Technical equipment for production

Equipment for the production of knives are complex mechanisms that are controlled using computer technology. The MF 223 machine is often used for work. To organize a production where all parts will be made independently, you will need several conveyor lines.

Each will be responsible for one specific detail. Manual labor will only be needed to supply the workpieces and control the quality of the output. Therefore, the bulk of investments will be in machines. Otherwise, production will look like a small workshop that produces single copies.

Knife handles

In parallel with the department where equipment for the production of knives operates, there will be a workshop for the preparation of handles. Handles are installed after heat treatment. This should involve robotic manipulators that ensure factory quality. Depending on the material and shape of the handle, the line is configured for different operations. The choice of handles should be given special attention. Potential buyers first look at this element. It should be made of high-quality plastic, rubber or wood.

Operation of a knife production machine

In order for the machine to work, you need a template that will be used to copy the shape of the future knife. It is made manually or on special CNC machines. In order for a machine for the production of knives to work for a long time and produce high-quality workpieces, templates should be made of hard alloys.

Based on economic calculations, a decision needs to be made. Either the entire line will be fully automated, or specialists will be hired to operate semi-automatic machines. For the latter case, the master who operates the machine should have access to sharpening at different angles and special cutters for complex profiling.

Stages of self-production

When the first stage has been completed and the type of future knife has been selected, the preparatory work is not yet completed. Before you start manufacturing, you still need to select the necessary materials. The most important element of any knife is the blade. The next stage begins with the selection of the steel necessary for its manufacture.

Steel selection

The type of knife dictates the operating conditions. According to these conditions, you need to choose the steel that will best meet the tasks assigned to the blade.

The most important characteristics of the blade that should be taken into account when choosing a steel grade are:

- hardness obtained as a result of heat treatment according to the required regime;

- impact strength, which is responsible for resistance to chipping and brittle fracture;

- corrosion resistance necessary for work in special conditions and in contact with liquids;

- wear resistance required under conditions of increased loads on the blade.

Bulat and Damascus have earned great popularity as materials for blades. But to obtain such blanks you need the knowledge and experience of a professional blacksmith. Even if you know how to use blacksmithing equipment, they are quite difficult to produce. Not every experienced blacksmith is capable of this. You can buy a ready-made product, but it will be quite expensive.

More often, more affordable alloy steels are used, which are much easier to work with. In our country, the following grades of steel are most often used for the production of knives:

- 95Х18 is the most widespread and popular knife steel, also known under the designation 9Х18. The main advantages of this brand are high corrosion resistance and unsurpassed strength even with such a high hardness as 64 HRC. If heat treatment is carried out until the value reaches 62 HRC, the blade will be almost completely protected from edge chipping during impacts.

- 50Х14МФ is a common stainless steel for the production of cutting tools. Scalpels are often made from it. Provides blade hardness up to 58 HRC. Holds an edge perfectly.

- X12MF is a steel with good impact strength, classified as die steel. It can be heat treated up to 62 HRC. The blade holds an edge well, is not subject to brittle fracture, but is extremely sensitive to corrosion. It is necessary to carefully care for a blade made of this steel.

- HVG is a tool steel with acceptable hardness and excellent impact toughness. Does not break under severe shock loads.

- 50HGA is a spring steel, therefore it is well suited for harsh operating conditions, but it rusts very actively.

- 40X13 - also spring steel, but stainless. Happens quite often. However, difficulties arise during operation due to the low durability of the cutting edge.

Other brands are used less frequently because they are less common or do not have the necessary characteristics.

Work order

The process of making a knife yourself contains a large number of stages. Each of them deserves a detailed description, including all the nuances and advice from experienced craftsmen. Simplified, all actions can be divided into the following operations:

Read also: What kind of cast iron is steel made from?

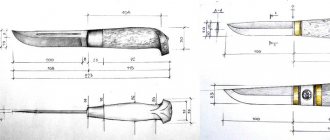

- Drawing up a drawing. Based on the purpose of the product, it is necessary to carefully consider the shape of the blade and the method of attaching the handle. Many successful solutions have already been found, so you can take your favorite model as a basis.

- Receiving the workpiece. Gone are the days when a knife blank had to be reforged from an old part. Nowadays it’s quite simple to buy a piece of rolled steel of the selected steel of the required length. However, this does not completely eliminate the need for blacksmithing. The best structure of the material is obtained only in the process of drawing a billet from long products. If forging is not possible, you can purchase a blank in the form of a strip, but its mechanical characteristics will be slightly lower.

- Mechanical restoration. It is most convenient to perform the initial processing of the contours of the future product on a milling machine. You can use an emery sharpener, but you should strictly monitor the heating of the steel. When making slopes it will be very difficult to do without a cutter. If the situation is hopeless, you can process it with sandpaper, but it will be very difficult to maintain the geometry.

- Heat treatment. The hardening and tempering process is recommended to be carried out in accordance with the recommendations of the reference books. In the absence of equipment and the ability to control the temperature, it is possible to control the temperature by heat colors, but this process requires the help of an experienced craftsman.

- Making the remaining elements of the knife. At this stage it is necessary to make the handle, pommel and guard, if provided for by the design.

- Assembly and final processing. The creation process is completed by assembling the finished product, sharpening and polishing.

If you have experience working with metal, it is not so difficult to make knives with your own hands at home. Videos on this topic, shot by experienced craftsmen, will always help you understand the intricacies of all stages of production. With each new blade you make yourself, the level of skill will increase, which will allow you to create beautiful samples with high technological properties and decorative characteristics.

Investments : from 290,000 rubles

Payback : from 4 months

A knife is the oldest cutting tool. Despite its centuries-old history, its appearance has remained almost unchanged. The basis is still the blade and the handle. At the same time, the scope of application of the tools is varied: housekeeping, hunting, fishing. Therefore, the business related to the production of knives will always be relevant.

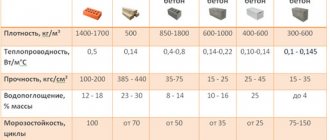

Materials for the production of knives and requirements for them

With a large number of types of knives, steel with different properties is required. For example, a typical kitchen appliance requires a material with a hardness of 48 to 57 HRC. In the case of a hunting knife, this figure should be higher.

Therefore, steel grades for the production of knives are selected based on the conditions of its future operation. In addition to hardness, there are a number of other requirements:

- the cutting edge must retain its shape for a long time and be hard;

- steel should not rust from household liquids;

- the knife must be elastic;

- hardness should allow sharpening at home;

- If possible, a balance should be maintained between the blade and the handle.

It is quite difficult to satisfy such requirements with just one grade of steel. Therefore, several varieties are the most popular: CPM S30V and 154 CM. But sometimes there are domestic analogues of D2, as well as AUS 8. Having chosen the grade, steel should be purchased in bulk from the manufacturer. This option will be much more profitable.

Purpose and characteristics

The production of any knife is always preceded by the selection of the required type. Not only the characteristics of the future product, but also the conditions of its manufacture depend on the purpose and operating conditions.

Read also: Which is better, a jigsaw or a circular saw?

The following types of knives are most often made independently:

- Hunting blades are the most favorite blades among masters. They have the opportunity to realize the full potential and knowledge of the creator, because the most serious requirements are imposed on products of this type. The main purpose of a hunting knife is to cut prey, so special attention is paid to the high hardness of the blade and its ability to hold an edge for a long time and not become dull. We must not forget about maintaining the required impact strength, which determines the ability of the blade to resist chipping in the event of an accidental impact on the bone of an animal. The inability to change the blade during hunting dictates the need to maintain high wear resistance.

- Tourist ones are very popular among lovers of outdoor activities. The conditions for their use determine the main tasks of such blades: cutting branches, planing wood chips, and solving a wide range of small hiking tasks. In nature, there is no way to correct the blade or sharpen it if it becomes dull, so special requirements are placed on the durability of the cutting edge. The high hardness required to maintain the required sharpness should not cause increased brittleness. This blade is often used as a substitute for an axe. Therefore, the butt of the blade must have considerable width and strength in order to withstand impacts.

- Survival knives are a derivative of tourist knives. Such blades are equipped with special devices for survival in difficult conditions. However, in the production of such products, in pursuit of the maximum number of functions, they often forget about the main purpose of the blade, paying less attention to the quality of its manufacture. The need for additional equipment may force the manufacturer to reduce the blade, reduce the thickness of the butt, which will negatively affect the performance of the product. Often the best solution is to choose a travel model that is more adapted to special conditions. It is better to have all other devices present in survival knives separately and not integrate them into one product.

- Kitchen knives are also popular for making yourself. Models on sale with a high-quality blade are usually very expensive, so making them yourself is profitable from an economic point of view. The special characteristics of the blade have requirements similar to those of hunting models. The blade must have high hardness in order to hold an edge perfectly and easily cut any product. Moreover, the blade should not chip when colliding with bones and a cutting board. This requirement is especially relevant, because solid glass cutting boards are now quite widespread.

There is often a misconception in which the purposes of a camping knife and a hunting knife are confused. Among newcomers to the field of tourism and hunting, there is an opinion that it is possible to make one universal blade that will cope with all the necessary tasks with equal success. However, this is not the case.

Touring models are designed primarily for rough work. High hardness is also important for them, but fragility when working at fracture is strictly unacceptable. For hunting models, hardness always comes first, because their most important characteristic is the sharpness of the blade. Cutting prey with a camping knife is quite problematic due to the relatively soft blade, and a hunting blade can simply be broken if you try to use it instead of a camping one.

It is impossible to create a universal blade for all conditions. You always have to improve some qualities by reducing other characteristics. If you plan to solve a wide range of tasks, it makes sense to make several knives, each of which will perform its own function.

Materials for making knife handles

For the full operation of the enterprise, equipment for the production of knives must include, as already mentioned, a device for making reliable and comfortable handles. Of course, you can order ready-made pens from other companies. But it’s still more reliable to have your own production.

For wooden handles, choose hardwoods with high viscosity. Plastic handles are made individually using injection molding. Since the convenience of a knife primarily depends on the handle, its shape is specially profiled for fingers.

Making a grinder from Chapai

Grinders “Ot Chapaya” enjoy absolute authority among specialists for their thoughtful design, functional versatility and high quality workmanship. The family of these machines was developed by Andrey Chapai, an engineer and entrepreneur from Kovrov, who died at the beginning of 2021.

Today his wife continues to produce and sell them.

Grinder from Chapai.

Chapaev machines are capable of processing wood, metal, plastic, and stone. They are ordered by people who need constant use of this tool and its special settings. Such grinders are an example of homemade devices with high productivity.

Sales of finished products and advertising

When starting a knife manufacturing enterprise, you should know in advance for which consumer the product is intended. If these are kitchen appliances, then the buyers will mainly be housewives and professional chefs. In the case of a hunting knife, this could be all men.

An online store is perfect for selling and attracting customers. Its service is inexpensive and requires minimal staff to ship and process orders. Advertising can also be organized on the Internet. Particular attention should be paid to various thematic communities and forums.

Making a hunting knife at home

The process of making a handmade hunting knife is no different from the step-by-step instructions given above and the main idea is to accurately adhere to the dimensions according to the prepared sketches.

Hunting knife

A distinctive feature of a hunting knife is its configuration: the center of gravity of the blade is shifted to the handle and the blade is narrower in comparison with it. The handle at the base has a protective limiter, which allows you to protect the hunter’s hand during a strike. The material of the handle should be chosen in such a way as to prevent the hand from slipping from it. The average length of the blade is usually 12-15 cm with a width of 25-30 mm.

Any craftsman, inspired by a photo he liked on the Internet, or an unusual product spotted from a friend or store, can easily bring all his ideas to life, all you need to do is have a minimum set of necessary tools and the desire and result will not be long in coming!