Sewerage

Author Dmitry 779

Date

Feb 14, 2016

0

1 312

Share

Every city dweller has an idea of what a poorly functioning city storm drain is. As a rule, after a person steps in a puddle on the asphalt, a lot of dirt remains on his shoes or boots, as a result of which the quality of the shoes he wears deteriorates.

- LiveJournal

- Blogger

Storm drainage is necessary to protect the foundation of the house and basement from flooding and destruction

- Purpose and specifics of the storm drainage device

- Classification according to the method of collecting drains

- Preliminary calculations and design

- The process and specifics of installing storm drains

For a city resident, the loss of shoes is considered minor damage, but for the owner of a private house it is more serious damage.

To prevent the destruction of the foundation, as well as to prevent precipitation from getting into the basement of the house or destroying the planted plants, the owners of country cottages or summer cottages drain storm water from the house.

A simple storm drain can be installed by any owner of a private home who is not a builder by training and does not have experience in this field.

However, installing an external storm drain is not considered the easiest process. The complexity of the work lies in the preliminary preparation of the project and carrying out specific calculations.

This material talks about how storm drainage is installed in a private house - how to independently carry out drainage in a private house (installation of storm drainage).

The process and specifics of installing storm drains

The rules for constructing storm drains are similar to those used when installing conventional gutters. However, if the house does not have a drainage piping system, it must be installed.

Construction of the roofing component

When installing a drain, home owners perform the following actions:

- holes are made in the floors of the house for water collectors. After installation and installation of rainwater inlets on bitumen, the places where they adjoin the storm drain are carefully sealed;

- then, install drainpipes and risers;

- elements of the drainage pipeline system are attached to the cottage or country house with clamps;

- upon completion of the work, trays are installed - when installing a linear type drain or a water drainage tube, if the drainage pipeline system is installed according to a point pattern.

Water drainage from the roof

Installation of the underground part

After drawing up a storm drainage plan - taking into account the slopes and the specific installation depth of the channels installed in a particular region of the Russian Federation - a trench is made.

If you need to insulate the pipeline with geotextiles and crushed stone, or you need to build a sand cushion, the plan for installing the underground part of the sewer system also takes into account the power of the storm drainage elements.

Next, perform the following actions:

- Before starting installation work, the bottom of the trench is compacted. At the same time, large stones are removed from the trench, the holes from which are subsequently filled with soil;

- a sand cushion is placed on the bottom, the thickness of which is 20 cm;

- the result is a pit in which the collector is installed. A plastic container purchased in advance is used as a collector. However, you can make a collector well yourself - just pour the concrete solution into the pre-prepared formwork;

- Next, tubes are placed in the grooves, which are connected into 1 system using fitting pipeline elements;

- then, inspection wells are placed on straight 10-meter branches of the storm drain;

- Sand traps are installed at the connection points between the water collectors and the pipeline;

- As a result, all elements of the storm drain are connected into 1 circuit. In this case, the junctions of such elements are carefully sealed.

Before filling the trench, its performance is checked by pouring water into it.

If no weak points are found during testing of the trench, then after the test the pipeline system installed in the trench is buried, filling it with soil. Also, in such a situation, gutters and drainage trays with gratings are installed on the storm drain.

Upon completion of installation, the owner of the cottage or summer cottage connects the storm drainage system to the general sewer system.

So, when installing a storm drain yourself in a private household or in a country house, you need to use all the recommendations and rules for installing a drainage system that were given in this article.

Using this information, you can easily troubleshoot problems that arose during the installation of the storm drain.

By improving the storm drainage in the house and in the surrounding area, the life of the house is extended, puddles and slush do not form on the roads to the cottage or dacha, and the rotting of plants also stops.

WATCH THE VIDEO

Each owner of a country house can independently install a storm drain - without turning to professional builders for help. In such a situation, you just need to get to the heart of the matter - and everything will work out.

Where do you need a well and a collector?

As in any system consisting of underground pipes, there must be a well in the storm sewer.

Its installation is advisable in the following circumstances:

- if 2 or more flows converge;

- when it is necessary to radically change the height, direction of the pipeline or its slope;

- if there is a need to switch to a larger pipe diameter.

Wells are also provided at established intervals of straight sections of the system. If the diameter of the well does not exceed 150 mm, then the next one is located at a distance of 30 to 35 m. With a diameter of 200 mm - from 45 to 50 m, and if the diameter is 0.5 m, the interval is increased to 70-75 m.

The diameter of a well in a private house does not exceed 1 m. The deeper the well, the larger its diameter should be.

Some owners lay out wells the old fashioned way from brick or reinforced concrete rings. Others prefer more advanced materials - plastic and fiberglass. According to their design, wells are either collapsible or solid.

They have the shape of a cylinder with a completely sealed bottom and a hole at the top. There are nozzles for connecting pipes. Several assembled storm water inlets are also used as wells.

To redirect the collected water to ground treatment facilities or to a sewer, a collector is included in the system. Sometimes its role is played by a large plastic well. It is converted into a storage tank by hermetically sealing the outlet pipes. To use water, a submersible pump is used.

Large cross-section pipes are also used for the collector - reinforced concrete or plastic with all pipelines connected to them. On the construction market you can also purchase ready-made containers for underground use. There are multi-chamber tanks where rain and melt water are treated according to the same principle as in septic tanks.

Preliminary calculations and design

Construction of a storm drain without carrying out calculations is a waste of money.

After all, if the installed simple stormwater system does not work well, then there is no need to install it at all. At the same time, you need to spend a lot of money on installing too powerful a storm drain.

Information required for calculations

When designing a storm drain, the following data is used:

- the average volume of precipitation recorded by meteorologists in a particular area. Such information can be found in SNiP 2.04.03–85;

- meteorological information on the frequency of rainfall and snow depth. Such data is also used when installing storm drains to drain melt water;

- data on the drainage area - roof area. In such a situation, not the full value is taken into account, but the value of the projection of the area in the plane.

When constructing a linear stormwater system, the drainage area is equal to the sum of the areas of all drainage objects;

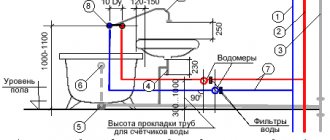

The principle of operation of the sewerage system in section

information about the physical characteristics of the soils that make up the suburban area.

Also, when carrying out calculations, pay attention to the presence and location of underground communication drainage systems already erected on the site

Calculation of the volume of drainage drains

The volume of drainage drainage is calculated using the following formula:

The correction factor values used in this formula are used at the following sites:

- 0.4 - on areas covered with crushed stone;

- 0.85 - on a concrete platform;

- 0.95 - on asphalt;

- 1.0 - on the roof.

After determining the volume values, the diameter of the pipeline drainage system is calculated according to SNiP.

Determining the installation depth of channels

Installation of trays or pipeline channels is done at the same depth at which they are installed in a particular region.

Owners of dachas and private households can find out specific depth values from a construction company or from a neighbor who has already installed a storm drain on his property.

In the central regions of the Russian Federation, storm drains are installed at a depth of 0.3 m, if the diameter of the tray is 50 cm as a maximum. Large reinforced concrete, metal or plastic drainage trays and pipes are installed at a depth of 0.7 m.

Due to the high cost of excavation work, many owners of country houses do not make deep indentations into the ground. In addition, when installing a storm drain with your own hands, there is no need to bury it too deep underground.

According to GOSTs, collectors and inspection wells are installed at the level of seasonal freezing, and not below. Also, these storm drain elements can be installed above this level - while the collectors and inspection wells are insulated with geotextiles and crushed stone, which protects the storm drain from freezing.

Due to the small recess, the complexity of installation is significantly reduced.

In such a situation, storm channels are installed at a specific angle to the drainage and treatment devices of the drainage system.

Construction and location of wastewater pipes

Accordingly, the installation level of the entry point into the collector well is below the installation level of the catchment or tube, which extends from the rainwater inlet. When calculating the depth of their installation, an installation plan is drawn up in advance and, taking into account the slopes of the drainage channels, all the necessary calculations are made.

Standards and norms of slopes

According to GOST, tubes with a diameter of 150 mm are installed at an angle of 0.008 (the amount of inclination is measured in mm/m). The tubes, which have a diameter of 200 mm, are placed at an angle of 0.007.

Depending on the characteristics of the area where the storm drain is laid, installers slightly change the values of the pipe slopes.

A slope of 0.02 is made at the junction of the drainage channels and the drainage basin, because in such a place the drainage speed increases.

Water flows slower to the sand trap than in other areas of the storm drain. In such a situation, suspended particles settle. In this regard, the angle of inclination in this place is made the smallest.

Catchments in storm drains that have a drain with a sand trap (drain funnel) are placed in those places where the pipe slopes intersect with each other.

What does a storm drain consist of?

Before you buy a storm drain, you need to decide what elements it consists of. In fact, its design is standard. But different systems may have some differences related to their purpose and landscape features.

Among the main elements of storm drainage are the following:

- Storm water inlets. An important component of the system. They are installed in places where water accumulates, on areas impenetrable to water.

- Filter cartridge. It is used for storm drainage to filter mechanical impurities, heavy particles, and petroleum products.

- Door pallets. They perform the same task as rainwater inlets. Typically, pallets are installed where there is a door, where water should not accumulate: under garage doors, building doors, at the porch, under the gate.

- Trays and gutters. They direct water from the rainwater inlet to the collector. They are mounted above the ground on a slope so that water flows by gravity.

- Sand traps. These devices are special filters for storm sewers that prevent sand, soil and other small particles from entering the drainage system along with water.

- Pipes. They perform the same task as gutters. They are also installed on a slope, but already underground. They are used when it is not possible to lay a gutter or ditch.

- Inspection wells. They are used for periodic inspections, repair work, and removal of blockages.

Sand trap installation

Video - installation of a sand trap

Before you begin installing sand traps in a storm sewer system, you should familiarize yourself with some important principles that should not be neglected in the process:

- The first thing you should take care of is the presence of a ditch for the sand catcher, which is lined with sand with the addition of gravel or crushed stone.

- Precisely determine the location for installation, which should be in the gap between the gutters and the drain transporting water to the central receiver.

- Care should be taken to ensure that the top of the cleaning device is protected by a grid with locking joints. For devices made of concrete, gratings of similar material are usually used. Cast iron lattice structures are used for concrete fixtures.

- The last nuance will be to provide sufficient space for periodic cleaning of the device from accumulated debris and sand. Regular cleaning of this device is very important, since when the sewer system is heavily contaminated, not only does the work stop, but buildings and roads also begin to be destroyed due to the fact that water begins to wash them away.

Considering the difference in overall dimensions of devices relative to the place where the sand trap is used, it is better to consider the installation using the example of a private house or plot. The correct installation process can be described by the following steps, the material of the device is plastic:

- To prevent the sand catcher for storm drainage from floating up, care should be taken to lay a concrete slab that secures the sand catcher using belts. The dimensions of such a slab should not be smaller than the size of the device, even a little larger, and it should weigh more than a sand trap with water. It is possible to use metal plates in this design.

- The calculation of a concrete slab is made based on the fact that its specific gravity exceeds 2.5 times the mass of water. If the sand catcher has a volume of 2 m3, then the mass of the slab should exceed 800 kg, taking into account that its thickness is 15 cm. Calculations for other situations are carried out in a similar way.

- To attach the belts to the slab, it is necessary to construct locking connections, which must be attached to holes prepared in advance. Locks can be attached either using anchors or using welding equipment.

- If the sand trap is installed at a high level due to the fact that groundwater is quite close, then the installation is carried out excluding weighting agents.

- If the device is installed where a sufficiently large load on the soil layer is expected, then the slab must also be laid at the top of the structure.

- In the outer part of the pit, the sand catcher is secured using belts, after which up to 40 cm of sand fraction or crushed stone is poured onto the bottom and compacted.

- After this, the device itself is installed for cleaning sand from waste water streams, which must be filled 1/3 with water.

- The next step is to fasten the device using a belt structure and fill everything with sand and soil up to 2/3 of the level of the sand trap. The backfill is compacted every 30 cm.

- If the cleaning equipment was installed without a weight plate, the backfill can be made into a single layer.

- The last step in installing a sand trap for storm drainage is to connect it to the entire system, and then continue backfilling until it is all the way to the top. It should also be compacted thoroughly.

Species diversity of designs

There are two characteristics that underlie the division into types of sand traps. The first is the shape that the device has; some operating features depend on this.

| Type | Description |

| Horizontal | This type of sand catcher is an elongated rectangle, which is represented internally in two parts. One of them is the operating area of the device, the other is for the deposition of dirt particles, which accumulates debris in its internal space. The movement of water inside a sand trap for storm drainage of this type occurs in a forward direction and in a circular flow. |

| Vertical | It is designed in such a way that, due to the vertical location of the container, dirt particles settle to the bottom spontaneously, and cleaner water passes further through the system, exiting through the hole intended for this purpose. |

| Tangential | This type of sand catcher works by installing drains that run tangentially. Due to this, the incoming water flow collides with the walls, after which it swirls. The created water vortex helps clean the water flow from dirt impurities that settle at the bottom. The remaining water flows unhindered through the stormwater system. |

| Aerated | It is represented by a rectangular container that contains a special filter element called an aerator. The filter purifies the flow of water entering the sewerage system. |

Important: sand traps of the tangential and aerated types are considered to be among the most effective in operation; they are capable of retaining 95% of mud particles and sand.

The second feature that is included in the gradation of sand trap varieties is the material that was used in the production of the device:

| Concrete | Plastic | Polymer concrete |

| The very first material that began to be used in the manufacture of sand traps. at that time, this was the only opportunity to design a device that was reliable and best met the necessary requirements. To this day they have the status of the most durable devices for cleaning sand from sewers. | Devices made from such material are much easier to install and are not too inferior in strength qualities than the previous ones. There is a possibility of use on an industrial scale. | A relatively new material in the production of sand traps, which is characterized by high strength parameters. In addition, replacing part of the composition of the material for production reduces their cost in relation to those made from concrete. |

Of the listed varieties, regarding the material of manufacture, we can distinguish those made from plastic. Their advantages over others are as follows:

- Due to the fact that high-strength plastic is used in production, sand traps are not subject to deformation even with strong impacts and changes in temperature, and are also resistant to substances of chemical origin that can be aggressive.

- Plastic devices have special holes that simplify the connection of gutters and the sewerage system itself. The diameter of the hole is the same as the holes intended for pipes and is equal to 100 mm.

- The ease of transportation of the devices is due to the fact that the plastic material is small and the devices themselves are small-sized.

- The possibility of using this type of device for any storm sewer system. It is possible to install them both in a private house or cottage, and in parking lots and car washes.

- The plastic structure of the sand trap traps up to 95% of the debris coming with water flows through the sewerage system, because it is equipped with special lattice devices inside the structure.

- Belongs to class C in terms of load level.

Principle of operation

The functioning of sand traps is based on the use of gravity

When calculating the characteristics of a structure, it is taken into account that sand and other heavy particles should precipitate in them, but impurities of organic origin should not settle. For urban wastewater treatment plants, sand traps are built from reinforced concrete elements

Aerated sand traps are structures with translational and rotational movement of liquid. They are constructed in the form of elongated tanks. The rotational movement of wastewater in these sand traps is created by the aeration of the wastewater that is contained in it. In addition, horizontal and vertical sand traps are designed (design of a receiving unit).

Due to the movement of water, each particle in the drain is influenced not only by gravitational, but also by centrifugal forces. As a result of this, an intensive process of separation of sand from water and organic particles occurs, which, due to growth, remain in a suspended state.

The amount of sand that falls in aerated sand traps depends on many factors:

- length of the sewer network;

- slopes on pipeline sections;

- the sewage system used;

- composition of wastewater;

- network operating conditions, etc.

For the city sewer network, the following volume of sediment in sand traps is accepted per person per day (with a humidity of about 60% and a density of 1500 kg/m3):

- with a general alloy system - 0.04 l;

- with separate – 0.02 l.

Fig 02 – Sand trap

Characteristics and Features

Aerators are tripled along the wall of the aerated sand trap (45–60 cm from the bottom of the tank), under which trays are laid to collect sediment. For efficient operation, the bottom of the sand trap is arranged with a slope of 0.2–0.4 to collect sand. When calculating a sand trap, a rotational speed along the perimeter of the structure’s section is assumed to be 0.25–0.3 m/s and a translational speed of 0.08–0.12 m/s. The residence time of wastewater in an aerated sand trap is 2–3 minutes.

To maintain the required rotational speed, 3–5 m3 of air per 1 m2 of structure area is supplied to the sand trap tank per 1 hour. The rotation is maintained at a constant level without reference to the volume of incoming wastewater. If all necessary conditions are met, the output from aerated sand traps is a sediment with a minimum amount of organic impurities. The resulting sediment contains up to 95% sand, which does not rot during long-term storage.

Aerators, which are used in sand traps, are made of plastic pipelines with holes up to 5 mm. Sand is removed from the surface of the tray using a flush pipeline. The sediment is washed off without stopping the structure. The wastewater cleared of sand is fed into settling tanks.

Fig 03 – Diagram of an aerated sand trap

In addition to aerated ones, other types of sand traps are used at urban sewage treatment plants:

- horizontal (more than 10,000 m3/day) – elongated rectangular tanks with linear movement;

- vertical - with the movement of wastewater from bottom to top (rarely used in modern conditions);

- tangential, which are a structure with rotational movement of wastewater (up to 50,000 m3/day).

The installation of sand traps is mandatory in structures with a volume of processed wastewater above 100 m3/day.

| We work all over Russia | Contacts. Tel/f +; [email protected] |

- Terms of use

- Personal data processing policy

Features and purpose

Storm drainage, or, as it is often called, rainwater drainage, is a system of water pipes, as well as filters and various devices used to effectively remove excess moisture from the local area.

This is the main task of storm drainage, but the range of functions is not limited to drainage:

- with the help of a stormwater system, you can organize watering of the garden and vegetable garden on your personal plot; the positive effect of melt water on the growth and development of plants is known to every summer resident;

- increasing the durability of the building and improving the strength and strength of its supports - this is due to the fact that rainwater drainage eliminates excessive flooding of the foundation, and in addition, prevents the development of fungus and mold;

- high-quality filtration of water and purification from sand and other types of impurities;

- maintaining the integrity of paving slabs and asphalt coatings, which are often destroyed under the influence of pounding jets of water;

- minimizing the risk of water flowing into the base;

- complete elimination of the formation of puddles and dirt on the site after rain.

Description and principle of operation of sand traps

Sand traps are used to retain sand and other impurities from wastewater with a particle size of more than 0.15-0.25 mm at wastewater flow rates of more than 100 m3/day. The number of sand trap compartments is accepted to be at least two, both of which are working. Depending on the direction of the main flow of wastewater, sand traps are divided into vertical and horizontal, which, in turn, are divided into simple and aerated. The type of sand trap must be selected taking into account its throughput, wastewater composition and local construction conditions.

Horizontal sand traps with circular movement of wastewater are designed to remove sand from wastewater that has a neutral or slightly alkaline reaction. Wastewater is supplied to sand traps and removed from them by trays. To turn off the sand traps from operation, shutters are installed on the supply trays in the distribution chamber. Sediment from sand traps is removed by hydraulic elevators. The supply of working fluid to the hydraulic elevators and the removal of pulp are carried out by independent pressure pipelines, through a switching chamber equipped with valves.

Horizontal sand traps with linear movement of wastewater and a throughput capacity of 70-280 thousand m3/day are used at a number of sewer aeration stations. Sand traps work effectively when the average speeds are equalized along their length. This is achieved by using single flat gratings at the inlet device, made of wooden rods 15 cm wide with gaps of 6 cm. In sand traps with gratings of this design, the water load is increased by increasing the flow rate while maintaining the efficiency of sand retention.

Aerated sand traps are used to separate mineral particles contained in wastewater with a hydraulic particle size of 13–18 mm/s.

The supply of wastewater to the sand traps and its removal are carried out by open trays. The aeration system uses air from a pump-air station. The sediment is washed into the sand trap bunker by a hydromechanical system, including a longitudinal tray and pipelines with sprays; the sediment is removed from the bunker using a hydraulic elevator. Aerated sand traps are made in the form of horizontal tanks. Aerators are installed along one of the walls at a distance of 45-60 cm from the bottom along the entire length of the sand trap, and a trench for sand is installed under them. The cross section of the bottom is sloped

i = 0.2-0.4 to the central tray for gravity discharge of sand mass into it.

Vertical sand traps consist of a receiving and settling compartment and a sedimentary part. The sand trap can be round or rectangular in plan and should consist of two sections.

When the throughput of mechanical treatment facilities is more than 100 m3/day of wastewater, a vertical sand trap of a tangential type or a sand trap with a downward-ascending movement of liquid is used.

The operation of such sand traps is based on a qualitatively new principle. Wastewater enters the sand trap tangentially, resulting in its rotational movement. The sand contained in the wastewater is pressed against the walls due to centrifugal force and is separated from the water as a result of the resulting downward flow.

The removal of water from the sand trap by a central telescopic pipe further intensifies the separation of sand by creating a water funnel around the receiving hole of the pipe. Sand is washed from organic impurities during its removal in a screw sand washer.

Tips for choosing

It is recommended to rely on the following criteria when choosing a sand trap:

- the material of the product and its weight must be suitable for storm drainage;

- it is necessary to choose the optimal form for draining;

- the device must withstand high water speed;

- the dimensions of the device must be selected taking into account the entire sewerage system;

- the model should capture as many mineral impurities as possible.

The use of sand collectors will increase the permeability of water through the pipes and increase the service life of the entire drainage system.

Principle of operation

Of course, the easiest way is to choose and purchase a ready-made sandblasting unit, but not everyone can afford it.

A way out of the situation may be to rent the device, but in this case its service life will be limited, and in the event of any breakdown, you will have to pay for repairs.

Anyone who is familiar with the basics of mechanics and regularly needs a sandblasting device designed to process various types of surfaces, but does not have extra money, can easily assemble it with his own hands.

Such an automatic homemade sandblasting machine, if the assembly technology is followed, will in no way be inferior in its functionality to a device assembled at a factory.

In this case, you will have to make some efforts and acquire all the necessary materials and tools that will be required during the work process.

First of all, it is necessary to thoroughly study the principle of operation of the sandblasting machine and understand the basic diagram of its operation.

The compressor, which is part of the operating circuit of the device, supplies air under high pressure, which, capturing the abrasive material, is delivered to the surface requiring treatment using a nozzle.

For a homemade device, it is better to use a factory compressor capable of creating the required pressure. In some cases, it is possible to create the necessary pressure in the system using a gas cylinder.

In addition to the air source, the general design of the device must include supply hoses of a given diameter, cables, and a main power source.

The operation of a sandblasting unit is also impossible without a special nozzle, which has some design features.

It should also be noted that the nozzle material should be either tungsten carbide or boron. You should absolutely not use nozzles made of cast iron or ceramics, as they will fail very quickly.

The photo below shows sandblasting machines and factory-made nozzles, which are suitable for processing various types of surfaces.