People who have their own summer cottage, a house near the city or at a great distance from it, are well aware of how to provide water to all the necessary niches: a vegetable garden, a bathroom, perhaps even a bathhouse, in the absence of a central water supply. Some people carry water from a well with their hands, although this takes a huge amount of time, while others take care in advance to make their work easier, reduce time costs and buy special devices for pumping liquid out of the source.

Such devices are pumps for wells and for water supply at home. Which one is better to choose depends on the needs of the users. They come in two types: submersible and surface. With them, long, exhausting work will become a pleasure. This article will discuss in detail some models, as well as provide recommendations on choosing the appropriate option for your site.

Types of pumps

There are several types of well pumps. Each type has its own advantages, functionality, method of application and installation. They are classified according to two main parameters.

- By source of intake:

- Superficial;

- Submersible.

- Based on the operating principle:

- Vibrating;

- Vortex;

- Water ring;

- Centrifugal.

Let's look at the operating principle of each type.

Superficial

Such pumps are installed above the water level or outside the well. They are not aquatic. The principle of operation requires the use of a hose, one end of which is attached to the unit, and the other is lowered into the water. They are used to lift liquid to a height of no more than 10 meters. It works due to the rarefied air, which pushes the liquid to the surface.

Advantages:

- Easy installation;

- Have the ability to independently repair;

- Short service life;

- Affordable price.

Flaws:

- Part of the power is spent on suction, so the pressure will be weaker;

- Noisy during operation;

- Damage to the mechanism due to accidental ingress of air;

- Small diving depth.

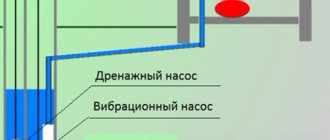

Submersible

This type of units is the best choice for the home, cottage, garden and vegetable garden. They are also called deep ones. This mechanism is fully or partially immersed in water. They are used to lift liquid to a height of more than 10 meters. In this case, you should consider the following points: the immersion depth of many models should not be more than 7 meters, and the minimum distance from the pump to the bottom is 1 meter. The system works by relying on water pressure supplied from below by a liquid. The operating principle of submersible pumps requires a sealed housing made of waterproof polymers or stainless steel. They also have protective functions and insulated electrical wiring. Using a submersible unit, you can build a home pumping station.

Advantages:

- Easy installation;

- Works silently;

- Maximum depth of use;

- The mechanism is designed with overheating protection;

- Power consumption creates maximum pressure;

- Long service life;

- They have automatic adjustment.

Flaws:

- Difficult to maintain;

- High price;

- Cannot be used in shallow wells;

- If the distance is less than 1 meter to the bottom, debris may fall into the water.

Vibrating

In this system, the vibrator starts working from an electromagnet. Next, water is supplied. The piston vibrates at a frequency of 100 times per second. The vibrator has a control valve. It creates water pressure in the pipe.

Advantages:

- Inexpensive;

- Easy to use.

Flaws:

- Has low throughput;

- Short service life;

- Works at shallow depths.

Vortex

The water supply occurs due to the formation of a vortex, which arises as a result of the rotation of a wheel with radially mounted blades.

Advantages:

- Creates a lot of pressure;

- They have self-priming ability;

- They are not afraid of air getting in.

Flaws:

- Designed for pumping with clean water;

- Low efficiency;

- A small gap between the blades leads to rapid wear of the system.

Water ring

They are also called vacuum. These units include several gaps through which suction and rise of water occur. The system is designed in such a way that when the wheel rotates, the space between its blades alternately increases and decreases.

Advantages:

- With a small size they create good pressure;

- Does not require installation of a gearbox;

- Does not require air removal.

Flaws:

- They break down quickly when solid particles get inside;

- Big size;

- Low efficiency.

Centrifugal

The release of liquid to the surface occurs thanks to several wheels, which are located inside the pump and are connected to each other by blades. During operation, the distance between them is filled with liquid, the wheel rotates and centrifugal force acts. It increases the pressure at the edges and reduces it in the center. The difference in pressure forces water through the outlet pipe.

Advantages:

- Reliability in operation;

- Working depth from 8 meters;

- Works without noise;

- Sufficient power.

Flaws:

- When used in a shallow well, it sucks up debris from the bottom;

- Expensive for the price.

How to decide on the type of pump

If you want to organize water supply for a country house or summer cottage by digging your own well, you must also take care of the method of extracting water from it. This problem is most easily solved using an electric pump. Before purchasing a suitable model, it is necessary to formulate the technical requirements for the unit, which will be discussed in this section.

Submersible or surface well pump

There are two main types of pumps available for domestic use: submersible and surface pumps. Their choice is largely determined by the depth of the well and the level of the water surface relative to the surface of the earth.

Surface pumps are installed on specially equipped sites or in utility rooms. To collect liquid, they are equipped with a receiving pipeline with a check valve that prevents spontaneous emptying of the system. At the moment of start-up, the impeller rotating at high speed creates a vacuum, sucking water from the well, which is then pushed out through the pressure fitting at high pressure.

Surface pump installed near the well.

Theoretically, the possible suction height of such pumps cannot exceed 10.3 meters. In real conditions, depending on the design features and manufacturing quality of the pump, it reaches 5-9 meters. To reduce the distance to water, such units are installed in the immediate vicinity of the well neck or inside it on rigid supports or a floating raft.

Surface pump installed inside the well.

Option to install a surface pump inside a well.

The advantages of such models:

- relatively low requirements for the tightness of the structure and the quality of the materials used;

- affordable price;

- easy maintenance.

There is a way to extract water with a surface pump from a depth of 25-40 m using a lowering ejector. At the same time, the piping of the unit becomes more complicated and a significant part of the power spent on the operation of additional equipment is lost.

Pumping station with a remote ejector.

Submersible pumps are lowered directly into a well or other body of water used as a source of water. They do not have problems associated with suction and the risk of jet rupture, but there is a possibility of picking up soil particles or plant debris. They are usually equipped with a receiving mechanical filter. The housing of such units is made of expensive stainless steel, and all current-carrying elements are placed in a sealed casing.

Strengths of this equipment:

- no problems with filling and suction;

- easy start;

- compact sizes.

During operation of the submersible pump, it is necessary to monitor the condition of the receiving grid and prevent dry running if the liquid level drops.

What you need to know about pump performance

Pump performance shows the maximum amount of water it pumps per unit of time. It is expressed in m3/hour or l/min. At the factory it is determined under ideal conditions for the equipment. In reality, the flow rate strongly depends on the hydraulic resistance of the system, which is usually displayed in the performance graph attached to the passport.

When choosing a unit for a well, they are guided by the number of residents and plumbing fixtures, including the needs for watering the garden. Sometimes the decisive role is played by the fluid replenishment rate associated with the throughput capacity of the aquifer. Pressure tanks with water reserves or hydraulic accumulator tanks included in the pumping stations supplied by the manufacturer help smooth out peak loads when using not the most powerful models.

Pump head

The pump head is expressed in meters of liquid column. It is equal to the maximum height to which it can be raised, although the consumption in this case will be minimal. In a stable pumping mode, pressure is spent not only on overcoming the difference in elevations, but also on the hydraulic resistance of the pipelines and the fittings installed on them.

When choosing the required model, the buyer must take into account the position of the upper point of liquid consumption, the pressure required for normal operation in front of the plumbing fixtures and the length of the pipes, for every 100 meters of length of which up to 1 bar is lost.

Pump efficiency

The efficiency of a pump, like any other mechanism, shows the ratio of useful work to the amount of energy expended. The higher it is, the more economically the equipment is operated, the lower the payment to power engineers will be. This indicator depends not only on the design of the machine pumping liquid, but also on the chosen water distribution scheme in your home. Typically, for submersible units it is slightly higher than for surface ones, since they do not have to waste energy on suction.

If you notice an error, a non-working video or link, please select a piece of text and press Ctrl+Enter .

0

Criteria for choosing a pump for a well

When purchasing a device, you should rely on several important parameters. If installed incorrectly or choosing the wrong model, the system will not last long. To avoid mistakes when choosing, we take into account the following factors under which the pump will operate.

- Performance. You need to know how much water the pump can pump in a set period of time. The performance of the unit also changes depending on the purpose of use.

- Power (pressure). This indicator affects the water pressure from the source. To calculate the expected pressure, you need to know the depth of the well and the length of the pipeline.

- Electricity consumption. This point plays an important role in choosing a pump. First of all, this is due to saving money on electricity.

- Dynamic and static water level of a well. These are indicators of the volume of water with the pump turned on and off. That is, the depth from the surface to the water surface.

- Suction depth. This is the depth of the well from which the liquid will be raised.

- Well diameter. It will help you find out the volume of water in it.

- Height of the water column.

- Degree of contamination of the well. Some pumps can only operate in clean sources.

The above criteria must be checked with the technical characteristics of the pump, which are indicated in the attached product data sheet. The pump performance must match the capabilities of the well. Otherwise, the mechanism will fail.

Pumps with immersion up to 15 meters or more

Now there is a selection of pumps that can be submerged to 15 meters or more, relevant for deep water layers.

"GRINDA GLP-36-11"

This pump is characterized by quiet operation and a vertical installation method. It belongs to low pressure devices and has a throughput capacity of 2.1 cubic meters of liquid per hour. The unit is equipped with heating protection and a sensor that monitors the liquid level.

You can immerse the pump to 11 meters and you will immediately begin to feel a drop in pressure. That is, this indicator for this model is maximum. The power of the device is 0.3 Kilowatt with a classic power supply of 220 Volts.

Pump "GRINDA GLP-36-11" submersible type Source zubr-online.ru

Pros:

- affordable price;

- unpretentiousness at work.

Minuses:

- weak pressure with increasing immersion depth.

Reviews from the owners say that this is a good and affordable solution for watering the garden, but it is not very suitable for reliable water supply.

How to care for well units

Any device eventually needs maintenance. If this procedure is performed in a timely manner, the service life of the pump can be extended by ten years. The well pump is not protected from natural influences. These include dust, dirt, dirty water, leaves, etc. All of this is a reason for preventive maintenance of systems.

Signs that indicate an indispensable requirement for servicing the mechanism:

- Unpleasant taste and smell of water;

- Changes in water color;

- Unusual noise during operation;

- Deviations from pressure indicators;

- Deviations in the performance of electrical appliances;

- Plaque on the body;

- Deterioration of dynamic and statistical water levels.

How the rating was compiled

When choosing which pump is best for a well, many factors should be taken into account, and when compiling a rating of pumps for a well, we took them into account. The rating was based on user reviews and the evaluation criteria they used when purchasing equipment and using it. The result was the following list:

- Pump type . Only submersible units were considered.

- Production material – housing, mounting elements and working elements.

- Popularity of the model according to user reviews.

- Pressure loss – along the length of communications.

- The company's reputation and the overall quality of the unit.

- Difficulty in repair and availability of service.

- Compliance with the stated indicators.

- Service life before the first repair - under warranty and in fact.

- Cost of equipment.

- Technical indicators - quiet operation, weight, immersion depth, power, pressure, productivity, size and level of automation.

- Type of immersion - horizontal and vertical.

- Ease of use.

- Economical operation.

Reviews are one of the most accessible selection criteria Source cnnturk.com

Conditions under which the pump will operate

When buying a pump, you need to decide on its operating conditions. If the unit is purchased for the purpose of extracting only drinking water, then you can buy a regular model with average power and a lower level of electricity consumption. If a pump is needed for household services and for watering the garden, then you should opt for powerful models that can work with contaminated water.

You also need to consider what time of year the pump will operate. If the device is purchased with the expectation of working all year round, then it is necessary to think in advance about its location in order to avoid breakdowns from adverse weather conditions. If you purchase a product only for the summer season, then such pumps will be more sensitive to water quality and air temperature.

Submersible pump for water supply - connection diagram

The well pump is lowered into the source strictly in its center to avoid the float touching the walls; it is tied to a rigid transverse pipe, angle, or metal profile inserted into the punched hole in the walls along with the pressure pipe of the water supply. The second option - hanging the pump on a transverse support located on top of the well walls - is simpler, but to connect to a water supply line located underground, you will still have to go down into the well. The calculated point for installing the pump from the surface of the earth is the depth of soil freezing in winter; the entire water supply system is deepened to a distance of about 0.5 below this mark.

To supply water to the house, pipes made of low-density polyethylene (HDPE), specially designed for use in water supply systems, are usually used. The pressure pipe is connected to the electric pump with a plastic fitting; its further connection to the water supply line is also made using an adapter corner plastic coupling; when supplied to the house using HDPE fittings, the line is easily connected to the internal water supply system.

Pumping equipment is connected according to a standard scheme using a pressure switch, pressure gauge, hydraulic accumulator (allows you to maintain pressure in the system), using special fitting plumbing fixtures (five-inlet fitting). Unlike downhole types, the dry-running relay can be excluded from the control automation - the submersible unit is protected from winding burnout by a float switch.

Rice. 10 Connection diagrams for a well electric pump

List of the best manufacturers of units for wells

The quality of the purchased pump depends not only on its technical characteristics, but also on the manufacturer. There are companies in more demand among buyers in the market for these goods. These include:

- Grundfos. This is the most popular foreign brand.

- "Livgidromash" The most popular domestic manufacturer.

- Gardena. The German manufacturer has a diverse range of models.

- Pedrollo. One of the largest Italian companies.

- Rucheek-Technopribor-1. Pumps of this brand are manufactured in Belarus and are distinguished by their quality.

Manufacturers most in demand on the market

When studying pumps for submersible wells, which one is better, it is not least worth paying attention to the manufacturer. We have prepared a list of the five most popular companies producing pumping equipment for household use among buyers. It looks like this:

- Grundfos is one of the most reputable companies specializing in pumping equipment. Production began in Denmark in 1945 and today it is a powerful concern, which includes more than ten companies. It has representative offices in more than 50 countries.

- "Wilо SE" - this manufacturer from Germany has been operating since 1872. It produces high-class pumping units not only for everyday use, but also for use in industrial facilities.

- ESPA is Spain's leading manufacturer of pumping units, known for its innovative developments. The company has long received an international vocation; it has been operating on the market since 1952.

- "LEO GROUP" is a company from China that produces equipment used for pumping various liquids, in particular water.

- "AquArio" is a company from Italy widely known in the CIS for its high quality electric pumps.

There is practically no difference in the quality of equipment between market leaders Source eurosantehnik.ru

Rating of 10 popular well pump models

When purchasing this type of product, the question becomes acute about how to choose a unit that is not expensive, and which company is better. Even among the best manufacturers there are both expensive and budget options. They differ in the material used and the functions they have. We provide an overview of the 10 best pumps, according to consumer reviews.

GARDENA 6000/5 Comfort

High pressure submersible pump. Country of origin: Germany. Immersion depth up to 12 m. Motor power: 1050 W. Capacity: 6000 l/h. Pressure 45 m. Multi-stage suction system (4th stage). Mains voltage: 220V.

GARDENA 6000/5 Comfort

Advantages:

- Electronic water level sensor;

- Protected from overheating;

- Stainless steel filter;

- Non-return valve installed;

- There is a fastening cable 15 meters long;

- Double gaskets;

- Convenient to use;

- Energy saving;

- Lasting;

- Long lasting.

Flaws:

- High price - from 23 to 35 thousand rubles;

- Automation may generate an error when the tap is not completely closed;

- Over time, the check valve may leak;

- The system may shut down involuntarily.

Pedrollo NKm 2/2 – GE

Centrifugal submersible pump made in Italy. Immersion depth: 20 m. Pressure: 48 m. Network voltage: from 220 to 230 V. Power: 550 W. Capacity: 4800 l/h. Multi-stage suction system (2nd stage).

Pedrollo NKm 2/2 – GE

Advantages:

- High-quality assembly;

- Resistant to dirty water;

- There is protection against overheating;

- Automatic control of water level (presence of a float);

- Long power cord – 20 m;

- Low power consumption.

Flaws:

- High price - from 20 thousand rubles.

Grundfos SBA 3-45 A

An automated submersible pump from a Danish concern, which is assembled in Italy. Head: 30 m. Motor power: 1050 W. Capacity: 3000 l/h. Immersion depth: up to 10 m. Mains voltage 220V. Single stage suction system.

Grundfos SBA 3-45 A

Advantages:

- Good performance;

- Does not create much noise during operation;

- Protection against overheating and dry running;

- When the water level is low, the float switch will operate.

Flaws:

- Plastic outlet fitting;

- Average price: 19 thousand rubles

Rucheek-1M 40 m

The vibration submersible pump is produced in Belarus. Pressure: 60 m. Network voltage: 220 – 230V. Power consumption: 225W. Capacity: 960 l/h.

Rucheek-1M 40 m

Advantages:

- There is a temperature sensor;

- Good performance;

- Minimum power consumption;

- Lower water intake;

- Low cost - from 2 thousand rubles.

Flaws:

- Strong body vibration.

Hammer NAC 1000A

Centrifugal surface pump manufactured in China. Power: 1000 W. Head: 45 m. Capacity: 4600 l/s. Mains voltage: 220 – 230V. Immersion depth: 8 m. Filtered particle size: 3 mm.

Hammer NAC 1000A

Advantages:

- Multifunctional;

- Availability of inlet and check valves;

- There is a filter;

- Works quietly;

- High-quality assembly;

- Affordable price – from 6 thousand rubles;

- Long warranty.

Flaws:

- There is no protection from dampness and precipitation;

- Short electrical cord 1.2 meters long;

- Suitable for wells with high water flow;

- Not protected from dry start.

Grundfos SB 3-35 M

Electric submersible pump. Denmark is the country that produces them. Motor power: 800 W. Capacity: 3000 l/h. Immersion depth: up to 10 m. Pressure: 35 m. Network voltage: 220V. Single stage suction system.

Grundfos SB 3-35 M

Advantages:

- Moderate starting current;

- There is protection against overheating.

Flaws:

- There is no built-in automation;

- There is no protection against dry running;

- High price - from 19 thousand rubles.

DAB DIVERTRON 1200 M

Submersible pump of Italian origin. Power: 750 W. Mains voltage: 220 V. Pressure: 47 m. Capacity: 5700 l/h. Immersion depth: 10 m. Multi-stage suction system.

DAB DIVERTRON 1200 M

Advantages:

- Good automation;

- Electronic control of water level;

- Dry running protection.

Flaws:

- The cable is attached to a plastic handle;

- Sensitive to temperature changes;

- React to power surges;

- High price - from 19 thousand rubles;

- Lots of plastic in the unit.

LIVGIDROMASH Malysh BV 0.12-40-U5 16 m

Vibrating submersible pump. The old name was “Rucheyok”, and the current name was received at a plant in the city of Livny in the Oryol region of Russia. Capacity: 1500 l/h. Power: 240 W. Immersion depth: 3 m. Pressure 40 m. Mains voltage 220 - 230 V.

LIVGIDROMASH Malysh BV 0.12-40-U5 16 m

Advantages:

- Good performance despite low energy consumption;

- When positioned horizontally, it pumps water over long distances;

- Resistant to impurities;

- Easy to maintain;

- Low cost - about 2 thousand rubles.

Flaws:

- Vibrates strongly during operation;

- There is no water level tracking sensor;

- There is no thermal protection.

GARDENA 5500/5 Inox Premium

The centrifugal submersible pump is assembled in China. Immersion depth: 20 m. Pressure: 45 m. Network voltage: 220 – 230 V. Power: 850 W. Capacity 5500 l/h.

GARDENA 5500/5 Inox Premium

Advantages:

- Good pressure during deep immersion;

- Made from high quality stainless steel;

- Does not cause problems during operation;

- Automatic water level control.

Flaws:

- Poor level of engine protection;

- Dry running protection must be installed independently;

- High cost - from 19 thousand rubles.

Pumps with immersion up to 20 meters or more

These pumps are the most “deep” and are useful in areas where you have to dig a well several tens of meters deep to get clean water.

"URALSIB RODNICHOK BV-0.12-63-U"

As the name suggests, this is a domestic development, and quite a worthy one at that. The pump is a vibration type and operates completely silently. Water intake is carried out from the bottom of the device. The device can be immersed to a depth of 20 meters.

Pump "URALSIB RODNICHOK BV-0.12-63-U" submersible type Source grizzly-tool.com.ua

Our recommendations for choosing a product

You should not buy equipment “by eye”, as you will not achieve the desired result.

Please pay attention to the following criteria:

- Cheap pumps tend to fail very often. The cost of repairing them is comparable to buying a new device. Based on this, we advise you to focus on global brands that have shown good results. Moreover, progress does not stand still and customers are offered new technological solutions, for example, the use of parts made from innovative materials.

- The energy efficiency indicator is indicated in the technical data sheet. The higher the efficiency, the better.

- Options protect the system from overheating, overload and impeller displacement.

- The “soft start” function promotes slow acceleration of the pump, which avoids network overload, reduces the risk of wear and tear on the device and ensures optimal operating conditions.

- Compactness avoids high installation costs.

Deep or superficial

For shallow wells and boreholes, surface devices are most often used. This is due to their following advantages:

- Easy to install and maintain . The device does not need to be immersed in a water source, so its operation is easier to control. You can install such a pump in any place convenient for you. And in order to start supplying water, just lower the hose into the well and connect the device to the network;

Surface models can extract water from the very bottom of the source

- Low cost . The price of surface models is lower than the cost of submersible ones;

- Ability to extract water from the bottom . Deep devices are installed at a certain distance from the bottom; accordingly, they are not able to completely pump out water from the source. Surface units do not have this drawback, so they can supply water not only from wells and boreholes, but also from reservoirs.

These devices also have quite a few disadvantages:

- Low power. These devices are recommended to be used for water sources with a depth of no more than 6-8, maximum 10 meters;

- Fragility. Surface devices heat up more than deep ones and fail more often;

- Noisy. During operation, the devices make a lot of noise, so it is better to install them outside the house or, at least, in a special non-residential area.

Deep well pumps allow you to supply water from great depths

The main advantage of deep models is their power - they are capable of pumping water from the deepest artesian wells. At the same time, they do not bother you with their noise.

Another plus is higher efficiency. But, of course, stationary deep-sea devices are much more expensive than surface devices.

Therefore, the choice depends on the type of water supply source, as well as the tasks facing the device. If you want to purchase a pump for a summer house that you will visit from time to time, you can purchase a portable surface pump. If you have a house in which you plan to live permanently, it is more advisable to choose a stationary deep-well unit.

For watering from a pond

Which pump to choose for watering your garden? When choosing such pumps, it is necessary to take into account the condition of the water in the river, pond or lake. If it is clean, then it is quite possible to buy surface models, but for heavily contaminated liquids, drainage pumps are used. We described the first ones above, we can only clarify that they provide a strong stream with which you can water the beds located at a distance of 50 meters. The main thing is to choose the right intake hose that goes down into the pond. Rubber options should be excluded immediately, since there is a high probability of compression of the hose as a result of the accumulation of rarefied air, which leads to a suspension of water supply and overheating of the engine.

Product selection based on operating principle

All pumps operate according to the same scheme: a vacuum is created inside the unit, due to which the resource is taken and further moved through the pipes. That is, a portion of water enters the vacuum chamber, and the next one displaces the previous one and so continues in a continuous process until moisture leaves the point of use on a constant basis and with good pressure.

According to their design and operating principle, pumping equipment is divided into three main types. Let's take a closer look at each of the options.

Centrifugal pumps

The main working element of this technique is a wheel with blades, which acts as a drawer of the medium through the inlet pipe. Increased pressure is created at the walls of the vacuum chamber, which ensures pushing into the pressure line.

AMETHYST - 02 M Residential building for up to 10 people or up to 2 cubic meters/day.

Aeration unit AS-1054 VO-90

Main table dispenser AquaPro 919H/RO (hot and cold water)

Vortex

A distinctive feature from the previous version is the shape of the working blades on the wheel and the presence of special recesses on the walls of the chamber. Thanks to these mechanisms, the intake and advancement of liquid occurs not only due to centrifugal force, but also under the influence of turbulent acceleration. This device is capable of generating a moisture flow with higher characteristics.

Advantages of the vortex apparatus:

- It has a low cost due to its ease of implementation.

- Ability to operate in an environment with a gas component.

Minuses:

- Fragility.

- Failure to transfer a contaminated resource, even to a small extent.

Electromagnetic or vibration

When current passes through the windings, a magnetic field is created in the magnet coil. The force generated in this case with a frequency of 50 Hz retracts the core. It moves a rubber membrane (piston), which pushes a portion of water into the system. The check valve prevents the return of the working fluid at moments between cycles.

Advantages:

- High reliability. It will last for several decades if used properly.

- Increases working life by preventing overheating.

- It has good insulation of the housing and electrical wires.

Flaws:

- Outgoing waves from vibrations can eventually destroy unprotected well walls.

- Critical for processing liquids containing solids.

- The package does not include automatic control elements.

- Not very high performance.