Purpose of products

The following types of knives are distinguished:

- Household knives for crafts, they are used for cutting wood products and other craft materials.

- Kitchen products for cooking. These products are subject to more stringent requirements; the steel must not rust and remain in a sharp state for as long as possible.

Kitchen:

- Pencil pens were used by clerks to sharpen goose feathers. They were made foldable. Therefore, the term has taken root for all types of folding products.

- Cutlery sets are used as part of cutlery sets.

Dining rooms:

Hunting - intended for use in cutting carcasses and removing skins. A necessary function may also be to inflict fatal blows on the animal (hunting situations can get out of control).

Hunting:

Combat - here different manufacturers offer their range of blades. Demand creates supply. In every country there are dozens of firms that are looking for contracts for the supply of weapons. Therefore, these products are presented most fully on Internet resources.

Combat:

Survival knives - this name was invented relatively recently. There are many options, but the survivalists themselves can be reread on one hand. Here are blades for universal use, more like hunting accessories.

Survival knives:

Knife shapes and corresponding sharpening angle

The shape of the knife blade may vary. Accordingly, you need to be able to use each option. It is even more important to have the skill to correct the blade correctly. The most common options that housewives find in the kitchen are knives with the following blade shapes:

- razor;

- wedge-shaped;

- Japanese;

- bullet-shaped;

- chopping "Chinese".

PHOTO: kavkazsuvenir.ru A high-quality sharpening will be one in which all parameters are met.

For each option, they try to select the angle individually; for this you can use a special meter. It is also necessary to take into account the type of material from which the blade of the blade is made. They are often made from:

- stainless or carbon steel;

- Damascus steel;

- titanium alloy;

- zirconium alloy and high carbon steel.

Usually the edge is made from one type of raw material. But to improve the strength properties, various additions are possible.

Table for sharpening knives by corners

The table can help you figure out which sharpening angle to choose for a kitchen knife. When using it, there is a high probability that the edge of the blade will become smooth, even and will have good cutting qualities. See below for details.

| Type of knife and its purpose | Sharpening angle, º |

| Dining room | 55-60 |

| Home kitchen | 30-35 |

| Professional (chef, kitchen) | 25-30 |

| For professional cutting of vegetables | 35 |

| Fish processing knife | 25 |

| Folding and hunting | 30-35 |

| Deboning, cutting | 25-30 |

Much also depends on the hardness of the blade material. The values provided in the table are suitable if the HRC hardness is in the range of 50-60 units.

PHOTO: opticalmarket.com.ua The width of the bevel and the width of the approach must be taken into account when choosing a sharpening method

Independent determination of the knife sharpening angle

When the question arises of how to measure the sharpening angle of a knife, you can act in various ways. Many people purchase special tools for this purpose. However, why not save money and use the budget method described in the instructions below.

Take scissors (non-cutting ones will do) and place the cutting edge between their ends so that there is no gap. On a white sheet of paper, draw a line with a dot at the end. We compare with it the angle between the blades of the scissors. Opposite the opposite blade (closer to the edge) we place a thin but visible point

It is important that it is not greasy. The accuracy of the measurement depends on this. Draw a second line (connect two points with a ruler)

We should have a corner. Take a protractor and determine the degree of the angle. Each indicator will be individual.

In small kitchen knives the sharpening rate may be similar

Please note that knives with a Scandi trigger must be sharpened only at the calculated angle. To avoid mistakes, you need to double-check it two or three times, using different scissors.

Having figured out how to determine the sharpening angle of a knife, you can begin to select sharpening devices.

PHOTO: promzn.ru Follow safety precautions when sharpening blades

Materials for making blades

Knife types:

A variety of steels and alloys are used for manufacturing. The following classification is accepted:

- Mild structural steel is used for folk types of products. Usually produced by forging from porous iron, obtained by direct smelting from ore, bypassing the production of cast iron. Technologies came from China and Central Asia. Found in North and South America.

- Carbon steel is used to produce cutting tools with high hardness (HRC 55...64). Such materials began to be used from the middle of the 17th century. Analysis of earlier products shows that the quality of the material is low. To give greater strength, the blades were made wide and thick, making it easier only by turning the fullers along the length.

- Stainless steel most often does not have high strength. It is viscous and plastic. The main advantage is that it is not subject to corrosion. Used to make blades in cutlery.

- Alloy steel (the so-called carbon stainless alloys) acquires its properties due to the introduction of a number of elements (manganese, chromium, titanium, molybdenum, aluminum and other metals). It is better suited for making blades.

- Damascus steel is obtained by mechanical forging of different types of materials. Initially obtained by forging low-carbon strips of metal with graphite. As a result, cementite and spherical graphite were obtained in the blade, giving the product high hardness and wear resistance.

- Titanium powders sintered into a single body (some incorrectly call this consistency an alloy). Titanium oxide on special binder materials has wear resistance to abrasion, but is brittle. The technology for producing a thin flat blade is quite complex; several industries in the world have mastered it. Therefore, they are the only suppliers to the knife market.

- Zirconium alloys (sintered zirconium dioxide, similar in properties to titanium powders) are used to make stainless steel blades. Resistant material to acids and alkalis. The products are quite expensive, but restoring their sharpness on your own is quite problematic. It is easy to damage the cutting edge.

Overview of species

Depending on the quality of the planer knives, the operating speed of the tool is determined, as well as the final result.

Also, the type of blade affects the way the surface is processed and the shape that can be obtained at the end of the work. Manufacturers of machine tool equipment produce several types of planes, each of which differs mainly in the type of blade provided in the design.

If we classify planes according to the method of surface treatment, then the following types of knives are distinguished.

Direct

With their help, it is possible to process small-sized workpieces. If desired, you can choose a quarter to carry out the necessary work. The blades have a classic straight shape and are positioned at a specific angle to create the desired result.

Rounded

Demanded for processing large surfaces. Such blades are used when it is necessary to organize a neat and smooth transition between planing planes.

Curly

This category includes planes, the knives of which allow you to achieve complex geometric shapes when processing a wooden surface. Structurally, the blades resemble the knives of classic planes, however, they have a number of features. By using curly knives, they create a wave-like surface shape and imitate “aged” wood. To determine a suitable knife, manufacturers use special markings that can be found on the surface. This way, when purchasing a blade, you can quickly choose the appropriate option.

Spiral

Provides the most accurate cut. They are installed mainly in lightweight planer models, which are easy to operate. The advantage is the ability to adjust the planing depth. Knives built into the design of woodworking equipment differ not only in the shape of the surface sharpening, but also in a number of other parameters.

Choosing the optimal angle and correct sharpening of knives

Please note that the angle parameter must be individual for each tool type. For example, kitchen, professional and hunting will differ greatly according to these marks

Let's consider this parameter for each type of blade separately.

PHOTO: inha.ruMusat should be kept strictly in the position as shown in the photo

At what angle should you sharpen a kitchen knife?

There is no need to set the sharpening angle for kitchen knives, since in most cases mechanical sharpeners are used as an assistant. In such devices, an optimal inclination is already provided between the metal washers, which subsequently come into contact with the cutting edge when it is pulled through.

If you use such a device constantly, you will not be able to achieve the ideal sharpness of the knife. The worst case scenario is that the tool becomes completely dull and there is a need to buy a new one.

Choosing a sharpening angle for a hunting knife

But for hunting knives, mechanical pocket sharpeners are popular. With their help, you can quickly bring the edge into working condition. The device is a rod that has grooves for inserting blades.

PHOTO: truehunter.ru An old-fashioned way to sharpen hunting knives with a sword belt

When sharpening the latter, be sure to maintain an angle of 30-35º. However, it all depends on the size and length of the working surface of the blade. It is advisable to check the indicator so as not to damage the instrument.

Features of sharpening a plane knife

The sharpening angle of the hand plane knife is selected individually. This is affected by the rounding of the cutting edge and the intensity of use. Also, each model has individual parameters for this.

Sharpening is carried out in two stages: primary, which involves bringing the knife and clamping it directly next to the sharpening wheel. During secondary processing, it is necessary to wash the blade in a soapy solution and bring it back to the sharpening wheel with the same side. This technique allows you to remove the smallest metal residues

Please note that the grinding wheel speed should not exceed 600-700 rpm

Sharpening a fillet knife

The sharpening angle of a fillet knife and a vegetable knife is approximately 10-20º. The main thing here is to make correct and sharp cuts, since the blade works with soft products. As a result, you have to make thin and even ultra-thin cuts in meat and vegetables. Also, such tools do an excellent job of slicing snack foods (fish, sausage, cheese, feta cheese).

PHOTO: youtube.com A fillet knife should have a thin shiny edge

Rules for sharpening a Yakut knife

The sharpening angle of a Yakut knife is 5º or even less. This is due to its small size and exceptional purpose. Usually they try to process such a tool manually. They do it with a bar. Movements are performed from top to bottom.

Periodically, the blade must be wetted, as it tends to overheat and lose cutting quality. Only one side of the blade must be sharpened, and you can begin processing and returning cutting properties only when the shine at the tip completely disappears.

PHOTO: truehunter.ru A Yakut knife is sharpened no more than once every two to three months

Methods for sharpening a knife

So, we have become familiar with the types of sharpening, we can determine which blade of a particular knife belongs to and move on to the process of sharpening it.

Sharpening goals:

- restoration or change of the factory profile (we correct descents and approaches);

- return of primary acuity (work with RK);

- fine-tuning – we remove scratches and burrs of the cutting edge, thereby strengthening it.

It is also important to understand what material we are dealing with. Chef knives – stainless steel is quite pliable with high anti-corrosion properties (420, 425, 440A). It is easy to maintain their sharpness with almost any sharpening device. More wear-resistant steels are more difficult to sharpen - they are more finicky, require more professionalism and specialized sharpening devices with the ability to adjust the angle and polish the blade.

In general, you can restore sharpness using different devices:

- sharpening stones of various grain sizes (require certain skills and abilities);

- machines (option for professionals);

- electric sharpeners (they sharpen quickly, but cut off a fairly large layer of metal, which shortens its life)

- mechanical sharpeners (the simplest, most compact);

- ready-made sets.

Photo instructions on how to sharpen a knife

Basic rules for sharpening

The main condition for sharpening cutting tools is compliance with safety precautions. Otherwise, a person may damage the outer skin and blood vessels, which poses a health hazard. If you have no experience, it is recommended to initially sharpen inexpensive knives to acquire the required skills. When sharpening, it is very important to follow the following rules:

during turning, it is important not to put pressure on the tip of the knife so as not to damage the integrity of the cutting edge; at the beginning of sharpening, coarse-grained whetstones should be used, at the end - fine-grained whetstones; to facilitate sliding and reduce the amount of metal dust generated during sharpening of the blade, you need to moisten the sharpening stones with water or soap solutions; ceramic tools are sharpened only with diamond sharpening stones; when sharpening blades made of damask or Damascus steels, you cannot use diamond stones; It is important to periodically inspect the sharpened surface of the blade so as not to cut off excess steel; knives with a wavy edge can only be sharpened on a special machine, and after repeating the procedure twice, its blade will become straight.

For sharpening, you must use only serviceable tools. Defective sharpening devices can deform the blade and cause harm to human health.

After completing the procedure for sharpening the blade, it is necessary to completely grind it using fine-grained whetstone and GOI grinding paste, made on the basis of chromium oxide. The finishing of the tip is carried out on a special belt or leather surface.

Edge sharpening

For small knives, small sharpening machines are used.

Machine for sharpening small knives:

As in the previous case, all the elements are here, only their sizes are slightly smaller. Using such a device you can sharpen cutting edges. You can determine the sharpening angle using a simple protractor. It is attached to the bar. Then the resulting value is multiplied by two.

Edge wear due to use:

If the blade is used for a certain time, then its cutting edge loses the planes that form it. Sharpening restores the original angle values.

Possible flaws when sharpening an edge:

If the optimal angle is not maintained, then the planes forming the edge will be sharpened incorrectly. Beginners are recommended to use the pre-painting method. Paint is applied to the plane, and then they are guided as the blade is sharpened. If you manage to set the sharpening angle correctly, the tool will remove paint and metal evenly over the entire surface of the plane.

Blade sharpening angles:

In practice, they use special tables where the optimal angle values can be determined for each type of blade.

Video: which knife sharpening angle is better to choose?

How to check the sharpness level of a knife

You can evaluate the sharpness of a sharpened object in the following ways:

- You should try cutting a piece of paper or a tomato with a knife. A dull tip will not be able to cut these objects.

- Hold the blade up to the light. If the edge continues to cast glare, the point will need to be re-sharpened.

- Japanese method. It involves rolling newspaper into a roll. The resulting structure is wrapped with tape around the edges and placed vertically on the table. It is necessary to hit the roll with a sharpened object. If the structure was cut into 2 parts, then sharpening was successful.

The safest method of checking is the use of specialized devices - protractors, which determine the correct sharpening angle.

They consist of a protractor, a movable ruler, a stopper, a vernier and a micrometer feed screw. To measure, you need to attach the device to the surface of the blade and record the obtained values. Some inclinometers have an electronic display that allows you to display measurement results on the screen in electronic form. It is not recommended to check the sharpness of the blade using your fingers. If you accidentally press on the tip, there is a risk of cutting the skin.

How to make a kitchen knife sharpening angle on a grinding machine

On a grinding machine, sharpening a kitchen knife should only be carried out by an experienced person; you will need to maintain a sharpening angle of 30-35 degrees during all work. And you can do it like this:

- Determine in what position the knife will come into contact with the grinding wheel according to the desired parameter.

- Prepare a “support”, a retainer - it can be either a long metal plate or a plastic strip.

- Turn on the machine, bring the blade to the circle at the correct angle and apply the lock on top. Do not press the blade tightly, as this will damage the metal.

First, one side of the cutting edge is sharpened on a grinding machine, then the other. It is impossible to hold the metal on a rotating circle for a long time - due to friction at high speed it will heat up and lose its quality characteristics.

Watch the video on how to quickly sharpen a kitchen knife on a machine:

Features and design

As you know, a planer is used to perform rough and fine finishing of wood structures and surfaces. Today, classic hand planes have been replaced by electrical equipment. The operating principle of both tools is the same. The planer removes a layer of wood due to the blades provided in the design. The procedure is called planing. The knife has a special sharpening, and the element is located at a certain angle, which allows you to achieve the desired result.

The design of knives includes such elements.

- Chamfer. It can be detected from the back of the blade. With its help, it is possible to reduce the force of penetration of the knife into the tree.

- Front corner. Its position coincides with the angle of inclination of the knife, which is located in the tool body.

- Working angle of sharpening. It has its own value, which is determined by subtracting the chamfer angle and the tilt angle.

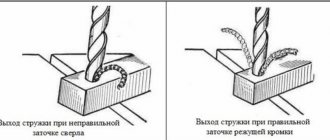

The most important is the front angle. It affects the smoothness of the treated wood surface. The rake angle is also responsible for the load on the blade and the conditions for removing chips formed during operation.

Pocket sharpener from Gerber

It is inconvenient to carry an abrasive stone with you, and you still need certain skills. There is an easier way to sharpen a blade - use a pocket mechanical sharpener such as the Bear Grylls Field Sharpener from Gerber. Its main advantage is versatility and compactness. You can always take it with you on a hike, hunting, fishing, etc. At the same time, it provides four working areas for rough sharpening and finishing. The diameter of the device's nuts is ideal for sharpening serrated blades from the BG series, and the angle of the carbide and ceramic guides is ideal for straight-ground blades. This ready-made template greatly simplifies the sharpening process, allowing you to maintain the blade in perfect condition.

Formation of slopes

Device for sharpening and grinding triggers:

The machine contains the following elements:

- A stand with a movable ear attached to it. It can be moved in height. As a result, the sharpening angle will change.

- The rod goes through the eye. An abrasive tool is attached to it. The most commonly used tool is a whetstone.

- A holder is a device in which a blade is secured. The design provides for a rotation of 180⁰. It's easy to flip the workpiece over so you can turn from the other side of the blade.

- The work is done by moving the whetstone from top to bottom.

View of the device from another angle:

Attention! Some novice specialists try to sharpen by moving back and forth, but there is little benefit from such work. When moving backwards, the stone does not touch the blade

At this time it may partially cool.

Adjust the sharpening angle using a special protractor:

Homemade devices

Since professional sharpening devices cost a lot of money, many owners make such devices on their own. The designs of homemade knife sharpening machines presented on the Internet are divided into several main types.

Common knife sharpener design Source odstroy.ru

A practical solution is those options that provide the ability to set the desired sharpening angle, depending on the type of knife (kitchen, tourist, universal, hunter or survivalist knife).

Popular devices are those in which the knife is fixed motionless, and the abrasive surface (the same sandpaper) is fixed at the required angle. After adjusting the angle, all that remains is to sharpen the blade, periodically removing waste so that it does not spoil the cutting edge.

Some craftsmen copy the design of the factory model, making a sharpener in which the bars are hidden in a body with a hole, while one abrasive sharpens the edge, the other polishes it. Devices are made in which a block is fixedly fixed, and the performer remains to control the vertical movement of the knife, which is quite simple with a certain skill.

Diagram of a simple sharpener Source bassin.ru

Blade shape

Knives are tools that combine two main elements - a blade and a handle. At the same time, the most important difference lies precisely in the design of the blades and the presence of components. The most important part that needs constant care and regular sharpening consists of:

- Cutting edge and its height.

- Butt and its thickness.

- Rectangular section and its height.

- Descents and their heights.

- Cutting edges, their heights.

- Thickness of cutting edges.

Most often, blades have the following blade shape:

1-5 — Wedge-shaped; 6 — Razor; 7 — Chisel (one-sided or Japanese); 8 — “Chopping Chinese”; 9 — Bullet-shaped.

Operating rules

In order for the processing of a wooden surface with a plane to be of high quality, it is necessary to take into account a few simple rules.

- Before starting work, you need to configure the tool. The chips must be continuous and uniform in thickness.

- When working with a plane, you need to stand to the right of it so that the body is parallel to the surface being processed and moves with the device. Movements should be uniform. This will be achieved by placing your leg forward, which will be responsible for redistributing the load.

- For successful work, it is recommended to securely fix the part. The tool is held with the hands and the surface is processed by running it parallel to the installed workpiece.

A planer is a dangerous tool, so you should avoid any contact of the device’s blades with the surface or your hands. These rules will help make operation comfortable.

In the next video you can learn more about the nuances of sharpening planer knives.

Types of edge processing

There are several technological operations to restore the cutting properties of the blade. The need to use each of them depends on the type of tool, its condition, and the stage of restoration of properties. They are very important for understanding how to properly sharpen a knife at home. Here are some of the edge processing methods:

- Edge restoration. Removing metal to form a new edge.

- Rough sharpening. Processing using coarse stones or paper according to the method used.

- Fine sharpening. The same as described in paragraph 2, but using fine-grained abrasives.

- Edit. Light sanding to maintain acceptable sharpness.

- Polishing. Achieving a mirror effect without significant changes to the edge.

For example, straight razors are straightened before each use and even during the shaving process, but they are processed on stones only a few times a year, and the edges do not require restoration for years. A hard steel kitchen knife may need abrasive only once a year, while butchers using carbon steel tools can only get by with sanding every few cuts.

At what angle should knives be sharpened, depending on their purpose?

Sharpening knives at different angles is possible using only professional tools: machines or manually on stones. Household sharpeners, which are widely available in stores, are mostly set at 35-40º.

Kitchen knives

As a rule, household sharpeners provide a sharpening angle of 40-45º, and they also remove too much metal. If you need to get a different cutting edge angle, you need to use an abrasive stone.

| Illustration | Description of action |

| PHOTO: kitchendecorium.ru | A little water is applied to the sharpening stone. Then it is recommended to wipe it with a sponge with a drop of dishwashing detergent |

| PHOTO: kitchendecorium.ru | We set the sharpening angle according to the pattern, in accordance with the table provided earlier. We remember the position of the blade and try not to change it while working. |

| PHOTO: kitchendecorium.ru | The blade is sharpened with smooth movements without excessive pressure. The movement is forward, with the blade away from you, from the handle to the tip of the blade, as shown in the illustration |

| Burrs form on the cutting edge, which must be removed using musat. |

| Editing is performed by progressive movements of the musat on both sides of the blade. |

Hunter knives

It is recommended to sharpen hunting knives using special mechanical sharpening machines. Instructions using an example model.

PHOTO: tsprof.comExterior view of a professional sharpening machine model Blitz

| Illustration | Description of action |

| Installing a whetstone in the clamp |

| On the compensating mechanism we set a value equal to the thickness of the abrasive stone |

| PHOTO: YouTube.com | Add oil to the special hole |

| Install the knife on the frame mount |

| We set the angle. On this model, the working range of the sharpening angle is 16-50º |

| Using reciprocating movements we sharpen the blade of the blade |

how to choose the optimal sharpening angle

Firstly, there are standard recommendations that can and should be followed. They were developed a long time ago and have been tested by more than one generation.

Knife sharpening angle. Table

| Type of knife (work performed) | Sharpening angle, degrees |

| Fish cutting (filleting) | 25 |

| Boning knives (cutting meat) | 25-30 |

| Chef's knives (chef's work) | 25-30 |

| Kitchen knives (home chopping, slicing) | 30-35 |

| City knives (folding, penknives) | 30-35 |

| Vegetable knives (peeling vegetables, slicing) | 35 |

| Camping knives (hiking, survival knives) | 35-40 |

| Hunting knives (cutting large trophies) | 40-45 |

In Zlatoust, gunsmiths adhere to a sharpening angle of 40 degrees. Considering it "universal". Maybe this is the “golden mean”?))

Well, seriously speaking, it is simply impossible to take into account all the needs of clients. Therefore, we sharpen it at 40 degrees. Who needs more or less? Resharpen.

The photo shows an H1 knife from a 330CC arms company with a sharpening angle of 40 degrees.

Sharpening angle and other factors

Many factors influence the ability of a cutting tool to maintain its edge. The sharpening angle is just one of them. If due attention is not paid to the heat treatment of steel, then at low values, sharpen the knife at least 50 degrees, it will quickly “sag,” and at high hardening values (overheating), the cutting edge may simply crumble.

There is also the so-called “scandi” sharpening, when the bevels on the knife are made on a belt grinder almost “to zero” with a slight microfeed. Such knives are designed for heavy “batoning”, when you can easily chop even logs with them, striking the butt with another log or a hammer.

The photo shows a NePropadu knife from our catalog with a Scandi sharpening angle.

The situation may be like this: good steel, hardened according to all the rules, but “sharpened on a grindstone,” that is, on a high-speed abrasive wheel. Such a knife will also not hold an edge for long.

Therefore, when purchasing a knife, pay attention to what manufacturer is behind it. Veteran gunsmiths, as a rule, take all these parameters into account when making knives.

Sharpening angle “so that the nail can chop”

Everyone has probably heard the story about how a Damascus/damascus/super steel knife cuts a nail. Reveal a secret? Even an ordinary “Chinese steel” is capable of such a trick. What can we say about damascus or damask steel?

The conditions for such a focus are:

- steel hardness is in the range of 56-61 HRC and .

- . sharpening angle 50-60 degrees.

Cut nails for your health if you need it ((. Don’t believe me? Write below, we will conduct such a test and film everything on video.

How to choose the right sharpening angle?

Experimental! Refer to the table at the beginning of the article and try deviations up or down based on your goals. Carbon steels, by the way, allow the use of a sharper sharpening angle. Therefore, for knives made of Damascus or cast damask steel, it is possible to deviate in a smaller direction (within reasonable limits) without fear of jamming the cutting edge.

For reference

When purchasing blades for making knives yourself from our catalog, you can order the required sharpening angle. We will happily sharpen them to 25, 30, 35, 40 or 45 degrees using Swedish Tormek equipment. And so that there is no misunderstanding: when we talk about the sharpening angle, we are talking about a full angle, not a half angle. The diagram below shows exactly the half angle. Multiplying it by 2, we get the full one.