologies for single and small-scale production.

. bent profiles in mechanical engineering and construction.

In this short article we will briefly look at the technological process of manufacturing a bent channel and perform calculations in Excel of some important, in my opinion, technological dimensions.

The manufacturing technology of a bent channel is shown in four figures below.

1.

Place the workpiece by pressing it against the working surface of stop No. 1.

2.

Press the pedal of the sheet bender and make the first bend.

3.

Let's reinstall the semi-finished product by pressing it against the working surface of stop No. 2.

4.

Let's press the pedal of the sheet bender - make the second bend - the channel is ready!

Corner bending methods

Several basic methods are used to obtain structures of a given shape and profile from a metal corner, namely:

- cold bending,

- hot bending,

- shaping by cutting, bending and welding the finished product.

Cold bending of a metal corner, in turn, is divided into:

- free bending is when the corner is bent without the use of special equipment;

- bending using a rolling mechanism on a specialized profile bending machine.

The use of cold bending of a metal corner, unlike other methods, has certain advantages, namely:

- this is the least expensive method of giving metal a given shape, and does not require the use of additional equipment for heating, cutting, welding and subsequent processing of the metal;

- the resulting frame has greater strength, since it eliminates possible defects characteristic of heating, cutting and welding;

- finished structures are guaranteed to last longer due to the fact that the integrity of the metal profile structure is preserved during processing;

- the likelihood of metal corrosion occurring over time is reduced.

Basic methods of bending beams and channels

The channel, like its closest relative - the I-beam, can be bent in three directions: along the flanges, that is, in the horizontal plane, and along the walls (vertically).

In the latter case, bending can be carried out with the shelves inward or outward. According to the characteristics of the deformation that the workpiece acquires, smooth bending and local bending are distinguished. The result of a smooth part is a curved part with one or more radii. With a simpler, local one, a profile is formed with straight ends joined at the desired angle (usually by welding). The advantage of smooth channel bending is that it does not violate the integrity of the workpiece and does not have welds, which, despite their strength, become “vulnerable zones.”

And finally, according to the technology used, bending can be manual or automatic. Manual is performed according to a pre-drawn radius template. When working with hard materials such as steel, an acetylene torch is used to heat the bending zone. This operation can be carried out even in a garage, but a high-quality result is not guaranteed.

In contrast to this semi-handicraft method, automatic bending of the channel on profile benders helps to avoid heating the workpiece, and due to the system of rollers that the profile passes through, the radius can be maintained as accurately as possible. This method is also distinguished by its versatility, efficiency and the possibility of mass processing of workpieces.

Bend a corner radius

Bending a metal corner along a radius is a rather complex technological operation, since any bending is a simultaneous compression of the inner and stretching of the outer layer of metal, and, in the case of a profile in the form of a corner, such processes cannot proceed evenly, which will be accompanied by an attempt to longitudinally displace one from these layers.

Directly for a metal corner, two main methods of bending in the profile plane are used - this is when one of the shelves lies in a vertical plane, and the other in a horizontal one, and its bending will be:

- inside the radius of curvature of the deformation, in which case it will be greatly compressed,

- outside the radius of curvature of the deformation, accordingly, it will stretch.

Cold bending of a metal corner using the rolling method on special profile bending equipment allows you to bend both a steel corner and an aluminum profile, thereby obtaining products of almost any radius with an ideal shape.

You can see how to bend a corner along a radius with your own hands in this video.

It is worth keeping in mind that for both hot and cold bending methods there are maximum radius values that directly depend on the size of the corner flanges and its thickness. So, you can simply calculate the radius by which it is permissible to bend a corner, according to the following values:

- the permissible radius for an equal-flange corner must be a minimum of 45 times the width of the shelf;

- for an unequal-sided profile, the permissible radius cannot be less than 45 times the width of the shelf for a larger shelf and 50 for a smaller one.

But it is better and easier to be guided by the values given in the tables.

Tables of the minimum permissible bending radii of steel angles depending on the type, size and ratio of the shelves

Features of bending an I-beam

An I-beam is a standard profile that bends only radially (smoothly). Depending on the purpose of the deformed product, two types of work are distinguished:

- flat bending (for example, for rails);

- edge bending (for load-bearing structures).

I-beam bending is performed only on profile bending machines. The “on edge” method requires special machines that prevent the sides from collapsing and maintain the profile cross-section.

The smallest bending radius depends on the profile dimensions and is set by the machine manufacturer. The process is carried out by analogy with a channel with any type of beams (column or wide-flange).

To ensure that the workpiece does not turn out crooked, careful monitoring of each stage of work by the operator of the unit is necessary. Although modern machines do not require human participation in operations, they will not be able to affect the rigidity of the structure if the initial parameters are set incorrectly. Therefore, work on the machine is performed smoothly, preferably in leisurely approaches. If you need to obtain the minimum radius for a specific I-beam, it is better to divide the bending process into several stages.

At home, bending an I-beam is hardly possible. This is a dimensional and durable profile that will not be taken by devices for bending the same aluminum profile. The method described in the section “Bending a channel at home” will also not work, because the shelves extend on both sides of the transverse segment. If you make a cut on two parallel shelves, bending will cause the other two to break. If the latter are pre-cut, the structure of the material will be disrupted, and the I-beam will cease to perform its load-bearing function.

The tips above will help beginners bend a metal channel or I-beam. In many cities of the country there are enterprises that are ready to perform the described work on roll forming machines. Contacting them is much more profitable than buying equipment with your own money. Bending a channel at home is not difficult if you have the right tool at hand. If you know other ways to smoothly or locally bend profiles, share your skills in the comments to the article.

How to bend a corner into a ring with your own hands

To do this, it is best to use the hot method of metal processing. But you can achieve a given radius only with the help of a pre-prepared template. We preheat the metal and begin to bend the template evenly, while the horizontal shelf must be adjusted during the entire bending process using a sledgehammer or hammer, otherwise the shelves will not maintain the original angle of 90 degrees to each other.

It is necessary to heat the metal to half the value of its melting point, so, for example, an aluminum corner will have to be heated to at least 250⁰ C, and a steel profile - to 600⁰ C. To do this, you will need a natural gas burner or a gasoline blowtorch, and it is best to use welding acetylene cutter if the corner is large.

Using an angle grinder and a welding machine, you can also bend a steel corner into a ring, but for this you need to make fairly accurate calculations, mark and outline the sectors to be removed, bend and weld the seams. Unfortunately, no matter how hard you try, in this case you will end up with a circle in the form of a rounded polyhedron.

How to bend a channel radius?

Best regards, Vyacheslav

Best answers

On the left ring - 20 cuts, on the right - 40 cuts, modeled in Corel on a scale of 1:1 25 mm or centimeters? 25 mm can be bent without any cuts...

AutoCAD won't draw it itself. Similar things can be found in the Handbook of Mechanical Designers, for example by Anuriev. All sector sizes, radii and clearances are given there. If you don’t find a reference book, draw it to scale and determine the number of cuts on the drawing, taking into account the gaps for the welds.

To protect against bending, on the convex side, it is also necessary to weld several stops along the bend.

Of course you can, but you also need to know the discreteness.

Can be bent with cuts. But I myself saw how they bent the rail only by heating it with a cutter.

-answer

This video will help you figure it out

Answers from experts

Notch the grinder, then weld the joints. Unless, of course, there is a factory nearby

You definitely can't do it with your hands

On rollers. By heating. With cuts. In short, no problem.

A barbell. On two articulated supports. You can estimate the weight by calculating

The radius of the arc is in the STUDIO. And - which way should I bend it? Towards the stiffeners, or towards the base? Or, even towards one rib. Options - from “Only with welding” to “Throw on the supports and jump”

Depends on the radius.. Tips - from rollers to cutters..

How to bend something that was deliberately given the geometry of inflexibility? Obviously only by deforming this something, or by making a composite product. Read SP 16.13330.2011 Steel structures.

There are special machines

The truck frame spar has a complex configuration and is designed not only for bending, but also for torsion. Stamping is the simplest and most technologically advanced method, namely from strip. The same applies to trailers and semi-trailers. In Russia, everything is usually simplified to the level of a cart.

Most likely because it is much easier to buy sheet metal and bend it into a channel shape yourself. It will be much cheaper than buying rolled profiles, and even cheaper than buying a bent profile outright. Apparently the design load allows this.

It's cheaper that way. And it is quite enough.

1. Perhaps they are not satisfied with the standard profile, they need their own non-standard shelf height size, for example 107mm. 2. Perhaps they are not satisfied with the thickness of the wall, it is approximately two times thinner than the shelves, for example, shelf No. 14 has a 10mm wall and a 6mm wall. If you also process it, it will be very thin, there will be little allowance. Such thin walls do not provide strength or rigidity; the designer laid a bent strip. 3. It might be cheaper. 4. Perhaps someone from the supply department receives kickbacks for this (buying a strip in a certain place, well, shares with whomever it is necessary, of course)

5. Perhaps the design documentation and technology are outdated and not technologically advanced, and there is no desire or opportunity to make changes due to the fact that this will lead to other changes in the design, etc.

Sorry, but channel bars are widely used for simple, no-bend truck frames. In other cases, it is easier to stamp a spar of a complex shape than to make it from a channel.

At 90 degrees

Almost all buildings have a rectangular shape, so the most common action with corners is the need to bend them at 90 degrees.

Bend the corners 90 degrees for the future frame is quite simple. First you need to make a development in the place of the future fold. To do this, mark two corners on one of the shelves in different directions from the normal, 45 degrees each, and cut them out with a grinder. Carefully and slowly bend the corner and weld the cut area using electric welding; it is recommended to preheat the bend area so that the second shelf does not crack or break during bending.

Acceptable design dimensions for correctly marking and bending metal corners at 90 degrees are shown in the table:

Today, many DIYers use aluminum for almost everything. Its characteristics allow it to be used without any problems for furniture, for creating garage accessories, etc.

Tsvetprokat aluminum corner offers to purchase on the most favorable terms. This publication will describe various techniques that will make it possible to bend aluminum without damaging it. If you start bending an aluminum part mechanically, cracks may appear in the metal and the part will simply break at the bending point.

How to bend a channel radius

Channels and I-beams are standard profiles and are used in a number of areas where increased demands are placed on the rigidity of structures made from them. It is more difficult to give curvilinearity to strong workpieces with a U- or H-shaped cross-section. To bend a channel or I-beam, you will need special equipment. Next - about specific ways to give profiles a non-standard shape.

Features of channel bending

The channel is symmetrical only along a conventional horizontal plane. This complicates its bending, which is performed in three directions:

If you bend a metal channel along the shelves using special equipment, the risk of deformation of the shelves is eliminated. In the second case, their distortion is possible due to the increased pressure of the working element of the equipment.

There are three types of U-shaped channel bending:

At home, it is almost impossible to bend a channel smoothly - this requires profile bending machines, which are very bulky and expensive. The local bending method is used by many amateurs who need a bent profile for certain purposes. Moreover, for this, a couple of tools are enough, which a real craftsman always has at hand.

Using a homemade rolling machine

A homemade machine can be made from everything you have at hand:

Everything, of course, depends on the dimensions of the aluminum profile itself, as well as on the required bending radius. Such homemade machines allow you to achieve very positive results, in principle, without heating the part.

Success is achieved through gradual, slow bending over a large area. As a result, local stresses do not arise in the metal. You can be sure that cracks will not appear.

However, there is an easier way. All you need is a gas burner and large pieces of wood. Initially, it should be noted that you will not get the expected result the first time. To understand the technique, it is recommended to practice cutting the profile.

Channel bending methods

The advantage of the smooth method is that it preserves the integrity of the workpiece. There will be no welding seams on the channel, which will preserve its strength characteristics and corrosion resistance. Channel bending is carried out slowly, gradually, until the product takes on the required shape.

There are the following ways to smoothly bend a profile:

- Manual. You will need a gas cutter or an acetylene torch and a template made of a sheet of metal on which the radius of the intended bend is drawn. Restrictors are welded to the sheet. One end is fixed with a vice. The profile section is heated and bent close to the limiters. The latter can also be welded on the convex side so that the deformable workpiece holds its shape better.

- Machine tool. Units whose task is to bend a dimensional channel are called profile benders. They are also suitable for other types of profiles. The operation of making a workpiece convex/concave is called rolling. The metal passes through large rollers fixed at a certain distance and is deformed. The advantages of the method are the ability to do without heating the workpiece, speed of operation, versatility (there are machines for the largest channels), bending accuracy. Disadvantages are the impressive size of the equipment and high cost. Roll benders are used only in enterprises producing rolled metal or similar products.

Profile bending with a gas torch

Using a gas torch, it is necessary to heat the aluminum profile exactly at the bending point and next to it. The main heat of the flame should be concentrated at the point of bending.

After the required temperature has been reached and the profile has become noticeably more plastic, a steel metal pipe of suitable diameter is applied to the bending metal. Strictly speaking, its outer diameter will be equal to the bending diameter of the aluminum profile.

It is necessary to work with thick gloves, as the metal becomes very hot. Leaning the pipe against the profile, we begin to carefully bend it. Apply jerky, soft movements (you don’t have to constantly pull the profile to bend).

We watch the place of bending. If we see a change in color, continue heating with a gas burner. The final result will be achieved much faster than using homemade rolling machines.

The video demonstrates how you can bend an aluminum profile at home:

Metal landing.

Sheet metal bending, called upsetting, is used in cases where one sheet must overlap the edge of another sheet (Fig. 1).

Channel bending at home

Construction workers probably wondered how to bend this profile. In garage conditions, only local bending is possible, since there is hardly room for a bulky machine. To work, you will need a welding machine, as well as a grinder with both types of discs.

The sequence of work is as follows:

This method is the only correct one that will allow you to bend a metal channel without the use of expensive equipment.