What is a dowel-nail

This fastener consists of two parts: the nail itself - with or without threads, and the body, usually plastic. For the dowel, a hole is drilled in the material in which the spacer body is held by the tendrils directed backwards. When driving a nail, the spacer body expands and is firmly fixed with large teeth.

- The nail may look like the most ordinary one: it is cylindrical in shape, sharp at the end, with a head and cut along the length of the body.

- There may also be an additional detail - a restrictive cuff. The washer is placed at the end of the nail and moves to the head during installation. The cuff prevents the nail from falling into the hole. This option is used for fastening to stone, concrete and brick. Accordingly, in this case there is no spacer body, and the rigidity of the fastening ensures the movement of the cuff.

The material for nails is high-strength steel grade - B, VK, KK 70 grade. Often the dowels are coated with anti-corrosion zinc. The body is made of polypropylene, polyethylene and polyamide. There are also metal ones.

An ordinary dowel-nail is not used for fixation in hollow brick, cellular concrete and other similar materials, since its spacer body is not sufficiently developed and is not fixed in such material. However, its special modifications can be fixed even to plasterboard sheathing.

Dowel-nail with a hidden side (photo)

Installation features when working with dowel-nails

When working with brickwork, you need to take into account that the brick may be hollow. Therefore, you need to carefully select a place for the dowel, carefully drill a hole at low speed, then insert the dowel into it and drive a nail.

Working with concrete walls is similar, but here you no longer need to maintain a low drilling speed when making a hole. Plasterboard bases require special care due to their low ability to bear loads. First, a hole is made in the plasterboard base, then a plastic spacer is inserted into it and a dowel nail is screwed into it.

In this case, it is not advisable to hammer the fasteners by force using a hammer. No less caution and attentiveness must be observed when connecting ceramic and facing tiles with nails; before starting drilling, you must first mark the place with a glass cutter, making a hole, and only after that start drilling slowly and carefully.

Product classifications

When choosing a mount, 5 main factors are taken into account:

- load magnitude - on the dowel, on the surface, on the structure;

- nature of the load – stationary, dynamic;

- type of fixation;

- nature of the material - stone, concrete, brick, drywall;

- surface structure – wall, ceiling.

Actually, fasteners are available in several types for different methods and materials.

The video below describes the rules for choosing dowels:

By type of installation

A dowel, or rather, a nail, can have a slightly different structure, so you need to work with it with different tools.

- Manual installation - that is, using mechanical tools. Nails for such work are divided into 2 types:

- without thread - the nail is driven in with a hammer, there is no way to unscrew it;

- threaded nail - driven or screwed in. Its main advantage is the possibility of dismantling.

- Installation using a construction and installation gun - the nail has a limiting cuff, but does without a spacer body. This option provides much faster installation and is also designed for a higher load.

- The most common are nylon dowels with or without threads with a diameter of 2 to 16 mm. They are used for fastening into standard building stone - brick, concrete, and can withstand from 200 to 450 kg of stationary load.

- Dowel for aerated concrete - the material is considered to be relatively low-porous, so such fastening is quite acceptable. The dowel is held in place by spiral ribs and wedging when driving a nail.

- Frame - have a large length, from 60 to 360 mm. They are produced in 2 types: for solid solid material and for hollow slotted material. The spacer part of the dowel is elongated and is designed so that when passing through the slotted base, the dowel will engage several jumpers, which will ensure fastening.

- Distance dowels allow you to fasten elements - sheathing, for example, at some distance from the wall. The distance can vary from 1 to 30 mm. The distance dowel is divided into 2 parts - one for the rail, the second for the material, and are connected with a screw of a special design. In this way, you can compensate for numerous wall irregularities and obtain a perfectly flat surface.

- Universal – capable of “independently” determining the presence or absence of voids. When fixed into a solid material, the spacer body expands and is tightly fixed, and when it gets into voids, it bulges and adheres to the support.

- Metal dowels behave in the same way , that is, with a metal body. They are designed for fastening to thin-walled surfaces, but at the same time hold a sufficient load. When the screw is screwed in, the metal dowel bulges and is pressed against the thin support.

- The nail dowel provides quick installation of sheathing, baseboards, slats and other things when it is necessary to strengthen a large number of elements. The nail here is knurled in the form of reverse cones. It is inserted together with the dowel into the drilled hole through the rail and driven in with a hammer. Cannot be dismantled.

- Products with spring-loaded folding strips - butterfly dowels - are used to fix objects to a hollow surface - to false ceilings, for example, when installing a chandelier. Having passed through the hard layer, the dowel opens under the action of a spring and rests against the sheathing from the inside. Typically, the model is sold with hooks or threaded rods.

- For fastening heavy weight structures - garage doors, sun awnings, etc. - into concrete and solid brick, metal dowels with threaded rods or bolts . The fasteners are designed for very heavy loads - up to several tons.

By surface material

More interesting from the user's point of view, since it allows you to determine which fasteners are suitable for which wall or ceiling.

- Dowels for drywall and porous concrete - both metal and plastic, have a tip in the form of a feathery drill and a large thread on the spacer body. For such dowels, a hole is not drilled, but the entire structure is screwed in with a regular screwdriver.

- The insulation holder is a special dowel for fixing a heat insulator or hard foam material. Holes for it are drilled in brick and concrete, but the dowel itself is driven in without a nail.

- A very specific type is an injection dowel . A mesh anchor is inserted into the hole for the fastener, then a dowel is driven in and a quick-hardening compound is injected with a syringe through the protective sleeve. Under its pressure, the anchor mesh inside the material expands, forming an anchor in the form of a ball. When fixing into a slotted brick, it is allowed to use a dowel without a mesh.

Read also: Kit for chrome plating at home

The length, thickness, weight of dowel-nails are discussed below.

Existing types of hardware

As part of this article, we offer you several types of this hardware:

Universal. Combines perfectly with all kinds of building materials. Multifunctionality comes down to the fact that this product can be used in hollow, sheet, solid and other surfaces. Reliability of fastening is guaranteed by toothed locking elements . The presence of such construction auxiliary items prevents the nail from twisting in the material. Its scope of application is very wide: from fastening household items to collecting construction and installation elements.

Spacer. The dowel is characterized by a four-sided expansion. Due to this, a uniform load on the material is maintained. Effective when fastening in hollow and solid surfaces. When installing a spacer dowel, damage to the surface of wood, tiles, plaster, etc. is avoided. This is achieved due to the special structure of the dowel neck. Accordingly, it is effective when fastening ceramic sanitary equipment.

For aerated concrete GB Core specialization is aerated concrete. It is especially effective for installation and repair work: fastening roof structures, suspended ceilings and much more. The main feature is that they are used for both internal and external fastening. A secure fit in the soft material is guaranteed thanks to the external ribs, which feature a spiral shape.

Turbo Dowel FTP D and FTP. Used for fastening various elements in aerated concrete. Has a nylon dowel. Can be used in combination with wood screws and metric threads. Has a self-tapping thread. There is a modification of this metal hardware. Used for work on aerated concrete and metric blocks.

Brass dowel (RAD). If the surface is thin and solid, then this type of fastening is used. To attach it, it will be enough to make a shallow hole. Let's say installation in combination with bolts and metric threads.

Weight and dimensions

Products are produced in very different sizes, given how different the purpose may be. The parameters are marked with 2 numbers: the first indicates the diameter, the second indicates the length in mm.

- The parameters vary from 5*23 to 10*160. The load that the product can withstand must be indicated.

- The weight of the product for different sizes and materials, of course, is different, but since the fastener itself is still small, the weight is indicated not as 1, but as 1000 nails.

As an example, the table shows dimensional data for a dowel-nail with a polypropylene spacer body.

| Designation | Hole diameter, mm | Nail diameter, mm | Dowel length, mm | Nail length, mm | Min. depth for through installation | Max. thickness of attached material | Weight 1000 shi, kg |

| 6*40 | 6.00 | 40 | 4 | 42 | 50 | 10 | 3,3 |

| 6*60 | 6.00 | 60 | 4 | 62 | 70 | 30 | 4,89 |

| 6*80 | 6 | 80 | 4 | 82 | 90 | 50 | 7,28 |

| 8*60 | 8 | 60 | 5 | 62 | 70 | 20 | 8,5 |

| 8*80 | 8 | 80 | 5 | 82 | 90 | 40 | 11,02 |

| 8*100 | 8 | 100 | 5 | 102 | 110 | 60 | 13,78 |

| 8*120 | 8 | 120 | 5 | 122 | 130 | 80 | 16,53 |

| 8*140 | 8 | 140 | 5 | 142 | 115 | 100 | 19,3 |

| 10*100 | 10 | 100 | 7 | 102 | 150 | 50 | 15,32 |

The dimensions and weight of the product for a construction and assembly gun vary within smaller limits.

| Designation | Weight 1000 pcs, kg |

| 4,5*30 | 5,1 |

| 4,5*40 | 6,45 |

| 4,5*50 | 7,7 |

| 4,5*60 | 8,84 |

Next, the technical characteristics of dowel-nails will be considered.

Specifications

GOST 28457-90 regulates the technical parameters of the expansion dowel-stud. Based on this document, various specifications are being developed. Moreover, if there is a technological justification, the length, diameter of the nail and its structure change.

However, the basic requirements of GOST regarding dowel-nails must be met.

- Dowels are made from wire rod of class VK or KK grade 70. Products must undergo heat treatment. The hardness of the nail should be between 53–56 HRC. An ordinary dowel may have a lower hardness - 51.5 HRC.

- Curvature of the rod is allowed within the following limits:

- 0.1 mm for length less than 50 mm;

- 0.15 mm for lengths above 50 mm.

Read also: Machine for producing sawdust briquettes price

The remaining characteristics are determined by the specifications compiled on the basis of the document. It's time to talk about installing dowel-nails.

Characteristics of fasteners

The 6x40 dowel is covered with a plastic shell that performs a spacer action. The main rod is made of galvanized steel. The hole for such a fastener is made using a 6 mm drill. After drilling, the sleeve is secured, and then the nail is driven in with an ordinary hammer.

If any other fastener cannot be removed in the future after installation, then the 6x40 nail can be unscrewed using a screwdriver. The diameter of the plastic element of such a dowel is 6 mm, and the length is 4 cm. The nail itself is half a centimeter longer , but its diameter is 2 mm smaller.

A 6 by 40 dowel nail can be screwed into wood, brick or concrete. can be used quickly install and secure various objects .

The main element of such hardware is a cone-shaped metal nail that decreases in diameter downwards. It can be driven into the wall with a hammer. To secure it in the surface, you can also use a screwdriver: it has a special thread for this purpose. If you want to get the job done as quickly as possible, it is better to use a hammer.

Installation features

Fastening with different dowels and for different materials is slightly different. What is important here is not so much the nuances of the fixation procedure itself, but rather the correct choice of fasteners.

This video will tell you about the quick installation of dowel nails:

Bricks

Working with solid brick is simple and is most often done:

- in the right place - if it is a brick, then usually its center, drill a hole. At the beginning of drilling, it is better to reduce the speed, since there is a high probability of cracks forming. With a hole depth of 10 mm, the speed can be increased;

- crumbs and dust are blown out of the hole. You can use a vacuum cleaner;

- hammer the dowel using a regular hammer.

Concrete

Fixing to concrete will require another tool:

- first, the hole is marked with a center punch and then punched with a punch to the required depth;

- The diameter of the drill must match the diameter of the dowel. The length of the hole should exceed the length of the fastener by 5–6 mm;

- Remove dust from the hole and drive in the dowel with a hammer;

- Hammer or screw in a nail.

Drywall

When attaching to drywall, great care will be required:

- a hole of the required size is made in the material;

- insert the dowel all the way, gently tapping it with a hammer;

- screw the nail in with a screwdriver or screwdriver.

Ceramic tile

When working with ceramic tiles, the fragility of the material is taken into account:

- mark the attachment point on the tile and use a metal screw to make a hole 0.5 mm deep - in fact, they only cut through the enamel;

- then drill through the tile and the material behind it using an impact drill;

- insert the dowel all the way and screw in the nail.

We will tell you below about prices for dowels for attaching thermal insulation with a plastic or metal nail, as well as other models.

Choosing a dowel.

In addition, it is necessary to take into account the diameter of the future hole. For example, a dowel is ten millimeters in diameter, which means the hole needs to be made with a drill with a diameter of eight millimeters, using the impact drilling mode. And then this drill is replaced with a drill with a diameter of ten millimeters and the drilling process is completed. These manipulations allow you to obtain a hole of the desired diameter with smooth edges.

Wall material

For a concrete wall, a Pobedit drill bit is suitable. But it is worth remembering that the drill must be three millimeters longer than the dowel. And if the hole is made exactly the length of the dowel, then the fastener will not go in all the way. When drilling, construction dust always collects in the depths. If the wall material is loose, it is necessary to select a drill of a smaller diameter than the dowel. For example, the dowel is eight millimeters, and the drill needs to be six millimeters. Then the fastener will fit tightly into the hole.

Cost of materials

The cost of fasteners is more than affordable, even when it comes to very special products.

- The price of an ordinary one ranges from 8 to 35 rubles. per piece depending on size and expected load. The universal model costs from 31 to 38 rubles, the facade dowel costs 35–39 rubles. per piece

- Dowel-nails for insulation - umbrellas, are even cheaper - from 5.30 to 8 rubles. per piece A product with a metal case is estimated at 31–35 rubles, but it can be less.

A dowel-nail is a very common type of fastener, valued both for the variety of models and for the ease of fastening. The fasteners are designed for widespread use during construction and repair work.

Even more useful information about installing dowel nails is contained in this video:

To make dowels, completely different materials are used. There are both metal fasteners (“crocodile” for aerated concrete, spring or mounting dowel-nail), and polypropylene (universal or “carrot”, spacers, OLA), nylon (DRIVA).

Marking of dowels

The marking of dowels consists of two quantities: the diameter of the product (or width) and its length.

Expansion and universal dowels are available in a wide range of sizes: there are three or more lengths per diameter size. The running gears are 6x30, 10x50 and 6x37, respectively.

In one of my articles I already wrote about the weight of nails, but today we will talk about the dowel-nail. The dowel-nail is designed for quick installation in concrete walls, bricks, etc. Made from high-strength steel grades St. 50, 60, 70. The surface of the dowel is coated with an anti-corrosion material - yellow zinc.

The advantage of this installation is its quick installation; to do this, you need to drill a hole, insert a dowel and hammer it in.

Read also: How to drill a hole in marble

Dowel-nail types

Classification by type of installation of dowel-nails:

.

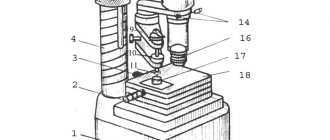

— Fig 1. Dowel-nail with manual installation.

— dowel-nail with manual installation. In turn, it is divided into nails with threads and without threads. One of the main advantages of a dowel-nail with a thread is the ability to dismantle it from concrete or brick using a screwdriver and grooves in the head of the nail.

.

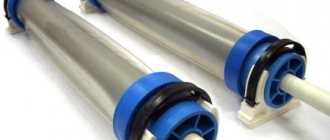

- Rice. 2. Dowel-nail for construction and installation gun.

- dowel-nail for construction and installation gun. It works in conjunction with a construction gun, which targets the required part to the base of the structure. This type of installation can withstand greater loads than manual installation.

The material from which dowels are made is plastic (polypropylene, polyethylene, nylon). These dowels can support fasteners from 200 to 450 kg in concrete and from 150 to 400 kg in masonry. Also, dowels are made of steel and, like nails, have a zinc coating. They are used in heavy-duty fasteners weighing up to 5 tons.

Rice. 3. Dowel-nail with metal dowel.

Classification by area of application of dowel nails:

— Plastic are one of the most common fasteners in business activities.

— Metal – these dowels are designed for fastening various parts to cement and drywall.

— Expansion – such dowels have a significant expansion area. Rotating them in the material is not possible due to the special design in the form of locking tendrils.

— Facade – the use of such dowels is limited to attaching thermal insulation materials to concrete, brick, etc. They have serrated plates at the base of the dowel.

Dowel-nail technical characteristics.

Fig.4. Dowel-nail dimensions.

Dimensions and weight of dowel-nail.

Table 1

Dimensions and weight of polypropylene dowel-nails with a hidden side.

| Designation, mm | 6x40 | 6x60 | 6x80 | 8x60 | 8x80 | 8x100 | 8x120 | 8x140 | 10x100 |

| Do, diameter of the dowel hole, mm | 6,00 | 6,00 | 6,00 | 6,00 | 8,00 | 8,00 | 8,00 | 8,00 | 10,00 |

| L, dowel length, mm | 40,00 | 60,00 | 80,00 | 60,00 | 80,00 | 100,00 | 120,00 | 140,00 | 100,00 |

| Ds, nail diameter, mm | 4,00 | 4,00 | 4,00 | 5,00 | 5,00 | 5,00 | 5,00 | 5,00 | 7,00 |

| Ls, nail length, mm | 42 | 62 | 82 | 62 | 82 | 102 | 122 | 142 | 102 |

| T, min. depth for through installation, mm | 50 | 70 | 90 | 70 | 90 | 110 | 130 | 115 | 150 |

| H, min. anchorage depth, mm | 30,00 | 30,00 | 30,00 | 40,00 | 40,00 | 40,00 | 40,00 | 40,00 | 50,00 |

| Da, max. thickness of attached material, mm | 10,00 | 30,00 | 50,00 | 20,00 | 40,00 | 60,00 | 80,00 | 100,00 | 50,00 |

| Min. pull-out force, kN (concrete B25) | 1,60 | 1,60 | 1,60 | 2,40 | 2,40 | 2,40 | 2,40 | 3,40 | 2,40 |

| Min. shear force, kN (concrete B25) | 1,80 | 1,80 | 1,80 | 2,90 | 2,90 | 2,90 | 2,90 | 2,90 | 4,10 |

| Nominal weight 1000 pcs., kg | 3,30 | 4,89 | 7,28 | 8,50 | 11,02 | 13,78 | 16,53 | 19,30 | 15,32 |

table 2

Dimensions and weight of polypropylene dowel-nails with a semi-cylindrical side.

| Designation | T min. depth for through installation, mm | N min. anchorage depth, mm | Da max. thickness of attached material, mm | Min. breakout force, kN concrete B 25 | Min. cutting off force, kN concrete B 25 | Weight 1000 pieces, kg |

| 5x35 | 45,00 | 30,00 | 5,00 | 0,90 | 1,30 | 3,30 |

| 5x45 | 55,00 | 30,00 | 15,00 | 0,90 | 1,30 | 3,80 |

| 6x40 | 50,00 | 30,00 | 10,00 | 1,60 | 1,80 | 4,20 |

| 6x60 | 70,00 | 30,00 | 30,00 | 1,60 | 1,80 | 11,10 |

| 6x80 | 90,00 | 30,00 | 50,00 | 1,60 | 1,80 | 14,30 |

| 8x60 | 70,00 | 40,00 | 20,00 | 2,40 | 2,90 | 9,50 |

| 8x80 | 90,00 | 40,00 | 40,00 | 2,40 | 2,90 | 14,30 |

| 8x100 | 110,00 | 40,00 | 60,00 | 2,40 | 2,90 | 14,80 |

| 8x120 | 130,00 | 40,00 | 70,00 | 2,40 | 2,90 | 17,30 |

| 8x140 | 150,00 | 40,00 | 80,00 | 2,40 | 2,90 | — |

| 8x160 | 170,00 | 40,00 | 90,00 | 2,40 | 2,90 | — |

| 10x100 | 115,00 | 50,00 | 50,00 | 3,40 | 4,10 | — |

| 10x120 | 150,00 | 50,00 | 85,00 | 3,40 | 4,10 | — |

| 10x140 | 175,00 | 50,00 | 110,00 | 3,40 | 4,10 | — |

Table 3

Dimensions and weight of dowel-nails for construction and installation gun.

The importance of choosing a drill

The relevance of choosing a drill is necessary in cases where we are talking about attaching paintings, furniture, lighting, and other accessories to the surface. The durability and reliability of fastening depends on the choice of drill for the power tool.

What you need to know when choosing a drill for a dowel

It is recommended to select a drill for the dowel hole, taking into account the following parameters:

- Estimated loads on fasteners

- Surface and finishing materials used

- Fastener diameter