Centrifugal water pumps are more popular than many pumping devices for similar purposes, which is explained not only by their performance characteristics, but also by their versatility. The use of centrifugal water pumps allows for the efficient functioning of various systems, which include autonomous water supply, drainage, irrigation and fire extinguishing systems, as well as drainage and sewerage systems.

Household grade centrifugal pump

General information

To understand the principle of operation of the pump and why it is designed this way and not otherwise, you first need to define what an autonomous water supply is. This is a complex system with different effects depending on the type of product. It consists of many elements and provides water under pressure. The key element of this system is the pump, of which there are countless varieties. There is submersible and surface. The predominant manufacturers are:

- China;

- Russia;

- European countries.

But effective operation is ensured only if the equipment is complete with a battery and automation.

The pump sucks water from a source, for example, a well, collects it in a special container, and then delivers it under pressure to the consumer. The main difference between the pumps is in the characteristics and dimensional data. It is important to choose this equipment correctly so that the water supply is ensured at the proper level.

Possible malfunctions of the cooling system pump

A failure of the coolant pump can lead to the shutdown of the entire system. This can seriously affect the condition of the engine. The most common pump problems are:

- Wear of the seal (oil seal). In this case, a coolant leak occurs.

- Impeller failure. When the impeller is destroyed, fluid injection becomes worse (pressure drops) or stops altogether.

- Bearing jamming. If the pump's lubrication deteriorates, which can also be a consequence of leaking coolant, the pump begins to operate intermittently.

- Increased play between the impeller and the pump shaft. During operation, the impeller attached to the shaft may become loose, which leads to unstable operation of the pump and other breakdowns.

- Chemical corrosion. Most often, this problem affects the pump impeller and occurs if low-quality fluids are used.

- Destruction due to cavitation. Air bubbles that may arise during operation of the pump intensively destroy it from the inside, which leads to fragility of parts and their damage by corrosion.

- System contamination. Chemical deposits and simply dirt that gets inside the pump over time form a hard coating on its parts, which makes it difficult for the impeller to rotate and the passage of liquid.

- Bearing destruction. In this case, a characteristic whistle appears when the pump operates. It is difficult to replace such bearings, and therefore in this case the pump is simply replaced.

- Broken drive belt. If a low-quality belt is used or is not replaced in a timely manner, rupture or slippage may occur.

If the engine cooling system is stopped for just 5-6 minutes, the engine may overheat. The action of high temperatures disrupts the geometry of the cylinder head and leads to damage to the crank mechanism. You should not ignore minor malfunctions of the cooling system, as they can lead to serious repairs in the future.

About water supply and its pressure

When planning to choose a liquid pump, you need to look at its parameters. All characteristics are important, but one of the key ones is the water flow rate. It is necessary to calculate how many cubic meters of water the home owner spends per hour to find out which option is suitable.

The next, no less important characteristic is pressure. It indicates with what force the unit will supply water. This parameter is calculated according to how far the water source is from the house. The pressure is lost under the influence of height and forks in the pipeline, so it is better to provide a small margin when calculating.

When looking for a model to use at home, the scope of choice narrows. There are deep and surface pumps. The first are used for wells less than 10 meters deep. They are fixed on a special platform.

The latter are suitable for use in wells and wells whose depth exceeds 10 meters. How the pump is controlled is important. It will be easiest for those whose choice falls on automatic control.

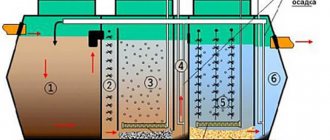

Design of centrifugal pumps

The pump body is made of metal or impact-resistant plastic; the outer part has lugs for mounting on the frame and there are eyes for moving the product with a crane beam. The power drive shaft is connected to the pump shaft using a coupling with damping elements. The impeller may have open vanes or vanes placed between 2 discs. The rotor is mounted on 2 bearings, cantilever structures are available. The bearing supports are equipped with oil seals, the rear support is closed with an additional cover.

The pump body is assembled from several sections connected by screws or bolts. There are sealing gaskets between the parts; to ensure the tightness of the joint line, it is necessary to ensure parallelism of the surfaces. Main pipelines are connected through flange joints equipped with O-rings. The efficiency of the equipment depends on the dimensions.

Industrial pumps have an efficiency of up to 92%, small-sized household products have an efficiency of 60-70%.

https://youtu.be/bqt4ipc73eQ

The design of the centrifugal pump provides for the installation of additional components:

- mesh filter that retains sand and rust;

- a check valve that prevents liquid from being pumped into the suction channel;

- a safety valve that shuts off the water supply during plant downtime;

- throttle unit, which allows you to change the cross-section of the inlet channel and pump performance;

- frequency converter that changes the operating speed of the electric motor;

- pressure gauges that determine the degree of vacuum at the inlet or pressure in the pressure channel.

Automatic control of a centrifugal pumping station is allowed. A sensor is installed in the discharge channel that takes into account the volume of liquid passed through. An additional level sensor is placed in the container to be filled. After reaching the required value, the sensors send a signal that goes to the control unit. The converted pulse is transmitted to the power drive, which closes the valve of the inlet line, and at the same time the power drive of the pump stops.

Surface and submersible types

The surface pump is mounted outside the well. A pipe comes out from the bottom and goes to the equipment that pumps water. A significant advantage of this model is that it is easy to install and maintain. Thanks to this, if it fails, you do not have to resort to the help of specialists.

The main disadvantages of these pumps:

- Low power reserve.

- Using a fan as a cooling tool, while submersibles cope with overheating using the water around them.

- Limited functionality.

Submersible models are divided into ordinary and deep. They differ in their maximum immersion depth. The advantages of immersion-type products are ease of cooling and the fact that they do not freeze in winter. The design of a water pump of this type, its repair and maintenance are quite problematic, but the frequency with which they have to be used is quite low.

Design of piston pumps and principle of operation

The very first hydraulic machines that converted the mechanical energy of piston movement into mechanical energy of a liquid and were known even before our era were piston pumps. Having undergone various additions, the principle of their operation has not changed since then.

In a piston pump, due to a cyclic change in volume, the cylinders are cyclically filled with liquid and then displaced.

The simplest example of the operation of any modern piston pump can be the working cycle of a simple single-stage hydraulic machine, consisting of a cylindrical working chamber with two pressure and suction holes and a piston performing reciprocating movements inside it. To convert rotational motion into reciprocating motion, the design provides a crank mechanism.

Liquid suction in such a device occurs due to the creation of low pressure in the working chamber while the piston moves to the right with the discharge valve closed, and the pressure of the pumped liquid opens the suction valve and the working chamber is completely filled.

Then, during the return movement of the piston, excess pressure is created in the cylinder, much greater than in the discharge pipe. The suction valve closes, and the discharge valve opens for supply, due to which the process of pumping or displacing a liquid equal to the volume of the working chamber into the pressure manifold of the pipeline occurs.

The useful volume of the working chamber is the difference between its maximum and minimum volumes, determined by the position of the piston.

The continuity of supply of working fluid depends on the frequency of movement of the piston. To ensure that the pressure inside the pressure pipeline is stable, double-acting hydraulic units with several working chambers are usually used; more precisely, the cylinders in them are divided into two equal parts, each of which has suction and pressure pipes equipped with valves. This design allows different parts to have different pressures. While in one part, under the action of the movement of the piston, the suction process occurs, in the other, injection occurs and vice versa. To combat pulsation, air caps and hydraulic accumulators are used.

Single-acting piston pumps include plunger pump, slider pump, and diaphragm pump. The diaphragm differs from the plunger only in the presence of a special active or passive diaphragm in its working chamber. Active diaphragms, transmitting force to the liquid from the rod, are under high pressure and therefore, due to their low fatigue strength, are used in low-pressure piston pumps with a large number of swings. But passive diaphragms only separate the liquid that transfers energy from the plunger to the pumped liquid and therefore they are used in pumps with high pressures with a small number of swings.

Double-acting piston pumps have a more complex design, providing a more uniform supply of the pumped liquid due to the presence of two or more working chambers. Each chamber operates as a single-action pump, and in the so-called differential pumps in the right working chamber, used as an auxiliary one, there are no valves, but due to its presence, the fluid supply does not depend on the movements of the piston.

The ability to regulate pressure pressure by varying the frequency ranges of the piston stroke, small dimensions and interchangeability of component parts are the main advantages of piston pumps.

The disadvantages include the impossibility, due to high inlet pressure, of sequentially connecting several piston pumps into one circuit, the inability to pump liquid media with abrasive particles, the need for an additional cooling system and an additional seal between the piston and the cylinder walls of the working chambers. And also, unlike other positive displacement pumps, piston pumps are not reversible due to the presence of valves, since they cannot operate in hydraulic motor mode.

Centrifugal and vibration

Centrifugal pumps are more suitable for home use, since their operation scheme is simpler and more efficient. Its design includes a shaft on which the blades are located. In this case, all the pressure force is concentrated at the edges of the blades. But to use this equipment, it is necessary to install a filter, because it does not react well enough to pollution and loses power because of it.

Knowing well the purpose and design of a centrifugal water pump, you can choose the appropriate model. You can check the availability of additional components in the design with the seller.

Vibrating ones do not lose effectiveness due to poor-quality and sand-contaminated water, but constant vibrations lead to silting of the source. As a result, the performance of these devices is less than that of vortex devices.

How does a water pump work?

The purpose of pumping equipment is to deliver liquid to the point of water collection. Regardless of the design features, the principle of operation of the water pump is the same. When the electric motor is turned on, a vacuum is created in the working chamber. Low pressure inside the housing promotes the suction of water, which moves to the outlet pipe. The outlet pressure has a force sufficient to overcome the hydraulic resistance of the pipeline.

Diagram of water movement in a vortex pump

The type of unit and the design of the working body determine the features of its operation.

Centrifugal pump

Centrifugal-type units are characterized by a combination of high performance and pressure. Optimal performance characteristics ensured their popularity among consumers. What does a centrifugal water pump consist of:

- body made of durable material - steel, brass, bronze, cast iron;

- a rotor rotated by an electric motor;

- impeller with blades (impeller);

- branch pipes – inlet and pressure.

Design of a centrifugal pump

The rotating blades of the impeller create centrifugal force inside the housing. The liquid is drawn in, pressed against the walls of the chamber, and then pushed out into the pipeline under pressure. The universal type of equipment is distinguished by a wide variety of models. The units are classified:

- by installation method - submersible, semi-submersible and surface;

- in the direction of the shaft - horizontal and vertical;

- by the number of impellers (stages) - single-stage, multi-stage.

Attention. The water supply equipment operates continuously, so durable and safe materials are used for its manufacture.

Advantages of centrifugal type devices:

- Operates at temperatures up to +3500.

- Durability and long service life.

- High efficiency.

- Affordable price.

For organizing water supply and irrigation, console-type models are recommended. They are designed for pumping liquids with impurities. Multi-stage installations will ensure high productivity and uninterrupted water supply. Cantilever structures require protection from external influences, so they are placed indoors.

Vortex pumps

Thanks to its design features, the equipment is capable of creating powerful pressure. How does a vortex type water pump work? When rotating, the impeller blades form a vortex of the pumped liquid. This property makes it possible to provide high pressure with small installation dimensions. Compact models are used for irrigating gardens and vegetable gardens. They are not sensitive to air bubbles entering the liquid, but quickly fail when mechanical impurities enter the water.

Vortex mechanism

Advantages of vortex units:

- Compact size.

- High pressure, installation pressure exceeds that of centrifugal models by 3-5 times.

- The simplicity of the design facilitates maintenance and repair.

- The equipment is capable of self-priming liquid.

Disadvantages include low efficiency (about 45%) and sensitivity to abrasive particles.

Vibration pumps

Vibrating-type units are used to organize irrigation and water supply of private farms and cottages from an individual source. The equipment is unpretentious in operation and can be used when pumping contaminated liquids. The operation of the device is associated with the influence of a magnetic field on a coil with a core. The metal core is connected to a flexible diaphragm which, when flexed, creates low pressure in the suction chamber. The liquid enters the housing, and when the core and diaphragm return to their initial position, it is pushed out through the outlet pipe.

Vibration units

Advantages of vibration units:

- The ability to pump contaminated water, which is used when pumping wells and boreholes.

- Affordable cost of equipment.

- The absence of rubbing parts increases the service life.

Vibration pumps are not without their disadvantages:

- Sensitivity to voltage changes.

- Destructive effects of vibration on well walls.

Advice. If power surges frequently occur in your home, it is worth installing a stabilizer. This device will protect pumping equipment.

The choice of pump should be approached responsibly, taking into account its reliability and consumer characteristics. The main criteria for choosing equipment: pressure, productivity, sensitivity to contamination and power consumption. The unit should be purchased taking into account the operating conditions and purpose, then it will last the maximum period.

Control option

Automatic models can be used over a long period of time without intervention from the user. They have many sensors:

- pressure;

- dry running;

- short circuit protection.

If there is a threat of a short circuit, clogging or any other problem that could lead to equipment failure, the control circuit turns off the pump.

Manual type models are used in a completely different way. Their structure also differs from other species. Repairs to such a unit are required much more often. Therefore, automatic control is more suitable for domestic use. It may cost more, but over time this choice pays off.

Heat pumps - operating features

Heat pumps are used to select and transfer natural heat for heating purposes. The operating principle of heat pumps: the condenser is a heat exchanger that generates heat for the consumer, and the evaporator utilizes low-grade heat.

Types of heat pump units:

- vapor compression;

- absorption;

- electrochemical;

- thermoelectric.

Various designs of heat pumps can provide heat extraction from the air, rocks, soil, and reservoirs.

Based on the type of compressor, the devices are divided into open centrifugal, piston, semi-hermetic and hermetic.

Grundfos models

It is unlikely that there is a person who has not heard of the products of this company. Now it is the most widespread and largest manufacturer of such equipment, which supplies submersible, vortex, circulation, drainage and vibration models. The buyer, in turn, gets a large selection and can choose any pump depending on his needs.

All equipment from this manufacturer is equipped with many sensors to protect against breakdowns. The range includes pumps of all types of power - both low power for wells and more powerful ones for mine wells. Models are of good quality, from parts to assembly itself.

Household and industrial hydraulic machines

The types of pumps existing today have different classifications. One of them concerns the scope of application of such devices and distinguishes between household and industrial ones. The first of these machines are used for sewerage, heating and water supply in residential and industrial premises.

Industrial pumps are designed for use in various systems and installations. They are used to supply water, pump oil products and aggressive substances, as well as to carry out many other specific actions.

Consumer Reviews

To select a suitable pump, you need to know well the conditions of its use and the characteristics of the model. But it doesn’t hurt to study what consumers think about them. The problem is that all manufacturers praise their products, but not everyone can boast of good reviews. Many people have bitter experiences with the chosen product. They can share it completely free of charge.

It is not worth buying equipment from a Chinese manufacturer, because the quality leaves much to be desired. This is the opinion of users. But buyers report that there will be no difficulties with equipment from Vilo, the main supplier from Europe. And SAER pumps are repaired in service centers for a long time and often. It is better to look for a middle ground when good price and quality are combined.

Circulation pumps - operating principle

A circulation pump is a unit that is installed directly into a pipeline to force liquid or coolant through it. Circulation units are preferably equipped with a “wet rotor”, which is placed in this liquid. Lubrication and cooling of its moving parts occurs with the same flowing liquid, thanks to which such pumps operate for a long time, silently and reliably. Due to the action of centrifugal force, water is thrown into the pipeline from the pump housing. They differ in power, purpose, design features.

Circulation pump units are used in heating and cooling systems.

Circulation pump for heating

The circulation pump is one of the most important elements of heating systems, without which the operation of the latter is either impossible or has extremely low efficiency. Forced circulation of the heat exchanger (water, working medium) using the unit reduces fuel consumption, increases heat transfer and increases the overall temperature in residential or non-residential premises.

Installing a circulation pump

Installation method:

- on horizontal pipelines - with the electric motor up;

- on vertical pipelines - so that the motor axis is in a horizontal position.

Installation of a circulation pump

No additional supports are needed to provide rigidity; the pump operates with minimal vibration.

Areas of application: hot water supply and heating systems for residential buildings, public and administrative buildings, industrial buildings.

Review of domestic products

Domestic manufacturers cannot boast of quality. An example would be the “Bison ZNVP-300−25”, popularly called “Rodnichok”. It is perfect for shallow wells - up to 5 meters. This vibration type pump can deliver 1400 l/h at a head of 60 meters. This is quite enough for home use.

Another simple model from the Russian one. It has similar characteristics to the previous model, but demonstrates low productivity - 700 liters per hour. 0.2 kW - this is its power, this explains the low productivity. The only good thing is the price: with the listed characteristics it does not exceed 1100 rubles. This is an excellent choice for those whose well is shallow (no deeper than 10 meters).

Fecal submersible pumps

It is not always possible to connect to a central sewer system in a country house. In this case, a submersible fecal pump can become an indispensable assistant.

Design features

This type of pump allows pumping not only liquids, but also particles of different sizes. Therefore, it can be used for draining wastewater, as well as for pumping liquid from areas that are constantly subject to flooding.

All external elements of the unit are made of stainless steel or cast iron, since it is forced to be in constant contact with a highly active environment. Installation of such a unit should be carried out directly in the water, at best at the very bottom. Thanks to the automated internal system, the work takes place autonomously. The pump is also equipped with guides located on the walls, which greatly facilitate the installation process. To do this, a cable is attached to it, which ensures a safe descent.

Often, submersible fecal pumps are equipped with a special grinder, which allows pumping of the largest and most solid inclusions in the pumped liquid. In the absence of such an addition, the device is capable of transporting particles with a diameter not exceeding 4 cm.

Advantages

Based on the delivery method, submersible fecal pumps are divided into: centrifugal, vortex, vibration, and auger. Centrifugal units are the most popular.

The positive properties of this device include:

- possibility of pumping particles with a diameter of 8 cm;

- high functionality;

- long service life;

- fully automated operation;

- maximum transportation range is 30 m;

- significant savings in money.

All the positive properties of the unit are obtained through a well-thought-out device, which includes a check valve, grinders, and a filter mesh.

Types of positive displacement pumps

There are various devices in which the working body is a chamber. Among them are the following units:

- Rotary. These are pumps that have a fixed casing that encloses vanes, blades and other similar parts. The movement of fluid in this case is facilitated by the movement of the rotors.

- Gear. This is the simplest type of positive displacement pump. These devices move fluid in the process of changing the volumes of the cavities of gears interlocked with each other.

- Impeller. If you look at such a pump disassembled, you can see an impeller whose blades are made of elastic material. It is located inside an eccentric housing. What happens when such a device operates? The blades bend and rotate, displacing liquid.

- Cam. In these pumps, two independent rotors rotate, which promotes the movement of liquid throughout the working chamber. Cam mechanisms are widely used in the production of dairy products, drinks, jams, etc. And all this is due to their ability to pump liquids containing large inclusions. Also, this type of pump is used in the pharmaceutical industry.

- Peristaltic. In these pumps, the main working part is a multilayer flexible hose made of elastomer. When the engine is turned on, the shaft with rollers begins to rotate in such a device. They compress the sleeve, facilitating the movement of the liquid inside it.

- Screw. A stator made of elastomer is inserted into the housing of these pumps. It contains a metal rotor that has a helical shape. How will the liquid be pumped in this case? After turning on the motor, the rotor begins to rotate, changing the volume of the internal cavities. This is where the fluid moves.

Jet hydraulic devices

These pumps, unlike many other similar machines, are not capable of creating excess pressure at the outlet. Their operating principle boils down to converting the potential energy of a liquid into kinetic energy. However, jet pumps have no moving parts. The main working mechanism in devices of this type is a jet of liquid or gas.

Such pumps can be water jet (for example, hydraulic elevators). In them, the working fluid transfers its kinetic energy to the pumped substance. Among the jet pumps there are also airlifts. They are supplied with compressed air by a compressor. Next, the air-water mixture is set in motion by the lifting force of air bubbles.

Centrifugal hydraulic machines

Let's consider the types of dynamic type pumps. The most common of them are centrifugal devices. These pumps are used to supply hot or cold water, as well as for pumping aggressive and viscous liquids, waste water and mixtures of water with slag, soil, peat, etc.

How does a centrifugal pump work? Being between the blades of a rotating impeller, the liquid particles receive kinetic energy from it. In this case, centrifugal force arises. It moves the liquid further into the motor housing. This operation occurs continuously due to pressure, which ensures a constant supply of new liquid particles to the pump.

According to their purpose, centrifugal pumps are classified into:

- used in the operation of operational equipment of thermal power plants;

- various technical purposes.

What are the types of centrifugal pumps belonging to the first group? Devices used for water circulation are divided into circulation and recirculation. Pumps installed for heat transfer are divided into boiler and network pumps. When preparing drinking water, condensate centrifugal pumps are used, and in the feeding system for steam turbine servomotors, injection pumps are used.

What devices are used for various technical purposes? These are types of centrifugal pumps such as utility, fire, drainage, etc.

Recently, new developments of such devices have appeared. Among them, sand centrifugal pumps are especially popular. They are used for pumping hydraulic mixtures. That is why such pumps are installed in places where there is sand in the water, as well as all kinds of solid substances of industrial origin.