Is it possible to drill tiles, wood, tiles and metal with a hammer drill?

A rotary hammer is a screwdriver, drill, jackhammer and construction mixer in one tool. How to use a hammer drill in different modes, what materials can it work with, and how to properly care for this tool?

A hammer drill is a versatile electric tool that can perform many tasks. With its help, you can drill holes in hard surfaces, tap walls, and also work in chipper mode. At the same time, the safety of the work carried out corresponds to a high level, and even a person far from the construction industry can learn how to use a hammer drill. From this article you will learn how to drill various materials with a hammer drill, prepare it for work, and also care for it.

How to drill a concrete wall using a hammer, drill - for drainage

The walls and ceilings of modern buildings are often made of monolithic reinforced concrete slabs. It is well known that concrete is a high-strength material, the processing of which requires knowledge of its processing technologies. In particular, a concrete wall must be drilled using a special tool: a drill or a hammer.

READ Bosch Gsr 12v 30 Review

Content:

- Drilling tool

- Drills, drill bits, bits for concrete

- Video: SDS-max, SDS-plus drills

- How to work with a regular drill with a rod drill

- Diamond drilling method

- Video: diamond drilling technique

- Drilling tips

What materials is the hammer used for?

Can a hammer drill drill into wood, metal or tile? Is this tool used as a concrete mixer? Many people have similar questions before buying a hammer drill. After all, you want to get the most out of an impact drill. Therefore, below are all the functions of the rotary hammer with brief explanations for each of them.

Rotary hammer functions

Drilling tiles. The drilling site is marked, and a hole is drilled at low speeds using a special drill for tiles without impact mode. Having reached the wall, the drill changes.

Drilling wood. In drilling mode without impact, at maximum speed, when using wood drills.

Drilling metal. Not recommended. It is possible to drill only thin sheet steel using special metal drills.

Stir the solution. Not recommended. You can burn out the engine due to too much load. Used only for mixing small quantities of solution with low viscosity.

Tighten screws and self-tapping screws. Not recommended. Firstly, it is extremely inconvenient due to the significant dimensions of the hammer drill. Secondly, due to the high power of the tool, there is a high risk of overtightening.

Thus, you can perform many operations with a hammer drill, but this will not always be advisable. Still, the main purpose of this tool is drilling and chiselling concrete surfaces. Therefore, it will last as long as possible when used as intended.

Drilling tool

Concrete drill

Organization of work on making holes in concrete requires a special approach, which involves choosing suitable tools and special drills (ordinary drills are not suitable in this case). The following tools are best suited for this purpose:

- Choosing a drill

impact drill (impact drill); - Drill made of tungsten carbide and cobalt alloy;

- Diamond drill.

A rotary hammer or perforator provides a rotational and translational movement of the drill bit (drill bit), which makes drilling concrete much easier.

Some experts believe that in most everyday situations this can be done with a regular drill, which does not have an impact function. But in this case, to successfully complete the work, you will need to use a special metal pin, the thickness of which is approximately equal to the diameter of the planned passage. With the help of this pin, the intended drilling site is “packed”, and the concrete periodically breaks as it sinks into the wall. Several small holes can be drilled with a regular drill.

Preparing the hammer drill for work

Depending on the purpose for which the hammer drill will be used, the procedure for preparing it may differ. However, in most cases, before using a jack drill, you should perform the following steps:

- Study the tool and its instructions in order to comply with safety precautions and operating rules;

- Select a drill according to the type of surface, as well as the depth of the hole;

- Insert the drill into the chuck;

- Adjust the drilling depth. If a hole is required not through, but of a certain depth, you should install a limiter - it will not allow the drill to go beyond the mark;

- Plug in the hammer drill, select the required drilling mode and get to work.

Drilling tool

Concrete drill

Organization of work on making holes in concrete requires a special approach, which involves choosing suitable tools and special drills (ordinary drills are not suitable in this case). The following tools are best suited for this purpose:

Drill selection

impact drill (impact drill);

A rotary hammer or perforator provides a rotational and translational movement of the drill bit (drill bit), which makes drilling concrete much easier.

Some experts believe that in most everyday situations this can be done with a regular drill, which does not have an impact function. But in this case, to successfully complete the work, you will need to use a special metal pin, the thickness of which is approximately equal to the diameter of the planned passage. With the help of this pin, the site of the intended drilling is “packed”, and the concrete periodically breaks when immersed in the wall. Several small holes can be drilled with a regular drill.

Rotary hammer operating modes

Each rotary hammer has three operating modes: drilling, hammer drilling and impact mode. Depending on what material is being worked with, one or another mode is selected.

The drilling mode is used to make holes in hard materials - tiles, wood, plastic, metal, etc. The hammer drill in this mode performs the function of an ordinary drill. To activate it, switch the toggle switch to the position opposite the drill icon.

Drilling with a hammer drill

How to drill metal with a hammer drill? Select a drill of the required diameter for metal. If the diameter of the hole or the thickness of the metal is too large, it makes sense to start with small drills, gradually widening the hole formed. Hammer in drilling mode. The surface must be marked so that the drill does not “walk.” Let's get to work, controlling the heating of the motor.

How to drill tiles with a hammer drill? This operation is also performed in drilling mode. Use special drills for glass and ceramic tiles with a tungsten carbide tip or pobedit drills.

The location of the hole is marked, adhesive tape is placed on top (so that the drill does not move), or the drilling points are marked. When the tile is drilled through, the drill and mode are changed to hammer drilling (in the case of a concrete wall).

The drilling mode with impact on the switching switch is indicated by the image of a drill and a hammer. It is used for drilling holes in fragile materials - concrete, plaster, brick, etc. In this mode, the drill simultaneously rotates and strikes, due to which the material is destroyed, and dust and fragments are thrown out.

The impact mode is turned on to perform chipping, chiseling and gating. On the toggle switch this mode is indicated in the form of a hammer. Depending on the functions performed and the characteristics of the material, various attachments can be used: blades, peaks, chisels, etc. In this mode, the tool does not rotate, only chiseling.

Many modern rotary hammers also have a reverse mode. It will be very useful if the drill gets stuck. When this mode is turned on, the motor rotates in the opposite direction.

How to work with a regular drill with a rod drill

Diamond drilling in concrete

Once all the accessories needed for the job are ready, you can begin the hole preparation procedure . Before starting the procedure, we recommend reading the following expert recommendations:

- When working with a conventional drill, it is necessary to ensure that the drill does not overheat, for which it is periodically cooled in cold water.

- After penetrating the concrete a little, use the same pin you want to insert into the cavity and hit it with a hammer several times (while rotating).

- Then drill a little more and repeat the same steps using the pin.

Tips for using rotary hammers

Below are a few tips that will allow you to use your hammer drill more productively and safely:

- In the mode of chiselling and drilling with chiselling, you should not press hard on the body of the tool - this will only lead to overheating of the engine and waste of energy, but will not speed up the work process.

- Accurate selection of equipment for each type of work is the key to successful and quick completion of the assigned tasks.

- When working locally with a rotary hammer, you can avoid lengthy cleaning of the room if you hold the hose of a running vacuum cleaner under the place of drilling or chiselling. If it is necessary to screw screws into a concrete surface, metal anchors are inserted into the drilled hole. If the loads are expected to be insignificant, you can limit yourself to plastic dowels.

- Use water to cool drills and remove dust only after familiarizing yourself with the composition of the drill. The fact is that some carbide drills can break when cooled with water.

- To drill large-diameter holes, use special diamond core bits instead of a drill - this will reduce labor costs and save time.

Tips for caring for your hammer

The time for its maintenance and the overhaul interval directly depend on how timely and competently the complex of work on caring for the punch is carried out. Much attention should be paid to lubrication of gears, especially if work is carried out on concrete structures, the drilling of which is accompanied by the formation of large amounts of dust.

Using a vacuum cleaner can be a good defense against it; many models of power tools are even equipped with special devices for attaching the hose. It should also be taken into account that when operating at low speeds, the equipment quickly heats up, so constant monitoring of rest and work is necessary.

After use and disconnection, it is recommended to clean the instrument with a soft cloth. If necessary, you can use a soap solution. Particular attention should be paid to keeping the ventilation openings clean. It is equally important to carry out regular inspections of the equipment on a regular basis.

Also be sure to lubricate the nozzle shanks before starting work. This is necessary to avoid excessive stress on the drill bit due to friction. Failure to do so may result in costly repairs.

READ How to Cut a Windshield Alone

When can you work with a hammer drill?

Carrying out repair work using a hammer drill in an apartment building is inextricably linked to causing inconvenience to neighbors. To avoid conflict situations or even fines, you need to know your rights and responsibilities. In accordance with the rules for the use of residential premises, it is prohibited to create noise and vibration during the period from 23:00 to 7:00. This means that at this time, not only can you not work with a puncher, but you can’t even talk loudly, sing or play musical instruments.

Working with a hammer drill during the reconstruction or redevelopment of premises in apartment buildings is prohibited on weekends and holidays, because this action results in noise and/or vibration. It is also not allowed to perform such work on weekdays between 9:00 and 19:00.

It should be understood that the noise level coming to neighbors from the operation of a hammer drill directly depends on the quality of the sound insulation performed and the thickness of the floors in the house.

How to drill with a hammer drill

if this is your first time encountering this tool and you don’t know its specifics? Naturally, like any power tool, a hammer drill is a source of increased danger. I will not talk about what to do to avoid electric shock and set out all sorts of other common truths, since you can read all this in the passport that comes with the instrument. We'd rather talk about something else.

What do you drill with a hammer drill?

As a rule, they are used to drill into mineral materials based on concrete and cement, as well as stone, asphalt and even earth. A hammer drill is also used for stirring dry construction mixtures and not only them - in normal drilling mode it can drill wood, metal and even tighten self-tapping screws. In addition, the tool, which has a chipping mode, can be used for rough chipping and dismantling work.

Drill with a hammer drill

, holding it straight, without pressing hard (or not pressing at all if the material is soft, such as foam concrete). It is better to first “pass” tiles, plastic baseboards with cable channels and the cable channels themselves in the drilling mode, and then, when you need to drill the wall, turn on the impact mode.

Dangers of asphalt drilling

Drilling asphalt with a hammer drill may be required for various reasons: for example, it will be work on installing hemispheres, or repairing a fence. The asphalt is laid on a dense bed of sand and crushed stone, which is well compacted with a roller or tamping machine.

However, when you start drilling asphalt and reach the pad, part of it softens from the vibration of the drill and displacement. This causes the pieces of crushed stone to begin to move relative to each other, and this can cause the drill to become jammed in the hole. If you feel that the crushed stone has begun to “tumble,” then you should work especially carefully, and at the first sign of the drill being pinched, immediately release the hammer drill, otherwise you may dislocate your arm.

Next, you need to carefully release the drill (to do this, you need to try to loosen it - first just with your hands or pliers, and then with a hammer, and you should not knock too hard). If that doesn’t work, you’ll have to chip away at the asphalt around the drill and then release it (this happens very rarely and mainly with small-diameter drills).

Dangers when excavating in concrete

When drilling holes of great depth (usually these are penetrations for laying cables, and their depth can sometimes reach one meter or more, since it is necessary to drill through solid walls), another danger arises.

Deep in the penetration, the drill can get caught on the reinforcement, and then the hammer drill can literally be twisted out of your hands. For this reason, you should not press on the tool, and you should hold it so that your hands do not cross (as, indeed, always). Complicating matters is the fact that the drill bit follows the path of least resistance and can therefore bend and change direction. As a result, the inlet hole may be a little 30 centimeters further than the outlet.

Thus, if you choose a place without reinforcement, you can still stumble upon it. It is difficult to avoid this, so you need to drill the penetrations very carefully and evenly.

Hidden wiring in walls and plugged distribution boxes

A considerable danger is also posed by distribution boxes immured in the walls, which everyone has long forgotten about (even housing clerks), but they nevertheless contain current-carrying wires. Such a box is usually easy to find by the “empty sound” when tapped, but it happens that it is deeply walled up.

Hidden wiring is even more dangerous, given that it can be routed haphazardly. It is argued that the wires should only pass at right angles, and they are supposedly brought to the consumer exclusively from above. This is complete nonsense, because, unfortunately, they laid (and are still laying) cables at any angles, leaving copper-aluminum strands in the walls and grounding them to the fittings. Therefore it is highly desirable

have an electromagnetic radiation detector or a non-contact probe with which you can find current-carrying wires in the walls and bypass them.

What time can I use the hammer

To avoid problems with neighbors during renovations, you should focus on the following standards regarding acceptable noise levels.

Source

The neighbor who loves to work with a hammer at any time of the day or night is a frequent subject of household jokes. But it happens that the joke turns out to be true, and the next weekend, when you want to sleep, you wake up to the annoying sound of construction equipment. At this point, everyone is asking whether it is possible to drill on weekends, disrupting Stihl and sleep, is there any liability for this and where to complain. This article answers all these questions.

Portal about construction

Drilling in concrete is very difficult, as anyone who has had to deal with a similar problem will tell you. To adequately overcome the resistance of a resistant material, you need to know some of the features of concrete drilling, plus be able to apply knowledge in practice. So, let's find out how to get out of the situation without any problems.

Which drill to drill concrete

To drill a concrete wall, craftsmen use drills with a Pobedit tip.

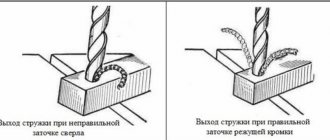

A simple drill will not cope with such a task. If you need to make a small hole (less than 13 mm in diameter), then a drill is used, and in other cases, a hammer drill. It is significantly more productive than a drill due to the presence of a device with an impact function and a higher drilling speed. When a hammer drill is not at hand, then a regular drill with a drill made of hard alloy with asymmetric sharpening will do.

Before starting work, it is necessary to mark the drilling location with a core. It is also advisable to minimize the spread of dust throughout the room by attaching a simple device to the hammer drill cartridge - a cap from a tin can. Most of the dust will settle there. In order for the plastic dowel to fit fully into the hole made, experts recommend making the recess a centimeter longer than the size of the fastening element itself.

During rotation in concrete, the drill heats up due to friction, which leads to a decrease in its working properties, so the drill is periodically moistened in machine oil or ordinary water.

For high-quality drilling, it is preferable to choose a tool equipped with a building level. If such a thing is not provided in the hammer drill, it doesn’t matter; an ordinary small level secured to the body with electrical tape will do.

It happens that you need to drill through concrete, but the drill at hand is too short. Then a blind hole is drilled from the inside along the entire length of the existing drill, and a magnet is placed in the resulting socket. From the reverse side, another magnet is used to determine the location of the first one, and drill at the intended point.

If metal reinforcement interferes with drilling, then change the concrete drill to one that is designed for working with metal. After which they continue with the same drill.

Before drilling into a concrete wall, you should make sure that penetration into the material will not damage any communications.

Tips for drilling concrete

Users are often interested in how to drill concrete with a screwdriver and whether it is possible. Concrete is a fairly strong material, so you need to take into account the diameter of the hole and its depth. If a hole with a diameter of more than 10 mm is provided, then drilling one will be difficult.

When drilling concrete, use drills with a diameter of 3-5 mm . Particular attention should be paid to the speed. If you screw in simple fasteners, 500 rpm will be enough. But for drilling you will need 1300-1500 rpm.

Another criterion for concrete work is torque . For such purposes, select a screwdriver with a rating from 90 to 140 Nm. It turns out that you can drill through a concrete wall with a screwdriver. The tool will also be useful for drilling brick walls.

Some craftsmen use a screwdriver to drill holes while fishing . A lot of torque is needed here. Separate Makita models and Metabo tools can handle this.

A screwdriver can easily drill concrete up to 10 mm

Specific recommendations for drilling

To make holes in thin concrete partitions, a punch is used: it is made from an 8-millimeter drill, the end of which is sharpened into a “swallow’s tail.” The drill needs to be turned and hit with a hammer.

When drilling in the ceiling, to prevent concrete crumbs from falling into your eyes, it is recommended to attach a protective funnel to the tool.

To secure the screw in concrete, a piece of nylon is driven into the hole. Then they lightly melt it with hot metal (nail), after which the screw is screwed in. The nylon hardens and holds the mount firmly.

A piece of copper or aluminum tube can serve as a substitute for a dowel. It is crimped to the required size, inserted into the hole and screwed.

Watch the video: How to drill concrete

How to work with a regular drill with a rod drill

Diamond drilling in concrete

Once all the accessories needed for the job are ready, you can begin the hole preparation procedure . Before starting the procedure, we recommend reading the following expert recommendations:

How to combine a regular drill with a hammer drill

The hammer drill is used both by professional builders and for home work. But even the best tool will not be able to cope with its task if the drill bit for the hammer drill is chosen incorrectly - without taking into account the surface material and its hardness. Most models are used to perform certain functions, but if you change the equipment, the hammer drill can easily serve as both a drill and a screwdriver. To replace attachments, a special cartridge is used - an adapter, which allows you to quickly change the functions of the device.

Types of drills for hammer drills

It should be immediately noted that a drill is an accessory for a drill, and a drill is used in rotary hammers. The difference is explained by the fact that the hammer drill makes holes, but does it with simultaneous chiselling, that is, drilling is obtained.

Tips come in the following types:

- chisel;

- drill;

- lance or chisel lance;

- channel drill;

- crown.

A drill, similar to an ordinary twist drill, is used to make round holes, usually for a dowel or dowel-nail. In construction stores it is often defined as a drill bit for a hammer drill.

The chisel is designed for removing plaster, tiles, tiles or any other worn-out coating. It is convenient for them to carry out dismantling by simply prying up the material to be removed.

The lance is convenient to use when scoring or punching holes in concrete or other hard surfaces. The tool has a noticeably larger diameter than a drill and is characterized by increased “bounceability”. This tip is used when it is necessary to make larger holes, which can be achieved using a drill.

A channel drill is indispensable when you need to make grooves for wiring or installing interior items: guides for plasterboard structures, fastening sliding or false walls.

The crown is used to make holes for placing switches and sockets. Modern drills for rotary hammers are available in any size, among other things, for installing these electrical devices.

Drills are made from steel grades:

For processing hard materials, drills are equipped with heavy-duty soldering.

Even particularly strong metal drills for rotary hammers are ineffective when processing thick material. Their scope of application is limited to thin sheet metal.

Based on the type of working tip, drills are classified into the following types:

- Screw type, designed for making deep holes. Thanks to the spiral design and significant torque, crumbs and dust are removed, the load on the hammer is reduced, and the work time is reduced.

- Drill with a slight slope of working chutes. Used for work that requires little force, for example for making many shallow holes in relatively soft materials.

- A drill with a significant inclination of grooves, characterized by high drilling speed. The load on the hammer drill from such drills is higher than when using auger drills. Designed for making deep holes.

- Drills with one or more spiral grooves or grooves of a special shape. This tip ensures high drill stability, balanced rotation, and reduced vibration load on the hammer drill.

No less important is the shape of the rear part of the drill, clamped in the chuck - the shank.

The most commonly used:

- SDSplus. Used for low and medium power hammer drills. The depth into the cartridge is 4 mm, the size of the “tail” is 10 mm.

- SDS is a special guide system. The drill is held in the chuck by clamps. The diameter of the tail part is 10 mm.

- SDSmax. Format used in a powerful professional tool. The diameter of the shank is not 10, but 18 mm, the recess into the chuck is 9 mm.

- SDStop. Used primarily in BOSH rotary hammers. The tail size is 14 mm.

- SDSquick. It is also a development and is used in instruments of this brand only.

For a certain type of cartridge, only use drill bits of the same type. Otherwise, the “tail” is not fixed and wobbles under load, which can cause injury.

How to combine a hammer drill with a regular drill

In drills, torque comes from the electric motor shaft to the chuck that secures the drill, and only the direction or speed of rotation changes. The shaft and drill rotate together. The clamp is a collet device that secures the shank.

Rotary hammers use a universal chuck, which is used both for drilling and when chiselling is necessary. In it, torque is transformed into reciprocating movements or rotation. For this reason, hammer drill chucks must be able to withstand both axle load and torque.

Under certain operating modes, these loads can act simultaneously, therefore the use of simple collet clamps, like a drill, is unacceptable.

The device of the adapter chuck for the drill

The drill shank, inserted into the clamp, has a cylindrical or conical shape. It has two pairs of grooves running along its entire length - two open and two closed.

The typical design of the cartridge is as follows:

- a splined bushing mounted on the motor shaft;

- sleeve ring;

- a cone-shaped spring supporting the ring;

- retaining balls placed between the sleeve and the ring;

- a casing that covers the entire assembly.

The drill is secured when the shank enters the sleeve. In this case, the open grooves coincide with the splines, and the balls supporting the ring fit into hidden holes. As a result, the drill is prevented from falling out of the clamp; torque is transmitted from the shaft through splines. The heel of the shank receives impulses from the hammer hammer.