We recommend purchasing:

Installations for automatic welding of longitudinal seams of shells - in stock!

High performance, convenience, ease of operation and reliability in operation.

Welding screens and protective curtains are in stock!

Radiation protection when welding and cutting. Big choice. Delivery throughout Russia!

Composition, structure and purpose of steels

The most common steels of the austenitic-ferritic class include steel types 08Х22Н6Т, 12Х21Н5Т, 03Х23Н6, 08Х18Г8Н2Т, 08Х21Н6М2Т, 03Х22Н6М2. The microstructure of chromium-nickel steel 08Х22Н6Т and chromium-nickel-molybdenum steel 08Х21Н6М2Т is shown in Fig. 18.1. The amount of austenant and ferritic phases in steels of this class usually ranges from 40-60%. The chemical composition of austenant-ferritic steels is given in Table 18.1, mechanical properties - in Table. 18.2.

Austenitic-ferritic steels have relatively high yield and strength limits and satisfactory ductility and impact toughness, as well as high corrosion resistance and good weldability. This makes it possible to reduce the specific metal consumption in the manufacture of chemical equipment designed for strength, due to a decrease in sheet thickness. According to the state diagram Fe-Cr-Ni alloys have some characteristic features; the region of existence of a two-phase austenitic-ferritic structure in them is in the temperature range 20-1350 ° C; when steel is heated above a temperature of 1100 ° C, austenite transforms into ferrite and the more intensely, the higher the temperature and duration of heating , at temperatures above 1200 °C, a complete γ→α transformation occurs; upon subsequent cooling, the reverse transformation of ferrite into austenite occurs. The final ratio of the number of structural components depends on the cooling rate of the steel. During isothermal exposure in the temperature range of 700–800 °C, the formation of a brittle component of the σ phase is possible in steel. Austenitic-ferritic steels are supplied in a hardened state at temperatures of 950–1050 °C. The difference in Cr and Ni content between the austenite and ferrite phases is 2–5%. Austenitic-ferritic steels lose toughness when heated in the temperature range 450-650 ° C. This is due to the fact that the brittleness caused by the precipitation of carbides is enhanced by the action of the so-called 475 ° brittleness.

The approximate purpose and operating temperature of austenitic-ferritic steels are shown in Table 18.3.

Physico-chemical properties of stainless steels

Austenitic steels

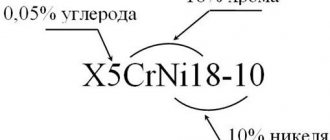

During crystallization, austenitic steels form a single-phase system with a face-centered crystal lattice. One of the most prominent representatives of the class is alloy 08Х18Н10. Due to the high nickel content in stainless steels of this class (up to 30%), the austenite phase remains stable down to – 200 °C, and the carbon content does not exceed 0.12%. Steels with this structure are characterized by the absence of magnetic properties. Most of them have good machinability.

Austenitic steels are necessarily subjected to heat treatment - hardening, tempering or annealing. The cooling rate practically does not change the hardness, but it affects the resistance to liquid and gaseous aggressive media, stabilizes the grain size and resistance to deformation.

Additional elements are introduced into the alloying systems of austenitic chromium-nickel steels:

- molybdenum – to prevent pitting and operation in reducing atmospheres

- titanium and niobium – for protection against intercrystalline corrosion.

- silicon – to increase acid resistance;

- manganese - to improve casting qualities.

Ferritic steels

This class includes chromium steels with low carbon content. They have a body-centered cubic lattice, which determines their magnetic properties. Ferritic steels have lower corrosion resistance compared to austenitic steels and cannot be strengthened by heat treatment, but have higher technological properties. They are easier to machine and weld better, and their cost is significantly lower. At temperatures of 300 – 400 °C, steels acquire high ductility, and they can be used to produce volumetric stamped parts of complex shapes.

The chromium content in such steels reaches 27%. Molybdenum, titanium and aluminum are used as stabilizing additives.

Martensitic steels

Alloys of this class contain at least 0.15% carbon and 11% chromium. Martensite has a microscopic needle-like structure and, when magnified, looks the same as carbon steel after hardening. The crystal lattice has a tetragonal shape and is characterized by high internal stresses. This determines high strength properties and hardness. For example, for 40X13 it is up to 52 - 55 HRC. Molybdenum, niobium, vanadium and tungsten are introduced as additional alloying elements. Martensitic steels, due to their high hardness, are difficult to cut and have low ductility.

One of the main technological properties of corrosion-resistant steels with this structure is the ability to self-harden. Martensitic transformation occurs upon cooling in air. To increase heat resistance, steel after hardening is tempered with sorbitol or troostite.

Weldability of steels

Austenitic-ferritic steels are characterized by an increased tendency to grain growth in the heat-affected zone when exposed to the welding thermal cycle. Along with the growth of ferrite grains, the total amount of ferrite increases. Subsequent rapid cooling fixes the resulting structure. The grain size and amount of ferrite, as well as the width of the overheating zone, depend on the heat input of welding, the ratio of structural components in the initial state and the sensitivity of the steel to overheating. The ratio of the number of structural components (γ- and α-phases) in the initial state largely depends on the Ti content in the steel. The amount of titanium in the steel also determines the stability of the austenite phase against the γ→δ transformation during welding heating. The higher the Ti content, the more sensitive the steel is to overheating (Fig. 18.2). Due to grain growth and a decrease in the amount of austenite, a decrease in the impact toughness of the metal in the heat-affected zone and the bending angle of welded joints of austenitic-ferritic steels are observed. Steels that do not contain Ti are less sensitive to welding heating—these are steels 03Х23Н6 and 03Х22Н6М2.

Welding technology and joint properties

Austenitic-ferritic steels can be welded using both manual and mechanized electric arc welding, as well as other welding methods (electron beam, electroslag), plasma arc, etc.). Welding methods with low heat input are preferable. The welding technique and modes of austenitic-ferritic steels do not differ from those generally accepted for the entire class of stainless steels. When choosing types of seams for welded joints, it is recommended to be guided by GOST 5264-69, GOST 8713-70, GOST 14771-69, OST 26-291-71 and enterprise standards. Preparation of edges for all types of welding is carried out mechanically in order to eliminate the occurrence of heat-affected zones (HAZs), which reduce the regulated properties of welded joints. Welding materials used for welding austenitic-ferritic steels are given in table. 18.4 and 18.5. The joint seams made with the specified welding materials have an austenitic-ferritic structure. The amount of ferrite phase in welds is 15–60% and depends not only on the welding materials used, but also on the share of the metal being welded in the weld metal, and on fluctuations in the chemical composition within the grade. The highest percentage of ferrite phase in the seams is observed during automatic submerged arc butt welding without cutting edges using Sv-06Kh21N7BT wire. Due to the high ferrite content, the seams are sufficiently resistant to the formation of hot cracks. Changing the content of the ferrite phase in the weld due to alloying or heat treatment leads to a significant change in its mechanical properties. The yield and strength limits with sufficiently high ductility and toughness of the weld reach a maximum when the percentage of austenite and ferrite phases in it is equal.

Mechanical properties of welded joints

Mechanical properties of seams and joints made with welding materials specified in table. 18.4 and 18.5 are given in table. 18.6. Analysis of the mechanical properties shows that the highest strength of welds during automatic submerged arc welding of chromium-nickel austenitic-ferritic steels can be obtained by using Sv-06Kh21N7BT (EP500) wire, and for chromium-nickel-molybdenum steels - using Sv-06Kh20N11MZTB (EP89) wire. The combination of sufficiently high strength and ductility is achieved when using Sv-03Kh21N10AG5 (EK-91) wire for automatic submerged arc welding of chromium-nickel austenitic-ferritic steels, and Sv-03Kh19N15G6M2AV2 (ChS-39) wire for chromium-nickel-molybdenum steels. It is preferable to use these wires when welding steel of significant thickness (>10 mm) end-to-end, without cutting edges. To improve the ductility of welded joints of austenitic-ferritic steels, if the dimensions of the products allow, heat treatment can be carried out - hardening from 1000 °C with cooling in water.

Method for determining the ferrite phase content in a product

Usage: can be used to control the ferrite phase content in austenitic and austenitic-ferritic steels of mechanical engineering equipment, including welded joints and surfacing. The essence of the invention: a method for determining the content of the ferrite phase, according to which a local measurement of the content of the ferrite phase in the base metal, welds and surfacing of equipment is carried out using a magnetic method, for which the content of the ferrite phase is first measured on a reference sample at various levels of its loading, the voltage and change are recorded content of the ferrite phase, establish the relationship between voltage and the change in the content of the ferrite phase, determine the magnitude of the voltage acting in the controlled zone of the equipment, after which the content of the ferrite phase in the controlled zone of the equipment is measured and a correction is made to the obtained value for the voltage value in accordance with the relationship between voltage and changing the content of the ferrite phase. Technical result: the ability to obtain comparable values of the ferrite phase content in different laboratories by eliminating the error caused by not taking into account the voltage operating in the controlled area.

The invention relates to the field of monitoring the ferrite phase content in austenitic and austenitic-ferritic steels of mechanical engineering equipment, including welded joints and surfacing.

A metallographic method for determining the content of the ferrite phase is known. (Industry instructions for determining the content of the ferrite phase in the deposited metal of welding and surfacing materials, welds of austenitic stainless steels and anti-corrosion surfacing of equipment and pipelines of nuclear power plants. AOI-6-83. Ministry of Energy and Electrification of the USSR. M. 1984, p. 9). The disadvantages of this method are the impossibility of non-destructive testing, the need for an atlas of the microstructures of the controlled metals with different amounts of ferrite, the subjectivity of the operator’s assessment, the dependence on the technology of etching the section and the diameter of the field of view of the microscope. A volumetric magnetic method of monitoring the ferrite phase using a ferritometer is also known (Control of the ferrite phase with welding of equipment and pipelines of thermal power plants and nuclear power plants. Issue 1. Thermal power plants, district heating and heating networks. Series 1. Energy and electrification. M. INFORMENERGO, 1986, p. 3). The disadvantages of this method are the need to cut samples from the controlled metal and the impossibility of carrying out non-destructive testing of the ferrite phase in the base metal, welds and surfacing directly in equipment. The closest, adopted as a prototype, can be considered a local magnetic method for determining the content of the ferrite phase. (Industry instructions for determining the content of the ferrite phase in the deposited metal of welding and surfacing materials, welds of austenitic stainless steels and anti-corrosion surfacing of equipment and pipelines of nuclear power plants. AOI-6-83. Ministry of Energy and Electrification of the USSR, M. 1984, p. 8). The disadvantage of this method is that it does not take into account the influence of mechanical stresses on the content of the ferrite phase. A method is proposed for determining the content of the ferrite phase in austenitic and austenitic-ferritic steels, based on performing a local magnetic method of measuring the content of the ferrite phase in the base metal, welds and surfacing of equipment in which previously measure the content of the ferrite phase on a reference sample at various levels of its loading, record the voltage and change in the content of the ferrite phase, establish the relationship between voltage and change in the content of the ferrite phase, determine the magnitude of the voltage acting in the controlled area of the equipment, after which the content of the ferrite phase in the controlled area is measured equipment zone and make a correction to the resulting value for the voltage value in accordance with the relationship between the voltage and the change in the content of the ferrite phase. The proposed method makes it possible to increase the accuracy of determining the content of the ferrite phase and reduce the spread of measured values by bringing them to a zero voltage level. The method is carried out as follows. In the controlled zone of the structure, the sign and magnitude of the voltage are determined. From a metal that is adequate to the metal of the controlled zone of the structure, a reference sample is made that has no residual stresses, and it is subjected to tension or compression, depending on the sign of the stresses acting in the controlled zone. In the process of loading the reference sample, the dependence of the voltage and the content of the ferrite phase is established. Based on the magnitude of the voltage in the controlled zone of the structure, based on the specified dependence, the correction value for the content of the ferrite phase is determined, bringing it to a zero voltage level. Using the described method makes it possible to obtain comparable values for the content of the ferrite phase in different laboratories by eliminating the error caused by not taking into account the voltage acting in the controlled zone .

Claim of the invention

A method for determining the content of the ferrite phase in a product, including local measurement of the content of the ferrite phase by a magnetic method, characterized in that the relationship between the change in the content of the ferrite phase and the mechanical stress applied to the sample is first determined on a reference sample, after which the content of the ferrite phase in the product is measured and a correction is made to the resulting value taking into account the mechanical stress acting on it.