SHARE ON SOCIAL NETWORKS

FacebookTwitterOkGoogle+PinterestVk

Step drills for metal (herringbones) are used when it is necessary to process sheet material whose thickness does not exceed 4 mm. The use of such products requires certain skills from the master. To purchase and properly operate the necessary tool, it is recommended to pay attention to some nuances.

Step drills are ideal for metal up to 4mm thick

Step drills for metal: how they differ from cone drills

Step and cone products have many common features. These tools primarily have similar edges. Their edges are very sharp, which significantly increases the effectiveness of the tools during operation. The advantages of step and cone tools include the fact that they save time and also simplify sheet metal processing. The main disadvantage is the price of step drills for metal and conical parts.

Step drills have sharp edges in the form of steps, while conical drills have a smooth surface

What are the differences between stepped and cone products? The main distinguishing feature with which you can easily determine the type of drill is the design of the main element of the product - the head. This part, regardless of the type of tool, has a conical shape.

The head of a step drill includes several steps with sharp edges. This design increases the efficiency of the tool. In turn, conical products are characterized by a smooth surface.

Features of the shape are the main criterion that distinguishes conical products from step drills for metal. Cone options are less expensive, but they are not very convenient to use. A stepped tool allows you to make a hole of the required diameter even if a person has no experience working with such a device. This is achieved through a clear division of the part into steps (levels).

Advantages

A step drill can be used to drill plastic, copper, aluminum and other materials.

When drilling holes, the chamfer is automatically removed

Advantages:

- The quality is superior to conventional drills;

- may have a titanium coating, which extends service life and increases the strength of the cutting edge;

- universal - replace a whole set of drills;

- allow you to drill perfectly round holes that do not require additional processing;

- you can drill a hole of a sufficiently large diameter;

- high performance.

What kind of work can you use herringbone drills for?

Functional parts of this type are used to create holes in metal sheets. Such drills belong to the category of specialized tools, so their cost is quite high. Often this fact stops buyers from making a purchase. However, the purchase of such a product may be justified, for example, in cases where precision is required when performing work.

Step drills are mainly used to create holes in metal.

Each level of the step tool has a unique diameter that increases as it approaches the base. The convenience of this type of design is undeniable, since it is very easy to select the desired diameter during drilling.

Such products are used to make holes in metal. Herringbone drills for metal are distinguished by high quality drilling. Moreover, this is noticeable even when very thin sheet material is processed. Other drills do not allow making a smooth hole in a metal sheet up to 1 mm thick.

It is worth saying that step-type tools are used not only for metal processing. They can also be used for drilling holes in the following materials:

- plastic;

- drywall;

- tree.

Herringbone drills can produce perfectly straight holes

If you need to make a hole in a pipe, it is also recommended to use a metal step drill. Reviews about such a tool can be studied on the Internet. It should be said that step drills are often used to grind the edges of holes made with other tools. Metal shavings can also be removed manually, but this is much more difficult.

How to properly drill holes with a cone drill: instructions

The operation of a conical cutting element has some peculiarities when comparing this process with the use of conventional spiral devices. Thus, in order for a beginner who has no experience with such a tool to understand the features of use, he must study the instructions. It is not recommended to deviate from the work algorithm during work, as this can lead to various problems.

When choosing a tool into which a cone drill will be installed, it is worth considering that it must reach a speed of 3 to 5 thousand rpm

To study the technical characteristics of the cutting part, you can additionally familiarize yourself with its drawing. Drills and their diagrams can be easily found on the World Wide Web. The first stage is preparatory. First, you will need to purchase and prepare all the necessary tools and materials. Let's look at what exactly is needed in this case:

- conical cutting tool;

- drill;

- workpiece in which the hole will be made.

The choice of a conical tool depends entirely on the diameter of the hole to be made in the workpiece. When choosing a drill into which the drill will be installed, it is worth considering that the tool must be able to develop the required speed (from 3 to 5 thousand rpm). Before starting work, experts advise fixing an additional handle on the drill. Sheets made of steel, soft metals, as well as a variety of synthetic materials can be used as a workpiece.

Conventional drills with conical shanks are much more difficult to use for making holes in metal. Such products have a simple design, which does not contribute to accurate work performance. After preparing all the necessary tools, you can proceed directly to drilling the workpiece. The procedure in this case consists of 4 stages.

Having fixed the drill, you need to choose the correct direction of movement of the tool chuck

First of all, you need to fix the cutting device in the chuck of the electronic tool. Next, you will need to select and apply the appropriate markings in the place that was chosen for drilling the hole.

At the next stage, the cutting device is applied to the surface of the workpiece and drilling is performed. It is important to remember that the product must be located in a strictly perpendicular position in relation to the workpiece. During the drilling process, this angle must be strictly observed. Metal drills, which have a conical shape, are used to make different diameters and are independent tools.

The final stage is gradual introduction into the metal material with increasing speed. The end result of this work is a neat hole, the edges of which are free of burrs and any other defects.

Note! Many craftsmen note that the ease of use of such a drill is its main advantage. Therefore, such cutting products are great for beginners who do not have relevant experience.

The cone drill for metal must be strictly perpendicular to the workpiece

Step drills for metal: main advantages

Tools of this type have many positive qualities that determine their high efficiency. Of course, the main disadvantage of such a product is its cost. The price for stepped parts varies from 2 to 5 thousand rubles. The final cost of a drill is influenced by the following factors:

- material of manufacture;

- strength class;

- presence of spraying.

The price of step drills is completely justified, since their advantages greatly simplify the work of drilling holes in a variety of parts. One of the most significant advantages of such products is their versatility. One cutting tool can be used to perform a huge number of tasks, which is very convenient.

Metal step drills are efficient and versatile

Another advantage of such drills is their high strength. In particular, it is worth paying attention to their cutting edges. The strength characteristics of these elements not only ensure high precision during operation, but also extend the service life of the tool.

Speed of operation is also a positive characteristic of these products. The herringbone drill bit has a pointed tip that allows it to be used on very tough metal surfaces (such as stainless steel). A metal drill is a specialized tool. When using it, there is no need to use additional devices (centering part, etc.).

The design features of the stepped tool make it possible to make precise holes with smooth edges. Thus, when using such a product there is no need to use a grinding machine or a needle file.

It is also worth noting that such products are installed both on hand-held drills and on professional stationary machines. Before purchasing a herringbone drill, it is recommended that you familiarize yourself with its varieties. This will allow you to select the best step-type metal drill, taking into account individual criteria.

One of the main advantages of such drills is strength and speed of work.

Scope and design features

Cone (or step) drills have a long working life, which is ensured by the high strength of their cutting edges. Unlike a conventional drill, a cone drill allows you to perform technological operations that in any other situation would require the use of several tools. It is this versatility that largely explains the high cost of drills in this category.

The conical drilling tool, due to its design features, allows processing at high speed, at which the quality of the edge of holes formed even in thin sheet material is not reduced.

Step drill device

Cone drills can make holes not only in metal, but also in drywall, wood, plastic, etc. They also successfully cope with dense metal, which cannot be said about any other type of drilling tool.

The sharp tip of the step drill not only eliminates the need for a centering tool, but also easily cuts into the structure of even the densest metal. The resulting hole does not require additional processing using a needle file and a grinder.

Most step drills are capable of drilling through metal up to 4mm thick

The progressive channels of the step drill, arranged in a spiral, are made in different sizes with a smooth transition. This design feature increases the efficiency of the cone drill when working with thin sheet metal by at least 50%. In addition, when drilling metal parts with a tool with such spiral translational grooves, its smoothness is ensured.

Cone-type drills can be used either in conjunction with a manual drilling device or when installed on special equipment.

An abrasive coating based on diamond or titanium chips can be applied to the working surface of step drills (this does not contradict the requirements of GOST). This coating of the cutting surface significantly increases its strength, which makes it possible to minimize the frequency of sharpening. Naturally, you can count on this advantage of using a sprayed cone drill if the rules for its operation are followed and the permissible load on it is not exceeded.

These drill bits are made from high quality high speed steel with titanium coating.

One of the tasks that can be solved with the help of a cone drill is the correction of defects in holes produced by a tool of another type. Such defects, in particular, include torn edges. Step-type drills are practically irreplaceable in cases where it is necessary to obtain high-quality holes in thin sheet metal, products made of fiberglass and other polymer materials.

Considering all of the above, we can conclude that cone drills are even more versatile than traditional twist-type tools. That is why they will not be superfluous at the production site and in the home workshop. How convenient and effective a cone tool is, the cost of which depends both on the diameter of the working part and on the type of spraying, can be judged by the video of processing with its use and by reviews from specialists.

Design and characteristics of a cone-step drill

These instruments have a rather complex design. Their configuration may differ depending on the variety. Let us consider in more detail what parts such products consist of. The top of the drill is represented by a pointed tip, which makes it possible to cut into metal of any density without much difficulty.

Other tools are also used for processing metal sheets, for example, crown tools. A metal drill of this type does not require the use of auxiliary centering devices, but it is not suitable for working with thin metal. Spiral analogues also do not allow such work to be performed accurately.

Step products are very effective when working with aluminum, steel, copper and other sheets and pipes. Tools of this type are shaped like a cone, which includes 2 grooves. They promote drilling of materials. During operation, when moving to the next level, a chamfer is formed for the hole that is created by the previous step.

Due to their design, step drills are suitable for working with copper, steel and aluminum sheets

A 4-32 mm step drill for metal also has an opposite end, which is mounted in the tool chuck. The opposite end, or tail, has the most suitable design for this and consists of six edges. The advantages of such tools are undeniable, which is why many craftsmen recommend them for working with metal parts.

Drills for ceramics and glass

Ceramic tiles or glass are drilled with a crown or a special spear-shaped tool. Its tip is made of either pobedite or tungsten carbide. If a specialized tool for glass or tiles is not available, you can use a concrete drill

It just needs to be sharp, and you need to work with it carefully, since its shape is not entirely suitable for such work.

Spear drill bit for ceramic tiles and diamond-coated bit.

A crown for glass and tile is almost no different from a crown for stone. Only on its cutting edge instead of teeth there is a diamond coating.

A tool called a ballerina is used to drill large holes in tiles. It resembles an ordinary compass. Drilling is done from the underside of the tile. The drill speed is set to minimum.

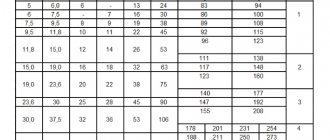

Types and sizes of stepped metal drills

Stepped tools used to make holes are classified according to several criteria. In order to select the necessary product, it is recommended that you familiarize yourself with each of its types in more detail. The first factor by which such drills are differentiated is dimensions. Depending on this criterion, the following drills are distinguished:

- small;

- average;

- big.

Step drills also differ in coating material. Today you can purchase cobalt metal drills, as well as titanium analogues. The second type of products has higher strength, which is reflected in their cost.

The diameter of the step drill can vary from 4 to 38 mm

The design of drills of this type assumes the presence of a groove. The most common drills are those that have a straight flute. The second configuration option is to arrange the channel in a spiral. On sale you can find models that have a combined type of groove for chip removal (longitudinal-spiral).

Note! Step drills need to be sharpened from time to time. Sharpening will be more difficult if the tool has a spiral groove.

Of course, one of the most important characteristics of any tool is its size. The steps in such a drill can have different pitches. This indicator may differ depending on the type of product. It is also worth paying attention to another important criterion - the diameter of the metal drill. This parameter varies from 4 to 38 mm. The diameter limit may be lower. It all depends on the number of steps in the instrument. The height of one step is usually 0.5 cm.

Number and shape of working grooves in stepped products

One of the most important indicators of such stepped tools is the number of cutting edges. It is important to understand that this parameter has nothing to do with the drill steps. The cutting parts are located on the grooves of the conical product. In addition to their main function, they perform another one: they remove chips that are formed during the work process.

Grooves in step drills help guide chips while working

Grooves can be of 3 types: straight, spiral, and longitudinal-spiral. Each variety has its own advantages and disadvantages. An example is a straight edge that is easy to sharpen. However, during operation it does not behave as smoothly as a spiral one.

Despite its high cost, the step tool replaces a complete set of metal drills. It is much easier and more convenient to operate one product. The number of grooves is an indicator on which the quality of sheet metal processing depends. The quality of drilling may vary depending on the speed at which the material is processed.

When choosing a drill for making holes in metal material, you need to focus on several points. It is not recommended to purchase the first product you come across, as it may not be suitable for a particular job.

Features of the shape and dimensions of conical drills

To correctly select a conical cutting device, it is necessary to clearly understand what shape options for these products are available on sale. Each type of product has its own advantages and disadvantages. Let's look at three main types of such tools:

- ordinary (stepped herringbone);

- truncated, without a guide point;

- combinations of two conical parts.

The maximum diameter of cone drills for metal is 60 mm

The latter option consists of two segments, each of which has a different angle of inclination of the surface. The grooves that these products include can also have different shapes.

Helpful information! The maximum diameter of such drills may vary, but most often there are models in which this figure is 32 mm. A 4-32 mm cone drill for metal can be purchased at a specialized store or ordered online.

Today on sale you can find larger models of drills, for example, stepped products with a maximum diameter of 40 or 50 mm. It is worth saying that this figure for the largest models does not exceed 60 mm.

When choosing a conical cutting device, it is also recommended to pay attention to the shape of its tail. This drill element is used to secure the tool in the drill chuck. The following shank shape options are available:

The tail part of a cone drill for metal can be cylindrical, triangular and hexagonal

- cylindrical;

- triangular;

- hexagonal

The last two varieties are recommended by many craftsmen, as they allow the drill to be more tightly fixed in the working tool. When using triangular and hexagonal specimens, rotation is eliminated, therefore reducing the risk of injury when drilling a metal surface.

Smooth products expand closer to the tail section, which is fixed in the chuck. They, unlike stepped ones, do not have a clear gradation of diameters. In the stepped version of the conical cutting tool, the height of the levels is 5 mm. However, in some cases this indicator may be different (for example, 4 or 6 mm). Metal drills have a pitch that is 1 mm up to a step with a diameter of 12 mm. Larger levels are characterized by a step of 2 mm.

It is important to remember that you can determine the maximum permissible thickness of the metal material at which it is permissible to use a particular drill yourself. This parameter, as a rule, completely repeats the height of the levels of the conical device.

The height of the levels in step drills for metal is 2-6 mm

Color of step drills used for metal processing

All step tools used for processing metal sheets of small thickness are divided into groups according to quality. Identifying a particular drill is quite simple. All you need to do is pay attention to its color. The following instrument options are currently available for sale:

Step drills come in black, gray, dark and bright gold

- gray;

- black;

- golden (dark);

- golden (bright).

Gray drills. This color indicates that the material for the manufacture of the product is ordinary steel, which has not undergone additional processing. These tools do not have high strength characteristics. One of the advantages of such devices is their low cost.

Related article:

Metal lathe for home: types and technical characteristics

Features and benefits, device. Review of TV-4, TV-6 and TV-7 machines. CNC machine. Recommendations for selection and prices. Working on the machine.

Black. This color indicates that the steel product has undergone additional treatment with steam heated to high temperatures. This enhances the technical characteristics of the tool and extends its service life. The price for such products is higher than for gray ones.

Note! The material and the product itself made from it must comply with all the parameters specified in GOST. Gray metal drills are not suitable for long-term use.

Black drills are treated with high temperature steam, which increases the technical performance of the tool

Golden (dark). Such instruments undergo quite intensive temperature treatment. This type of procedure helps eliminate stress in the metal product. The result is a durable part that is best suited for extended use. The cost of such drills is quite high.

The color of the drill is not related to its configuration. All products have a special channel. The presence of a groove allows for efficient drilling of metal. Special curved channels can also be found in other products that are used for drilling metal. A good example in this case are metal screws with a drill.

Golden (bright). Another option for step type drills. This coloring is obtained by applying a special protective coating of titanium to the surface of the product. Such tools have the highest strength.

Recommendations from experts on choosing a cone drill

Many people who are not well acquainted with the features of various cutting attachments find it difficult to decide on the purchase of such a tool. In order to avoid making mistakes when choosing, you need to understand a few basic points.

First of all, you need to remember that all nozzles differ in color. This is a very important point, since its technical characteristics depend on the color of the product. For example, the steel color of the working part indicates that it has not been subjected to additional temperature (or any other) treatment.

Steel-painted fixtures are not characterized by high strength and, accordingly, are more susceptible to wear. They are recommended to be used exclusively for making holes in thin-sheet material, as well as for processing plastic, drywall and wood. Cone drills for metal of this type have the lowest cost.

The black color of the cutting tool indicates that the product has undergone additional high-temperature processing. Such devices have higher strength, which helps to increase their service life.

Smooth cone drills widen closer to the tail and do not have a clear gradation of diameters

Note! The tool must be selected based on its operational purpose. The dimensions of the product may vary, so it is worth deciding in advance which holes will be made with it. Most often on sale you can find conical drills for metal 6-36 and 4-32 mm.

Another option common in the modern market is golden cones. These models have a protective coating of titanium nitride. Due to this, their technical characteristics significantly exceed previous analogues.

Related article:

Step drills for metal: the best solution for beginners and professionals Step drills for metal. What are they used for? Advantages of step drills. Varieties. Tips for choosing.

In stepped options, the height of the levels, as mentioned above, averages 5 mm. Metal drills should not have a deviation in this indicator of more than 1 mm. This is worth remembering when purchasing a tool.

What else should you pay attention to? The brand of the instrument plays an equally important role. Craftsmen do not recommend buying products made by little-known Chinese companies, since in this case the chance of purchasing low-quality or defective products increases significantly. Domestic drills have a shorter working life when compared with their foreign counterparts.

On sale you can most often find conical drills for metal 4-22 and 6-36 mm

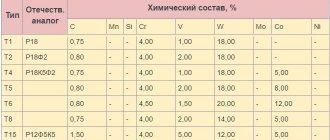

Marking of cone cutting tools: what you need to know

The technical characteristics of such cutting products are indicated in the form of markings that are applied to the outer surface of the tail section. Knowledge of the basic designations allows you to select a high-quality product that is most suitable for specific operating conditions. Let's take a closer look at what information is encrypted in the marking:

- material of manufacture;

- diameter;

- accuracy class.

Deciphering the marking is a very important stage, so it is worth familiarizing yourself in more detail with its possible options. Most products of this type have a pitch of 1 mm. Metal drills, which have a herringbone shape, differ in different dimensions. This information must be included in the labeling.

Most often, the letter designation is the beginning of the marking. Most drills that can be purchased today are marked with the letter "P". This designation indicates that high-speed alloy steel was used to manufacture the device. This material has high strength characteristics.

Technical characteristics of conical drills for metal are indicated in the form of markings on the surface of the tail section

Next comes the next letter, followed by a certain number. This designation contains information about the metal that was used as an additive to the alloy steel. The number indicates what percentage of alloy is in the product.

Note! Marking is not applied to products whose diameter is less than 2 mm. Metal drills of this type have a shank that is too small.

After the percentage of minor metal, the marking indicates the maximum and minimum diameters, as well as the accuracy class of the device. It is worth noting that the letter designation HSS is often found on such products. Metal drills of this type are made of high-speed steel. After the initial mark, the marking contains information about the additional material used in the production of the product.

Criteria for choosing step drills for metal: which one is better to buy

When choosing such products, it is recommended to pay attention not only to their color, but also to some other points. For example, a high-quality 4-32 mm tool costs at least 1 thousand rubles. The dependence of price on diameter can be seen not only in stepped products. A 3 mm metal twist drill will cost less than the same tool with a 10 mm cross section.

Drills from American and German manufacturers are considered the highest quality and most durable.

Drills produced by domestic companies, as a rule, have a more attractive price. However, experts give preference to products that were manufactured by foreign manufacturers. The working life of drills from German and American brands is much higher.

When choosing, you need to pay attention to the final and initial diameters. In this case, a certain pattern can be traced. The more steps, the higher the cost of the tool. As an alternative to the stepped product, you can purchase a set of spiral devices. Metal drills of 10 mm or more still do not work so well. However, the cost of such a kit is usually lower.

To identify high-quality steel, there is a special marking. The letters HSS are indicated on the body of a product intended for processing metal sheets at high speeds. The quality of the steel in this case does not allow the drill to deform even with severe overheating.

Another important criterion that is worth considering is the possibility of repeated sharpening of the tool. This procedure is regulated by regulatory documentation (GOST). Thus, if you wish, you can familiarize yourself with all the nuances of this operation and carry out it yourself.

The drill must be made of high quality steel, this is indicated by the HSS marking

Advantages and disadvantages

The advantages include:

- have a long working life (due to the increased strength of the cutting surface);

- carrying out several operations simultaneously, that is, the versatility of the tool (drilling, chamfering, cutting, grinding);

- high speed of drilling holes without reducing the quality of hole edges;

- high accuracy of the drilling operation (a slight decrease is observed only in holes exceeding 15 mm);

- obtaining an almost perfectly smooth edge;

- the possibility of obtaining a so-called triangular hole;

- completely eliminates the need to use a centering tool at the preparatory stage;

- the ability to drill holes in very hard materials without compromising quality.

Variety of step drills

Of the inherent disadvantages, the most serious is the high cost of the tool.

How to sharpen a drill for metal: step-by-step instructions

In the process of using a stepped tool, its edges become dull. Sharpening allows them to return to their previous characteristics. It is easiest to entrust such work to qualified specialists. Therefore, it is recommended to contact specialized workshops, which can be found in every city. This option has the following advantages:

- the diameter of all tool levels is maintained;

- the correct angle of the cutting edges is not disturbed;

- The possibility of overheating of the product is eliminated.

You can sharpen a metal drill yourself at home. However, to do this, you need to carefully read the basic rules that you need to follow while working.

It is worth knowing that the cutting edges of each step must be identical. Sharpening should not damage them. Compliance with the exact original dimensions guarantees high-quality sharpening. After performing this procedure, the angle corresponding to the planes of the edges should be the same as before sharpening.

A special machine is required to sharpen the drill.

Before starting this work, you need to prepare a support stand. An even better solution is to fix the drill. The moving element is much easier to damage during sharpening. It is important to remember that this procedure uses abrasive materials that belong to the fine-grained category.

Various devices can be used for these purposes. Sharpening drills for metal is best done on a machine. This equipment must contain a special abrasive wheel. The outer surface of such a tool contains fine-grained sandpaper.

The quality of the work performed is quite easy to determine. To do this, you need to pay attention to the shape of the chips that are formed during the drilling process. If sharpening was carried out without errors, then the chips will have the correct dimensions.

Sharpening a metal drill with your own hands using hand tools is done when the drill has a straight groove. Instruments with a spiral channel are not recommended to be processed without special equipment. To perform this operation, you can also use a grinder and a special circle.

Sharpening must be done carefully and correctly so as not to damage the drill

Sharpening cone and step drills

Sharpening on professional equipment

During operation, the cutting edges of the tool gradually become dull and require sharpening. The most correct decision in this case is to contact a specialized workshop that has the equipment and specialist to perform such work. By paying a certain amount, you can be sure that the drill will be returned to you in working condition and you will not have to decide on purchasing a new one. This sharpening guarantees:

- maintaining the diameter of all stages,

- maintaining the correct cutting edge angle,

- no overheating.

Sharpening by hand

However, it is not always possible to find craftsmen who will undertake sharpening of a conical step drill. Most workshops refuse, citing the complexity of execution and insufficient experience of workers.

Therefore, quite often you have to sharpen the drill yourself. In this case, the following basic rules must be observed:

- the cutting edges of each step must remain identical with precise dimensions;

- the angle of the edge planes remains unchanged as a result of sharpening;

- the distance between the cutting angle and the opposite side surface on each diameter must be the same;

- sharpening is carried out in the presence of a support stand or with rigid fixation of the drill;

- Only fine-grained abrasives are used for work;

- when performing, one should focus on the maximum possible restoration of the original geometric shapes of the cutting edges.

Good results can be obtained if you use a sharpening machine with an abrasive wheel, the surface of which is covered with sandpaper. The quality of the sharpening performed is determined by the type of chips formed during drilling. With a high-quality result, it will be the same shape and size.

If the grooves have a rectilinear shape, sharpening can be done manually using an even rectangular block, processing several edges at the same time.

If the machine is replaced with a grinder, it must be well fixed in a stationary position and sharpening must be carried out with a strong support bar to hold the drill.

And yet, if you have the opportunity to entrust sharpening to specialists, take advantage of it. Lack of practical skills can lead to damage to an expensive tool and unexpected material costs.