A wide variety of communications and highways are laid in the home of a modern person. One of the most important is sewerage, which performs the functions of collecting and discharging wastewater. During its operation, sewer gases are generated. They are a very specific cocktail of ammonia, methane and other similar substances. These substances are dangerous to human health, so they should not be allowed to enter living rooms.

To eliminate this problem, a special design is used, the main part of which is the fan pipe. The product serves to maintain the proper level of pressure in the sewer and to remove gases formed in the sewer.

Return to content

What it is

A drain pipe is a part of the sewer system pipeline that connects it directly to the atmosphere and eliminates the emptying of water seals of plumbing fixtures from possible vacuum when draining waste water.

In turn, a water seal is a specially curved sewer pipe at the outlet of a plumbing fixture. It is naturally partially filled with water, which acts as a water plug to prevent unpleasant air from entering the sewer pipes directly into the room. For example: the water seal of the toilet is made in the housing, and a special product is screwed to the sink - a siphon.

Important! If there is no drainage pipeline in the sewerage system, then at the moment of draining a certain amount of water, water plugs may disappear at nearby water seals and then not very pleasant sewer odors will freely seep into the living quarters through the empty pipes.

Toilet drain pipe

The drain pipe is also called the ventilation of the sewer system. Its presence in the sewer allows you to solve two important problems simultaneously:

- Ventilation removes harmful gases from the sewer system;

- Pipeline ventilation maintains atmospheric pressure in all elements of the sewer system, preventing air rarefaction from occurring when large volumes of water are drained simultaneously.

Hence the conclusion: the drain pipe is an important attribute when installing a sewerage system in residential buildings.

Typical installation mistakes

If an inexperienced person undertakes the installation of this structure, he may make a number of mistakes, including: Bringing the riser inside the room in the attic. This decision is most often made by those who do not want to deal with removing the pipe through the roof. As a result, gases will accumulate and sooner or later penetrate into the living space.

By following this link https://vse-postroim-sami.ru/engineering-systems/drainage-systems/8652_ustrojstvo-livnevoj-kanalizacii-princip-raboty-konstrukciya-snip/, you will learn about the rules for arranging storm drainage. You may also be interested in an article on how to properly build a septic tank. Read about how to choose the right dry closet for your dacha here.

Installation of various exhaust devices, for example, a deflector, on the structure. Inexperienced builders believe that this way they can achieve better traction. The presence of such a device leads to the accumulation of condensate on the inner surface of the riser, which subsequently freezes and impairs the removal of sewer gases.

Installation of a vent pipe on the external wall of the building. This design is also susceptible to freezing due to condensation inside, so it cannot function normally. Output of the riser under the roof overhang. In this case, there is a possibility that the structure will be damaged by snow masses.

The installation procedure for a fan pipe is quite simple and does not require high qualifications, and it does not matter whether you need to install a new product or replace an old one. The main thing is to carefully study the installation instructions and strictly follow the requirements of construction documentation.

Return to content

Device

The presence of drain risers in the sewer system of multi-apartment residential buildings is mandatory and is regulated by current government documents and building regulations. As a rule, sewer ventilation risers are made straight, due to the fact that the processes occurring there are gravity, not forced, and it is necessary to minimize the number of outlets and various narrowings for the most free passage of air flows.

Sewage systems in individual houses do not have such volumes of wastewater as in multi-apartment residential buildings, therefore the requirements for the installation of drain risers are less complex and allow for significant deviations for the sake of practicality and minimizing construction costs.

Fan riser installation

The sewer pipe is basically the upper continuation of the sewer riser, so it must end at the roof of the building. A standard deflector must be mounted at the end of the pipe, so that the distance from the surface of the roof ridge is 30 centimeters higher. It is not recommended to install sewer ventilation on the façade of the building.

Important! You cannot install the outlet of the sewer riser in the attic of the building or near windows and near balconies.

To install a fan riser, you can use pipelines made of any materials. Thus, plastic, cast iron or steel pipes must meet only one condition - to be corrosion-resistant, since sewer gases will contain many aggressive substances.

Is installing a high-performance aerator sufficient to eliminate the waste pipe?

So, having decided to get rid of the bulky drain pipe in the bathroom, according to clause 3.15 of SP 30.13330.2012, the property owner will receive nothing more than an unventilated sewer riser - without communication with the atmosphere. However, it is still important for him to ensure the normal flow of two processes (they are described in the section “Why extend the riser?”) - the removal of decompression loads and the removal of gaseous products from the system.

The first decompression task, as has already been found out, is helped by installing a suitable air valve.

The set of “Buts” is caused by the implementation of the second condition. Indeed, clause 8.2.22 of SP 30.13330.2012 clearly stipulates that such unventilated risers can be equipped if the ventilation mode of the external network is maintained. How will toxic gaseous products of organic decay be removed? Let's consider two typical situations - for sewers in a private house and in an apartment building.

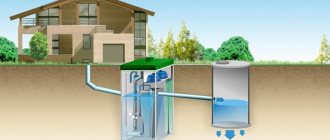

In a private house

Owners of separate low-rise housing solve waste disposal problems by installing local treatment facilities, storage tanks, or through traditional cesspools. A prerequisite for the operation of these sanitary facilities is the installation of ventilation ducts. Depending on local conditions, they can be manufactured in various ways, for example, as shown in Figure 6, pos. 2-4.

Figure 6. If in a private house you cut off the drain pipe (item 1), installing an aerator (item 5), then the instructions in clause 8.2.22 of SP 30.13330.2012 on ventilating the external network - removing toxic gases from it, when using additional additional communications (items 2-4) – complied with.

In an apartment building

Ventilation of risers in apartment buildings was initially designed based on the free communication of the sewerage system with the atmosphere (Figures 1 and 2). In fact, it must be carried out through the highest point of sewage communications, that is, through a drain pipe leading to the roof. Refusal of the hood (Figure 7) is allowed only in exceptional situations. In SP 30.13330.2012 it is described for exploited roofs in clause 8.2.20. In this case, it is indeed permitted to install an air valve at the mouth of the riser on the top floor. However, according to clause 8.2.22, the regime for removing sewer gases from the external network must be maintained. Therefore, to ensure it, it is necessary to install auxiliary ventilation communications of the types indicated in Figure 6, pos. 2-4, which is quite problematic in urban areas.

Figure 7. Refusal of a drain pipe in an apartment building - sewer ventilation is impossible

Diameter

There are no special requirements for calculating the diameter of sewer pipes; for multi-apartment residential buildings, it should be equal to the diameter of the sewer riser itself. But for individual construction, it is allowed to use pipes with half the diameter compared to the main riser, so only air will pass through the drainage part of the pipeline, and it has several times lower density than the drained water at the bottom of the sewer network.

A 50 mm drain pipe is well suited for sewerage of an individual private house

Basically, when constructing an individual residential building, to calculate a separate sewer line, which includes a sink with a pipe with a diameter of 50 mm, a cistern with a hole of 70 mm, a main pipe from the toilet of 100 mm and a common riser, also of 100 mm, They use a fan pipe with a diameter of only 50 mm. Practice shows that this diameter is quite sufficient to maintain constant pressure and provide constant ventilation of the sewer system.

Ventilation system elements

The sewage ventilation system includes three elements:

- water seal;

- air valve;

- fan pipe.

A sewer water seal is a device in the form of a U-shaped pipe or channel, constantly filled with water and blocking the access of gases from the sewer system to the premises.

A siphon works on the principle of communicating vessels: when liquid is drained through one vessel, the second vessel overflows and drains into the riser.

After the drain is completed, the siphon remains filled with liquid and reliably blocks access to gases from the septic tank.

The water seal prevents the appearance of unpleasant odors in rooms if the following conditions are met:

- constant filling with liquid;

- the absence of decomposing organic residues in the plumbing fixture and in the siphon itself;

- The gas pressure in the riser must be equal to the air pressure in the rooms.

To comply with the first two conditions, it is enough to keep all wastewater receivers clean and periodically fill their siphons with clean water if they are not used for a long time. Equality of pressure is ensured by other elements of the system.

An air valve for sewerage is a device that allows air into the sewer riser and blocks the flow of gases from the riser into the premises.

In small one- or two-story private houses with bathrooms on the ground floor, it is rare to discharge large amounts of wastewater into a septic tank. In these cases, an aeration valve is quite capable of preventing gases from entering the premises.

Install it at the upper end of each riser (usually in the attic). In this case, the ventilation pipe must be installed on the septic tank, which is simpler and cheaper.

The valve system cannot replace siphons on plumbing fixtures; it only complements them. If the water in the siphons dries out, an unpleasant odor still appears.

Fan pipe

This is a ventilation duct connected to the top of the sewer riser and led to the roof.

This element allows you to eliminate unpleasant odor from the sewer in the most radical way.

The drain pipe in a private house performs two functions:

- equalizes the pressure in the riser with atmospheric pressure when discharging a large amount of waste;

- constantly removes gases formed in the sewer system, preventing their accumulation and entry into the premises.

A properly designed and installed sewer pipe on the roof almost completely eliminates the possibility of sewer gases accumulating and entering the house.

Only if the siphons dry out does an unpleasant odor still appear, but it is much weaker due to constant ventilation. It is best to use modern plastic pipes that are not subject to corrosion for installation of the ventilation duct.

How to install correctly

There are two prerequisites for installing a ventilation pipe in the sewer system of a private house:

- the diameter of the risers does not exceed 50 mm;

- the house has two or more floors and plumbing fixtures are installed on all these floors.

Since the installation of plumbing on the floors is planned in advance in the house design, a ventilation duct for the sewerage must be provided in the same design.

The parameters and installation of the drain pipe are regulated by the Construction Norms and Rules (SNiP 2.04.01-85* “Internal water supply and sewerage of buildings”).

The rules for installing a fan riser are simple.

The height to which the exhaust part of the riser is raised depends on the roof structure. It amounts to:

- if the roof is flat and unused - 0.3 m;

- if the roof is pitched - 0.5 m;

- if the roof is in use (structures are located on it) - 3 m;

- if the duct is located in a prefabricated ventilation shaft - 0.1 m from its edge.

The minimum distance from the exhaust part to windows and balconies is also limited. Horizontally it must be at least 4 m.

Vanes are not installed above the exhaust part of the ventilation risers (clause 17.18 of SNiP), since in winter a large amount of frost from condensate is deposited on them, as a result of which the channel is blocked.

A deflector can only be installed if the house is built in an area with a warm climate.

Sewage ventilation is routed to the roof separately from any other. The channel can be laid inside a prefabricated ventilation shaft, but it should not intersect with room ventilation or a chimney (clause 17.19 of SNiP).

The diameter of the fan pipe must be the same as the diameter of the riser. As a rule, the exhaust part and the riser consist of identical elements.

If there are several risers, they can be brought into one common exhaust part of the same diameter. In this case, the pipelines connecting the exhaust part must be installed with a slope of 0.01 (1 cm of decline per 1 m of length) towards the sewer risers (clause 17.20 of SNiP).

Any conscientious architect, when developing a house project, provides for the correct outlet of the drain pipe. However, after construction, many owners rebuild private houses, changing the layout. In this case, problems may arise with the correct outlet of sewer ventilation.

If the roof is pitched, it is best to remove the exhaust part at the top of the slope, as is done with a chimney. However, after redevelopment, the toilet may end up in a completely different place. Is it possible to move the sewer hood along with it?

It makes no sense to install a drain pipe at the bottom of the roof slope or even under the roof overhang: in winter, snow coming off the roof can damage it. In this case, the sewer ventilation pipe is brought out under the roof to its upper part and only then is the drain pipe installed.

In this case, the entire ventilation duct must be insulated so that condensation does not freeze in it.

If the exhaust part is slightly displaced relative to the riser, they can be connected with a corrugated plastic sleeve. As a last resort, the outlet for ventilation sewer risers can be made at the top of a blank wall in the backyard.

In this case, the pipe must be brought out through the opening in the wall at a distance of 30–40 cm. If it is brought out into the opening covered with a decorative grille, condensation during the cold season will settle above the hole and spoil the plaster.

Summary

It is not difficult to install the ventilation of the sewer networks of a low-rise private house yourself, subject to certain rules.

When installing plumbing fixtures only on the ground floor, there is no need to install a separate ventilation pipe for the sewerage system. In this case, the water piston effect can be eliminated by using an air valve installed at the upper end of the riser.

If plumbing fixtures in the house are installed on all floors, the uninterrupted functioning of the plumbing is ensured by a properly installed drain pipe. If the rules of SNiP are observed, problems with the operation of the sewer system do not arise.

Is a vent pipe needed in a two-story house?

Guided by building regulations, an exception to the execution scheme is allowed when constructing a sewerage system for a waste pipeline in individual houses. This conclusion is based on the fact that in small households large volumes of drained water cannot be generated simultaneously.

Fan riser in the room and vent pipe on the roof

Installing a drain pipe for the sewer network in low-rise construction will not always be superfluous, therefore it is recommended that at the stage of constructing a new building, the sewer system should be installed according to the traditional scheme with all functional elements. Although there are a number of clear criteria under which the installation of a sewage pipeline is a necessary condition for the proper functioning of the sewerage system, namely:

- There are two residential sections in the house, each with its own sewer system, which is combined into a common network;

- The house has more than two floors, equipped with common risers;

- There is a horizontal sewer distribution with three or more plumbing fixtures connected;

- The presence in the house of sewer risers made of pipes with a diameter of 50 mm;

- The presence of a swimming pool or similar structure that allows large simultaneous discharges of water into the sewer system;

- If there are individual sewer septic tanks located on the site directly next to the house.

In any case, when, during a single-stage discharge of water, a situation may arise in which the section of the sewer pipe is completely filled and it becomes possible to create a vacuum in the higher-lying water seals, then the installation of a drain pipe becomes a prerequisite for the proper functioning of the sewer system of the house.

Exiting a vent pipe to the roof of a two-story building

If a residential building is equipped with a small number of plumbing fixtures and mostly with small-diameter sewer pipes, then the use of a drain pipe is not necessary, since it will not have a significant impact on the operation of the entire sewer system, but will only require the expenditure of extra funds.

Advice: For one-story construction, installing fan pipes is not advisable.

Preparation for installation of the fan main

To install fan ventilation, you must use the same parts as for the drainage system, namely: fittings, pipes and fasteners. It is better to prepare all the necessary elements, materials and tools before starting all work. In most cases, plastic parts will do. The process can become more complicated if you need to replace an old metal structure with a new one. Let's discuss this process in detail.

Old cast iron fan lines that have been used for a long time fail. There is an opinion that it is impossible to replace metal lines with plastic elements, but this is nothing more than a misconception. Installing a plastic drain pipe instead of cast iron is possible, but only if all elements of the system are completely replaced.

Exit for drain pipe

According to experts, the fan line, which is assembled from elements of different materials, is not durable. It is best to work with similar materials. It is desirable that the material of the drain pipe matches the material from which the drainage system is made.

If the communication is made of cast iron, then the fan pipeline must also be made of this metal. If you have to combine different materials, it is better to first consult with an appropriate specialist and find out how such a pipe will behave. This can prevent significant reductions in ventilation performance.

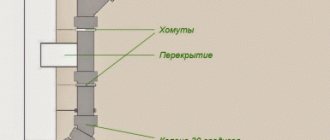

The installation of a fan riser requires the use of the most ordinary pipes and parts for connection. Parts are made of metal or plastic. To install the system you will need the following parts:

- pipe with bends;

- rubber cuffs for a tight and airtight connection;

- adapters;

- clamps for securing the main line to the walls.

Dismantling the drain pipe

If you first need to dismantle the old pipe, you will also need a sledgehammer, a drill, and a grinder. The area where all work will take place must be cleared of all unnecessary things. If there are flammable items, it is better to remove them too. If they are stationary, then they should be covered with fireproof material. During installation, you should not use the sewer, so if you have neighbors, it is better to notify them in advance. After this, you can turn off the riser and dismantle the old ventilation system.

Return to content

How to check

When purchasing an existing country house or cottage, you can easily check and make sure whether a drain pipe is present in the sewer system. So, if you suddenly flush the water from the toilet, it should not disappear from the water seals of the plumbing fixtures located above. But the characteristic appearance of squelching sounds in the siphons of sinks and bathrooms leads to the conclusion that not everything is in order with the sewage system in the house and this can subsequently lead to the appearance of unpleasant odors in the premises.

To check for the presence of a drain pipe in the sewer system of a house, you need to flush the toilet.

Installation of a new structure

Installation of a new product should start from the lowest sewer line or from the foundation if we are talking about a country house. It is necessary to drill holes in the wall to secure the clamps. You need to buy high-quality metal parts. Such elements give strength to the entire product. The line is installed and secured using clamps. Fan ventilation outlets are connected to the plumbing fixture and firmly fixed.

To achieve maximum tight and reliable contact of the riser with the fan device, it is necessary to use seals. Craftsmen recommend installing these elements using soap or silicone. In this case, the contact will be really reliable, but it will be difficult to remove it.

Fan pipe exit through the roof

It is also necessary to carry out soundproofing to protect residents from loud sounds from the sewer. The simplest, cheapest and at the same time reliable option is to apply polyurethane foam. The sewer pipe just needs to be filled with foam and allowed to dry. This building material perfectly absorbs all sounds. The only drawback of this method is the problematic maintenance of the sewer system.

A more acceptable option, which, by the way, is the only one when installing complex branches, is to use slabs and mineral wool for sound insulation. You can also purchase and install a box for sound insulation. This product is equipped with a window for checking the line.

Return to content

Installation

The requirements for the installation technology of sewer pipelines are the same as for other sewer pipes. This is how you can list the main installation conditions:

- Sections of pipelines laid horizontally must have a minimum slope of 0.02% towards the sewer stacks;

- Several sewer risers can be combined with one drain pipe;

- The direction of the waste pipeline can be changed after the last water seal and only above the level along the riser;

- When combining three or more pipelines, it is necessary to make a connection with angles of 45 and 135 degrees, respectively;

- When the roof or attic is in use, the fan deflector is installed at a height of 30 cm closer to the roof ridge;

- The exhaust pipe outlet is allowed no closer than four meters horizontally from balconies or skylights.

Installation diagram with roof outlet

Important! Any combination of pipelines of waste pipes, ventilation systems and chimneys is strictly prohibited.

System Design Principles

This ventilation device may be a separate pipe or have a more complex design. No matter how the riser looks, its design takes into account the following rules:

- the diameter of the mounted risers cannot be less than the diameter of the sewer line to which it is attached;

- horizontal elements of the ventilation system must be laid with a minimum slope of 0.02% along the movement of sewer gases;

- using one fan structure, you can connect a number of risers at the same time;

- changes in the direction of products are carried out exclusively above the level of products connected to the pipe;

Fan ventilation diagram

- the correct connection of a certain number of lines is ensured by the use of a fan tee; it is placed at an angle of 45 or 135 degrees according to the movement of wastewater;

- any changes in the system regarding the direction of the mains are carried out using a fan outlet, which is attached at an angle of 135 degrees;

- the fan pipe should rise above the roof surface to a height of up to half a meter;

- if the roof of the house is occupied or there is a living room in the attic, the product must rise at least three meters;

- the horizontal distance from the structure to the windows of living rooms must be at least four meters;

- it is strictly forbidden to remove the drain pipe and other ventilation lines at the same time;

- the upper element of the fan pipe should be in a cool environment, and the lower one in a warmer environment for good traction;

- it is prohibited to install a fan structure on the outer wall of a building;

- According to SNiPs, fan ventilation must be installed in multi-storey buildings, in buildings where the sewage system is equipped with an autonomous storage tank, as well as in buildings where the sewage system is equipped with lines with a diameter of no more than 0.5 centimeters.

Return to content

Do I need to insulate and soundproof?

It is not at all necessary to insulate sewer pipelines passing through residential premises, as well as sewer pipelines. But in an unheated attic it is worth making at least minimal thermal insulation of the pipes so that during severe frosts the ice does not freeze inside, since water vapor is much lighter than air, and they will tend to rise up the pipe, where they will freeze on the cold walls.

Insulated pipe

Sound insulation of the drain pipe must be carried out only if it passes openly through residential premises. If this cannot be avoided, then the insulation work is quite simple and is carried out in the same way as for all sewer pipelines with the same ease. The only thing that complicates the process is the variety of acoustic processes in pipes, which directly depend on the materials from which the pipelines are made.

Thus, the sound insulation properties of cast iron pipes are much better than those of their plastic counterparts. This is due primarily to the properties of the granular structure of cast iron and the larger wall thickness, so such pipes, as a rule, do not require additional sound insulation.

Sound processes occurring in plastic pipes can be divided into four main components:

- Impact nature, when falling water and feces repeatedly hit the walls of the riser;

- Atmospheric nature is the penetration of wind and precipitation noise through the outer part of the pipeline;

- Resonant nature from the presence of extraneous noise in the pipes caused by the interaction of the sewer pipeline with the building structures;

- Vibrations that occur when there is contact with any operating equipment.

Sound insulation of a drain pipe

The main part of the work on sound insulation should be carried out at the design stage of a residential building, so that all sewer risers do not pass through residential premises and are installed exclusively in special boxes or sewer shafts, which themselves are shielding devices and prevent the spread of noise .

If, after all, the vent pipe is located open in a living room, then it can be easily soundproofed by wrapping the pipe with strips of inexpensive polyethylene foam in two or three layers.

Installation rules

To properly install a fan riser, you must comply with the following requirements:

- The outlet of the riser should not go into the attic, but into the street. If sewer gases escape into the attic, it will smell bad and the humidity will increase (which will lead to mold).

- The diameter of the drain riser must be no less than the diameter of the sewer riser. More is acceptable, but not required.

- The pipe outlet should not be located close to a wall or near other structures (windows, balconies). Otherwise, stains from gas emissions may appear on the wall, and an unpleasant odor will be felt in the rooms near the outlet.

- The outlet should not go under the roof overhang, otherwise in winter the pipe may be damaged (due to ice or melted snow).

- For private houses, it is enough to use 1 vent riser. Lines from all plumbing points must be cut into it using tees, crosses and adapters.

- There must be a temperature difference between the lower and upper points of the pipelines (it’s warm at the bottom, cold at the top).

- The fan riser can be laid in the ventilation shaft, in one box. However, it should not be connected to ventilation ducts leading to residential premises and chimneys (according to SNiP).

- It is permissible to connect several sewer pipes to one drain riser.

Installation rules (video)

Types of scheme

According to the “direction” of the output, there are 2 options for laying:

- Horizontal - when the pipe is discharged not through the roof, but through the wall. The method is relatively rare and can only be used in private construction, in cases where for some reason the output cannot be made through the roof. In this case, a grille is installed on the hole, not a deflector.

- Vertically - the most common option: the riser is led up through the roof.

Vertical passage, in turn, is divided into 3 more subtypes:

- An outlet with a slope of 90 degrees: a branch is made from the riser at a right angle, from which there is then another branch, and from this there is a straight section extending above the roof.

- An exit with a slope of 45 degrees: a branch is made from the riser at an angle of 45 degrees, another branch is made from it, and from this there is a straight section extending above the roof.

- Vertical outlet: The riser simply continues until it exits above the roof.

The exhaust pipe exits through the roof: how is it done and what height should it be?

The section of the vent riser located outside, above the roof, must meet certain requirements:

- The height above the roofing material of the roof in use must be at least 3 meters.

- The height above a flat roof that is not in use must be at least 30 cm.

- The height above the pitched roof must be at least 50 cm.

- The horizontal distance between the pipe outlet and the nearest window (balcony) must be at least 4 meters.

- The outlet should be covered by a deflector on top. It is needed to prevent debris, insects, birds, and precipitation from getting inside.

If it is possible to draw a line through the pediment, it is better to implement this option rather than passing through the roof. In this way, you can save yourself from troublesome work with roofing material and further sealing.

How is the output through the roof made? (video)

Installation errors

The installation of a ventilation riser for a sewer system may be carried out with errors. Of the most common:

- Dismantling the riser (intentionally or unknowingly) in apartments (multi-storey buildings).

- Output under the roof overhang.

- The use of pipes of different diameters when creating a sewer system.

- Output of the riser to the attic.

- Fastening the riser to the external wall of the building.

Do you need soundproofing for a drain pipe?

Sound insulation is needed if the pipe passes through living rooms. In this case, the noise of water and air will be heard in the rooms. The pipeline itself will also make noise due to vibration and resonance.

Noise insulation of areas passing through non-residential premises is not required. If the riser is laid in the wall, and the thickness of the partition is small, then at the construction (repair) stage it is recommended to perform at least “light” sound insulation.

Ideally, the issue of sound insulation should be addressed at the design and construction stage of the building. The riser needs to be “hidden” in a separate box (shaft), or planned so that it does not pass through the living quarters. It is also recommended to use special “silent” pipes (thick-walled polypropylene products).

The sound insulation process itself is carried out using “shells” or roll insulators that are wound onto the pipeline. The thicker the layer, the more effective the insulation will be.

Is it necessary to insulate the drain pipe?

Insulation of fan risers is necessary more often than sound insulation - because warm, moist air, rising up the pipe, will condense on the walls and freeze. As a result, the pipeline freezes, becomes clogged, and stops working properly.

Insulated section of pipeline in the attic

It is necessary to insulate areas passing through unheated rooms (attic, basement).

Insulation is done in the same way as sound insulation: using rolled heat insulators or “shells”, which are fixed around the pipe.

Replacing a drain pipe: operating rules

It is necessary to replace the pipe (a section or the whole) if it is damaged or severely clogged (important for old cast iron structures).

In short, the replacement process is divided into 2 stages:

- Dismantling the old line.

- Installation of a new line.

The main rule of work when replacing a riser in apartment buildings: before replacing a section in your apartment, you must notify your neighbors about the time of the work. During this period, residents will not be able to use the toilet, sink, sink, bathtub, or washing machine.

Briefly, the dismantling process looks like this:

- The riser is completely turned off.

- All connections to the riser are cut off.

- The riser itself is dismantled.

After this, a new line is installed, to which the taps are connected in series.

About cleaning air ducts: methods, rules, frequency

Which exhaust duct to choose: comparison of options

Related Posts

Alternative

Sometimes it happens that it is simply impossible to install a ventilation pipe on the roof of a house due to the weather, the special complexity of the highways or the features of the building. In this case, installing an air valve on the sewer is used. They regulate intrasystemic pressure.

One ventilation valve is installed on the upper outlet of the sewer riser. It has a spring and a special seal made of high-quality rubber. When a vacuum appears in the air of this system, the vacuum valve simply opens, thus easily allowing fresh outside air into the system. After normalizing the pressure, the valve diaphragm closes tightly, thus effectively preventing various odors and unpleasant odors from entering the house.

Vacuum valves are also required in horizontal parts of the entire pipeline. Their total number and exact location are determined by the total length of the lines, as well as the total number of connected plumbing fixtures.

Building a house without high-quality sewer ventilation is currently not recommended. A system such as a vent riser will easily stop various odors and vapors from entering the residential part of the house, and will also provide a comfortable environment for all residents.

Selecting a water supply system and scheme for the design object

When determining the scheme of water supply networks, it is necessary to take into account that the most economical and simple schemes are obtained in cases where water taps and appliances are grouped and located on the floors of the building one above the other

Structurally, internal water supply networks can be made with upper and lower wiring, dead-end or ring. In residential and public buildings, bottom distribution of main pipes and dead-end networks are most often used.

The section of the network connecting the external and internal water supply systems to the water metering unit is called the inlet. When the external water supply is located parallel to the main facade of the building, the inlet is designed perpendicular to the building, symmetrically to the location of the sanitary fixtures. If there is a hot water supply installation in the building, the inlet should be made into the water heater room, if there is a basement - into the basement, if there is none - into the stairwell or underground channels. In the case where the street water supply pipe runs parallel to the end wall of the building, an input device may be installed through the end wall. The input length should be as short as possible. The input is laid at the depth of the street water supply network with a slope towards the street network.

To measure water flow at the entrances to the building and at the entrances to the apartments, measuring devices are provided - vane or turbine meters (water meters). They can be simple or with a bypass line. Main pipelines, distributing sections of the network and connections to devices are laid with a slope of 0.002....0.005 for draining water.

To water the territory and green spaces around the buildings, watering taps are installed, connected to the internal water pipes of these buildings (one watering tap per 60–70 m around the perimeter of the building.

The choice of internal water supply scheme is made after comparing the value of the specified guaranteed pressure in the city water supply network at the entrance to the building (Hg) with the value of the required pressure (Ntr), determined as a result of hydraulic calculation. The simplest and most common scheme - without installation for increasing pressure and water tanks - is used for round-the-clock water supply from the city network at Нg > Нtr. In the case when the required value of the guaranteed pressure is not provided only at certain hours of the day with insignificant water consumption, it is possible to use a water supply scheme with the installation of a water tank, filled periodically under the influence of an external water supply without boosting devices. To increase the pressure when there is a constant lack of it, it is possible to use local installations: a pumping installation that constantly maintains the required pressure in the system, or a pumping installation operating with a water pressure or hydropneumatic tank.

Sections and sewerage diagrams

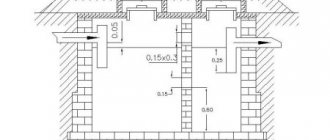

Diagrams of risers, as well as sections of sewer systems, show the location of risers and pipelines along branches and risers.

Using the letters A and B on the section that depicts the outlet pipeline next to the KK-1 sewer well, the places where there are branches from the main pipe are indicated. In addition, this section shows data such as pipe diameters, installation locations for inspections, cleanings and other fittings, as well as slopes and lengths of sections. The letters A and B, which are indicated for the sewer risers StK1-1...StK1-3 on the sections, indicate those places where the riser is connected to the main outlet into the sewer well KK-1. The place where the outlet from the sink is connected is indicated by the letter G. The siphon (hydraulic valve), located in front of the P/1 sink, is shown in the section along the outlet from the sink.

The diagrams also contain indications of those places where branches from risers should be laid along the floors to sanitary fixtures. The diagram of the risers of the K1 sewer system (Ø 100) contains instructions for the installation of inspections and the location of branches. To ensure ventilation of the risers, asbestos-cement pipes with a diameter of 150 millimeters are used. They are brought outside through the attic, and weathervanes are used to complete them.

Tips for repair and operation

Correct joining and routing of sewer lines is possible only with the help of standard drain tees and bends.

The height of the pipe above the roof must comply with established building codes and regulations.

To ensure good traction, the beginning of the fan riser in a private house should be located in a room where the temperature is higher than outside the building.

The top edge of the vent pipe should not be placed in the attic. Otherwise, the rafters may rot, and the thermal insulation material of the ceiling will become saturated with moisture.

Installing a deflector has advantages and disadvantages. This device prevents clogging of the ventilation, and in some cases increases draft. But in the cold season, the deflector contributes to the formation of condensation and subsequent icing, which will lead to a decrease in the ventilation opening.

Between the riser and balconies/windows, a distance of 4 meters or more is maintained. Sewage ventilation cannot be combined with a chimney or conventional ventilation.

You should not spend a lot of time dismantling cast iron joints. It is better to immediately cut them with a grinder and carefully break them with a hammer. You should not dismantle cast iron pipes yourself - they are very heavy.