Nowadays, PE pipes are especially popular in the building materials market. They are used for the construction of various process pipelines, utilities for industrial and domestic purposes. Polyethylene pipes are used for the construction of various process pipelines, utilities for industrial and domestic purposes. They are most often used for cold water supply, transportation of various chemicals, and also as impassable channels for electrical and telephone networks.

In this case, it is important to carry out a high-quality connection of polyethylene pipes. Below we will consider the main types and categories of detachable and permanent connections of PE pipelines. There are two types of connection of polyethylene pipelines: Permanent connection using butt or sleeve welding. When making this connection of polyethylene pipes, the ends of the pipelines are heated, followed by joining under pressure until a continuous seam is formed. Detachable connection using crimp connections, compression fittings (collet mate) and steel flanges. This type of joining is simple, but it is less practical and requires additional costs for the purchase of fittings. Welding using electrothermal couplings To perform this type of welding of rolled polyethylene, you must have special couplings and welding equipment.

Couplings for welding have heating elements in their body, which subsequently shrink (weld) the coupling. This method is used for welding rolled polyethylene in cramped conditions (pits, trenches). The electrofusion coupling can withstand a pressure of 1.6 MPa.

The disadvantage of this method is that it requires significantly more material costs than the butt method. Scheme of connecting pipes using an electrothermal coupling. The welding process can be divided into several stages: centering the pipe and couplings along the required axis; preparation, cleaning and degreasing of external surfaces pipes at the junction; coupling attachment and connection of the welding machine; immobilization of the joint; welding with heating, melting of polyethylene and shrinkage of the coupling; turning off the power and cooling of the coupling. This type of welding of PE pipelines is used for joining pipes with a diameter above 50-63 mm. The butt connection is performed in several stages: Before welding, the axes of the pipelines being welded are aligned in a central machine. After fastening, the end parts of the pipelines are aligned and cleaned of grease, dust and dirt. Mechanical processing of the ends on a trimming machine. Checking parallelism with the obligatory check of the interplanar gap. Warming up the end parts parts of pipes using a thermal tool. Welding with subsequent cooling. Removing the tool, inspecting the outer surface of the weld. Connection using steel flanges. In some cases, when it is impossible to weld, installation is carried out using flanges. Flange coupling refers to detachable types of connections and is most suitable for connecting PE products with pipeline fittings and steel pipelines.

Flange joints of pipes are made using adapter bushings that are tightly welded onto the ends of PE pipes, or using metal slip-on flanges. A sealing material (rubber, PON, etc.) must be placed between the flanges. The advantage of this installation method is that later it will be possible to disengage the flanges and clean the system.

Flanges of water pipes can be flat or profiled (with a shoulder, stop or cone). Detachable connection using compression fittings. Connecting pipes without welding is possible using compression mounting elements. This method is often used for small diameter pipes (up to 63 mm) and systems with a large number of branches, since any welding will entail an increase in the cost of installing the system. Achieving tightness occurs due to an internal seal made of wear-resistant rubber and a cut metal sleeve.

To carry out the work, you will need a set of profile keys and a special knife for cutting pipes at right angles. The collet clamp can withstand pressure of 2.5 MPa. Assembling the connector is easy and simple, the main thing is that the dimensions of the fittings exactly match the dimensions of the water pipes. Socket joining of pipes is less common.

The rolled products are connected into a socket, and tightness is achieved by sealing the socket with a rubber ring. This installation is more suitable for non-pressure systems based on polyethylene. Finally, I would like to note that when choosing the type of connection of PE pipes with fittings, it is necessary to take special responsibility in the choice of tools and equipment for installation. Now you can, without any problems, choose the methods that suit you for installing conventional and profile polyethylene pipelines. Share a useful article: Similar articles:

Pipes made from low-density polyethylene (HDPE) are among the most popular building materials. Not a single process of constructing modern buildings can be done without them, where they are used to create water supply and sewerage systems. The ease of working with this material, its elasticity and the presence of many ways to connect polyethylene pipes allows you to install the pipeline quickly and at minimal cost.

The connection of polyethylene pipes can be detachable or permanent

Advantages and features of application

Polyethylene pipes are made from low-density polyethylene. This material is abbreviated as HDPE. It is characterized by increased strength and elasticity, and has good performance properties:

- chemically neutral, can be used for transporting food products;

- smooth walls prevent the formation of plaque inside;

- not subject to corrosion;

- small coefficient of thermal expansion - about 3% at maximum heating (up to +70°C);

- They react normally to the freezing of water inside, due to elasticity they increase in diameter, and after thawing they return to their original dimensions.

One point to remember! If you need pipes that are resistant to freezing (for example, for installing water supply in a country house), when choosing, look at the description or technical specifications. Not all types of copolymers used for pipe production tolerate freezing well. So be careful.

The main disadvantage of polyethylene pipes is the restrictions on the temperature of the transported medium: it should not be higher than +40°C, that is, only cold water supply can be made from HDPE; they cannot be used for hot water and, especially, heating.

Polyethylene water pipes are available in different diameters

Another point: polyethylene does not tolerate UV radiation well. When constantly exposed to the sun, the material loses its elasticity and, after some time, breaks (some manufacturers make HDPE pipes that are UV-resistant, but they are more expensive). Therefore, open laying of water supply pipes from plastic pipes is very undesirable. But it is very possible to run a pipe in a trench from a well or borehole to the house, and distribute cold water throughout the house. This is a fairly economical and convenient solution, since the installation and connection of polyethylene pipes is not very difficult. If we are talking about a detachable connection, then it does not require any equipment. All you need is fittings and hands.

Types of cross-linked polyethylene pipes

According to their purpose, cross-linked polyethylene pipes are divided into:

- universal – they can be used for installation of heating systems and heated floors;

- specialized - products that are intended either for the installation of water heating or for the installation of a heated floor system.

We recommend that you read: Copper pipes and their use in air conditioners

To install a water supply system, you can use any category of polyethylene pipes.

According to the method of stitching ethylene polymers, the pipe material is marked accordingly and is divided into:

- PEXa – peroxide firmware;

- PEXb – gas treatment;

- PEXc – electron bombardment;

- PEXd – chemical exposure to nitrogen compounds.

Market leaders in the production of high-quality cross-linked polyethylene pipe materials:

- RAUTITAN. Pipes of this brand are produced by a German concern. The consumer is offered 4 types of pipes in a size range from 12 to 250 mm.

- WIRSBO. Pipes from Finnish manufacturers who specialize in small and medium diameters from 12 to 150 mm.

- GOLAN. The Israeli brand offers the largest selection from 12 to 500 mm in diameter.

The cost of cross-linked polyethylene pipes from global manufacturers varies within close limits. Difference in price for fittings.

Note! The best result when installing communications is obtained when using pipes and fittings from the same manufacturer, since this guarantees the uniformity of the raw materials.

Which polyethylene pipes are better?

For the production of water pipes, two grades of polyethylene are used - PE 80 and PE 100. The hundredth polyethylene is more dense and durable than the eightieth. For water supply systems in a private home, the strength of PE 80 is more than enough - they can withstand pressure up to 8 atm. If you like a large margin of safety, you can take them from PE100. They work normally at 10 atm.

First of all, you need to choose a manufacturer

What you should pay attention to is the country in which the product was produced. The leaders in quality are European manufacturers. High precision execution guarantees high system reliability. Average quality and prices are from Turkish companies, in the cheaper price segment are Chinese manufacturers. Their quality, as usual, is also much lower. It’s difficult to give advice here; everyone chooses at their own discretion (or what is available in the region).

How to correctly and reliably connect a HDPE pipe?

The technology for connecting HDPE pipes, in contrast to connecting metal pipelines, can be carried out either by welding or using special parts. And if the tightness of the welding structure is beyond doubt, then the quality of the connection using fittings depends on the correct installation.

What are HDPE pipes?

HDPE is polyethylene made under low pressure. HDPE is obtained by polymerization of the organic substance ethylene at temperatures up to 120 ͒ C under pressure up to 2 MPa in a solution of a special catalyst. The resulting material is also called high-density polyethylene (HDPE) because it is denser and stronger than other polymers.

Note! Modifications of HDPE are used in the creation of boats, body armor and the construction of hazardous waste processing sites, as well as for the manufacture of pipes. The variety of applications proves that low-density polyethylene is a very durable and airtight material.

Advantages and disadvantages of HDPE pipes

The advantages of HDPE pipes include:

- Immunity to any kind of solvents. At temperatures up to 80 ͒ C, HDPE pipes do not dissolve at all. When this temperature is reached - only in special solvents. Water is harmful only at temperatures above 180 ͒C.

- Do not corrode. This problem is known for all metal pipes, which, under the influence of water and air, begin to oxidize over time. HDPE pipes are not susceptible to corrosion because they contain no metals.

- Smooth inner surface. Roughness and unevenness lead to the accumulation of various types of contaminants. Over time, such dirt can almost completely block the lumen. HDPE pipes are smooth, so nothing interferes with the laminar flow of liquids through them.

- Durability. Manufacturers promise that their products can last up to 50 years. It is worth considering that this figure was obtained theoretically. High-density polyethylene was introduced into service about 60 years ago, so reliable data on such a service life have not yet been obtained.

- Flexibility. HDPE pipes are very flexible, they can even be rolled. This is an undeniable advantage if they are laid through uneven terrain.

- High strength. HDPE is a durable, airtight and at the same time elastic material. It does not leak, does not break or bend. Thanks to their flexibility and strength, they have proven themselves well even in seismically active areas.

We recommend that you read: 4 ways to install HDPE pipes with your own hands

A significant disadvantage is the instability of the material to ultraviolet rays.

HDPE pipes are laid only underground or indoors away from sunlight. When exposed to sunlight, high-density polyethylene becomes brittle and begins to deteriorate. The decay process occurs quickly, such pipes need to be replaced.

It is important! When choosing HDPE pipes, you should pay attention to the markings. Each color means its area of application: blue - drinking water supply, yellow - gas supply, without marking - technical water supply.

How to connect HDPE pipes

There are also two types of connections: permanent and detachable. Both methods allow you to create reliable adhesion, but each of them has its own pros and cons, which are important to consider when installing pipelines.

Permanent connections

Permanent connections are made by welding. This method assumes that the pipes are tightly connected and it is no longer possible to separate them.

Permanent connections require the use of a special welding machine. It is expensive, which increases repair and construction costs.

In addition, if the connection is incorrect, it is no longer possible to disconnect and reconnect the pipes; new ones must be taken.

But this method also has its advantage - high tightness. They can even be used for gas supply without fear of gas leakage at the connection points.

Permanent connections are always made by melting and welding HDPE.

There are two ways to create such a connection:

- Butt to butt welding. The ends of the two pipes are placed in a special apparatus that melts them and welds them together. It is important to maintain a certain temperature and exposure time, otherwise damage can occur.

- Electric couplings. These are special connecting parts that are made of polyethylene and contain a metal heating coil inside. The coupling is connected to a special apparatus, the spiral begins to heat up under the influence of electric current, melts the ends of the pipes and welds them to the coupling. This results in a reliable permanent connection.

Detachable connections

The detachable connection method is a structure that can be dismantled. In this case, the pipes are connected using special sealed compression fittings. Such fittings or couplings are reusable and can be separated and reconnected if desired.

The advantage of detachable connections is the fact that the structure is easy to install; you do not need to purchase special equipment for this. Installation this way is much cheaper, since the couplings themselves are inexpensive.

If any section of the system needs to be replaced, there is no need to dismantle the entire system. It is enough to disconnect the fittings between which this section is located, remove it and place a new one there.

But the tightness of such a connection depends on the correct installation.

It is recommended to make those parts of the system that are subject to the greatest load permanent.

Detachable connections also come in two types:

- Connection with compression fittings. One of the simplest and most reliable methods. It is only important to firmly secure the coupling to the pipes.

- Socket connection. It is rarely used, since such a connection does not have sufficient tightness. To create it, one end must be wider than the other. One pipe with its narrow end is inserted into the wide end of another pipe. To increase the tightness, a special gasket is placed between them.

At the moment, fitting connections are more often used because they are reliable and easy to install.

Connection fittings

A fitting is a connecting element of a pipeline necessary for installing pipes at their joints, turns, increasing or decreasing the diameter or quantity. Fittings are different, depending on what section of the pipe they are attached to and what they are intended for. The most common types are:

- Direct coupling. Necessary for a simple connection of two HDPE pipes of the same diameter.

- Compensating coupling. Used when it is necessary to connect pipes of different diameters.

- Adapter. Necessary for connecting HDPE to pipes made of another material, for example, metal.

- Tee. Installed in places where two pipes are made from one pipe.

- Branch (corner, elbow). Bends are needed in places where the pipe makes a turn.

- Stub. Installed in the place where it is interrupted.

The assembly of pipes with compression fittings is carried out in four stages:

- Fitting. At this stage, a fitting of the required diameter is selected, the distance at which each pipe section will be inserted into it is determined, and marks are made.

- Preparation. For better sliding, the pipes are moistened with a soap solution.

- Installation. The fitting nut is unscrewed and the pipe is installed into it to the marked mark.

- Consolidation. The fitting nut is tightened as tightly as possible. The tighter the nut is tightened, the tighter the structure will be.

How to connect HDPE pipes to metal ones

At home, where ease of installation is important and all pipes have a relatively small diameter, special adapter fittings can be used to connect HDPE pipes to metal pipes.

At one end, such a fitting is made of polyethylene and is smooth. This end is intended for HDPE pipe. The second end of the adapter fitting is metal and has a thread. A metal part is inserted into it.

Installation of such a connection is similar to installation of a compression fitting.

For large diameter pipes, flange connections are used. They are also made of HDPE on one side and metal on the other. The second end has holes for bolts. The HDPE end is connected as a compression fitting, and the metal end is connected using bolts.

Source: https://InfoTruby.ru/polietilenovye/soedinenie-pnd

Types of HDPE pipe connections

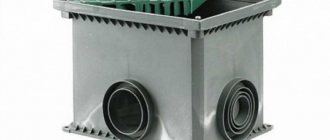

There are several types of connections for polyethylene pipes:

- detachable (on fittings or couplings);

- one-piece - by welding: using a special welding machine;

- electric couplings - a heater is built into such couplings; when electric current is applied to it, the polyethylene heats up and fuses.

Welding is used more often on larger diameters

They mainly weld large-diameter pipes, which are used to create main pipelines. Pipes of small diameters - up to 110 mm, used in private construction, are mostly connected using fittings. Couplings are used more often during repair work, since their installation takes longer.

Fittings for polyethylene pipes are shaped parts (tees, crosses, angles, adapters, couplings) with the help of which the required system configuration is created. Since independent connection of polyethylene pipes is carried out more often with the help of fittings, let’s talk about them in more detail.

An approximate set of fittings for polyethylene water pipes

Coupling connection methods

Using an electric coupling

This method of joining polyethylene products is used when there is limited space for welding. There are electric and compression couplings.

Electric coupling

Electric couplings have a built-in heating element that allows the connecting surface to melt. Let's look at how to connect polyethylene pipes using an electric coupling:

- Pipeline products to be connected are placed strictly on the same axis.

- A small area of the surface of the product from the edge of the joint is cleaned of dust and degreased. Then the surface layer of microscopic thickness is cleaned (removed).

- Electric couplings are put on the pipes and connected to the current source.

- Embedded internal elements heat the surface and slightly melt the polyethylene.

- Due to its ability to expand and increase in diameter when heated, the pipe creates the necessary pressure to obtain a reliable, tight connection.

The time during which it is necessary to supply electricity, as well as the moment of shutdown, is controlled independently by modern devices. All data for this operation is stored in the electronic memory of the device.

Using a compression sleeve

Compression couplings (fittings) allow you to connect polyethylene pipe products:

- same diameter;

- different diameters;

- with products having internal (external) threads, including steel pipes.

The advantage of this connection method is that there is no need for additional special equipment and the lower cost of fittings. Compression couplings are used to connect pipes in the following sequence:

- The coupling is partially disassembled, the union nut is unscrewed several turns.

- The surface of the pipe is cleaned of dust and the outer chamfer is removed from the end of the product.

- The distance to which the fitting should enter the product is marked on the pipe.

- With a certain force, the coupling is inserted completely tightly into the pipe to the mark.

- After tightening the union nut, a strong connection is obtained.

Compression connection

Tightness is ensured by an elastic sealing ring, which is held in place by a press-fit bushing.

For each type of compression coupling, the manufacturer indicates the force with which the union nuts must be tightened. If the tightening is weak, the necessary tightness of the connection will not be ensured, and excessive force may damage the polyethylene products.

Assembly on compression (crimp) fittings

An entire system is installed on one or two sides of the fitting (sometimes on three) to ensure the connection. The fitting itself consists of:

- housings;

- clamping nut;

- collets - a plastic ring with an oblique cut that provides a tight fit around the pipe;

- thrust ring;

- gaskets, which are responsible for tightness.

What does a compression fitting for polyethylene pipes consist of?

How reliable is the connection?

Despite the apparent unreliability, the connection of polyethylene pipes with compression fittings is reliable. Properly made, it can withstand operating pressures of up to 10 atm and higher (if these are products from a normal manufacturer). Watch the video for proof.

This system is good because it is easy to install yourself. You probably already appreciated this from the video. Simply insert the pipe and tighten the thread.

Summer residents, in addition to the opportunity to do everything with their own lessons, like it because, if necessary, everything can be disassembled, hidden for the winter, and put back together again in the spring. This is in case the wiring is made for irrigation. The dismountable system is also good because you can always tighten the undercut fitting or replace it with a new one. The disadvantage is that the fittings are bulky and internal wiring in a house or apartment is rarely made from them - the appearance is not the most pleasant. But for the water supply section - from the well to the house - it is difficult to find better material.

Assembly order

The pipe is cut strictly at 90°. The cut should be smooth, without burrs. There should also be no dirt, oil or other contaminants present. Before assembly, the sections of the joined sections are chamfered. This is necessary so that the sharp edge of the polyethylene does not damage the rubber sealing ring.

During installation, the connection of polyethylene pipes on the compression fittings is tightened by hand

The spare parts are put on the prepared pipe in this order: the crimp nut is tightened, then the collet, then the thrust ring. We install the rubber gasket into the fitting body. Now we connect the body and the pipe with the parts put on it, applying force - you need to insert it all the way. We pull all the spare parts to the body and connect them using a crimp nut. Tighten the resulting connection of polyethylene pipes with force by hand. For reliability, you can tighten it with a special mounting key. It is not advisable to use other tools for tightening: the plastic may be damaged.

Instructions for connecting polyethylene pipes using resistance (butt) welding

This method of connecting polyethylene pipes is used most often. The meaning of the method is that the products that need to be welded are secured in special clamps. These clamps are installed on common rails. Next comes trimming using certain saws. When you process the ends, they will need to be heated using an electric heater. The material must be heated until it becomes viscous and can be compressed with a hydraulic device.

It is resistance welding that helps maintain pipes’ flexibility without compromising their strength. It is worth noting that the quality of the connection depends on the category of equipment you will use. This means that the highest quality connection can be achieved by using a welding machine with a large number of capabilities.

In order for the connection of polyethylene pipes to be correct, you must adhere to the following procedure.

All pipes must be checked for correct shape. To make the joints fit better, they need to be cleaned and straightened. While in the welding machine, the joints should be exactly opposite each other. Next, you need to place a heater between the edges and turn on the device, allowing the pipes to begin to melt. After this, you should remove the heating element and join the ends together, using a little force. You need to hold them until the material becomes hard. At this moment, molten material will be squeezed out at the junction of the pipes - this will be a weld.

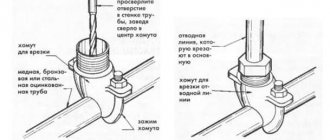

Saddles and their scope

In addition to fittings, there is another interesting device that allows you to make branches from a ready-made pipeline. These saddles are specially designed couplings. This coupling has one or more threaded holes. A tap is usually installed in them, and a new branch of the water supply is connected to it.

Saddles for polyethylene water pipes

The sedeks are put on the pipe and secured with screws. After that, a hole is drilled in the pipe surface with a drill and a thick drill in the branch. When it is ready, a crane is installed and the branch is assembled further. This is how the system is improved with minimal effort and cost.

Pros and cons of plastic pipes

The advantages of using plastic pipes for assembling water supply pipelines are due to them:

- Absolute corrosion resistance.

- High cross-country ability.

- Light weight. They are easier to transport and install.

- Resistant to acids and other aggressive environments.

- Elasticity, thanks to which communications do not break when water freezes.

- Ecological cleanliness. Plastic is safe for human health.

- Soundproofing property.

- Low electrical conductivity.

- High technology. Plastic pipes are easy to cut. They fit well at the end, connection with fittings or soldering is not difficult.

- Affordable price.

- Durability. Depending on the type, plastic pipes can last from 20 to 50 years.

- Attractive appearance.

The disadvantages include:

- Low fire resistance.

- Intolerance to exposure to direct sunlight.

- Not suitable for high pressure systems.

- Loss of strength under impact loads.

How to solder plastic pipes without a soldering iron

To solder plastic pipes, use a special soldering iron. But if you don’t have one, you can use a gas burner. The connection will be of high quality if the pipe extends into the fitting by 1.5–2 cm. In order not to violate this standard, you need to measure this distance from the edge of the pipe part in advance and put a mark with a pencil. Then you need to heat up the elements to be connected: the pipe from the outside, the fitting from the inside.

Well-heated parts are inserted into each other until the mark is applied. The formed compound should be cooled for 2–3 minutes without being exposed to any external influence.

To heat small-diameter parts, you can also use an old iron by attaching a Teflon nozzle to it. Further actions will be similar to the previous device.

How to properly connect plastic pipes through plastic fittings

To obtain a high-quality connection of plastic pipes through plastic fittings, I advise you to adhere to the following rules in your work:

- The cut on the pipe must be made even, at an angle of 90° to its axis.

- The end of the part must be thoroughly cleaned of burrs and dirt.

- Be sure to chamfer the end to eliminate the risk of material scuffing.

- A mark is placed on the surface of the pipe, beyond which the end of the fitting should not go.

- The parts fit into each other more easily if the end of the pipe is treated with liquid soap.

- Do not rotate the product inserted into the fitting. Otherwise, the structure of the material may be damaged and waves may form on its surface.

- The plastic pipe must be inserted into the fitting until it stops, especially those reinforced with aluminum foil.

- The nut must be tightened with care so as not to overtighten the joint being formed.

An educational video on the topic can be viewed at the link