The presence of a well, sewerage, drainage basin or laying of cables are integral components of the arrangement of the territory of a private farm. In addition to compliance with sanitary and hygienic standards and technical requirements, each owner counts on the long-term operation of these communications, therefore, first of all, attention is paid to reinforced concrete products. Their reliability, with the correct selection of the required dimensions of concrete rings for the well and proper installation, guarantees more than 100 years of trouble-free operation of the treatment system.

Concrete rings.

Types of concrete rings for a well

Well rings are cylindrical products made of reinforced concrete, used in construction for the arrangement of underground utilities. In addition to the construction of wells for drinking water, they are used in the assembly of sewer and waste columns, settling tanks and reservoirs for various purposes. Quality characteristics must comply with GOST No. 8020-90.

The production of reinforced concrete products is carried out by pouring a cement mixture into a mold (formwork), pre-reinforced with steel wire Ø 8-12 mm. Vertical rods should be provided at opposite ends of the product, which will subsequently be used as lugs for lifting the structure. Due to vibration, the material becomes compacted, which leads to loss of part of the volume. It is replenished by re-filling and the mold is shaken again, achieving complete elimination of air from the body of the product. The finished ring is obtained after the cement mass has set.

Tempering strength (50% of the required) is achieved within 7 days, and full strength - after 28-30 days. According to their purpose, reinforced concrete products are divided into the following types:

- Supporting ones, which are laid at the base of the well.

- Wall, used for narrowed areas of the structure.

- For drainage systems.

- For water and gas wells.

- For sewer and drainage networks.

- For protecting power supply cables.

Wall concrete rings.

In addition, they are classified according to the docking method. There are products with and without folds. The latter have flat and smooth edges and are installed one on top of the other. Such a connection requires precision, and subsequently additional sealing of the joints. The presence of folds - a recess at one end and a protrusion at the other - provides a more reliable locking connection.

There are also prefabricated structures consisting of several sections and monoliths made to order. The advantage of the latter is the absence of connecting seams, which have a risk of leakage, as well as the elimination of the need to adjust each subsequent element to the previous one. The dimensions of the monoliths are limited only by the conditions of transportation of the product to the installation site.

The last qualification concerns the form. Round and square are considered standard, but in accordance with the presented project, rings with a cross-section of any configuration and complexity can be made.

What types of rings are there? Types and purpose

Well rings are round reinforced concrete structures used for arranging utility lines buried below ground level. Depending on the structure being constructed, the following types of rings are used:

Sewage and water intake.

Products for laying underground cable electrical networks.

Gas pipelines and water intakes.

In addition, there are the following varieties on the market:

Rings with flat and locking ends.

Regardless of the type and purpose, the products are made of heavy concrete, grade 200-500 , and reinforced.

Advantages and disadvantages

Reinforced concrete structures have long occupied a leading position in the building materials market, but even when using them, the buyer must be prepared to encounter some difficulties. When compared with similar products made from other materials (plastic, polymer mixtures), undeniable advantages can be identified:

- suitability for all types of structures;

- affordability of prices;

- large selection of size models;

- durability and strength ensured by the use of heavy reinforced concrete grades 200-500;

- rigidity of the structure, which can also be installed on unstable soils;

- simplicity and speed of installation;

- the ability to produce components on site with your own hands;

- reliable protection against seasonal swelling of the soil and against entry into the groundwater system.

Reinforced concrete structures.

Disadvantages include:

- transportation difficulties;

- dimensions and weight, which require the use of special equipment during installation;

- lack of mobility (it is extremely difficult to move an installed well).

However, these difficulties do not affect the popularity of concrete rings in any way. Buyers are well aware of both transport and installation costs and are prepared for them in advance.

Types of connections

The most popular are concrete rings with a locking connection, the use of which facilitates installation and guarantees increased reliability of the structure during use. Structures that do not have key joints have a flat end.

Locks with tongue-and-groove joints at the ends require that, when installed, the protrusion must fit into the groove of the adjacent product. All joints upon completion of work are sealed using a rope and concrete mortar.

The advantages of locking connections are:

Types of concrete ring connections

- tight junction of rings;

- reliable fixation of products;

- quick installation of the structure.

The price of such products is higher than the cost of rings without locks, however, it is fully justified by the above-described advantages of concrete structures.

Concrete rings without a lock are fixed using special metal brackets and cement mortar.

Ring size

The height of the product, weight, volume, internal and external diameters, as well as the width of the walls - all these indicators make up its dimensional characteristics, which can be standard or non-standard. The latter includes rings made to special order or in small batches.

Depending on the purpose for which the utility line is installed, additional elements may be needed, including:

- Bottom plates that ensure the reliability and watertightness of the base (or rings with a solid bottom).

- Floor slabs that have a hole in the body of a smaller diameter on which a seat for a sewer hatch is mounted.

- Additional rings are products of a standard diameter, but with a smaller height, necessary to bring the well to the desired level above the ground.

Bottom plates.

Their use helps to increase the service life, protects against contamination and gives the structure a finished look.

How to choose

There are several aspects that need to be considered when purchasing reinforced concrete rings. This is compliance with the required volume of the septic tank, GOST, sanitary and hygienic requirements, and the strength characteristics of the product. The size determines the prices for the product itself, its transportation and installation, including preparatory excavation work. And depending on how much the ring weighs, it is necessary to use special equipment during installation.

A preliminary calculation of the required capacity helps determine the dimensions. When arranging a sewer system for a septic tank consisting of two sections (one section is just a cesspool), the formula is used:

V = (n*Q*t)/1000,

where V is the required volume in m³, n is the number of people in the house, Q is the water consumption per person per day, t is the number of days required for a full cycle of water purification according to SNiP. On average, this is at least 1.2 m³ per resident. Sanitary standards require that the liquid settle for more than 3 days in the primary treatment tank, where suspended matter settles and the action of anaerobic bacteria occurs. Therefore, if only 500 liters are discharged per day, its capacity cannot be less than 1500 liters.

Dimensions of rings for wells.

For a water well, complex calculations are not required, but the following factors must be taken into account:

- potential debit of the aquifer;

- planned consumption;

- financial expenses.

If the set is carried out on one standard ring with a height of 90 cm, then with a meter diameter the water supply will be 680 l, with a Ø 1.5 m - 1500 l, and with a Ø 2 m - 2800. Sales statistics say that for everything related to sewage , designs with a diameter of 1.5 m are more often used, and for wells - 1 m.

When choosing, you should also pay attention to the strength of the product (wall thickness, presence of reinforcement), which is especially important when working in problematic soils. The surface of the reinforced concrete products must be rubbed with cement mortar and free from chips, cracks and cavities. The presence of rust on the lifting eyes is unacceptable (they may break during installation). The permissible slope of the walls cannot exceed 1.5%. Upon purchase, a hygiene certificate and a passport must be issued, which indicate the date of manufacture, materials used, brand of concrete, whether it was steamed in the oven or not.

Deciphering the markings

Each reinforced concrete product, according to GOST standards, must have alphanumeric markings on the surface that correspond to its purpose and reflect two dimensional characteristics. The scope of application is marked with letters:

- KS - wall ring (through);

- KO - support;

- KSD - wall with bottom;

- KFK - septic tanks and fecal sewerage;

- KLK - storm drains;

- KGV - water and gas communications;

- KLV - storm water intake wells.

Ring markings.

The numbers indicate parameters, rounded up and expressed in decimeters:

- Inner Ø.

- Height.

So, for example, the marking KS 10.9 stands for “wall ring with an internal cross-sectional diameter of 1 m and a height of 89 cm.”

Standard sizes

GOST establishes a wide range of products, since the standard sizes must fully satisfy the needs of builders in arranging systems of any complexity. Therefore, they have versatility and great possibilities for compatibility. The dimensions look like this:

- Height. Three are considered standard: 29, 59 and 89 cm (in industrial construction, 119 cm is used).

- Wall thickness. Available in 7, 8, 9 and 10 cm.

- Inner Ø. Four main ones: 70, 100, 150 and 200 cm.

- External Ø. From 84 to 220 cm.

- Useful volume. Varies from 0.05 to 0.59 m³.

Standard ring size.

KS 25.12 has the largest dimensions, but it is not used in private construction, because it is not possible to install it without special equipment.

The weight of the ring depends on three factors:

- type of aggregate, brand of concrete;

- quantity and weight of reinforcement used;

- volume of concrete depending on wall thickness.

Each manufacturer uses its own technology, so the tonnage of even similar products varies depending on the supplier plant. You can only record the weight difference from 130 kg to 1.5 tons.

How to check ring size

Checking for compliance with GOST is carried out using two perpendicular diameters. At four points located in pairs opposite each other, the thickness of the concrete and the height of the reinforced concrete products are measured (for seam ones, additionally, the depth of the grooves and the dimensions of the tenon). A deviation of no more than 1.5% is considered acceptable. It is advisable to take measurements at both the top and bottom.

Dimensions of concrete rings.

Making reinforced concrete rings at home

If you need:

1) Non-standard sizes. 2) One or more rings of different widths. 3) One additional ring.

And if there are no special requirements for the precision of manufacturing the structure, then you can make them yourself. Having calculated the cost of a factory-made product, its delivery and installation, you can judge the feasibility of independent concrete work at home.

First of all, the required volume for concrete rings is calculated: outer and inner diameters, height. Based on design loads (self-gravity, weight of communications, thrust force of water, possibility of soil displacement), a structure made of pure concrete or reinforced is selected.

The reinforcement can be either steel or combined (using fiberglass, lighter, non-corrosive).

Based on these data, you will understand what volume and composition of concrete will be required for the product. When making your own well rings, you need large volumes of mixture - for which you may need to rent a concrete mixer. The approximate consumption for the manufacture of a product with a diameter of 150 cm is 0.3 cubic meters of ready-made concrete mixture.

For independent production you will need:

- cement grade M200 and higher;

- fittings;

- concrete mixer;

- wheelbarrow and large containers;

- form for filling - two collapsible circles, nested one into the other. Metal and wood are suitable for the form. To make formwork, cut up old metal barrels are suitable for the mold.

The inner part of the formwork must be at least 100 mm higher than the outer part.

How to make formwork with your own hands?

- Install the formwork, securing it vertically and sealing the seams.

- Install a reinforcing frame (welded or fastened rods).

- Prepare concrete according to the formula:

cement – 1 part;

sand – 2.5 parts;

washed crushed stone – 3-4 parts.

Water should not make up more than 50% of the mass of the concrete mixture. To increase the plasticity of the solution when laying it, add liquid detergent (1 tsp per 10 l) or dissolve washing powder (1 tbsp). To increase strength, use PVA glue or potassium glass in volumes of no more than 2%.

Attention! It must be produced at temperatures above 10 degrees. The finished product must be protected from direct sunlight and getting wet.

- Pour slowly, in layers no more than 20 cm high, stirring with a metal rod. Each of the layers must “settle down”, otherwise cavities will form.

- Upon completion of pouring, level the surface of the mixture and, if necessary, strengthen the embedded parts.

- Leave the product to set. To avoid cracking at high temperatures, wrap it in polyethylene. The minimum curing time is 4 days. The estimated period of strength gain is 21 days.

- First, the inner part of the formwork is removed, then the outer part.

Which manufacturer to choose

In the Russian Federation, about 250 manufacturers are engaged in the production of reinforced concrete rings, covering the entire territory of the country. Therefore, traveling outside your region in search of cheap prices is not economically profitable. The savings will be consumed by transportation. However, the products of some factories are in special demand. We can highlight:

- "VTG Stroy" in Mytishchi, Moscow region, shipping its products throughout the country. Their KS 10.9, KS 15.9 and KS 20.9 rebated and flat models complete with a lid and hatch are in particular demand. The average cost is 2.1 thousand rubles.

- OJSC "Plant of Industrial Construction Parts", operating for more than 45 years in Tyumen. It has its own accredited construction laboratory, which allows not only to monitor quality, but also to develop new technologies.

- in Novokuznetsk is a supplier of high-quality reinforced concrete products throughout the Kemerovo region. In addition to producing standard designs, the company is also willing to accept orders for individual projects.

- in Krasnodar is distinguished by a wide range and high production capacity. Prices for reinforced concrete products start from 1.4 thousand rubles.

These manufacturers strictly monitor production technology and guarantee the quality of their products.

Production Features

The production of concrete rings is carried out in strict accordance with the requirements of GOST 8020-90 “Concrete and reinforced concrete structures for wells”. In terms of quality parameters, the rings comply with GOST 13015-2012 “Concrete and reinforced concrete products for construction.” Classification of products occurs after determining their strength, water and frost resistance, and the grade of steel used to reinforce the structure.

Vibropress for concrete rings

In the process of producing reinforced concrete rings, specialized equipment is used: a vibropress or vibroforms. When using the second type of equipment, production is carried out using the casting method, and the beam crane is replaced by a manipulator.

When working with concrete rings, lifting equipment is used. Moving large items in production conditions, loading and unloading them is only possible using a compact truck crane with a lifting capacity of 5 tons.

Concrete mix recipe

Concrete products are made from concrete grade M200; when preparing the mixture, the requirements of GOST 7473-2010 “Concrete Mixtures” are observed.

The recipe for preparing 1 m3 of solution consists of mixing a set of ingredients: cement M200 - 0.3 tons, sand (1.5-2 mm) - 0.8 tons, crushed stone (diameter up to 10 mm) - 1.25 tons, special plasticizer ( proportions are indicated by the manufacturer of the product) and water - 0.150 tons. All components are placed in a concrete mixer and thoroughly mixed until a homogeneous mass is obtained.

GOST 7473-2010

Reinforcement

In order to improve the quality and durability of products, a special reinforced wire mesh with a cross-section of 4 and 5 mm is used when creating them. An alternative to wire mesh is stronger reinforcement with a diameter of 8 mm.

Example of reinforced concrete ring reinforcement

The metal reinforcement cage is installed in the mold before pouring concrete. To ensure that the metal mesh is completely poured and does not stick out from the concrete product, special star fasteners are used.

Before pouring the concrete mixture, the mold is treated with special oil. After the mixture has hardened, the formwork structure is removed, the product dries, gaining strength. To speed up the drying process, special thermal chambers are used.

Equipment for making rings

Mold production is carried out using external formwork and a core. Vibrating equipment allows you to achieve maximum product density. Different frequencies of vibration waves make it possible to influence all fractions applicable in the production process.

The concrete ring, made by pressing, has high strength and is distinguished by excellent surface quality.

It is possible to produce concrete rings in a home workshop. However, before starting work, you should make sure that this idea is feasible.

Molds for the production of concrete rings

Ring prices

The pricing policy is determined by the market, and therefore in different regions the same product will cost differently, but everywhere its price is directly dependent on the size. And if for KS 7.3 you will have to pay from 700 rubles, then for KS 20.9 - already about 4.5 thousand rubles. Purchasing from the manufacturer provides savings of 5-15% compared to construction markets. But when drawing up an estimate, in addition to spending on rings, the customer must keep in mind other expenses:

- digging a foundation pit for a structure;

- for delivery of products;

- for installation work;

- construction of a well house (optional);

- for additional materials, for example, cement for sealing joints or pebbles for the filtration bottom of a well.

It makes sense to cooperate with one supplier. In many cases, this will bring additional benefits in the areas of service, delivery and information support.

Advantages and disadvantages

The advantages of concrete rings for use in construction purposes are the following design properties:

- long service life (more than 10 years);

- affordable price;

- easy installation due to the correct geometric shape;

- high strength and operational reliability.

However, despite having a number of advantages, concrete rings have two significant disadvantages:

- additional costs for delivery and installation - the heavy weight of the structure will not allow you to install it yourself, so the services of special equipment will be required;

- Uneven load on the large mass of the ring can lead to the formation of chips and cracks.

Where are they used?

The scope of application of reinforced concrete rings depends on the materials from which they are made. For their production, different grades of concrete, crushed stone and sand with a wide granulometric composition, metal reinforcement or mesh are used. They provide a sufficient margin of safety for the use of concrete rings in the construction of wells for drinking water, wells, collectors, septic tanks, inspection tanks, sewers, and gas pipelines. Drainage systems are also mounted on reinforced concrete rings.

Return to contents

Compare reinforced concrete and polymer sand

| Characteristic | Polymer sand | Reinforced concrete |

| Transportation and installation | It has less weight, so transportation is greatly simplified. It is possible to transport with your own car. It is quite possible to do the installation yourself. The weight of the ring can be about 60 kg, so unloading can be handled alone | Weight on average up to 500 kg (one). For delivery it is necessary to hire transport. For installation, the use of lifting equipment is mandatory. Given the nature of the local area, this is not always possible. |

| Easy docking | The tongue-and-groove technology speeds up the assembly process. After connection, an impenetrable seam is formed that does not require additional sealing. It is enough to treat each seam with silicone | It is difficult to achieve a perfect fit and tight fit. After installation, the seam is sealed |

| Resistance to frost and moisture | Polymer sand copes with this perfectly, without damage | Reinforced concrete has large pores through which moisture will flow. Water that penetrates into concrete freezes and because of this gradually destroys it. |

| Resistance to aggressive environments | Polymer sand is neutral to various chemical environments. Ideally proven when used both in a cesspool and with drinking water | Reinforced concrete rings must be subjected to additional processing |

| Easy to process | To make a hole, it is enough to use a household power tool. The resulting cut is not afraid of moisture and contact with aggressive environments | It is difficult to make technological holes for laying a pipeline |

Installation and Installation

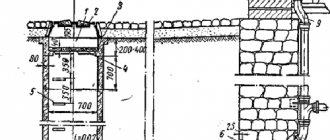

Installation of reinforced concrete rings is carried out in two main ways. Products can be laid using a technician in a finished pit, or installed using the deepening method. The latter method involves placing the first ring near the surface.

The product is buried by digging and throwing the soil to the surface. This is a manual installation method. The weight of concrete helps to implement it. The ring literally digs into the ground, pressing with its mass.

When working manually, when the first ring goes into the ground, a second one is placed on top, then a third, and so on down the list. We have to shovel when digging. The waste soil is lifted upstairs, loaded into buckets on ropes.

With automated installation, the ring is lowered by the machine. More important are the issues of pit preparation. If he needs a drainage pad, it needs to be made in advance. If the well has a bottom, it can also be reinforced and filled before installation. The second option is to purchase a main ring with a bottom.

The pit for the well is dug with a reserve of both depth and width. The last allowance is 10% of the diameter of the rings. About 15 centimeters are added to the depth. Installation of wells up to 1.5 meters deep is usually done manually. Ordering equipment is not cost-effective, because you need to install 1-2 rings.

When installing rings, it is important to seal the seams between them. Cement filling or coating with bitumen, that is, a set of resins, is suitable. The latter also serves as external insulation of the rings, preventing the contents of the well from leaking into the external environment. All that remains is to make holes for the entry and exit of sewer pipes in case the well is a waste well. There are rings with ready-made armholes.