Features and types of self-tapping screws

Today there is a huge amount of building materials, and therefore, varieties of self-tapping screws. For example, they differ in the types of surfaces they are intended for. There is a classification based on load and other parameters.

A self-tapping screw is a rod-shaped fastening device. It has a screw head and thread. Simultaneously with the transmission of torque, thread cutting occurs in the materials being connected.

Self-tapping screws are made from brass, as well as stainless or carbon steel. Taking into account the characteristics of the materials being fastened and the load level, self-tapping screws are selected according to the thread pitch:

- medium pitch is typical for universal products

- frequent pitch (2-start thread) is used for attaching to metal no more than 0.9 mm thick, no dowel is required

- a rare step is suitable for soft materials such as asbestos or plastic

- medium pitch with a herringbone profile is used when driving into dowels installed in brick or concrete

- asymmetrical step is an option for modern furniture designs made from a variety of materials

- variable pitch with notch ensures attachment to brick or concrete without installing a dowel

- Self-tapping screw of the confirmat type allows you to firmly connect furniture parts made of wood or chipboard with high precision

Self-tapping screws have a huge reserve of strength for both bending and shearing. The main task is to securely attach it to the walls. Here you need to take into account that materials with a more porous structure require long and thick dowels. This makes it possible to provide a larger engagement area.

Every set of tools should have dowel-nails; this is an indispensable component in many repair and construction works. Thanks to the type of nail in question, the installation process becomes efficient, which means that both effort and time are saved during fastening.

It should also be noted that dismantling, as well as installation of the dowel-nail, is quite simple, and fastening with such an element is very strong and durable. In order to quickly dismantle this element, you must first carefully unscrew the nail inserted into it from the dowel itself, and only after this procedure can you remove the “cut” of the nail with a regular screwdriver (preferably a Phillips screwdriver).

Among consumers during fastening work, it is common to use a 6x40 mm dowel-nail. The design of the fastening element in question is quite simple, which makes it convenient to use. The price category of this fastener is quite low, so purchasing such a product will not be difficult for anyone. At any point of sale of hardware and fasteners you can find an unlimited number of such nails.

PLUGS FOR MOUNTING IN PLASTERBOARD SHEETS

Polypropylene expansion dowel complete with attachment for fastening in plasterboard walls.

| Designation | Drilling diameter mm | Screw diameter mm | Quantity per pack pcs |

| TT 22 | 7-8 | 3.5-4.0 | 200 |

Self-tapping dowel made of ZnAI alloy for fastening in plasterboard walls. DRIVA SPA

| Designation | Drilling diameter mm | Screw diameter mm | Quantity per pack pcs |

| DRIVA-SPA | 4.0-4.2 | 50 |

Polypropylene expansion dowel for fastening in plasterboard walls. TNF

| Designation | Drilling diameter mm | Screw diameter mm | Quantity per pack pcs |

| TNF | 10 | 3.0-3.5 | 200 |

Polypropylene expansion dowel with screw. TNF-W

| Designation | Max, thickness of the object to be strengthened mm | Drilling diameter mm | Screw/hook size mm | Quantity per pack pcs |

| TNF | 5 | 10 | 3.5×55 | 100 |

Folding spring dowel for mounting in suspended ceilings. SPDK

| Designation | Drilling diameter mm | Weight kg/1000 pcs |

| SPDK M 3×85 | 10 | 1 1.5 |

| SPDK M4x75 | 13 | 14.0 |

| SPDK M 5×95 | 15 | 22.3 |

| SPDK M 6×100 | 25 | 37.5 |

| SPDK M 8×100 | 25 | 62.2 |

Where is the 6x40 dowel nail used?

The fastening parts in question are used everywhere and are considered universal nails. Their range of applications is quite wide; they can be used to attach various types of structural elements to materials such as stone, various types of brick, reinforced concrete, etc.

Experts do not recommend using dowel-nails for hollow-type materials and porous surfaces. A 6x40 dowel-nail, the technical characteristics of which will be discussed below, is driven in with a hammer, but before that, do not forget about the preliminary preparation of a special hole where the fastener in question will be inserted.

The high demand for the element in question is due to three criteria and, at the same time, the advantages of such a nail, namely: extremely simple design, low cost and practicality. Dowel-nails 6x40 are popular during the installation of support-type structures, because in this process you simply cannot do without them.

Technical characteristics of the fastener

Most construction and finishing works cannot be done without the use of this part. It should also be noted that the dowel-nail is always supplied exclusively as a set, so you don’t have to look for and purchase a separate “frame” for the nail.

We would like to inform you that under no circumstances should screws replace nails; this replacement will be inappropriate, incorrect and impractical. A 6x40 mm dowel-nail, the characteristics of which are its advantages in comparison with similar types of fasteners, can be made of different materials (nylon, polypropylene, polyethylene).

The fastener in question consists of several parts, directly from a dowel (hence the name of this type of nail), double-spacer, on the surface of which there are no tangential fixing elements in the form of ailerons, or, for example, mustaches. The top of the part (later the head) can be of several shapes - cylinder, mushroom-shaped and secretive.

The second element of the 6x40 mm dowel-nail is, directly, a nail in the form of a screw. It is usually made of carbon steel, but this is not the only layer that is used to cover the screw. Among other things, a zinc layer is applied to the surface of the fastening element in question, which serves both for protection and performs a decorative function.

On the rod of the fastening element there is a smooth part, as well as a tip. It is immediately worth noting that the shape of the head of the element in question will ultimately depend on the shape of the inlet hole.

Size

Dowels, like any other fastening elements, have different sizes, because they can be used on different materials and under different conditions. Let's look at the dimensions of the fastener element in question:

- The length of a 6x40 mm dowel-nail is 40 mm (this is the second number in the name of the part in question);

- The length of the nail itself, which is screwed into the dowel, is 45 mm;

- The diameter of the dowel is equal to 6 mm (the first number in the name) and the same parameter of the nail is 4 mm;

- The thickness at different ends of the part is different, the minimum is 10, the maximum is 50;

- Anchoring depth - 30.

How much weight can a dowel nail support?

When selecting fasteners, you should pay attention to the maximum possible operating load. It is also worth finding out about the recommended load. All these values are specified by the manufacturer.

After you have decided on the load that the dowel should withstand, pay attention to its diameter and length.

The dependence is directly proportional; the greater the thickness and length, the greater the load the nail can withstand.

Attention should also be paid to the surface material; for example, on foam concrete, not a single dowel can withstand significant weight.

buy dowel and nail in Minsk from us. For additional information, please contact our specialists; the phone numbers you can call are posted on the website. They will help you buy fasteners, taking into account all the features of the material and the load placed on it.

Material and coating

Most often, the part is made of various types of plastic (polyamide, polypropylene, etc. In practice, there are also dowels made of metal (rare cases, but they do occur). The nail in the element in question is an alloy of metals, but besides everything else , coated with zinc.

It is worth noting that there is a 6x40 dowel-nail with a thread, and there is one without it, so when choosing the fasteners you need, you should pay attention to this nuance.

Many fastening elements are used in construction work. A common one is a 6x40 mm dowel-nail. The main area of application of such elements is private construction. They are used for fastening metal profiles, cables, gutters, hanging objects and baseboards. Their main feature is that they provide reliable fixation of parts to the surface for a long time.

Dowels are divided into the following categories:

- - Universal. Used for hollow surfaces. Often, dowels of this category, if they have wide heads, are used for fastening insulation.

- — Spacers. They work on the principle of expanding the material of the sleeve, which is located in the hole; its peculiarity is that it is made of high-strength plastic. Special attention should be paid to the core; it is made of plastic or metal. This category is used for fastening to solid surfaces.

Characteristics of fasteners

The 6x40 dowel is covered with a plastic shell that performs a spacer action. The main rod is made of galvanized steel. The hole for such a fastener is made using a 6 mm drill. After drilling, the sleeve is secured, and then the nail is driven in with an ordinary hammer.

If any other fastener cannot be removed in the future after installation, then the 6x40 nail can be unscrewed using a screwdriver. The diameter of the plastic element of such a dowel is 6 mm, and the length is 4 cm. The nail itself is half a centimeter longer , but its diameter is 2 mm smaller.

A 6 by 40 dowel nail can be screwed into wood, brick or concrete. can be used quickly install and secure various objects .

The main element of such hardware is a cone-shaped metal nail that decreases in diameter downwards. It can be driven into the wall with a hammer. To secure it in the surface, you can also use a screwdriver: it has a special thread for this purpose. If you want to get the job done as quickly as possible, it is better to use a hammer.

FACADE AND FRAME EXPANDERS

Polyamide (nylon) expansion dowel for hollow (hollow) materials. Galvanized steel screw with hex head. TSXS

| Designation item mm | Max. thickness of reinforced mm | Drilling diameter mm | Min. fixing depth pcs | Col. in a pack pcs | Mt pull-out force kN | |||

| concrete B 25 | full brick | empty, brick | aerated concrete | |||||

| Т5Х-5 8/100 | 30 | 8 | 70 | 100 | 3.99 | 2.63 | 2.39 | 2.22 |

| Т5Х-510/80 | 30 | 10 | 50 | 50 | 4.01 | 2.63 | 2.39 | 2.22 |

| Т5Х-510/100 | 30 | 10 | 70 | 50 | 4.01 | 2.65 | 2.41 | 2.24 |

| Т5Х-510/120 | 50 | 10 | 70 | 50 | 4.11 | 2.68 | 2.42 | 2.24 |

| Т5Х-510/140 | 70 | 10 | 70 | 50 | 4.22 | 2.70 | 2.43 | 2.21 |

| Т5Х-510/160 | 90 | 10 | 70 | 50 | 4.25 | 2.71 | 2.47 | 2.22 |

| T5X -5 10/200 | 130 | 10 | 70 | 50 | 4.29 | 2.73 | 2.51 | 2.26 |

Types of dowels

As the fastener penetrates the wall, its plastic element expands and is therefore securely fixed. At one end there is a cuff designed to prevent the fastener from being completely immersed in the wall surface.

The shape of these cuffs can be different, and in this regard, several types of dowels are distinguished:

- "Mushroom Nail" . Its upper part is round. Used when increased downforce is required. Since such a cuff is quite thick, the pressure is distributed evenly, and the attached object is not damaged. After screwing or driving in the “fungus”, its upper part remains outside.

- "Nail-sunk" . It is used if you need to hide the head of a fastener in the wall. The nail head may have a flat surface. In this case, only a hammer is used to fix it in the wall, while the reverse process, that is, pulling out an already fixed nail, is not possible.

However, most often there are recesses on the head , which allow the use of devices such as a screwdriver or screwdriver for screwing. If the dowel was mounted into the wall with their help, then it can be pulled out if necessary. They can be used repeatedly.

Dowels are made from different materials. Metal fasteners are typically used to secure objects to a cement or drywall wall.

Most often they are used on the farm from plastic. If installed in a concrete wall, they can withstand a load of up to 450 kg. If the wall into which they are screwed is brick, then the maximum permissible load will be slightly less than 400 kg.

Fasteners of this type are also divided into several varieties, depending on the type of fastening:

- Dowel designed for manual installation. It usually has a thread. It can be easily unscrewed from the surface using a regular screwdriver.

- A dowel designed for fixation using a construction gun. Such fastening can withstand serious loads. If you need particularly strong fixation, then it is better to use this particular type of dowel-nails.

Molly dowel attachment

Dowel Molly

This type of dowel also has some installation features. A hole is drilled with an eight millimeter drill. Then a dowel is inserted into the drywall, which has a side with two teeth and is pressed tightly. This action will prevent the anchor from twisting when it is fixed. After this, using the screw that comes with the kit, using a screwdriver or screwdriver, the dowel is screwed tightly to the drywall. In this case, the central part of the sleeve is twisted, thereby providing excellent fixation to the object that will be secured.

Molly dowel installation

The molly dowel has a number of advantages, for example:

- Has the ability to withstand loads of up to 35 kilograms.

- The screw and dowel are sold as a set.

- If necessary, the structure can be dismantled.

In turn, it has one significant drawback, namely the high price. However, a molly dowel for drywall is ideal!

Purpose

Dowels-nails ( nail

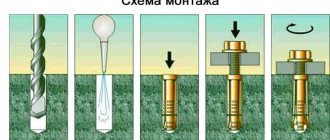

) have a great advantage compared to other types of similar fasteners - high installation speed. Fasteners are used to make detachable connections of attached structural elements to base materials made of concrete and reinforced concrete, natural building stone, solid (sand-lime and red) brick. Fasteners are not recommended for use on porous or hollow materials. During installation, the product is inserted into the hole prepared for it and finally fixed in the seat with light blows of a hammer. When dismantling, first completely unscrew the nail from the dowel using a regular Phillips screwdriver, and then remove the fastener itself from the material.

Dowel-nails 6x40 have a simple design, are classified as products in a low price category and are supplied in large volumes to the fasteners and hardware market. Low prices, simple design and availability have ensured their great popularity and high demand. They are simply irreplaceable when installing support structures for plasterboard systems and other types of finishing and construction work. Dowel-nails 6x40 are always supplied as a set. Replacing nails with ordinary screws is not permitted.

Installation type

There are two ways to install the fastener:

- Manual . You will need a hammer drill, screwdriver or hammer. You will have to drill a hole, insert a sleeve into it with your own hands, and then screw or drive in the rod.

- Automatic . Installation is carried out using a gun. Use a special nail without a dowel with a strength of 53-56 HRC on the Rockwell scale.

The second option benefits from high installation speed. But the first is good because the standard rod can be pulled out without damaging the material or design.

Design Features

Dowel-nail 6x4

includes two parts:

Double-spaced polypropylene, nylon or polyethylene dowel with a diameter of 6 mm and a length of 40 mm, which does not have tangential fixation elements (ailerons, whiskers). The head of the fastener on its non-expanding part can have one of the design options: mushroom-shaped, cylindrical and countersunk.

A nail-screw made of carbon steel, on the surface of which a protective and decorative layer of zinc yellow-passivated coating is applied. The fastener rod includes a tip, a metric thread part and a smooth part. The shape of the countersunk head of the nail-screw matches the shape of the inlet hole in the non-expanding part of the plastic dowel. At the end of the part there is a slot of the Pozidriv type No. 2 (aka: Pozi), designed for unscrewing the screw nail to be replaced from the seat.

DOCUMENT NAILS FOR QUICK INSTALLATION SM

Polyethylene expansion dowel for quick installation. Galvanized steel nail screw (yellow color). With a hidden side. SM-L

| Designation | Max, thickness of the object to be strengthened mm | Drilling diameter mm | Min. fixing depth mm | Quantity per pack pcs | Mt pull-out force [kN]1 | Mt shear force [kN]1 | ||

| concrete B 25 | brick masonry | aerated concrete | concrete class B 25 | |||||

| SM-L 6/40 | 10 | 6 | 30 | 200 | 1.47 | 1.11 | 0.56 | 3.23 |

| SM-L 6/60 | 30 | 6 | 30 | 200 | 1.45 | 1.12 | 0.55 | 3.26 |

| SM-L 6/80 | 50 | 6 | 30 | 100 | 1.47 | 1.11 | 0.55 | 3.33 |

| SM-L 8/60 | 20 | 8 | 40 | 100 | 2.26 | 1.67 | 0.78 | 3.82 |

| SM-L 8/80 | 40 | 8 | 40 | 100 | 2.27 | .68 | 0.78 | 3.84 |

| SM-L 8/100 | 60 | 8 | 40 | 100 | 2.27 | .64 | 0.79 | 3.87 |

| SM-L 8/120 | 80 | 8 | 40 | 100 | 2.21 | .65 | 0.74 | 3.89 |

| SM-L 8/140 | 100 | 8 | 40 | 100 | 2.28 | .65 | 0.77 | 3.93 |

| SM-L 8/160 | 110 | 8 | 50 | 100 | 2.26 | .67 | 0.75 | 3.97 |

| SM-L 10/100 | 60 | 10 | 40 | 100 | 3.18 | 2.69 | 0.91 | 4.71 |

| SM-L 10/120 | 80 | 10 | 40 | 100 | 3.11 | 2.66 | 0.90 | 4.72 |

| SM-L 10/140 | 100 | 10 | 40 | 100 | 3.11 | 2.60 | 0.91 | 4.76 |

| SM-L 10/160 | 110 | 10 | 50 | 100 | 3.13 | 2.62 | 0.91 | 4.80 |

With a mushroom-shaped side. SM-G

| Designation | Max, thickness of the object to be strengthened mm | Drilling diameter mm | Min. fixing depth mm | Quantity per pack pcs | Mt pull-out force [kN]1 | Mt shear force [kN]1 | ||

| concrete B 25 | brick masonry | aerated concrete | concrete class B 25 | |||||

| SM-G 6/40 | 10 | b | 30 | 200 | 1.47 | 1.11 | 0.56 | 3.23 |

| SM-G 6/60 | 30 | 6 | 30 | 200 | 1.45 | 1.12 | 0.55 | 3.26 |

| SM-G 6/80 | 50 | 6 | 30 | 100 | 1.47 | 1.11 | 0.55 | 3.33 |

Dowel-nail, main characteristics

The 6x40 dowel-nail is used for manual fastening of parts. The element consists of a plastic shell that performs a spacer action. Thanks to this device, high-quality fixation is performed at the location of the dowel. The main rod is made of galvanized carbon steel.

To make a hole, use a 6mm drill, then install the sleeve. Then a nail is driven into the dowel using a hammer. The usual fastening element is not subsequently subject to removal, unlike the 6x40 dowel, it includes a sleeve and a screw and is easily removed with a screwdriver. The dowel has a length of 40 and a diameter of 6, and a nail - 45 and 4. The thickness of the base with through penetration is 50, and the fixed sample is 10. The minimum immersion depth of the anchor is 30, weight 4.2 g.

The dowel-nail is used to fix metal profiles, gutters, cable ducts; it is used to secure hanging objects, baseboards, furniture, and others. I do not use such fasteners for hollow materials.

Working with dowel-nails and their structure

The dowel-nail can be used to work on wood, brick or concrete surfaces. The fastening element has a special shape and is intended for quick installation or fastening of various objects and materials. The main elements included in the composition are a nail with a cone-shaped thread, which tapers towards the bottom. This allows you to work with a screwdriver or hammer.

A nail dowel differs from ordinary dowels in that the main fastener performs the functions of a nail, but not a screw. Using a hammer, manual work with such elements is faster.

The plastic part of the element expands when driving a nail and is securely fastened. One extreme part of the dowel has a cuff; it prevents the element from being completely immersed in the hole, that is, it holds the top cap. The cuff has a different shape, which determines the type of dowels.

The mushroom nail is distinguished by its rounded finish. It is used when increased downforce is required. Due to the significant thickness of the cuff, pressure can be distributed evenly without damaging the fastener or fixed object.

To hide the head of the element flush with the surface, use a countersunk nail dowel.

The hat may have a straight surface or the presence of indentations. In the first option, the work is done only manually using a hammer. The second method allows you to use various devices, such as a screwdriver or screwdriver. Such elements can be pulled out, used several times or replaced.

Types of dowel-nails

Dowel nails can be made from various materials; plastic elements are most often used in households. Metal fasteners are used to secure various objects to a cement or plasterboard surface. Dowels of the spacer type have the largest zone of the spacer part, and antennae that have a blocking effect, due to this the elements are immovable. Facade dowels are used to fix thermal insulation materials to a brick or concrete surface. At the base of such elements there are serrated plates.

The dowel-nail may differ in the type of fastening

A manually installed dowel-nail can be with or without thread; such an element can be easily pulled out of a concrete or brick surface using a screwdriver.

Element for a construction-assembly gun. Such a gun attaches the part to the surface. This type of fastening can withstand significant loads, unlike the manual type. Dowels can be made from various types of plastic; the elements can withstand fasteners of up to 450 kilograms in a concrete surface, and up to 400 kilograms in a brick surface. The elements can be made of steel, and the coating is zinc, they are used for fastening heavy objects.