Area of use

Plastic wells have many advantages. The most important thing is that they are hermetically sealed, do not enter into a chemical reaction with the environment, and slowly change their properties. Light weight adds an advantage (it can also be a disadvantage). But installing plastic rings for a well is not always easy and they cost a lot.

Shape and size are selected depending on the purpose

Polymer wells can be used for various needs - from storing drinking water to organizing drainage and sewerage. Special plastic is used and its characteristics are selected for the area of application. So, here's where you can use plastic well rings:

- Storm drainage.

- Drainage system: inspection;

- differential;

- prefabricated

Polymer sand well ring h-200mm d-1000mm

The principle of assembling a sealed plastic well. In addition to the rings, the kit includes a bottom, cone and hatch

What are the advantages of using plastic for wells? First, moisture in any form does not get inside the solid body. This is true for drinking water. For wastewater collection, this is also important, as is the fact that the contents will not leak into the surrounding soil in any form. If we talk about stormwater and drainage, the important thing here is that the walls of the container are smooth and easy to clean. And one more thing - plastic does not react with either the contents or the environment.

To organize sewerage on the site, it is more convenient to use a prefabricated plastic sewer well

Another area where plastic well rings can be useful is restoration. The task is difficult and dangerous. Working in a dilapidated well, when the logs are almost rotten or the concrete rings have moved, is the height of recklessness. It is much safer and easier to restore it using an insert of food grade plastic rings. The disadvantage of this solution is the high price and reduction in useful volume. After all, the insert should be of a smaller diameter, plus they are made with stiffeners.

Restoration of an old well

If cleaning the well does not solve problems, since the structure requires major repairs, restoration is the most acceptable option. When the old concrete rings in the mine have crumbled, replacing them with a lightweight plastic pipe will be a successful and profitable solution. The price for restoration is reasonable, as it does not include water exploration and well digging.

Restoration work takes place quickly, even if the source has long been abandoned: pumping out water, dismantling and installing a plastic well.

- Guarantee of the quality of our services

- Sample contract for well services

- Areas where we work

Plastic rings for wells: materials

The raw materials for the manufacture of polymer wells can be different - from food-grade polyethylene to recyclable materials. Plastic rings for wells can be made of PVC (polyvinyl chloride), high-density polyethylene (HDPE), there are polymer sand and polypropylene (PP). For our climate, such parameters as frost resistance and the number of freezing/defrosting cycles that the material can withstand are very important. Well, the thickness of the walls, the size and number of stiffeners - all this is also important and must be taken into account.

Plastic rings for wells are made from polymers. There are options made from glass polymers - for use in heaving soils

The material from which the well rings are made is selected depending on the purpose of the well. For installing or repairing a drinking water tank, plastic ones made from food-grade polyethylene are considered the best. Moreover, the polyethylene must be primary, without foreign impurities or additives of recycled polyethylene (from recycled materials).

For difficult soils - heaving, clay, unstable - it is better to take polymer-sand plastic well rings. They are thicker (50 mm is not uncommon) and heavier. These characteristics make them suitable for use in difficult conditions.

Advantages and disadvantages

Polymer-sand prefabricated rings have positive and negative sides:

Pros:

- They are light in weight, which simplifies the transportation process. There is no need to rent lifting equipment. Additional load on the soil is also eliminated.

- Compact sizes. Prefabricated septic tank technology allows installation of the structure even in the basement.

- The ability to assemble it yourself without the involvement of specialists.

- High tightness.

- Operational life more than 15 years.

- The material used is resistant to aggressive chemical environments.

- Range of colors and sizes.

- Resistant to soil influence.

- Ease of processing.

- They do not allow moisture to pass through.

Cons: There are no disadvantages as such. The problem may come down to the wrong choice of components and cover, which cannot cope with the resulting load. Therefore, having made the right choice and performed high-quality installation, polymer sand products will last for decades.

Sizes, types and varieties

If we talk about height, plastic rings for a well can be like this:

- one-piece pipe of the required depth (insertion into ready-made reinforced concrete wells);

- a section several meters long (depending on the manufacturer), which can be extended with inserts to the desired size;

- sections of different heights (from 20 cm to 1 m) with a tongue/groove type lock and a rubber gasket;

- ring height from 20 cm to 150 cm with threaded connection.

This is just one of the manufacturers. Others will have different sizes

It’s also worth saying that there are options with and without a bottom, adapter rings for changing the diameter, hatches with plastic covers. Plastic rings can have bends of different sizes for connecting pipes, installing pumps and other equipment. There are options for the lower tiers - with the possibility of “anchoring”. That is, the whole system is very similar to a children's construction set with a certain set of elements. From these elements you assemble the structure you need.

Here is a groove into which a rubber gasket is placed or filled with a polymer two-component sealant (silicone can also be used)

The diameter of plastic well rings is from 60 to 100 cm. But you need to look at whether it is the internal or external diameter. For better resistance to soil pressure, the walls are made with stiffeners. They can be 5 cm or even more. So with an outer diameter of 90 cm, the inner one will be 78-75 cm (depending on the wall thickness).

Assembly features and prices

Plastic rings and pipes for a well do not require the use of additional elements or measures to increase the degree of tightness of the finished structure.

The price of rings or ring inserts is affordable to every owner of a country house. And the wear resistance of the entire structure and ease of maintenance more than pay for all the costs of installing a modern well.

The ease of assembly is due to several key factors:

- Light weight. The average weight of the rings is 40 kilograms

- Dimensions. At the request of the customer, the craftsmen will select the appropriate size of rings corresponding to the diameter of the future or existing well.

- There is no need to use heavy construction equipment.

- The ability to carry out installation in a short time using a team of two people.

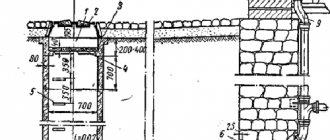

A well for drinking water from plastic rings: how to make

Plastic rings for a well are usually installed in a pre-dug pit. A hole is dug to the required depth, the diameter of which is 150-200 mm larger than the diameter of the rings being installed. The bottom is covered with geotextiles to prevent silting. The geotextile should extend onto the walls of the pit by at least 50 cm. A layer of crushed stone (about 20 cm) is laid on it, and the geotextile is folded over it. Crushed stone serves to filter incoming water. The following is the order of work:

- Assemble the pipe of the required length. When connecting (tenon and groove or thread), the joint is coated with polyurethane sealant. You can also use solid pipes of the desired size. They can be up to 12 meters, but if the depth is large, there will be problems with delivery.

- They lower her into the pit.

- Crushed stone is poured between the walls of the pit and the plastic. It will serve to neutralize spring heaving.

You can do it even alone

- Install a bottom filter.

- Connect the outlet pipes (if any).

- Install the cover.

As you can see, the biggest difficulty is digging a hole of the required depth. If the soil is dense and stable, the technique can work, but not to any depth. Very often you have to go deeper manually. Problems also arise if the walls crumble. Then you have to install rings as you deepen. In this case, you have to dig manually - either outside or in the ring, settling the column.

Sump pit made of 2 rings

| Reinforced concrete ring KS-10-9 | 2 pcs. | 4.800 rub. |

| Reinforced concrete cover D-1 | 1 PC. | 2,000 rub. |

| Polyester. Hatch green color | 1 PC. | 2,400 rub. |

| PVC pipe 110 5 meters. | 1m. | 680 rub. |

| Cement grade m-500 | 50 kg. | 260 rub. |

| Liquid glass | 1 l. | 70 rub. |

| Total: | RUR 10,210 |

| Digging a shaft for reinforced concrete rings | 2 pcs. | 4,200 rub. |

| Installation of reinforced concrete rings | 2 pcs. | 200 rub. |

| Sealing seams | 2 pcs. | 400 rub. |

| Breakdown of holes in reinforced concrete rings | for 1 answer | 300 rub. |

| Reinforced concrete cover D-1 installation | 1 PC. | 1,000 rub. |

| Hatch polyester. installation | 1 PC. | 1,000 rub. |

| Digging a 5 m trench. | 1 m/p. | 2,500 rub. |

| Installation of PVC pipe 5 m. | 1 m/p. | 650 rub. |

| Total: | 10,250 rub. |

Total (Work + Materials): RUB 20,460. * concreting the bottom 1,000 rub. sand for adding the customer.

Prices valid until: October 6, 2018

Deepening an existing well

Water flow is constantly changing, and not always for the better. If there is not enough water in the well, they try to deepen it. This is easier to do with plastic rings.

You can get rid of leaks in the drinking well by installing a plastic tab

Made of concrete, log

Plastic rings can even be used to deepen a well made of concrete rings. We remove the soil only in the center so that the concrete walls do not move down. They remain at the same depth. We deepen only the middle. The size of the “middle” should be larger than the outer dimensions of the repair rings. The disadvantage of this method is that the rings need a smaller diameter. That is, again, the water reserves will be smaller, but there is no need to dig a new well.

We raise the soil to the surface until there is sufficient water flow. Next, we clean the bottom, lay a layer of geotextile, and place its edges on the walls. We pour crushed stone, level it, and place the rings of the required height assembled on the surface on this pillow. Next, we install a bottom filter at the bottom, as in a regular well.

Here's an idea

Since plastic is lighter than water, the installed repair plastic rings must be weighted. For this purpose, any load is suitable, contact with which is not dangerous for water. Ideally, stainless steel chocks and large gravel boulders. This load can be removed in 6-9 months - during this time the soil will “squeeze” the rings and they will no longer rise under any conditions.

This method of deepening a well is safer, but it is not ideal. The result is that the water will be in the plastic insert. It's a little narrower, but it's better than nothing. Everything goes much easier than when trying to add concrete rings. They must be placed on top, and if the existing ones settle, it is unclear how the entire column will behave.

How to make a plastic well deeper

If your well is made of plastic, it is usually of small diameter and working inside is difficult and inconvenient. If you need to make it deeper, the plastic sleeve is taken out of the hole. Next, you will have to clean out the crushed stone that has fallen to the bottom, which filled the gap between the walls of the pit and the sleeve. Then they remove the bottom filter and begin to remove the soil to the required depth. In the future, the actions “inside” are no different: we remove the soil until the amount of incoming water becomes sufficient.

Polymer sand rings are used for sewerage and rainwater collection

On the surface, the required number of plastic rings are added to the finished body and the whole thing is installed in the shaft on a bed of crushed stone. The next steps are already known: we make a bottom filter, pour gravel between the walls. In general, not too difficult, apart from the ground work.

The disadvantage of this method is that if the soil is loose, this trick will not work. By removing the plastic sleeve from the well, you will deprive the wall of support. This can lead to complete or partial shedding. In this case, it may be more justified to install a well.

Step-by-step installation instructions

Having decided on the location and quantity of materials, we move on to the next stage - preparing the pit for the cesspool. It is dug to accommodate not only the septic tank chamber, but also the filter well. It’s up to you to decide how to dig – on your own or using special equipment. But the second option, although it requires financial costs, is much easier and faster.

We watch the video, we put how much into the pit:

The bottom of the pit must be concreted so that sewage does not seep into the ground. A cushion of sand is first poured in a layer of 40 cm. The bottom for the filter well is covered with crushed stone, gravel and sand up to half a meter thick.

Let's watch the video, the stages of constructing a cesspool from rings:

However, purchasing concrete rings for a toilet in a country house with a bottom can simplify the task - today such structures are sold on the construction market. In this case, it is installed at the very bottom, and ordinary ones are mounted on top of it.

Installation of rings is possible only with the use of special mechanization tools, since the weight of one reaches 400 kg and it is impossible to lower it manually. After installing the entire structure, each of its elements is fastened to the next one using concrete mortar. Additionally, you can use brackets or metal plates. This is necessary to avoid cracks in the structure during spring soil movements.

Then pipes are installed to organize drainage and to make an overflow pit. Experts recommend making the liner with a bend or a water seal in which the liquid will remain.

As waterproofing for this design, the Aquabarrier composition or special plastic cylinders selected according to the internal diameter of the septic tank are used. They do not allow wastewater to seep into the ground. The structure is covered on top with a concrete slab containing a hatch for pumping out sewage.

Cost of a ring toilet

Price has always been and remains a decisive factor when choosing a method for manufacturing a particular structure. When talking about how much a country toilet made of rings might cost, it should be noted that it is unlikely that you will be able to complete all the installation work yourself. You can’t do this without special equipment. Therefore, perhaps the best option would be to order his device from a special company. Usually their price is about 4,000 rubles for one ring. Although for a homemade design, the final cost will be significantly lower.

What should you pay attention to when arranging

Installation diagram

Although a cesspool with concrete rings is considered the best option in terms of quality and price, it is still necessary to adhere to certain rules when constructing it.

The pit for the septic tank is made with perfectly smooth walls and bottom for a better fit of the rings to the ground. It is better to entrust the installation of rings to the company.

Very often, those companies from which you order production are ready to help with installation for an additional fee. If you still decide to do this yourself, then first dig a pit. Then order rings according to its size. Because if they turn out to be larger and get stuck, you will have to spend a large amount for dismantling and reinstalling.

Let's watch the video, a little about this design:

Don't forget to punch holes in the rings for pipe connections. It is better if this work is completed before installation.

Taking into account all sanitary and construction standards, as well as being guided by the rules outlined above, you can arrange a cesspool with concrete rings on your site. But taking into account the above calculations, this option of local sewerage is more suitable for country houses with seasonal residence. Since it fills up quite quickly and requires pumping out.

Therefore, for a country cottage it is better to choose a more modern septic tank, the operation of which is based on treating wastewater and then using it for irrigation. This will help to avoid unnecessary costs and hassle with searching for and ordering a sewer machine and will significantly reduce the cost of a toilet for a summer residence.

Features of replacing a concrete well with plastic

Even with regular maintenance and cleaning, a concrete shaft requires major repairs or replacement after 20-25 years. Plastic rings allow this work to be carried out with minimal losses.

Signs that a concrete drinking well shaft needs to be replaced:

- presence of clay inclusions or sand;

- the appearance of blockages and turbidity;

- the appearance of an unpleasant odor;

- decrease in fluid level and volume;

- significant destruction of the concrete structure.

Rings for structural repairs should be 10-15 smaller in diameter than the concrete shaft. At the same time, you should not remove the old rings; they will become some protection against soil movement and a barrier to groundwater. Since concrete will continue to deteriorate, plastic rings for updating the well must be made of the most durable and wear-resistant material.

- We recommend sealing leaks and ring joints in an old structure with silicone.

- Use a monolithic pipe or assemble structures from several firmly bonded sections.

- Pump out the water, clean the bottom of the source and replace the filter layer.

- Lower the polymer pipe inside the concrete shaft.

- Fill the gap between the plastic and concrete structure with a mixture of small pebbles and sand.

- Wait until the water fills up and pump it out several times.

- When the water becomes clear, the updated well can be used as usual.

Plastic rings can also be used to repair a shallow old masonry utility well. As a rule, this is a square or rectangular structure. To restore such a structure, follow a certain sequence when performing repair work:

- remove the hatch;

- disassemble the top layer of brickwork;

- clear the mine of accumulated debris;

- collect the rings and lower them into the shaft, taking into account the commutation channels;

- fill in the voids between the pipe and the brick walls;

- install a new hatch.

If you use a solid pipe, then it is advisable to use it for a mine up to 5 meters deep. In this case, the lower edge must be installed on a flat surface. It is necessary to take into account the thickness of the one-piece structure and compare it with the load.