offers a full range of services for the development of projects and installation of water supply and sewerage systems for all types of industrial and commercial facilities. All work is carried out in strict accordance with the standards and requirements for these types of engineering communications. We guarantee the strength, reliability and durability of structures, as well as the completion of all work within the period specified in the contract.

Installation of cold water supply systems

This type of engineering communications is intended to provide industrial, commercial, and residential facilities with cold water used for drinking, production purposes and fire safety.

Such systems can be classified into two main categories:

- local;

- centralized.

The type of cold water supply system is selected according to:

- with a developed diagram of the external water supply system;

- with the requirements of sanitary and epidemiological services;

- with requirements for compliance with fire safety standards at the facility.

The main components of the design include:

- water supply source;

- water treatment and purification system;

- tanks for storing purified liquid;

- pumping stations;

- internal and external water supply networks.

Construction of water supply stations in cold water supply systems

The equipment is designed to regulate pressure in internal and external water supply networks. Their design consists of the following components:

- Pumps. The number of devices is calculated in accordance with the requirements of output pressure and fluid flow hourly. Performance indicators depend on the types and number of pumps.

- Shut-off valves and plugs. Required to stop pump operation and carry out repair and installation activities.

- Check valves. They are a type of plug that prevents the reverse flow of water.

- Pressure control sensors. Designed to send signals to the control panel in case of pressure drops.

- Pressure gauges. Designed for visual monitoring of pressure levels in pipelines.

- Control cabinet. Designed to start and stop pumps.

- Hydraulic accumulator. Compensates for excess fluid consumption when pumps are started frequently.

- Vibration load compensator. Designed to ensure smooth operation of pumps.

- Foundation. Strengthens load-bearing structures, regulates the level of installation of electric motors.

Types of pipes used during installation

Depending on the temperature regime, the purpose of the pipes and their use, when installing sewer pipes, specialists pay attention to the material of manufacture and diameter. The following pipe materials are now widely used:

- copper; - polypropylene; - metal; - made of polyethylene.

If the inlet pressure is low, then polypropylene, metal-plastic, cross-linked polyethylene can be used. For high pressure, it is recommended to use only copper pipes.

Installation of hot water supply systems

This type of engineering communications is intended to provide industrial, commercial, and residential facilities with hot water used for domestic and industrial purposes, as well as for heating purposes.

Such systems can be classified into two main categories:

- local;

- centralized.

The type of hot water supply system is selected according to:

- with a developed diagram of the external water supply system;

- with the requirements of sanitary and epidemiological services;

- with economic feasibility.

If there is no physical possibility of connecting to a central hot water supply system, hot water can be supplied autonomously. Based on the type of water heating equipment used, autonomous systems are usually classified into several main groups:

- Designs using double-circuit gas boilers. Such systems are optimal for small country cottages that do not require significant volumes of heated water supply. A double-circuit boiler allows you to heat a house, however, it has limitations related to the size of the built-in boiler or instantaneous heater.

- Designs using gas water heaters. Gas-type heaters operate using a flow or storage system, and are a universal autonomous device connected to a central gas supply pipe through main pipelines.

- Designs using electric water heaters. The function of a gas heater in such structures is performed by a heating element. When heated, this element converts electricity into thermal energy. These systems can be storage and flow type, with a water heating volume from 40 to 300 liters. Autonomous hot water supply systems using heating elements work efficiently, however, they require significant costs for electricity.

- Designs using indirect heating boilers. These designs are the most popular, as they combine high efficiency indicators with an affordable cost. The main component is the thermostat, which opens the power supply circuit when water is supplied to the pump operating in recirculation mode. Among the main advantages of these autonomous systems, it is worth highlighting the high heating rate, low cost of operation, and complete independence from the availability of electricity.

- Constructions using solar collectors. Such systems work by converting solar energy into thermal energy. There are flat-plate collectors and devices with vacuum pipes. Solar collectors as autonomous hot water supply systems are used less frequently than other systems. This is due both to their expensive cost and to certain limitations associated with the lack of sufficient sunlight in some regions.

Engineering communications are the basis of life support for buildings

Modern buildings are full of various life support systems and technical devices that create comfortable living conditions in them.

For the operation of most of these systems, a connection to central infrastructure communications is required, so there is a need to lay external utility networks to the buildings. In conditions of dense urban development, as well as the presence of a large number of owners of street networks and areas adjacent to the building, the implementation of a project for laying utility networks often becomes a problem. There are not many design and construction organizations capable of solving the administrative and technical problems of laying external networks to a facility in conditions of a complex interweaving of overhead and underground main communications. Take into account the interests of the owners and prepare in a short time a complete package of impeccable design documentation for external networks.

Features of the design of water supply systems for private houses

In small private buildings, the source of cold water supply may be a separate well. Its diameter ranges from 1 to 1.5 m. A prerequisite for drilling an individual well is the presence of a water measuring unit, consisting of a meter and a filter. In some node designs, data transmission to a common control center is carried out remotely.

The choice of the optimal option for supplying hot or cold water to an industrial or residential facility should be carried out taking into account its technical characteristics and the expected volume of work. Qualified specialists will answer in detail all questions related to the choice of a water supply system, calculate its approximate cost, tell you where to start, and help with the preparation of the documentary and design base.

What are the stages of installation of an external water supply system?

Installation of external networks includes the following technological stages:

- excavation of soil with subsequent arrangement of trenches;

- installation of sewerage and water pipes;

- insulation of the pipeline (if necessary);

- sealing the pipeline in the wall where input/output is carried out;

- hydraulic test of the system for leaks.

Correct selection of pipe diameters helps prevent pressure turbulence in the system, which leads to unpleasant noise in the water supply.

The minimum diameter of the external water supply depends on the length of the system and the average speed of water flow (approximately 0.02 km/s). However, there are also standard values:

- If the length of the system does not exceed 10 m, a diameter of 20 mm is sufficient.

- At 30 m you can limit yourself to a diameter of 25 mm.

- More than 30 m - 32 mm.

The maximum pipe length is 15 m.

Installation of pipes inside the trench is carried out in the direction from the water source to the house. Pipeline connections can be made by welding or using flanges and fittings.

Features of welded joints

The connection of HDPE pipes for external water supply is carried out using an electric coupling or butt welding. Electric coupling is used for:

- laying pipes with a small diameter;

- insertion into an existing pipeline;

- welding joints in hard-to-reach places.

The most effective and popular method is butt welding, which is performed using a heated tool. The range of welding equipment available today provides a variety of modifications and power. With its help, you can reliably fix each individual element of the system.

The quality of the connections depends on the skill of the specialist, the level of preparation of the surface of the elements being connected and the parameters of the tool itself.

When working with such equipment, it is important to follow some rules:

- the welded surface must be cleaned and degreased;

- The ambient temperature must not be lower than +5°C;

- if the pipe diameter is 50 mm or more, it is necessary to chamfer (this is done at an angle of 45°).

To get an even cut of pipes, it is advisable to use special scissors.

Installation technology using fittings and flanges

Flange connections are used for installing an external water supply system when the diameter of plastic pipes exceeds 63 mm. This technology is also used to connect control and shut-off devices. There is a large selection of standard sizes of products on sale, their installation is quick and simple. If the system is mounted externally (using fittings and flanges), be sure to adhere to the following algorithm:

- The pipe is cut according to the previously applied markings. As already mentioned, this is done using special scissors or a pipe cutter. It is important to make the cut at a right angle.

- The resulting surface must be cleaned of dirt. The use of detergents, including soap, is permitted.

- The fitting nut must be loosened 4 turns and the pipe inserted into it. After this, the nut is tightened tightly.

Insulation of the water supply system

The laying of water supply and sewerage systems should be carried out taking into account the climatic conditions of the area. If there is a risk of freezing, it is better to take measures to insulate the system. Thermal insulation materials have low thermal conductivity and are resistant to fire.

When using mineral fiber insulation, protection from moisture will be required, otherwise the insulation effect will be neutralized. It is much more convenient to use polystyrene foam. This is insulation consisting of 2 semicircles, which have a waterproofing layer on the outside.

Special attention should be paid to the entrance (exit) of the pipeline to the house, since this area is most susceptible to negative temperatures. Here, the use of a heating cable will help to increase protection against freezing. In order to save energy costs, you can install a temperature sensor that will automatically activate the heating wire when a critical value is reached.

Having insulated the pipeline, it is covered with soil. However, before this, the system’s functionality is checked.

Design and installation of sewer networks

The sewer network is an important component of the overall engineering system of any industrial, commercial, or domestic facility. The efficiency of work and the reduction of costs for carrying out repair and service activities during future operation depend on its competent planning and professional installation.

will help with the development of a sewer network project for domestic and industrial needs, and will also carry out its prompt installation within the time frame set by the client. Our specialists will help you choose the best project option and make adjustments to the existing project taking into account changing needs for wastewater disposal at sites.

To decide what type of sewer network needs to be installed at the site, you need to know that there are several main types of sewers. They can be classified according to a number of parameters:

- purpose – industrial, household, stormwater;

- localization – internal, external.

Industrial sewerage is designed for the effective disposal of industrial waste. It should not be integrated into the domestic sewer network, therefore the main requirement for its design is complete tightness before waste is discharged into the main line. Industrial sewerage is equipped with special inspection openings for routine checks and inspections. The inspection schedule is regulated by SNIP standards.

Today it is possible to design and install industrial sewer networks operating in the recycling cycle of industrial waste. In such systems, production waste is not completely discharged into the general pipeline, but goes through several stages of pre-treatment, some of which is then returned to production.

The domestic sewer network is designed to remove wastewater from buildings and residential and administrative facilities. Depending on the extent of coverage of the territory, it can be centralized or local. The first subtype is installed centrally for servicing large industrial facilities and populated areas, the second - for servicing individual buildings and structures.

Storm sewer networks are designed to drain stormwater (rainwater).

External sewerage as it is: revealing the secrets of professional builders

The installation of external sewerage includes the complex installation of two systems at once, each of which performs its intended function.

-

External networks of domestic sewerage.

The main task of such a system is to absorb contaminated water, and then purify it to such a state that it can be safely released into the ground. Why into the ground, and not into a storm drain on the street or outside the site? It is in the soil that natural bacteria will help complete the moisture purification process. Untreated water from domestic sewerage has an unpleasant odor and is unlikely to please visitors. - External storm sewer networks.

This system is known to many as surface drainage - open or closed. It is created with the aim of maximizing the collection of rain moisture and its timely removal outside the local area. Thanks to the external storm drainage system, puddles do not accumulate on the site during the snow melting season or heavy rains.

Thus, the sewerage system of external networks and structures includes sewer pipes for external sewerage, a filter well, a septic tank and a drainage system - “storm drain”.

Types and features of networks by location

Internal sewer networks are installed plumbing and piping systems that are located inside a facility. They can be made of cast iron, plastic, metal alloys.

External sewer networks carry out the task of draining wastewater and household waste from the facility. Their design is quite complex and includes cleaning systems, as well as large pumping stations. There are several types of external sewer networks:

- separate - having several channels for the removal of wastewater of different composition and nature;

- semi-separate - operates on the same principle as separate external sewerage, but has one significant difference - wastewater is processed in a single collector;

- general - all types of waste and waste are transported in a single stream.

Types of autonomous sewage systems

Autonomous sewer systems are in great demand and popularity today. Their demand is associated with the growing number of residential and industrial buildings isolated from external sewer networks. Another factor explaining the demand for such systems is their convenience and speed of installation work. There are the following types of autonomous local sewer systems:

- Dry toilets are an ideal option for a country house or summer cottage. The main expense item is related to the purchase of consumables and waste disposal. The design of such a system does not require the development of design documentation.

- Drainage pits are outdated, but still often used sewerage systems in private buildings. Their operation is associated with the need for constant pumping of waste products. However, this option is still in demand in some regions, since by definition it is the most affordable.

- Septic tank - provides a high degree of waste treatment, has minimal operating costs, and is suitable for small country houses.

- Biological treatment systems. Expensive, but multifunctional and efficient local sewer networks.

When choosing an autonomous sewer system, the main criterion is the mechanism for the movement of wastewater; this can happen by gravity or using special pumps. Each of these mechanisms has its own advantages and disadvantages, which must be taken into account when giving preference to one or another system.

The principle of gravity sewerage ensures that wastewater drains naturally, and it is important to correctly calculate the slope angle. This must be done at the design and installation stage. Also an important factor influencing the functionality of a gravity sewer system is the diameter of the pipeline intended for drainage. It is important to find the optimal balance between the angle of inclination and the width of the pipes. If they do not comply, users will face constant blockages and the need to clean the sewer.

Sewage systems designed on the principle of gravity flow have a number of advantages, the main ones being affordable cost, independence from the availability of electricity sources, and ease of operation. The disadvantage of such a system is the impossibility of its installation in the absence of a sump tank in close proximity to the object.

Local sewer networks, where wastewater is pumped using a pressure principle using pumps and pumping stations, are distinguished by their ability to transport waste over long distances. Such a network can be laid over any terrain. Its functionality will not be reduced, since the power of the pumps is sufficient for the effective operation of the structure in places where the bends change the direction of the pipes. The main disadvantage of such a pressure system is the dependence on the availability of a power source for uninterrupted operation of the pumps.

Installation of water supply in a private house

Using modern methods of water supply installation, we offer individual solutions for each client - optimal in individual cases. First you need to determine the source of water supply:

- Well.

- Well.

- External highway.

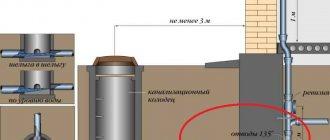

The following is the work on laying sewer pipes:

- Between the source and the pipe entry it is necessary to dig a special trench in a straight line, with a slope. The usual depth is 1-2 meters, but depends on the level of soil freezing. A layer of gravel and sand is laid at the bottom of the trench.

- A glass under the pipe is installed in the upper ring of the well. An insulated sleeve is placed at the entry point into the house.

- The pipe is being laid and connected to the pumping station.

- The pipe is covered with insulation and filled with soil.

An approximate diagram of the installation of water supply and sewerage in a private house allows you to assess the scale of the work. In practice, all installation work is preceded by careful network planning and design.

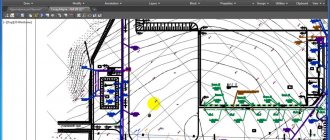

Design work

The installation of internal sewerage systems does not always require the development of design documentation. However, if we are talking about the installation of external sewerage networks, the project is mandatory. It must meet the requirements of legal and construction regulations, so its development should be entrusted to experienced professionals who understand the intricacies of installing external sewer networks for industrial and domestic facilities. Failure to comply with design standards, inaccuracies in calculations and drawings can lead to malfunctions of the entire system, disruption of the environmental situation in the region, and significant financial costs.

Design of sewer networks includes several main stages:

- Calculation of wastewater volume. This takes into account statistics on the number of intended users living in the area where the sewer network is planned to be installed. At this stage, the neutralization time, quantity and frequency of discharge of the cleaning reagent are also calculated.

- Then an internal piping plan is drawn up, taking into account the points of exit and delivery of wastewater.

- The next stage is tracing, that is, linking the sewer network to the surrounding area. At this stage, comprehensive geodetic work is carried out, the nature of the underground objects present, and the density of buildings on the area are clarified.

- After completing the complete collection of the necessary technical data, they are coordinated and transferred to paper and electronic media.

In finished form, design documentation for the construction of an external sewer network contains an explanatory note, technical description, drawings, diagrams, text and graphic files. The drawings must be correctly linked to the area, and they must include real figures and calculations indicating the exact dimensions of industrial and residential buildings available on the area. In the event that the territory for the construction of a sewer network is located on an already developed area, the regulatory authorities that issue a construction permit allow the technical part to be combined with drawings and plans.

Timing and cost of implementation of the sewerage and water supply system project

On our website there is a detailed price list, which indicates the cost of installation of water supply for objects of various purposes and of various sizes. In general, the final price depends on a number of factors:

- Scope and features of the water supply system. The complexity and price of installation of sewerage and water supply depend on the intended purpose of the system. We implement projects for drinking water, watering, fire protection and industrial purposes.

- Water supply system source parameters. The requirements for the power and performance of pumping equipment depend on this.

- Complex solutions. A turnkey water supply and sewerage system costs less in total than ordering the design, installation and supply of network components separately.

The cost of installing sewerage and water supply is calculated taking into account the optimal ratio of price and quality of materials, as well as necessary and additional work. The experience of our specialists allows us to make the most advantageous offer for any property, such as a private house, shopping center, industrial building, etc.

Installation of water supply and sewerage systems does not always require a one-time payment. If the installation is carried out by unskilled workers, then over time you will have to invest in correcting errors and troubleshooting problems.

The Obion company invites you to order turnkey installation of a water supply system for your home in Moscow and receive reliable and energy-efficient communications at a competitive price. To pre-calculate the cost of services, call us or send an e-mail to In addition, you can always get meaningful and useful advice in our office.

Features of writing an explanatory note for project documentation

An explanatory note is an important component of project documentation. It must be correctly composed and formatted. When obtaining permission to install an external sewer network, employees of regulatory authorities place increased demands on it.

The explanatory note should reflect the following points:

- stages of construction work;

- stages of installation (dismantling) work;

- number of contractors involved;

- amount of special machinery and equipment;

- quantity of materials used and their technical characteristics;

- master plan of the area;

- estimates.

Sometimes the project package of documents requires a detailed description of the wastewater treatment technologies that are planned to be used during the operation of the sewer network.

Road puncture main features

Puncture under the road (or puncture of the road) using the horizontal drilling method. Its advantages and features. The laying of utilities must be carried out in accordance with the requirements listed below. However, its advantages are quite obvious.

- Firstly, if there is a high groundwater content, there is no need to lower the water level when making HDD punctures under the road.

- Secondly, the cost of work and its completion time are reduced. Compared to laying pipe using other trenchless methods, this installation takes on average 40% less time. The horizontal drilling method does not require an additional installation of a starting pit with a thrust wall. Also, if a steel pipe with a diameter of DN = 500 mm is laid using the horizontal method, then the cost of this method ranges from 9 to 14 thousand rubles, which is 2-2.5 times less than with the auger boring method.

The particularity of the horizontal directional drilling method includes a direct analysis of the situation carried out on the project itself, based on the design documentation (profile, plan). The possibility of laying HDPE or steel pipe using horizontal puncture should be taken into account.

If the pipe diameter is up to 800mm, the HDD laying method can also be used, which requires the following conditions to be met:

- a pre-prepared place at the entrance trench for the location of the pipe, preferably its entire length. At the same time, the located existing communications should not interfere with the technological progress to the first pit;

- pre-prepared place for drilling equipment. Typically, the site is arranged over a length of more than 6 meters, taking into account the possibility of constructing an entrance trench.

Cases under the road. Features of their purpose and application

The cases are designed to protect pipelines when making punctures under railways, roads, tram and railroad tracks, local driveways and other additional underground communications. It should be taken into account that the diameter of the case must be 150-250mm larger than the diameter of the pipeline. The entire interpipe space should be filled with cement-sand mortar (grade M100). The case protects the pipeline from loads from transport, soil pressure, and unwanted effects of other communications.

Road puncture within the city

In a city, especially in its historically significant area or in the center, the laying of pipelines is socially significant. Therefore, closed pipe laying under roads is an ideal method that can withstand the pressure of heavy traffic of cars, public transport and pedestrians.

Puncture of the road within the cottage village

In any cottage village, piercing the road is an ideal solution for laying not only a pipeline, but also other additional communications. At the same time, the order in the landscaped area and the landscape are not disturbed. Using the HDD puncture method, it is possible to successfully lay such communications as gas pipelines, sewerage, water supply, low-voltage and high-voltage cables, and lighting cables. At the same time, traffic on the highway and access to residential areas are not blocked. Pedestrian paths, sidewalks, dirt and asphalt roads, and lawns remain intact.

Puncture under tram tracks and railway

Before starting work on puncturing the soil under tram tracks or railways, a PPR is developed, which indicates which directional puncture installation will be used. The PPR is subsequently coordinated with such services as the Railway Administration, RCS NODG, PCH, ShCh, and other railway services. After which an agreement is concluded for the establishment of insurance packages and an agreement for technical supervision.

The work performed must meet the requirements of design documentation, technical specifications and agreed upon work permits.

Road puncture installations

The ideal way to lay several pipes or pipes with a diameter of 100 - 800 mm under tram tracks or a railway is HDD puncture (horizontal directional drilling); for diameters from 500 mm to 1300 mm, auger installations or horizontal auger drilling installations (HSD) are used. After the work has been completed, a set of all agreed documentation is submitted to the route.

If you are interested in laying pipes under roads, puncturing under the road, puncturing using the HDD method, pulling pipes under the road, laying pipes under the road using the puncture method, trenchless laying of pipes under the road, installing soil puncture, laying pipelines under the road without opening the soil - Call us, we are always We are happy to solve all your questions.