Brief educational program: the well and its structure

A well is a depression in the ground sufficient to reach an aquifer and of an acceptable diameter for its construction and maintenance, designed to accumulate water for the purpose of organizing a water supply with drinking or industrial water.

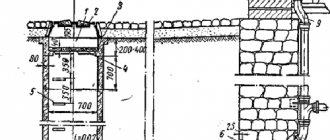

Schematic diagram of a classic well, assembled on concrete rings with a diameter of 1100 mm

Very often, it was not possible to organize water supply from open sources, such as rivers, lakes, streams and springs for objective reasons, for example, sufficient distance from a populated area, or unsatisfactory water quality.

In this case, the issue of sustainable all-season water supply with water of acceptable quality was resolved by constructing a well. At an early stage, the well served as a social element and provided water to the community of people, since its construction and arrangement was quite an expensive process in all respects.

Later, as productive forces grew and technology improved, wells began to appear in individual estate or courtyard designs.

Ancient capital wells were also made of stone, with the exception of the Russian North, where wood was the main construction and finishing material

Basic elements: simple, like everything ingenious

A classic well consists of:

- Trunk - rectangular, square or round cross-section extending from the surface of the earth to a dead end. It has a wide variety of depths, from 2.5 meters, in low-lying wet areas with closely located groundwater, the so-called high water, to 60 meters or more. Such wells reach the level of artesian waters. A classic example of such structures is the famous Arkansas wells, which provided drinking water to mail carriage horses in the United States during the era of mass development of the Midwest.

In today's America, legends about untold Indian wealth securely hidden in deep wells throughout the Great Plains are very tenacious.

In turn, the trunk has:

- Head or mouth, a section from the surface of the earth to a depth of approximately 1 meter and up to 1 meter away from the boundary of the trunk. In this area, work is being carried out to strengthen and waterproof the junction area in order to prevent subsidence of the lyadka and leakage of contaminated surface water into the shaft.

- The base, pit or sump, the lowest point in the well trunk, is slightly below the level of the main aquifer, the main function of which is to cut off large mechanical elements and mineral suspensions that fall into the trunk and further into the reservoir. Very often, such an area is covered with a mesh plate, and the pit acts as a kind of settling filter.

- A water reservoir is a section of a water column that is provided by the debit of a well, or in other words, by the constant influx of an aquifer. The working altitude of this area is not constant and may have significant fluctuations, primarily of a seasonal nature.

- Lyada, a closed structure in the form of a small house above the mouth of the trunk, which housed a lifting gate with a tub or bucket and which cut off the open mouth from elementary pollution from the surface, atmospheric precipitation and protected it from freezing in the cold season.

The nuances of lowering rings into a well without a tap

When starting work, you should take into account the large dimensions and considerable weight of concrete ring blocks.

It is almost impossible to cope with the installation alone. Features of the technology require the participation of at least two people. And for high-quality installation work, 3 workers will be required.

The distribution of responsibilities is as follows:

- the first helper on the surface is engaged in a winch, raising and smoothly lowering the reinforced concrete structure;

- the second, working below, is responsible for the formation of the column, installing and fastening the immersed rings, sealing the joints;

- the third is assigned the role of assistant.

Due to the massiveness of the concrete circles, lowering well blocks manually is accompanied by the risk of falling from a height, since the raised product initially hangs on a cable.

The instability of the tripod and insufficient reliability of the fastenings cause injuries. To prevent mechanical damage to the structure and injuries to operating personnel, it is recommended to choose a tower with an increased safety margin and a lifting mechanism with a metal cable.

We build a well ourselves: stages of a long journey

If you have decided that it is necessary to build a well on your site, before you begin directly laying it, you need to do a number of fundamentally important actions, in military terms, to carry out reconnaissance on the ground.

Reconnaissance and survey of the local population

The art of finding a water vein using a grapevine slingshot has been well known since ancient times.

At this stage, you will have to become district inspector Aniskin for some time and carry out a number of urgent operational measures:

- Carefully survey local residents about the availability of water and its quality in the immediate vicinity of your site.

- Visit your local geological exploration office and review geological maps for the depth, abundance and quality of local waters, again as applied to your site.

- Independently inspect the area for the presence of plants on it that indicate the proximity of groundwater. These are Norway willow, black alder, large burdock, common plantain and others.

- You can also localize a good place to lay a well if you systematically place a cast-iron frying pan upside down overnight in the area during the summer. Abundant condensation inside early in the morning can serve as a positive signal.

- For additional research, you can contact dowsing specialists or frame framers, who certainly have a positive reputation.

Willow is a time-tested, reliable neighbor to an underground water source.

And a young guy went to the mine: shaft sinking

The work of a digger can be entirely manual

At this stage, you will have to experience all the delights of the hard work of a Stakhanovite shock worker in the domestic mine construction industry.

And almost completely mechanized

The process itself consists of several stages:

- Estuary marking. Do not forget that the mouth should have a diameter of +50% of the cross-section of the main body of the trunk. At the finishing stage, this volume will be filled with clay for waterproofing and covered with reinforced concrete screed.

- Preparing the site for transshipment of supplied soil. Take into account the required loosening coefficient; for clay it is 1.5. That is, when excavating a pillar with a volume of 20 cubic meters. at the transshipment site for loading and removal you will have 30 cubic meters. do not place the dumping area directly next to the trunk of the future well. In order to minimize the pressure of the excavated soil on the walls, place it at a distance of at least 5-7 meters from the work area.

- Take care to ensure ventilation and drainage as work deepens. This is especially true at depths below the horizon of the maximum occurrence of perched water, which is 12-15 meters. Local ventilation can be provided by an axial high-speed fan with an impeller diameter of about 400 mm, and drainage by a low-capacity drainage pump.

- The provision of tools is as follows. To loosen the soil, you need a bayonet shovel, a short hoe, and a cleaver, which is a wide ax mounted vertically on a long handle. To excavate a stone, you need a pair of crowbars of sufficient length to handle the work. For loading, a shovel with a straight and conical edge and a scoop are required. As a universal tool, an American-style shovel.

- Lifting and transferring soil. To facilitate lifting, it is necessary to arrange a simple or double block on a metal or wooden frame. The use of such a system simplifies and facilitates lifting compared to direct manual lifting. Constantly monitor the integrity of the rope and the reliability of fastening the lifting vessel in order to prevent its accidental fall into the face of the shaft.

- Carrying out surveying work related to constant quality control of the vertical axis and diameter. These requirements can be met by using a plumb line and a diameter template, which can be used to carry out constant measurements of the quality of the work performed.

We prepare rings, but not wedding rings

Since the casing of the body of the trunk of the future well in our case will be done using concrete rings, their selection should be taken care of in advance.

With a fairly wide range of concrete rings on the market, finding a quality product in all respects is not at all easy

Important! Recently, plastic rings for lining the walls of wells have appeared on the market. Since there is no experience in the long-term operation of such products in the country, it seems premature to talk about such materials as a full-fledged alternative to traditional ones.

Making well rings from concrete is, if not complicated, then in any case a very responsible procedure. Therefore, take the choice of manufacturer and product quality very seriously.

- The basic, or rather generally accepted, diameter of a concrete ring of this type is 900 mm. It is this diameter that determines the normal operation and subsequent repair of a well made of concrete rings. In addition, the cost of such a product meets the optimal ratio for such an important criterion as price.

- It is worth paying attention to the quality of the ring body, the presence of locking elements, the tightness of the fit, the diameter of the mounting loops and other things.

- It would be useful to make sure of the positive reputation of the ring manufacturer, based on the systematic quality of products and a reasonable pricing policy.

Installation with a manipulator greatly simplifies work in all respects

- Calculate the possibilities of transporting and unloading products at the most reasonable price, and this can be provided by an on-board vehicle with sufficient carrying capacity, equipped with a crane-manipulator unit. Among other things, if such a CMU, in addition to a hydraulic boom drive, is equipped with a winch, then in addition to unloading, you can organize the installation of casing rings directly from the side.

Although manual labor flourishes wildly in the vastness of the country

Montage, how much is in this word

The actual installation of casing elements, when a do-it-yourself well made of concrete rings is at stake, can be done using two technologies. These are direct casing and blast casing. Let's look at them in more detail.

Direct casing is carried out along the finished trunk, starting from bottom to top. In this option, it is possible to greatly facilitate and reduce the cost of installing a well made of reinforced concrete rings by using a manipulative installation and combine delivery, unloading and installation into one complete operation.

However, this technology is possible if the well is driven through stable rocks that do not require fastening, or you can get by with a simple temporary structure supporting the support.

When mounting according to the bottom-up scheme, it is necessary to securely and without distortions place the main ring on the sole, since it ensures the reliability and alignment of the entire barrel set

If the excavation is carried out on unstable, sandy soils, prone to crumbling, quicksand, then casing the walls of the shaft is possible only by casing with blasting. What is it?

As the face advances, the rings are simultaneously lowered, or as experts say, rings move towards it. The rock removed from under the edge of the ring causes its independent movement from top to bottom following the face under its own weight at the initial stage, and under the weight of other rings at subsequent stages of work.

In this case, for the convenience and safety of work, a frame with a block is needed, which will ensure the forward and correct movement of the ring to fit onto the previous one.

The use of stationary block structures greatly simplifies installation and increases work safety

A word from Experienced. When installing rings with undermining, rings with a lock are required. Since the side rocks are unstable, closing the rings will prevent displacement and rotation of the rings, and will preserve the integrity and alignment of the structure, and a well made of reinforced concrete rings will serve faithfully for many years. If there is no locking element, the locking effect can be achieved by welding the mounting hinges and additional embedded plates using electric arc welding. It would be useful to recall the provision of local ventilation and other safety rules when carrying out hot work at depth.

When you are constructing a well from concrete rings, a kind of folk instruction written with sweat and blood categorically recommends cutting the seams where the rings meet each other.

There are several ways:

- This is a clay castle for a well made of concrete rings. It is ensured by laying a clay mortar of enriched fatty high-quality clay along the entire perimeter of the joint.

- Laying a polymer or rubber gasket along the diameter of the ring.

- Using a special waterproofing sealant.

Important! When using polymer, rubber tapes, or sealant for a well made of concrete rings, be sure to ensure that they are chemically inert and safe when in contact with water.

Accessories for a concrete well

Today, manufacturers produce concrete rings of different sizes, so choosing the ones that suit you is not difficult. The wells themselves are constructed from the same set of components, which include:

- bottom – reinforced concrete slab;

- rings;

- neck;

- cover with hatch;

- plate for a partition inside the ring - used to create multi-stage cleaning.

Dimensions of concrete rings

The size of the purchased rings depends on the type of well for which they will be used. The table below shows the main standard sizes used for the construction of sewer wells:

| Marking | Size(mm) | Weight, kg) | ||

| Inner diameter | Wall thickness | Height | ||

| KS-7-1 | 700 | 80 | 100 | 46 |

| KS-7-1.5 | 700 | 80 | 150 | 68 |

| KS-7-3 | 700 | 80 | 350 | 140 |

| KS-7-5 | 700 | 80 | 500 | 230 |

| KS-7-6 | 700 | 100 | 600 | 250 |

| KS-7-9 | 700 | 80 | 900 | 410 |

| KS-7-10 | 700 | 80 | 1000 | 457 |

| KS-10-5 | 1000 | 80 | 500 | 320 |

| KS-10-6 | 1000 | 80 | 600 | 340 |

| KS-10-9 | 1000 | 80 | 900 | 640 |

| KS-12-10 | 1200 | 80 | 1000 | 1050 |

| KS-15-6 | 1500 | 90 | 600 | 900 |

| KS-15-9 | 1500 | 90 | 900 | 1350 |

| KS-20-6 | 2000 | 100 | 600 | 1550 |

| KS-20-9 | 2000 | 100 | 900 | 2300 |

When purchasing, pay attention to the labeling; it contains all the necessary data, for example KS-20-9:

- KS – wall ring;

- 20 – diameter;

- 9 - height.

The diameter and height in the markings are indicated in decimeters.

Up the mountain! or surface work

After the question of how to dig a well from concrete rings has become somewhat clearer, it is worth asking the question of how to insulate a well from concrete rings.

The main function of insulating and protecting the trunk from freezing is performed by lyada. However, before starting its construction, it is necessary to implement such an element as a concrete blind area around the well.

Concrete edging of the neck of the well trunk should be done with approximately 50% overlap of its cross-section, as in the presented photo

As mentioned above, the blind area fastens the mouth of the trunk and serves as the foundation for the future lyada. However, before equipping the blind area, as mentioned above, the walls around the mouth of the trunk must be filled with clean clay and carefully seated, compacted thoroughly in several passes.

Concrete preparation for the well carried out in this way will make it possible to obtain a reliable foundation with a good hydraulic lock around the junction of the surface structure and the underground part, and to obtain a comfortable working area around the well.

Cross section showing the main structural elements

The concrete slab is poured using classical technology with the body of the slab reinforced with metal elements.

Lyada is built from wood, brick, wild and artificial stone. There are many options for constructive solutions and their implementation directly depends on a number of specific objective reasons, including financial capabilities.

Inside it there is either a manual gate for lifting water or a pumping station. When laying a water main with pump supply, it is necessary to provide either the possibility of discharging water from the system, or to ensure measures against freezing of the pump and communications in the cold season.

As long-term practice shows, making a concrete well yourself is still half the battle; it is necessary to ensure the repair of the concrete well.

Repair of wells of this type can be routine or major. Current repairs eliminate all minor deficiencies that arise during its operation, including periodic disinfection of the well shaft with bleach and special reagents.

Before disinfection, it is advisable to make a control sample on a small volume

Major repairs are more extensive and are necessary when:

- The level of the water column rose radically as a result of sand washing in the lower part of the trunk.

- Displacement and separation of rings with destruction of clay locks and seams.

- Decrease in water level and deterioration in its quality due to siltation of the catchment area.

- Breakthrough of the clay cushion at the site of waterproofing in the neck of the trunk.

Some of this work has to be done manually, with the maximum possible pumping of the water column from the trunk. It would not be superfluous to remind you about compliance with safety precautions when carrying out such work.

Sometimes it will be more rational to involve specialists from specialized and specialized organizations in carrying out such work.

Carrying out work on cleaning a well manually is associated not only with inconvenience, but also with a certain risk

Some work, such as sand and silt infiltration, can be done remotely. In this case, you will need a powerful drainage pump and a supply of clean water to supply it to the well shaft.

By supplying water and washing away the deposits with pressure, and then pumping out the excess, in some cases you can restore the normal flow of water without even getting your feet wet.

Remote cleaning is much safer, although it requires certain skills and additional equipment for the workflow

You can learn more about the operations during repair work from the video in this article.

Well installation

To install a sewer well using concrete rings, you will need to hire one or more assistants and rent special construction equipment. Installation steps:

- A pit of suitable size is dug.

- A cushion 10-15 cm thick is made of sand and crushed stone.

- The finished bottom is laid in the form of a slab or filled with concrete yourself.

- The first and then subsequent rings are lowered and leveled.

- The joints are sealed with cement mortar.

- Connecting a sewer pipeline.

- The finished well is covered with a concrete slab with a hole and a hatch.

- Filling the voids between the well and the pit.

After the cement mortar has hardened in the seams, the well can be used for its intended purpose.

General preparatory stages during construction

Professional teams who are engaged in laying an autonomous sewer system first of all visit the site and inspect it, selecting the most suitable location for the drainage well.

Next, a pipe laying diagram is drawn up, the depth and angle of inclination are calculated. This is important for gravity flow systems. Where it is impossible to meet this requirement, it is necessary to install a pump that will push waste into the septic tank under pressure. At this stage, the price for installing a sewer well and main line is already known.

When the calculations are completed, the marking of the site begins. To do this, use ropes and pegs where trenches for pipes will be made so that the main line is level. The place for the septic tank is calculated with a margin so that the distance between the walls of the pit and the concrete rings can be filled with sand.

Next comes the purchase of the required amount of materials that builders recommend using - concrete rings or plastic containers, as well as pipes of the required length, plastic inspection shafts, connecting elements.

Installing reinforced concrete rings under the sewer system with your own hands is a difficult task, because only a construction crane can lift the weight of the structure. It is recommended to find a technical solution with which the rings will be installed in the pit.

Digging a hole for a water intake well

The diameter of the hole should exceed the diameter of the ring by 20 cm. Firstly, this should be done in order to cover the outside of the rings with sand (with gravel or crushed stone), and secondly, it is more convenient to lower the rings into the hole.

Do not forget that it is better to place the well about 10 m from the house, so as not to disturb its stability.

A hole for a water well can be dug in two ways:

- All at once;

- With gradual lowering of the rings.

If you are digging the entire hole at once, take care of the safety measures for the digger by tying him with a thick rope (in case the earth collapses). You need to dig a hole in the dry summer so as not to confuse melt or rain water with the aquifer. On average, the depth of aquifer sand is 5-10 m. Now let’s move on to the option of installing reinforced concrete rings.