What it is?

This is a special container into which liquid flows from pipes installed on the facade of the house. This tank must be made of durable material as it faces soil pressure, mechanical loads and water pressure. Storm sewer inlets should not be subject to corrosion.

A rainwater well with a grate can be round, square, oval, or rectangular. This fact does not affect the performance characteristics in any way. The choice of form may be influenced by the design features and style.

Kinds

Stormwater receivers differ in size, weight, shape and type of raw materials.

They are made of durable materials that can withstand significant external loads from transport, soil pressure and powerful water pressure.

Concrete

Storm water inlets are divided into main, light and heavy.

- Trunk - massive reinforced concrete products with a wall thickness of about 50 mm. Installation of heavy structures requires special equipment and lifting equipment. Installed in areas of high loads: during the construction of roads, airfields, large industrial facilities. Capable of withstanding long-term external influences weighing up to 90 tons from heavy vehicles, aircraft and lifting mechanisms.

- Heavy - mounted on pedestrian squares, roads with limited traffic flow, gas stations and service stations. Reinforced concrete products with a wall thickness of at least 30 mm are designed for loads of up to thirty tons.

Grids and hatches for main and heavy rainwater inlets are made from cast iron.

- Lightweight ones are used for installation under drainpipes located on the facades of buildings, garden plots of private houses, and in pedestrian areas. They are mainly made of polymer concrete, with a wall thickness of up to 20 mm. They have a cubic shape. Equipped with plastic outlets. Standard parameters for lightweight rainwater inlets are 400×400 mm.

Fig. 3. Concrete storm water inlet.

Concrete storm water inlets are characterized by a long service life, reliability, and resistance to low and high temperatures.

In low-rise private construction, concrete structures are used extremely rarely due to their heavy weight and complex installation.

Cast iron

They are gaining great popularity in modern road construction due to their resistance to the aggressive effects of deicing agents and significant loads.

They are used to equip storm drains on sidewalks, roads, and other places where melt and rainwater may accumulate.

Cast iron structures are available in several modifications:

- DM - small storm water inlets weighing 80 kg, designed for loads up to 12.5 tons;

- DB - large rainwater reservoirs, weighing from 115 kg, withstanding loads of up to 25 tons;

- DCs are round receiving structures, weighing about 100 kg, with a design load of up to 15 tons.

Rice. 4. The storm water inlet is round. Cast iron.

Cast iron structures intended for private construction are marked “DB 1”. They are small in size and lighter in weight.

Cast iron rainwater inlets have significant advantages over similar structures made from other materials:

- high wastewater throughput;

- strength and resistance to mechanical loads;

- durability;

- environmental cleanliness;

- resistance to sudden temperature changes;

- affordable price.

Disadvantages include heavy weight and susceptibility to corrosion. In addition, cast iron parts of rainwater inlets often become objects of theft, and therefore require additional locking elements.

Plastic

Frost-resistant polypropylene, resistant to atmospheric and chemical influences, is used as a raw material in the production of plastic structures.

Plastic storm water inlets are very popular when installing storm drains in private homes, garden plots, on sidewalks, courtyard driveways and city roads.

Products are produced designed for loads from 1.5 to 90 tons.

The cast iron grate increases the strength of the structure and allows the use of plastic storm water inlets in traffic areas. To bring the system to the desired height, they can be installed in several levels.

The low weight allows the installation of plastic structures without the use of lifting mechanisms. They have a relatively low price. They do not emit toxic substances into the atmosphere or soil. Withstands temperature changes from -40°C to +90°C.

Plastic rainwater inlets are easy to maintain. To clean the container, simply remove the basket, remove debris, and rinse with water. In addition, plastic structures have smooth internal walls, allowing water to flow freely into the storm drain.

Composite

Round or square storm water inlets are made of polymer concrete or polymer sand. Composite structures can withstand loads from 15 to 40 tons.

According to their technical characteristics, storm water inlets combine the technical and operational characteristics of reinforced concrete and plastic products.

Grids for composite rainwater inlets can be made of cast iron or steel.

ACO Self rain inlet made of polymer concrete with a cast iron grate without edging 250x250x350 mm

In stock RUR 6,718

Buy in cart

ACO Self rain inlet made of polymer concrete with a cast iron grate with a galvanized steel edging...

In stock RUR 9,358

Buy in cart

Attachment for ACO Self rainwater drain to increase height without grille

In stock RUR 3,135

Buy in cart

ACO Self rain inlet made of polymer concrete with a stainless steel grate with galvanized edging...

In stock RUR 20,958

Buy in cart

What does it consist of?

If you compare storm drains, you will notice that they differ in weight, size and some other features. According to the standard, the depth of the device is 400 mm. As a rule, they are light in weight, except when cast iron is used as the material.

Please note! Reservoirs can be sold as a complete set or individual elements.

Consists of the following parts:

- The container itself.

- A basket that is installed inside the water intake.

- Partition or siphon.

- External grille.

In different types, these elements can be made of different materials, which affects the final quality of the product. As for the grille, it is necessary to choose a high-quality and durable one, since it encounters mechanical stress when pedestrians walk and even when hit by a car.

Installation technology

The efficiency of the rainwater drainage system depends on the correct choice of location.

When installing storm water inlets, the following rules should be followed:

- drainage structures are placed in areas of greatest accumulation of water;

- the outlet pipeline must be placed with a slope of at least 20 mm/1 m. item for pipelines Ø 110 millimeters. With smaller pipe diameters and contaminated wastewater, the slope increases;

- The drainpipe must be positioned in such a way that it is possible to easily remove the storm inlet grate and remove the sand trap container.

When installing rainwater containers, it must be taken into account that the sand collection basket must be cleaned every two to three months. To do this, you need to ensure its unhindered extraction.

Storm water inlets are installed in a certain order:

- The soil is excavated 300 - 400 mm below the height of the receiving tank.

- Sand preparation of the bottom of the pit is carried out with layer-by-layer compaction. Each layer of sand is spilled with water and compacted well.

- A layer of cement-sand mortar or concrete is laid at the bottom of the pit.

- A rainwater inlet tank is installed and connected to pipelines or storm drainage trays.

- The structure is verified by elevation marks so that the receiver grid strictly corresponds to the top mark of the road surface or paving slabs.

Rice. 6. Monitoring the position of the rainwater inlet.

- The structure is fixed with cement-sand mortar and covered with a grating.

- Storm sewer pipelines are connected to the storm water inlet, and the system is tested for functionality with a flow of water.

After installing the rainwater inlet, the seam between the structure and the adjacent coating is sealed.

How to choose

Regardless of the type of drainage tank, it is necessary to select it correctly. First of all, the following factors should be taken into account:

- Estimated amount of precipitation in your area and its intensity.

- The area of the rainwater collection system.

- Features of the landscape of the local area.

If we are talking about installation near the house, then it is enough to choose a lightweight plastic drain. If there is heavy rainfall in your area, then it is better to give preference to products made of cast iron, as it copes with heavy loads more effectively. It may be worth purchasing a device for several sections or a single section will be enough. Plus, it’s good when the design has a removable basket, a siphon and a primary filter for cleaning.

What are rainwater inlets for storm drainage?

A storm water inlet is a special container that is installed in places with the highest concentration of precipitation - rain, snow. The systems are installed above water pipes or in low areas of the site.

Storm drainage consists of several elements, the main one of which is a rainwater inlet. The devices have different designs. They are distinguished by the material they are made of.

An equally important criterion when choosing a specific model is the ability to withstand weight loads.

The device consists of a lattice frame, which is fixed on the surface of the water intake well.

Purpose

A drainage structure—a rain inlet—removes excess liquid, protects the foundation of a residential building from flooding with sewage, and protects asphalt and tiles from premature destruction due to the negative effects of moisture.

The condition of the building and the garden plot depends on how correctly the structure is selected and installed.

Locations

If the water intake element is installed incorrectly, this can lead to the accumulation of water in the local area. In this matter, it is necessary to build on the approved provisions of GOST and SNiP. The fundamental norm from which to build is SNiP 2.04.03-85 “Sewerage. External networks and structures." In particular, GOST 26008-83 provides for the mandatory installation of rainwater inlets in the following places:

- On long descents.

- In places where sidewalk paths intersect.

- In low areas along the terrain.

- In all places where there is no natural outflow of water from rain, melted snow, etc.

- Under the drainpipe.

- Along the edges of highways.

- Before entering the building.

Design features, application

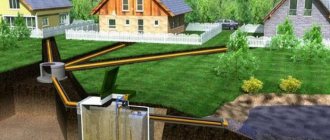

Point drainage systems of the standard S'park and Basic series are made of plastic and are used for local removal of wastewater. Can be installed under roof drainage outlets or at the lowest point on the site. Stormwater wells are designed to organize a point drainage system in areas of high dynamic load, in areas of heavy heavy vehicle traffic (roadsides, gas stations, sites of industrial enterprises, warehouse areas, etc.). In addition, the products are used as a sand trap for reinforced series concrete and polymer concrete trays with a hydraulic cross-section of 300, 400 and 500 mm, respectively, as well as a drainage well.

The design is thought out to the smallest detail; it is possible to install one on top of another to increase the height. For connections with trays and pipes, there are blanks for making holes (more detailed parameters can be found directly in the diagrams of a specific element).

Features of installation and installation with your own hands

The installation of the highway begins with earthworks. However, before this it is recommended to prepare a project and make a drawing. Thanks to this, you can determine what kind of installation scheme will be: point or linear. Moreover, before starting work, you should determine the dimensions of the blind area. The process looks like this:

- A pit is dug according to the depth of the purchased receiver. It is necessary to add 400 mm to this depth. As for the width, at the edges it should be 30 mm wider on all sides. This will allow you to install a well water receiver and fix it with concrete.

- Next, the base is prepared. A cushion of sand and crushed stone is made at the bottom. To compact it well, first water it with water.

- Pre-install it in the pit and connect it to the sewer and drain pipes. Make sure that the drainage level is completely maintained. The settling receiver must be level, and at the same time the pipes from it must diverge with a slope.

- After checking everything, pour a small amount of concrete onto the bottom.

- Next, press the rainwater inlet tightly, but so that the nozzles coincide with the pipes.

- It is also necessary to immediately fill the areas around it with concrete.

- Finally, all that remains is to complete the assembly by installing the basket, siphon, grill, etc.

Purpose and design of rainwater inlets

The presence of a storm water inlet in the storm water drainage system is mandatory, since it is through it that water enters the pipes or gutters. If we talk about the construction of a rainwater inlet for storm drainage, then it is a complex rectangular or oval-shaped structure, consisting of several parts.

Stormwater inlet installation diagram

A typical modern water receiver includes the following components:

- The grille covers the structure from above and serves not only for decorative purposes, but also to protect a person from possible injuries. In addition, plastic or cast iron storm inlet grates serve as a primary filter, that is, they do not allow large debris to enter the sewer system.

- A storm inlet is a square or round structure that serves to direct water into the drainage system.

- The sand filter is a part of the design that is not present in all models. Serves to prevent small particles of soil, sand and other debris from getting into the sewer with water. Such a filter is located below the rainwater inlet tray, so debris particles simply sink to its bottom, and the water rises to the level of the outlet from the inlet.

Note! The garbage filter must be cleaned regularly, otherwise over time an unpleasant odor may appear as water evaporates from the tray.

The grid prevents large debris from getting inside the receiver

Maintenance, operation and care

In order for the water drainage system, drainage and similar communications to work properly, it is necessary to take seriously the rules for operating the rainwater inlet. The whole point of care comes down to emptying the trash bin in a timely manner. 2-3 times a month is enough. If there was little rain during this period, then cleaning is not necessary.

Important! If there is heavy precipitation in your area, then care must be taken to clean not only the receiver itself, but also the pipes leading from it.

Types of rainwater inlet structures

Products are divided depending on the permissible load. Each type is marked with a specific letter:

| Marking | Load maximum (t) | Installation locations |

| A | 1,5 | Garden plots, sidewalks, places without access to vehicles. |

| IN | 12,5 | Near houses and garages, gardening and entertainment areas. |

| WITH | 25 | Highways, parking lots, gas stations. |

| D | 40 | Routes where heavy vehicles are allowed. |

| E | 60 | Sections of roads with increased traffic load, parking for trucks and special equipment, near industrial complexes. |

| F | 90 | Airfields, military bases. |

The size and weight of the device depend on the load class. The most durable structures are reinforced concrete and cast iron. Such storm drains can weigh up to several tons.

Stormwater volume calculator

Usually, the determination of the volume of storm drains is carried out when designing storm sewers in public utilities; in individual housing construction, calculations are not relevant if water is drained outside the site. It is clear that the standard diameter of outlet pipes is 110 mm. in a set with industrially produced storm water inlets, will ensure the transportation of any water volumes that may appear on the site after a rainstorm or spring flood.

Calculating the amount of storm drains is important if they are discharged into a storage tank, the volume of which must be determined to avoid overflowing. The easiest way to make calculations is to use an online calculator; in this case, the amount of water collected from the entire site is calculated using the following formula:

Q = q x F x Y, where

Q is the total volume of storm water on an individual site;

q is a coefficient characterizing the intensity of precipitation in a given area. Determined from tabular data from metrological or design organizations, as well as from special maps and diagrams for a given area, measured in liters per second per unit area (hectare).

F is the surface area of the area from which water is collected; it can be the roofs of houses and outbuildings or a landscaped area around a private house. For the convenience of calculations on calculators, this parameter is entered in square meters.

Y is a tabular coefficient characterizing the absorbing properties of the surface from which drainage is carried out. The standard calculator for calculations, instead of this Y indicator, includes a list of various surfaces: roofing, asphalt, paving slabs, turf.

After entering the data, the desired value is obtained in liters per second, minute, or cubic meters per hour.

Rice. 15 Drainage maintenance - examples