The question of how to make a nozzle for plucking poultry with your own hands most often arises among owners of small farms, who often have to deal with such a routine procedure as freeing bird carcasses from feathers and down. This work is especially tedious in cases where it is not large chickens or turkeys that need to be plucked, but quails.

The problem of tedious plucking poultry can be solved by purchasing or making a special device yourself.

There are several types of devices on the market today that are specifically designed for plucking poultry. They demonstrate high efficiency if poultry carcasses, which need to be cleaned of feathers and fluff, are first scalded with boiling water.

The principle of operation of most of these devices is based on the fact that the bird being plucked is affected by special pins - rubber pins, on the surface of which a specially shaped notch is applied. It is these pins that, when plucking chickens, quails or any other bird, grab the feather and pull it out of the skin.

Poultry fingers are soft to reduce damage to the carcass. Firmer fingers designed for waterfowl and game birds

As mentioned above, today several types of plucking equipment are offered, each of which is worth dwelling on in more detail.

Centrifuge-based plucking devices

A device for plucking poultry, operating on the principle of a centrifuge, is a predominantly round container, on the inner side surface and bottom of which the beating fingers are fixed. The bottom of such a container rotates at high speed during the plucking process, which ensures constant contact of loaded poultry carcasses with the beating fingers. As a result, the bird quickly frees itself from the feather. In order for such a device to work more efficiently, during the plucking process, water is supplied to its internal part, which, in addition, washes away the feathers that have already been plucked and protects bird carcasses from damage.

Quill centrifuges are available in various designs

Depending on the dimensions and technical characteristics of the centrifuge plucker, this device can be used to process poultry carcasses of various sizes. Thus, small devices are suitable for plucking chickens, quails and ducks, while larger pluckers, which consume more electricity, are used for processing geese and turkey carcasses.

It is advisable to purchase machines that operate on the principle of a centrifuge for small farms, and other types of devices are used to mechanize the plucking of poultry carcasses at home.

Rating of the best feather removal machines

The list of the best models is compiled based on product sales statistics, technical characteristics and customer reviews. This will help you see the pros and cons of feather removal devices in order to choose the best option in terms of performance, endurance and cost.

| Nomination | Place | Name | Price |

| Rating of the best feather removal machines | 1 | Stimul-PM-06 | 38 400 ₽ |

| 2 | Sprut-700 | 54 000 ₽ | |

| 3 | Hobby Farm NT-600WF | 32 400 ₽ | |

| 4 | MTM-600 | 45 000 ₽ | |

| 5 | Hobby Farm NT-600A | 32 900 ₽ | |

| 6 | PM40Q | 29 000 ₽ | |

| 7 | Electromash EM-600 | 26 800 ₽ | |

| 8 | Hobby Farm NT-500 | 25 900 ₽ | |

| 9 | PM-7M | 18 000 ₽ | |

| 10 | VolTera-PM3 | 13 000 ₽ | |

| 11 | Octopus Princess-200P | 10 600 ₽ | |

| 12 | VolTera PM1 | 7 660 ₽ |

Stimul-PM-06

Rating: 4.9

The feather removal machine is designed for plucking chickens, geese, ducks and other poultry. The upper part of the drum can be easily disassembled for cleaning and washing, so it is not difficult to keep the machine clean during everyday use. The equipment has a sufficient resource - all cleavers are designed to process up to 10,000 carcasses. The motor rotates the lower part by transmitting torque through a belt drive and is protected from drum jamming. The electrical part is sealed from leakage, which means the carcass can be watered with water from a watering can during the plucking process. The fletching machine has good stability during rotation. This is due to the large weight, because the drum walls are 1.5 mm thick. At the same time, the level of vibration is minimal and the feather removal device stands perfectly (does not jump) even on a hard floor, and not just in the yard on the ground. AISI 305 stainless steel is designed for food products and meets sanitary standards so that the machine can be used in food production.

The designers included 204 beating fingers in the device, which gently act on the carcass without damaging the skin. If one or two elements break over time, they can be replaced. This is the fastest machine available.

Advantages

- stable design;

- minimal vibration;

- easily disassembled for cleaning and washing;

- allowed for use in food production.

Flaws

- very high cost.

Sprut-700

Rating: 4.8

The universal type machine is capable of processing carcasses of chickens and adult chickens, turkeys, geese and ducks. The feather removal unit is equipped with a 1.5 kW single-phase motor, which can be connected to a 220 or 380 V network (ordered upon purchase, depending on the needs and technical conditions at the site of operation). The machine weighs 55 kg, so it does not wobble in place during active rotation of the lower part of the drum. Thanks to the diameter of the working part of 700 mm, 4-6 chickens or 2-3 ducks can be loaded into it at a time. In terms of productivity, the feather removal equipment surpasses that of many competitors - in an hour you can pluck up to 350-400 chickens or 150 ducks.

Experts included the feather-removable model in the review due to two factors. Firstly, it has a polypropylene tank with an antibacterial coating. This increases the level of hygiene in production. Secondly, there are three rows of striking fingers, each of which is designed for a different pen shape. Thanks to this, it is possible to remove up to 93% of the plumage, leaving a small part on the tail and wings.

Advantages

- The surface of the drum is easy to clean;

- antibacterial coating;

- several types of stylus fingers;

- remote control panel.

Flaws

- high price.

Hobby Farm NT-600WF

Rating: 4.7

The feather removal machine has dimensions of 675x750x990 mm and weighs 65 kg. This is a stable device that will not vibrate or move even on slippery floors. The working part has 135 fingers for faster feather removal. The engine power is 1.5 kW, which is above average and will pull even a large broiler of 3-4 kg. The drum diameter of 600 mm allows you to load several carcasses at once. The machine is suitable for farms and is designed for roosters, turkeys, laying hens, chicks and ducks. The manufacturer claims that the device plucks one chicken carcass in 15-40 seconds. A quail will take 10-20 seconds, and a large turkey can be cleared of feathers in 25-45 seconds. But it is better not to use the machine with geese, since it is not designed for this.

A special feature of the feather removal station with the index 600 WF in the name is the water supply function. Here the liquid flows automatically, so the operator does not need to do anything while plucking is in progress. This equipment makes the machine easier to use, especially when you have to work all day to prepare a large batch of broiler carcasses.

Advantages

- accelerated plucking of chickens in 15-40 seconds;

- there is an automatic water supply function;

- engine power 1.5 kW;

- key elements made of stainless steel.

Flaws

- difficult to carry due to weight of 65 kg;

- not suitable for processing geese.

MTM-600

Rating: 4.6

The feather removal device has a working part diameter of 600 mm and contains 106 fingers on the inner walls. The base rotates from an electric motor with a power of 750 W. In an hour, the machine is capable of passing through 150-200 chickens and up to 60 ducks. With its help, you can remove feathers from a turkey if it weighs no more than 10 kg. All bearings are protected by seals and are constantly lubricated, and the shaft from the engine has an additional cuff. In the reviews, owners like that the pen is raked out not just as it is filled, but forcibly. For this purpose, a rubber curtain is provided that pushes it towards the exit.

This is one of the best feather removal machines in terms of corrosion protection. For optimal plucking, users often pour water on the carcass. This causes rust to gradually appear on other cars. Here, all elements, including the shaft and mounting screws, are made of stainless steel.

Advantages

- the engine is protected from liquids by a rubber seal;

- completely made of stainless steel;

- the inside of the drum has a diameter of 600 mm;

- 106 beat fingers.

Flaws

- not suitable for turkeys weighing over 10 kg.

Hobby Farm NT-600A

Rating: 4.6

And here is another feather removal model from the Hobby Farm brand with an internal drum diameter of 600 mm, which allows you to load up to 3-4 chickens into it at the same time. The device with index 600A differs from the older one in the 600WF line in the absence of a water supply function, due to which the cost is a couple of thousand less. The equipment is made of stainless steel and weighs 70 kg. It stands stable in place and does not jump, but it is often inconvenient to rearrange it, so the pen-removal device is more suitable for stationary use. The machine has four legs and a rectangular body with a removable top. This makes the tank easier to clean. The pen removal tray is designed with a low descent and a large angle of inclination, so nothing gets clogged in it.

The feature of the machine is five rows of striking fingers. Although there are only 136 of them, this arrangement facilitates faster plucking. The feather removal unit also has an increased power of 2.2 kW. In practice, this means that the machine can withstand prolonged operation with maximum loads, and the motor winding does not overheat. We recommend this product for professional activities in breeding broilers and supplying carcasses to stores or selling them independently.

Advantages

- readiness to work “out of the box”;

- Belt drive better protects the motor from overloads;

- high quality stainless steel;

- powerful 2.2 kW motor.

Flaws

- high price;

- no water supply function;

- It weighs 70 kg, so it’s hard to carry even with two people.

PM40Q

Rating: 4.5

The feather removal machine has a small drum with an internal diameter of 400 mm. The powerful 1.5 kW motor easily rotates the working part at a speed of 260 rpm, which increases productivity. The tank and body are made of stainless steel and have excellent corrosion resistance. There is a channel around the perimeter with holes for water to pass through. It is supplied from the water supply through a hose and facilitates the process of removing feathers. Fluff and other waste comes out through a steel tray and is conveniently collected in containers. Buyers in the reviews are glad that the manufacturer provides 5 spare fingers in the kit, which are easy to replace yourself if necessary.

This unit is specially designed for delicate processing of quail carcasses with thin skin. To prevent it from being damaged during the plucking process, the manufacturer used feather picking fingers of shorter length and made of softer materials than those of competitors. Their number has been specially increased to increase productivity and amounts to 160 units. If you breed quails, then this is the best option for cleaning carcasses.

Advantages

- rubberized engine start and stop buttons;

- stainless steel body;

- there is a water supply system;

- a simple process for replacing damaged fingertips.

Flaws

- It’s hard to rearrange for one person due to the weight of 46 kg.

Electromash EM-600

Rating: 4.4

The machine for removing feathers from ducks, geese, chickens, broilers and ducks is an analogue of the MOP-2 model, used in poultry farms in the USSR. This is a simple unit that has been proven over the years and works flawlessly in everyday use. The device has an electric motor with a power of 1.5 kW, which is strong enough to pluck broilers not individually, but in groups. Up to 4 pieces can be placed in a drum with a diameter of 650 mm. The working part is installed on a durable frame made of 50x50 mm profile pipe. This ensures long service life without deformation, but contributes to the weight of 85 kg. The model is more suitable for one-time installation at a poultry farm for organizing mass feather plucking. Easy movement of the lower part is possible due to self-lubricating bearings. An improved pen release mechanism makes cleaning the tray easier.

This is one of the most durable cars. Its steel thickness on the rotating rotor is 2 mm. This characteristic makes the model resistant to increased loads and will help maintain integrity even if something jams.

Advantages

- consists of AISI 304 stainless steel;

- working parts are easy to clean and disinfect;

- improved pen removal mechanism;

- durable frame made of profile 50x50 mm.

Flaws

- weighs 85 kg.

Hobby Farm NT-500

Rating: 4.3

This is a model from a well-known global brand, but with a smaller diameter drum - 500 mm. This characteristic makes it optimal for loading roosters, broilers, layers and small turkeys. The device operates on the principle of a centrifuge, and water is supplied manually. Despite the small dimensions of the drum, the manufacturer provided the machine with a power of 1.1 kW, so it copes well with everyday tasks on the farm. From the reviews it is clear that the fingers are easy to replace yourself if necessary. Although the machine is produced at the company's production facilities in China, it comes with detailed instructions in Russian.

The company's developers used 120 pcs of updated shaped beating fingers, which are even more gentle on the carcass. Thanks to the new technology, the skin is almost not damaged even on chickens, so you can cook grilled or tobacco chickens with a beautiful golden crust.

Advantages

- easy replacement of fingers;

- reliable engines;

- durable frame;

- Excellent result in cleaning the pen.

Flaws

- The instructions recommend slightly fluffing the feathers on the carcass before loading for best results, but this will slow down the process.

PM-7M

Rating: 4.2

This is a very light feather model that weighs only 14 kg. This makes it easy to take it out into the yard to pluck a few carcasses and bring it back into the utility room after use. But the light weight is made possible thanks to the plastic case, which is quite fragile if you order the product online. Therefore, the manufacturer strongly recommends choosing additional packaging in a hard box. The device has dimensions of 570x570x650 mm and easily fits even in a closet. Judging by the reviews and videos, some people use it right in their shower in a private home to supply water from a watering can and pluck chickens for home cooking. The drum can be loaded up to 7 kg at a time. The operating instructions contain detailed recommendations for feathering each type of bird.

Experts singled out the machine for its innovative technology for manufacturing stylus fingers with a “sticking” function. They capture the feathers and prevent them from staining the already cleaned carcass. Thanks to this, productivity increases by up to 25% and the plucking time of one adult chicken does not exceed 30 seconds.

Advantages

- light weight 14 kg;

- plucking time 30 seconds;

- can load up to 7 kg at a time;

- innovative fingers with sticking function.

Flaws

- fragile plastic case.

VolTera-PM3

Rating: 4.1

And here is another compact pen removal machine - its dimensions are 43x46x67 cm and it weighs only 11 kg. It’s not difficult to bring it to the dacha or to relatives in the trunk of a car to facilitate the process of plucking and moving on to preparing a delicious dish. The machine is equipped with a 335 W motor, which saves energy. The feather removal unit works well at any temperature from 0 to 60 degrees. Plastic is not subject to corrosion and is easy to clean. If you want less water under your feet, then connect the drain directly to the sewer. The yellow cover will help protect the room from feathers flying out onto the floor and water splashing. The device for winding the power cord makes it easier to fold and unfold the device. You can pluck up to 120 carcasses in an hour if they are properly prepared beforehand (soak at 70 degrees and lightly fluff). The car is not suitable for professional activities, but in everyday life it will give a head start to other models.

Among household plastic feather removal units with low power, VolTera-PM3 is distinguished by its loading capacity of up to 2.5 kg. Thanks to this, the housewife will be able to pluck a broiler or several laying hens at once, rather than serving them one by one.

Advantages

- the drain pipe can be connected to the sewer;

- light weight 11 kg;

- compact dimensions 43x46x67 cm;

- plucks 120 carcasses per hour.

Flaws

- not suitable for turkey.

Octopus Princess-200P

Rating: 4.0

The Princess-200P machine has been developed for plucking very small quails or pigeons. It has a small loading tank with the ability to process up to 0.5 kg at a time. Translated into carcasses, this is 1-4 units. The 140 W single-phase motor consumes very little electricity. According to calculations, using this model it will be possible to process up to 120 quails per hour. The plastic machine has compact dimensions of 44x34x36 cm and weighs 10 kg - this is one of the smallest devices, for which the product received the name “Princess”. It has a neat appearance and convenient control levers. The drain pipe with a diameter of 75 mm can be connected directly to the sewer system to carry out plucking directly in the house.

The machine was added by experts to the list of the best for its long service life. The manufacturer indicates that the device is designed to pluck up to 200,000 carcasses. Although users did not count every processed quail, they confirm in reviews that the equipment is unpretentious and very hardy.

Advantages

- Beautiful design;

- convenient controls;

- consumes 140 W per hour of operation;

- light weight 10 kg.

Flaws

- loading up to 500 g at a time;

- not suitable for chickens.

VolTera PM1

Rating: 4.0

The “youngest” model in the line of the VolTera manufacturer is the PM1 machine. The feather removal unit has a power of 140 W and copes with 1-2 carcasses at a time. It is allowed to put quails, pigeons and small chickens in it. The machine measures 36x38x52 cm and easily fits on a shelf in the pantry. For more convenient carrying, a handle is provided. Control is carried out with one button on the side of the case. The use of white plastic makes it easier to see traces of dirt and remove them, making it easier to keep the device clean. Collecting feathers is helped by three rows of beaters integrated into the walls of the drum. To prevent splashing of water, a sealed lid is provided.

The feather removal device is the lightest among its analogues. Machine weight 5 kg. Even a very old person will not find it difficult to remove the device from the shelf and use it to quickly pluck domestic chicken without outside help.

Advantages

- consumes electricity economically;

- carrying handle;

- simple one-button control;

- It's easier to keep the drum clean thanks to the white body.

Flaws

- not suitable for large broilers and other large birds.

Drum pluckers

Common devices (including those for home use) are drum-type pluckers. They are a precisely centered drum, on the outer surface of which the beaters are fixed. During the plucking process, the poultry carcass is brought to a rotating drum, which can have different lengths. It should be noted that using drum devices for plucking small poultry is not entirely convenient.

A budget option for this type of device is a drum attachment for a drill for plucking poultry. Such attachments, although universal, are not very convenient to use. To process a poultry carcass using such a device, you have to hold it with one hand and use the power tool with the other to rotate the nozzle.

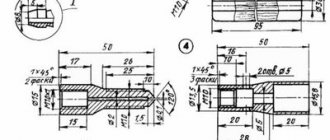

A simple plucking attachment consists of an aluminum body with holes for fingers and a shaft for mounting in a drill or screwdriver chuck.

It should be borne in mind that the drum-type feather removal attachment allows you to pluck only one poultry carcass at a time, so for farms where it is necessary to pluck several birds at once, it is better to purchase devices of other types. These are, in particular, feather removal machines operating on the principle of a centrifuge, or larger and more productive drum devices driven not by a power tool, but by a separate drive.

An even more budget-friendly device for this purpose is a drill attachment for plucking, the working part of which is not a drum with pins, but a sponge with a reinforced washing surface. Although this attachment looks primitive, it allows you to pluck poultry or wild birds quite effectively.

Serial feather removal equipment and special devices designed for plucking poultry are purchased mainly by farms and private entrepreneurs who regularly sell their products on the market or in retail chains. Many of those who breed poultry only for their own needs make such devices with their own hands from scrap materials, using only factory-made beating fingers, which today can be purchased at a low price. You can make your pen picker reliable only if you purchase high-quality strikers that will last much longer than those made by yourself.

How to choose a feather removal machine

First, let's note the key parameters for choosing poultry plucking machines. This will help you evaluate the potential of the models presented in the review and decide what characteristics to look for for your own needs. Here are a number of important factors to consider when choosing:

- Power.

The characteristics vary from 140 to 2200 W. The higher the number, the faster the rotor can rotate under load and not overheat. For professional activities, choose an indicator of 1500 W. - Productivity

. In an hour, one machine can pluck 120 carcasses, and another - 400 of the same size. Your choice depends on the volume of work, but more productive models are more expensive. - Capacity

. There are devices with drum sizes from 200 to 700 mm. The wider it is, the more carcasses it can accommodate at a time, which affects the speed of plucking a large number of birds. The size of the drum also determines what type of birds will fit in it. There are universal models for all types of birds (ducks, geese, turkeys, broilers, partridges, quails) and specialized ones for quails or laying hens only. - Material of the drum and other parts.

Equipment made from food grade stainless steel is stronger and more durable, but is more expensive. Plastic drums also do not rust, but are inferior in durability. But they are lighter, which reduces the load on the motor. - Number of fingertips.

The number varies from 90 to 200 pieces. The more there are, the faster the feathers are plucked. - Dimensions and weight.

If stationary use is intended, then the machine is installed once in a permanent place, after which it is not moved. Heavy weight of 30-80 kg provides good stability and low vibration. When you plan to regularly take the device outside, pluck the bird and return it to its storage location, look for small models weighing 10-15 kg. Although they bounce around a bit when spinning, they won't be difficult to wear.

Homemade pen removal attachments for power tools

The DIY drill attachment, which can also be used in conjunction with a screwdriver or sharpening machine, is easy to make. The main element of such a device is the drum, which must have sufficiently high rigidity. To make your own nozzle for plucking poultry, you can use the following algorithm.

- A bottom is attached to a section of a thick-walled pipe made of light metal using screws or welding, in the central part of which a hole is pre-drilled.

- A pin is inserted into the hole in the bottom of the drum and secured with two nuts. When selecting the diameter of such a pin, it should be taken into account that it must be securely fixed in the chuck of the power tool used to operate the pen removal attachment.

- Several rows of holes are drilled on the side surface of the drum along its entire circumference. They should be performed at the same distance from each other.

- Rubber strikers are inserted into the resulting holes.

If you have a suitable engine lying around on the farm, then it can be used to create a more powerful plucking device.

Such a feather plucking attachment, despite the simplicity of its design, can be used to process chickens, quails, ducks, geese and even turkeys. This attachment for plucking birds is also useful for hunters, who are also often faced with the need to process a large number of bird carcasses.

The simplest nozzle for plucking poultry can be made with your own hands from a piece of polyethylene pipe with a diameter of 100–120 mm. The two bottoms for such a nozzle can be made not of metal, but of hard plastic or plywood. In the center of both bottoms, holes are drilled through which a pin will be passed, intended not only for installing the attachment on a power tool, but also for tying the entire structure. As in the previous model of a homemade nozzle, holes are drilled on the surface of the pipe of this device into which rubber punching fingers are inserted.

The most affordable option for a homemade nozzle

Homemade devices

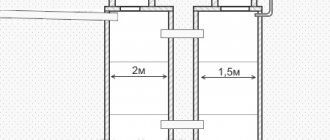

You can make a machine for plucking geese with your own hands. For this you will need:

- plastic barrel;

- frame welded from metal pipes;

- steel plates;

- rotary motor;

- switch for drive;

- disc from a washing machine centrifuge.

The bottom of a barrel with thick, strong walls is cut off. The centrifuge disk is separated from the walls. It contains 30-35 holes for beaters at equal distances. They are secured with screws and nuts.

The disk is installed on a metal base with a hole for water drainage and secured with bolts. The structure is placed on the frame and secured. The motor is mounted on the side, a transmission belt and a switch are installed. Then fix the barrel without a bottom (the fastening should be as reliable as possible). Holes are drilled along the perimeter of the barrel in several rows and the pins are attached. The operation of the machine is checked by connecting it to the electrical network.

How does a feather removal machine work?

How to make your own feather drum

The feather removal drum works on the same principle as the nozzle for plucking poultry, but differs in its longer length and, accordingly, the presence of a support axis at the free end. This plucking drum is driven by an electric motor and a belt drive.

Making a drum for plucking poultry is easy. For this you will need:

- a drum of any length with two axes (on the side surface of such a drum it is necessary to drill holes in which the rubber strikers will be fixed);

- a bed or frame on which the feather removal drum will be installed;

- low power electric motor;

- belt drive elements - pulleys and belt;

- a bag for collecting plucked feathers, which is suspended on the bottom of the device frame.

Homemade feather removal drum based on a drill

A similar plucking machine can be used to process poultry carcasses such as chicken, quail, goose, turkey, etc.

Do-it-yourself feather removal attachment for plucking poultry

It is important to understand that we are not talking about a large industrial feather removal machine, but rather a small and compact attachment for an electric drill.

Feather remover

This invention was developed and put into operation not so long ago. With the arrival of this assistant, it has become much easier and easier for private entrepreneurs and hunters.

The poultry plucking attachment is an alternative to the large machines that have long been used in industrial settings. You should not attach much importance to the word “homemade” in the product description. The device performs well when removing feathers from domestic and wild birds.

Attachments for plucking poultry and wild birds can be attached not only to an electric drill, but also to a sharpener.

The quality of feather removal will not be affected in any way by the age of the carcass or its size. The only difference that will be present is the time required to de-feather older, larger game. The drill attachment for plucking poultry works best when working with any type of bird.

How long does it take to pluck

To show the clear advantage of the bait, we can refer to the time it will take to remove feathers from various birds. Let's start with the smallest birds. For example, this device will process a small chicken in about 10 seconds.

For a bird such as a quail or dove, it will take a little more, only about 30 seconds. Larger birds, such as broilers, will be left without feathers in a minute, a maximum of one and a half. The poultry plucking attachment can handle a duck in about a couple of minutes.

For such results, you don’t even need to pre-steam the specimen. A larger bird, for example, a goose will be plucked in 2.5 minutes. For large turkeys this unit will take about 3 minutes.

A DIY poultry plucking attachment can handle even a bird as large as an ostrich. It will, of course, require a little more time, about 7 minutes.

Ways to speed up the feather plucking process

Immediately after the appearance of such devices, people began to think about how to speed up this process. It is because of this that attachments began to be used on various household devices and appliances, such as electric drills, screwdrivers, hammer drills, and knife sharpeners.

Do-it-yourself attachments for plucking poultry are made by many manufacturers. The operating principle of this device is no different. The difference between nozzles from different manufacturers lies only in the length of the device itself, its width, as well as the length and number of rubber fingers.

What are the advantages of the nozzle?

The attachment for plucking poultry does not have a very large list of advantages, but each item on the list is quite significant.

- The first and most significant advantage is that there is no need to soak poultry in hot water before plucking. The attachment performs well in conditions of dry cleaning of birds from feathers and fluff.

- The second and no less important point is the preservation of the presentation of the bird after plucking. During the process of removing feathers, the device does not touch or tear the skin of the animal.

It cannot be considered an advantage, but it is still worth noting that the average price of this product ranges from 2,000 to 3,000 thousand rubles. This amount is considered quite acceptable, given the degree of usefulness of the product in agriculture or hunting.

Negative aspects of the product

The feather removal attachment for plucking poultry, despite all its advantages, also has a small disadvantage, which, although not related to the technical side of the product, is still unpleasant. The essence of the drawback lies in the fact that buying this product is problematic. The device is practically not sold anywhere, like a regular product in a store.

All sales of this product occur through online stores.

What is a nozzle?

At-home poultry plucking attachments are centered, drum-shaped parts to which the plucking fingers are attached. Nozzles come in various types.

The division into types occurs according to the number of beating devices and their length. These same factors determine the purpose of the nozzle. Parts with pins 5 cm long are intended for plucking small species of poultry.

Devices with fingers 9 cm long are used to remove feathers from large birds. The number of fingers on the nozzle can also vary from 12 to 24 pieces.

What is attractive about the plucking attachment?

Naturally, the main advantage that all buyers of this product appreciate is the fast and high-quality completion of the task. But this is not the only thing that attracts users. The great demand for this product is also ensured by the high quality of the device.

Almost all European, Russian and Ukrainian manufacturers can guarantee that the product is manufactured according to all the rules and is therefore of high quality. The same cannot be said about the Chinese manufacturer.

The quality of such a part plays a decisive role, since the degree of plucking of the bird depends on it. The highest quality products are capable of removing feathers from even the largest and most mature birds.

The percentage of product sales on the market suggests that Russian-made attachments are in maximum demand. This is explained by the fact that these specimens have the best price-quality ratio.

An attractive fact about this device is that it does not leave marks after plucking on the very delicate skin of some types of poultry. The convenience of this device is also excellent, since the possibility of its use is limited only by the availability of an electrical outlet and a drill.

Nozzle properties

In addition to what has already been said, several more useful properties can be cited:

- Stainless and non-oxidizing materials are used to manufacture the device.

- The warranty period for this device is up to 10 years.

- Standard rubber pins are designed for a fairly large number of plucking operations. But even if they are worn down, it is possible to replace them with new ones.

- Most often, when purchasing a product, the kit already contains spare parts, such as pins. But even if they are unavailable, purchasing them separately in the store will not be a problem.

- The kit also includes instructions for using the nozzle, most often with detailed descriptions and illustrations.

Chicken Plucking Methods

At all times, manual plucking of poultry has been practiced, but thanks to progress, this process can be facilitated and significantly reduced by using mechanized devices. Their detailed characteristics will help you choose which one suits you best.

It will be useful for you to learn how to properly breed and keep chickens in the country.

Manually

Experienced housewives can handle feathers quite quickly and skillfully, but if there is not enough practice, then you will have to work hard.

The length of this procedure will depend on the age of the bird and the plucking method you choose.

The order of feather removal remains the same:

- start with the wings and tail;

- then move on to the thighs (don’t forget to clean the skin from the paws);

- Next come the breast, belly;

- then come the back and sides;

- and end with the skin under the wings.

Dry method

This is a labor-intensive option, so it is usually used only in cases where it is not possible to use alternative methods.

- Its advantages include:

- minimum preparatory actions and necessary tools;

- excellent preservation of the pen for further processing;

- The meat obtained after such plucking can be stored raw for longer without freezing.

- But it also has disadvantages:

- if you are plucking for the first time, there is a high risk of tearing the thin skin;

- fluff will scatter, interfering with work;

- stumps from large feathers often remain;

- Plucking will take much longer than with alternative methods.

Did you know? Chickens are the most common bird species on the planet.

Using the dry method, they begin cleaning the carcass as soon as possible after slaughter, so that the bird does not have time to cool down.

The step-by-step process is as follows:

- The chicken is laid on a flat surface or fixed on the knees - whichever is more convenient for you to work.

- The first to be pulled out are the large flight feathers on the wings in the direction opposite to their growth. Do this carefully; the risk of tearing the skin in this case is especially high.

- Next comes the turn of the front and back parts of the carcass, when small feathers and fluff are plucked out, periodically spraying them with water so that the fluff does not fly away.

- If large stumps remain, you won’t be able to get rid of them without scissors.

- The fine fluff can be scraped off at the end with a non-sharp knife.

This is how chickens are plucked using the dry method, after which you can begin processing the carcass for further storage or processing of meat.

Hot method

This method can safely be called the most common among housewives, because it greatly simplifies the process compared to the previous option and does not require financial costs, unlike the mechanical method.

- However, these are not all its advantages:

- the hot method is easier for beginners;

- also suitable for old specimens with rough skin and hard feathers;

- There are almost no stumps left.

- Its disadvantages include:

- the need for preliminary preparation;

- reducing the shelf life of poultry;

- deterioration in feather quality.

Did you know? The rooster is considered the unofficial symbol of two countries - France and Kenya.

Hot plucking proceeds according to the following scheme:

- Heat water to 80–90 °C in a container large enough to fit the bird carcass.

- When the water is ready, submerge the chicken completely in it for a minute.

- After this time, remove the carcass and let the water drain.

- Then you can begin the procedure, starting with the flight feathers and gradually moving to other areas. Thanks to scalding, the skin of the bird softens and the plucking process is significantly accelerated.

- At the end, you can scrape the carcass with a knife to remove fluff and stumps.

Combined method

As the name implies, in this method enterprising housewives tried to combine the advantages of two main methods. This became possible thanks to the use of steam, which opens the skin pores no worse than boiling water, but at the same time has less negative effects on the color and strength of the skin.

To use this method:

- Place the carcass in a small bag or wrap it in a thick, clean cloth.

- Now take an iron with steam supply and heat it up to maximum.

- Carefully begin stroking the carcass, without missing a single corner or fold.

- To achieve the effect, process the chicken this way for 10–15 minutes.

- After this, remove the material that was used to wrap the meat and begin plucking by hand.

Important! If there is no iron with the required function, then a cloth soaked in boiling water will replace it. Cover the bird with it and use a regular iron.

Mechanically

If desired, you can use a specialized apparatus to pluck chickens at home. This is a special attachment that fits onto a drill or screwdriver; its appearance resembles a brush for cleaning dishes. It is equipped with special rubber or silicone fingers and threads.

The fingers grab the feathers and, moving with the help of a motor, pull them out. The owner only needs to rotate the carcass in the desired direction.

Plucking chicken mechanically: video

However, the use of such an attachment leads to damage to the skin of the chicken, which results in loss of presentation. But plucking with this method is on average 3–4 times faster. You can find several options for such attachments on sale, so that every housewife can choose the one that suits her.

If attachments are usually used by those who do not often pluck, then for regular use it is better to purchase mini-versions of industrial machines. They look like small centrifuges, with the same fingers placed on the walls. As the tank rotates, the protrusions knock down the feather and it falls into the tray below.

Such machines practically repeat the design of professional devices, but for home use they have been simplified by removing some functions.

They take up little space in the kitchen and significantly save housewives time on processing carcasses. In addition, these devices are able to work with any method of preparing poultry: dry, hot, combined.

Important! Many farmers assemble chicken plucking machines with their own hands. Plastic or metal tanks, containers, or even old pans are used as a basis, and the hammer fingers are bought in the spare parts department.

Homemade do-it-yourself feather picker for plucking chickens, geese and ducks

Plucking carcasses is a long and unpleasant process.

To mechanize the procedure in the household, a feather removal machine was created, which can be purchased at a specialized store or made with your own hands from scrap materials.

What is a feather removal machine, how it works

The capabilities of the feather removal device are processing up to 30 carcasses in 60 minutes. The advantage is the preservation of the presentation of ducks and various birds.

Appearance of the structure:

- large capacity;

- a lot of rubber beaters on the bottom and walls of the tank (beaters are strong and elastic pins with threads located at the ends).

Operating principle of the device:

- Pouring a dead bird with boiling water.

- Throwing the carcass into the tank.

- Turning on the engine.

- Rotating a tank with a goose or other bird carcass.

- Contact of the product with the beaters (birds are thrown over the entire area of the drum).

- Feather removal process (duration: 2-3 minutes). It is necessary to periodically water the product (for faster and more thorough feather removal). In addition, water washes away unnecessary feather residues and protects carcasses from various damages.

- Taking cleaned birds from a homemade version of the device.

- Processing carcasses manually (after using the device, the plucking process takes a short amount of time).

Making a screwdriver attachment

The method is simple. It is not recommended to create fingers for the machine yourself.

Step-by-step creation of a nozzle:

- Design of the part (appearance – tin can). It is the used container that is not used (due to the thin and easily wrinkled sheet metal). For the workpiece it is necessary to use a pipe made of low-melting metal.

- Fastening the bottom part (screws are used).

- Drilling a hole in the central part.

- Securing the pin. This is done using nuts in the central part. The size of the pin is similar to the size of the drill attachment.

- Drilling a hole for the fingers (in the cylinder of the future machine).

- Inserting rubber bands into the hole made.

- Using a carcass plucking machine.

Do-it-yourself feather removal machine: making an economical option

Required parts:

- pipe blank (required diameter - 10-12 cm);

- material characterized by rigidity (for the bottom of the structure).

The initial stage is threading the pin and tightening the pipe. This is done using nuts. The final stage is equipping the structure with fingers.

Making a drum for removing feathers

To create a drum for a feather removal machine, it is necessary to have beaters.

The purpose of the parts is to remove feathers from carcasses. Making beaters at home is considered impractical. The only option is to purchase from specialized stores selling agricultural goods. You can purchase the part in online stores.

Do-it-yourself plucking machine for geese: step-by-step instructions

Simple manual labor can be easily replaced with automated one. Thus, plucking geese can be entrusted to a special device - a plucking machine. You can either purchase it or make it yourself.

It is difficult to deny the value of goose meat and feathers. Many people can handle cutting meat, but not everyone knows how to properly pluck a bird so as not to spoil the feathers themselves and not leave stumps on the carcass, which will reduce its value.

On a large farm there is no time for such a long procedure as plucking. However, it is quite difficult, so it is better to use a plucking device. The process of its creation lasted a relatively long time.

The main element of the device for geese is a drum in which oblong elements for plucking, called fingers, are placed.

In the middle, friction is provoked, which causes the fingers to cut into the carcass and tear out feathers. The drum is mounted on a moving axis.

The goose feather removal machine not only saves time, but also improves labor productivity. If you have a small number of poultry, then there is no point in buying an expensive machine; it is better to make it yourself. The devices differ:

- Dimensions;

- Power;

- Number of fingers.

If you make the apparatus yourself, you need to take into account the average size of poultry. A container that is too large will not work, since your fingers simply will not be able to reach the carcass.

Diagram of a homemade pinching machine

A homemade geese machine consists of:

- Drum;

- Fingers;

- Engine;

- Lower disk.

Working with a goose tweezer consists of the following steps:

- After slaughtering poultry, leave the carcass for a couple of hours;

- After this, dip it in warm water for 2-3 minutes;

- Comb all feathers thoroughly. Immerse in boiling water for 2 minutes. The main thing is not to keep it for too long;

- Place the carcass in a preheated machine;

- During the automated plucking process, pour boiling water over the goose. Take it out and rinse with cool water;

- Clean areas where feather cover has not been completely removed.