People who work with sheet metal know that tin snips are highly prized. With their help, you can divide workpieces into parts, cut holes, and make curved cuts. Beginners who have not worked with this tool need to know what types of scissors there are, how to choose them correctly when purchasing, and whether it is possible to make the device yourself.

Metal scissors

Areas of application

Metal cutting shears are considered an additional tool that is used in various industries. Their main purpose is cutting metal sheets. Secondary work performed by them:

- curved cuts of small radius;

- separation of metal blanks;

- trimming profiles when assembling a frame for drywall;

- figure cutting;

- cutting holes;

- cutting metal tiles.

Devices are used in construction, mechanical engineering, metallurgy, and household work.

Basic concepts about metal scissors

Metal shears are a hand tool, the device of which includes two knives with handles. They can be either manual or electric; both options are indispensable when carrying out repairs, in household or construction work. With their help, you can cut steel sheets of different thicknesses and achieve maximum accuracy of the linear dimensions of the workpiece.

There is an impressive number of different types of scissors, from solid stationary units with high power to mobile tools with low weight. They all differ in their scope of application, device characteristics and specifics of operation.

Features of operation

When working with metal with scissors specially designed for this purpose, no chips are formed, since the process of plastic deformation occurs, caused by the influence of force. By closing, two knives create a certain pressure, and the material is divided along a straight line. In order for the cut to be correct, the gap located between the two blades must have a certain size. If it is too small, the edges of the cut will turn out to be torn, and if it is too large, it will lead to the formation of burrs. The size of this gap depends on the thickness of the material.

The operating principles of metal scissors create some advantages when using them, among which the following cannot but be highlighted:

- Safety achieved by controlling every centimeter of the metal being cut. Unlike working with a jigsaw or circular saw, the risk of your hand slipping when using scissors is minimized.

- Functionality expressed in the ability of this tool not only to easily cut along straight lines, but also to cope with fragments of different configurations. Due to this, the scope of its use is significantly expanding.

- The ability to provide the most correct and precise cut.

- Creating minimal noise during operation, eliminating the need for personal protective equipment.

For carrying out procedures with galvanized steel, scissors are the ideal solution, since cutting does not damage its protective layer. The disadvantage of this tool is its low performance compared to electrical equipment with similar functions.

Classification of tools

Modern metal shears are distinguished by a variety of configurations and are divided into groups according to certain characteristics, such as:

- cutting principle;

- operating principle.

The specifics of cutting include the following types of tools:

- knife;

- die-cutting (notching).

Depending on how they function, scissors can be:

- mechanical (manual);

- electric.

Knife options consist of two single-edged knives and are designed to cut material only from its edge. The work of die-cutting tools is carried out by gouging out metal, usually applied to corrugated or profiled sheets. Knife models can be of two types, differing:

- the nature of the cut (left or right);

- type of cut (curve or straight).

For samples with a right-hand cut, the marking line is located on the right side of the cutting edge, and vice versa for options with a left-hand cut. The products cut the material according to a pre-created marking, over which the upper blade is located during operation. Straight models cut the material only in a straight line, and their shaped versions have the ability to maneuver, which allows you to obtain products with an original shape.

Purpose of models

Shears for metal belong to metalworking tools and are designed for processing workpieces by cutting. Depending on the type, they are used in the following actions:

- Straight cutting of metal sheets, which can be either flat or profiled; work can also be carried out with siding and metal tiles.

- Shaped cutting, which involves cutting out various configurations.

- Cutting pipes made of metal or metal-plastic.

- Cutting air ducts in a ventilation system.

- Cutting nails, electrical wires and tying wire.

- Work with different types of mesh: chain-link, reinforced for plaster and other similar options.

It follows from this that metal scissors are a universal tool used not only in construction work, but also for household purposes.

General classification

From the variety of all tools, we can distinguish certain types of metal scissors. In terms of quality, functionality, and reliability, professional and household models stand out. Based on the principle of operation, the following groups of tools are distinguished:

- Hand scissors for cutting metal are mechanical tools used for various jobs. They are activated by human efforts.

- Guillotine - desktop models, one part of which is fixed on the desktop, the other remains movable.

- Roller - the base on which the guides are fixed, a special knife on a movable carriage. They can only be used to make straight cuts. These are large structures that require additional free space for installation and operation. Equipped with fastenings for long workpieces. The second name is disc shears.

- Hydraulic - devices that are often used by rescue services to free people. During their operation, the force is evenly distributed along the entire length of the blade.

- Electric - models that are driven by an electric motor. Used for cutting metal sheets and cutting holes. There are spline, punch, cut-in, sheet, and perforated.

If we talk about the design and work being carried out, we can distinguish the following groups of tools:

- Straight - classic devices for cutting metal workpieces.

- Figured (radius) - used for figured cutting. The design has special bends that allow you to make uneven cuts.

- Universal - used to create straight, figured, curved cuts.

We must not forget about the existence of tools with an offset lower blade. They can be left-handed or right-handed. The first type of scissors has green handles, the second type has red handles. The principle of operation is that the lower blade goes to the right or left side when cutting.

Cutting metal with curly scissors

Types of scissors

There are two categories of shears for cutting sheet metal. These include:

- manual models;

- automated designs.

The first type is designed for cutting small parts made of aluminum or steel. They consist of two cutting bases and two long handles. The last parts create the necessary pressure during the cutting process. The longer the handles, the easier it is to cut iron.

At the end of the working process, the knives close together. In turn, they are divided into: right-sided and left-sided. This criterion ensures uniform division of the web clockwise and counterclockwise.

Manual models are divided among themselves according to the material and method of their manufacture:

- forged;

- cast;

- composite - lever.

What should you consider when choosing metal scissors?

Shears for cutting sheet metal come in different designs, sizes, and operating principles. When choosing them, you need to take into account the technical characteristics of the tool and a number of third-party factors:

- The location of the blades, the presence of additional bends. The shape of the cut will depend on this.

- Cutting edge capabilities. This parameter is selected depending on the thickness of the sheets you will have to work with.

- Comfort at work. It is important to hold the device with your hands, try to make cutting movements without workpieces, to understand how convenient the tool is.

- Operating principle. Depending on the budget, you can purchase a manual mechanism, hydraulic, or electric.

By understanding the above factors, you can easily choose metal scissors.

Types of instruments

Due to the fact that there are a huge number of different types of devices on the market, before choosing manual metal scissors, it is necessary to consider each of them in more detail in order to first find out the features.

Straight metal scissors

These models are designed for straight cuts. They come in two types. In the first, the incisors are located at the same level as the handles. During their use, it is comfortable to cut profiles, as well as metal sheets. In the second models, the cutting elements are shifted downwards in relation to the handles. Using such a tool, long longitudinal cuts are made. Thanks to the displacement of the handles, the cutters are prevented from getting stuck in the metal and the hands of the person cutting with the device are protected from cuts.

Metal scissors for shape cutting

Such models have blades rounded at the edges. Using them, it is possible to cut uneven rounded cutouts, level and round the perimeter of metal sheets.

If there is a need to make complex contours, then you should resort to the use of finger scissors, the peculiarity of which is the presence of thin and narrow cutting elements.

Metal snips for cutting holes

Models of the radius variety have short cutters, through which it is possible to make holes and circles of the required diameter.

Combined metal scissors

This tool combines several types at the same time; for example, using them you can make straight and round cuts. Combined scissors also include specialized models. For example, to cut materials for a roof, you can use roofing tools with a lower handle with a special bend, which makes it possible to apply more significant force and interact with workpieces up to 3 mm thick.

Tool manufacturers

There are several companies that occupy leading positions in the ranking of the best manufacturers of metalworking equipment in the CIS. It’s worth talking about them separately:

- Kraftool - classic hand tools for cutting sheet metal. Easily cuts through thickness of 1.5 mm. Having practical experience in using such tools, you can use them for both straight and curved cuts.

- Bison - scissors that are made of tool steel. The optimal cutting thickness is 1 mm. Intended for household use.

- Sparta is a tool that many despise, but after trying it they change their point of view. They are considered one of the best in terms of price/quality ratio. Easily cuts through metal sheets 1 mm thick.

The devices are used in construction, household, and industrial work.

Scissors from the manufacturer

Features of choosing a tool

When choosing scissors, the operational parameters and purpose of the tool are taken into account.

- Knives. Chrome vanadium steel is used for durable blades. Models made of stainless and chromium-nickel steel have proven themselves well.

- Cut thickness. Scissors should be selected for specific tasks. For cutting aluminum, copper, tin, and steel, scissors with a cut of up to 0.8 mm are sufficient. Reinforced models are capable of cutting metal up to 1.5 mm.

- Handles. The handles of the tool should be non-slip and comfortable for a secure grip.

- Length. The parameter shows the total length of the tool. The longer the scissors, the more force they can apply when cutting.

When choosing a tool, the tasks and characteristics of the material are taken into account

How to make your own instrument?

Some craftsmen who engage in metalworking, cutting sheets in garages and private workshops, make homemade scissors. This applies to roller structures. To make such a tool, you need to make a work table, attach guides to it, and make a roller with a pressure handle. The disc is made of a sharpened bearing. Using a handle, it is pressed into a metal sheet. After this, the master holds the handle and pulls the cutting disc towards himself along the guides.

Most tinsmiths do not recommend making homemade fixtures. This is due to the low level of safety, reliability, and efficiency of self-made equipment.

Cutting rules

When cutting metal with scissors, you need to take into account some features, follow a number of rules and remember about safety:

- You can cut thin metal without additional equipment. To do this, you need to place the sheet on a workbench, hold one edge with your hand, and cut the other along the intended line.

- When cutting thick metal, you need to secure one handle in a vice so that there is a stop. The pressing force increases, therefore, thicker sheets can be cut.

- Using straight scissors, you can cut holes in the center of the sheet. To do this, you need to make a hole in the center of the circle or at its edge.

When working with metal wire, you must wear protective gloves. To protect your eyes, you must use glasses and a mask. Direct the cut pieces of wire towards the workbench. Check the sharpness of cutting edges before work. Pass the device to other people only with the sharp ends facing you.

Metal scissors are necessary for construction, household, and industrial work. They help to perform a number of operations with metal sheets when it is impossible to use a grinder or a hacksaw. When choosing a tool, you need to pay attention to the technical characteristics of the product, and when working with it, take into account the rules.

Types of mechanical shears for cutting metal

Hand scissors for straight cutting are used only if you need to make a cut along a large diameter circle or in a straight line.

Mechanical metal shears, which are equipped with curved blades, are quite convenient for cutting holes or cutting parts of all kinds of elaborate shapes .

Mechanical finger products are characterized by the presence of rather thin blades. These scissors are used for the same purposes. Also, taking into account the location of the cutting blades relative to each other, these products can be cut left or right.

Manual chair shears are used to work with thick metal sheets, approximately 2-3 millimeters . For better convenience of work, there is a special bend at the end of the lower handle of these scissors; it is quite convenient to hook the scissors to the workbench, so that by pressing the upper handle with all your strength, this increases the cutting force.

Power mechanical scissors have a handle consisting of two levers secured by a hinge. This design feature allows you to cut metal products and sheets with a thickness of no more than 2.5 mm. Most often, the kit comes with replaceable disks and blades, which are used for cutting metal rods with a cross-section of up to 8 millimeters.

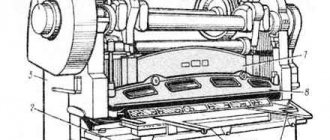

Lever mechanical scissors are mounted on a workbench with their base. These scissors have one blade in the body, and the other blade is movable and controlled by a handle. These models are used for working with soft sheet metals, for example, the largest thickness of a processed brass sheet is 6 millimeters, and a steel sheet is 4 millimeters .