When arranging a country house, it is very important to equip an efficient sewage system. A septic tank is most often used to dispose of wastewater. Conventional settling tanks have today been replaced by modern installations with forced aeration. Let's figure out what functions an aerator for a septic tank performs and how you can make it yourself.

To efficiently clean sewage, biological treatment methods are used that occur under conditions of forced aeration. All modern aerobic installations are already equipped with aerators. But if a regular septic tank is installed on the site, then it can be modified by equipping it with additional equipment, which will significantly improve the quality of cleaning.

How is the cleaning done?

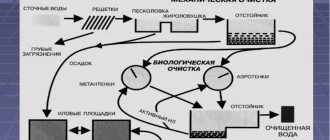

In fact, any septic tank is a sealed container in which wastewater treatment processes take place. Biological purification occurs due to the vital activity of microorganisms. Bacteria decompose organic matter to form water and insoluble sediment - sludge.

In conventional energy-independent installations, the main cleaning occurs under the influence of anaerobic bacteria. These microorganisms do not require oxygen to function. But anaerobes are not able to completely decompose organic matter; in addition, the processes under their influence proceed very slowly.

Advice! During the life of anaerobic microorganisms, methane and other gases are released. Therefore, the septic tank must be equipped with ventilation. Naturally, the smell coming from the septic tank is not the most pleasant.

To speed up the cleaning process, another type of microorganism is used – aerobic. These bacteria need oxygen, so the chambers are equipped with aerators.

Process technology

Aeration is the process of forced air supply under pressure. Air is supplied to the liquid medium in the form of small bubbles, and two processes are carried out at once:

- active mixing of the environment;

- saturating it with oxygen.

As a result, contaminated water is mixed with active biological mass, and this ensures complete purification of the liquid. When carrying out aerobic cleaning, methane and other unpleasant-smelling gases are not released, so a working septic tank does not cause discomfort to the people living in the house. However, the presence of ventilation when installing aerobic septic tanks is mandatory.

Video

The following video shows how to assemble an ejector aerator using available materials:

https://youtube.com/watch?v=zajecdTrEdg

How to assemble a wind turbine for a wind aerator, see below:

The popularity of artificial ponds has never faded. Now such reservoirs have reached a new level; they can be found in many private properties. The sizes can be very diverse, depending on the purpose of their creation. For the normal functioning of reservoirs, you need to take care of creating a pond aerator with your own hands, which is quite possible, so as not to spend money on ready-made models.

What are aerators needed for?

First of all, they provide purification and simultaneous saturation of water with oxygen, and this in turn prevents water from stagnating. In addition, without purification, the water will bloom, and the smell from it will become unbearable.

What should it be?

You can install a ready-made aerator in the septic tank or make this “device” yourself. What should it be like? High quality aerator:

- must be resistant to corrosion processes, the device will have to work in not the most favorable conditions, since sewage is a rather aggressive environment;

- the device must be reliable, since in most cases the aerator is installed at the bottom of the tank, so replacing it is a difficult task;

- the aerator must operate without creating significant noise, since the constant noise emanating from the septic tank cannot but irritate the residents.

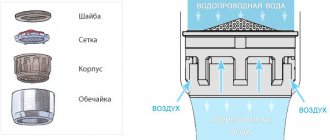

There are tubular and disk models, let’s look at their features.

Tubular models

The simplest option is a tubular aerator; features of this model:

- simple design, you can easily make and install it yourself;

- models in the form of flexible tubes are a universal option, they are easy to install and are durable;

- the likelihood of contamination of the holes is very low;

- When installed correctly, the air is evenly distributed throughout the medium without loss of pressure.

Disc models

Disk models are no less convenient to use, and their features are:

- this is an ideal aerator for high-capacity stations;

- disk models are produced in several sizes, the most popular options with a diameter of 0.225 and 0.31 meters;

- liquid getting inside the aerator is excluded, so the likelihood of clogging the hole is almost zero.

Aerator for septic tank

For a country house, the efficient functioning of the wastewater system is very important.

A sump tank is used to clean wastewater from private houses. The best option is to use a sump with a forced aeration function. For this device to work, you will need a special device - an aerator.

Purpose

Why is it needed? To do this, we will consider the processes of purification of drainage masses in the sump structure. A septic tank can have one, two or three compartments.

The operating principle of all sedimentation tanks is similar. In fact, everything is represented by an ordinary sealed container with the cleaning processes of the drainage masses occurring inside. Contaminated liquid from your home is pumped into it, processed and initially purified.

A septic tank made of concrete rings can also vary in size. So, one- and two-chamber septic tanks hold different volumes of wastewater. Whatever design is used, the purification property of the septic tank lies in the internal process that occurs, because of which the wastewater is purified.

Bacteria living in the sump trap the pollutants. Thus, due to the activity of microorganisms, biological purification takes place. Microorganisms decompose organic matter into liquid and insoluble sediment - silt. As a result, all harmful elements fall to the bottom of the sump.

These devices contain 2 types of bacteria - aerobic, which require oxygen to maintain life, and anaerobic, which do not need it.

Ventilation of the sump is necessary because these bacteria produce toxic gases.

The settling tank must have a ventilation system, since anaerobic bacteria release ha and, as a result, an unpleasant odor.

Conventional energy-dependent installations are designed in such a way that cleaning processes occur due to anaerobic microorganisms. But they do not completely decompose organic matter, and they also act rather slowly.

For better wastewater treatment, a biological treatment method is used, which occurs using forced aeration. Aeration is the forced supply of oxygen under pressure. Aerobic installations of new production already have an aerator. If you have a simple sump built a long time ago, then it can be improved by using additional equipment.

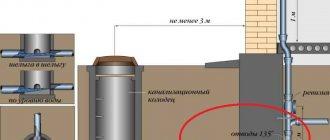

Simple settling tanks are equipped with vent pipes to allow gases from decomposed organic compounds to escape. But this type of system will not be able to create the volume of air you need in the tank.

The normal operation of a septic tank depends, in addition to ventilation, also on oxygen saturation. And if your task is to benefit the sump, then you need to provide properly functioning aeration and ventilation to remove toxic gases retained in it.

Therefore, a ventilation pipe is built into the septic tank, the function of which is to remove these gases using pressure. An important point is that the pipe must be at least half a meter above the ground. This helps to remove all toxic elements that cause harm and clog the sump.

And to do the job you will need an aerator. This device is installed on the bottom of the container, provides internal ventilation and, accordingly, air ingress. The treated oxygen is removed through the normal ventilation system.

Principle of operation

The aeration element in the sewer system serves as a distributor of air masses.

Better wastewater treatment occurs due to fine aeration. This is when oxygen enters liquid masses in small bubbles. The principle of operation is that the aerator has many tiny holes through which oxygen passes, supplied by the compressor. Oxygen passes through the aerator and forms many bubbles that are distributed throughout the liquid. The environment is saturated with air due to the fact that, according to the law of physics, oxygen bubbles tend upward, and a cleansing process occurs.

The active biological mass is mixed with contaminated water, which ensures complete water purification. During the cleaning process, no unpleasant-smelling gases are released and the operation of the septic tank does not create uncomfortable conditions for residents.

A septic tank can also have intermittent aeration. But you need to take into account the nuance that at the moment when air does not flow, the holes must be in the closed position, otherwise silt particles may enter the device.

Self-production and installation

If you want to modify a regular septic tank, you can make and install an aerator yourself. The work is not too difficult; even an inexperienced master can handle it. A simple tubular aerator is made as follows:

- the base will be a pipe with a diameter of 50 mm and a length of 1-2 meters, depending on the size of the tank;

- one end of the pipe is closed with a plug;

- a pipe is installed on the other, with the help of which the pipe will be connected to the compressor hose;

- 200-400 holes need to be drilled on the surface of the pipe. All holes must have the same diameter and be located evenly over the surface; only in this case will full aeration of the environment be ensured.

An aerator is installed in the second chamber of the septic tank, where wastewater enters, already initially cleared of large inclusions, which settle to the bottom of the first chamber.

Features of the creation process

Aeration makes it possible to obtain a healthy and attractive plant cover for the lawn. Thanks to it, the number of dry stems noticeably decreases, and the lawn is covered with less moss. Upon completion of this procedure, the plantings will be provided with moisture even during periods of drought. And in case of excessive moisture, the water will not stagnate, which will prevent rotting of the plants.

Aeration will be necessary if the soil layer is compacted, due to which the root system does not receive the required amount of oxygen, moisture, and nutrients. Difficult gas exchange is a common cause of stagnation of liquid on the surface. Because of this, there is an accumulation of carbon dioxide in humus, and this leads to oxygen deficiency. He, in turn, participates in the process of decomposition of organic components and oxidation of mineral elements. The result of this process is plant diseases.

https://youtube.com/watch?v=zajecdTrEdg

Aeration is performed in two ways:

- The first involves piercing the soil using metal teeth. This creates the necessary holes through which the air flow into the soil to the roots of the plants is restored.

- In accordance with the second method, aeration is carried out using hollow pins, with the help of which fragments measuring 1 cm - 2 cm in size are removed from the soil. The second method is considered more effective than the first, because such aerator attachments make it possible to remove a layer of dried grass from the ground. The timing of aeration is at least 2 times a year. However, the procedure can be carried out more often if the quality of the soil or its condition requires it.

Previously, aeration was carried out using forks and rakes, but today the industrial development of agricultural tools has made great strides forward. Currently, the market offers special devices for this purpose - aerators. These devices have their own varieties, differing in several respects.

What does aeration give?

Does it make sense to modify a septic tank by installing aeration? Installing and connecting the aerator allows you to:

- significantly reduce the time of wastewater treatment and increase the efficiency of treatment;

Advice! By reducing the cleaning cycle time, you can reduce the volume of the chambers, that is, make the septic tank more compact while maintaining the same performance.

- eliminate the appearance of unpleasant odor, which inevitably spreads when using anaerobic settling tanks;

- reduce costs for vacuum cleaner services;

- The risk of contamination of water and soil with sewage is completely eliminated.

So, an aerator for a septic tank is an installation through which the cleaned environment is saturated with oxygen necessary for the life of aerobic bacteria. Modifying a septic tank by installing an aerator and connecting a compressor to it will significantly increase the efficiency of the treatment plant and get rid of unpleasant odors.

Aerator for sewerage

Types and design of aerators

You can buy a ready-made aerator or you can equip it yourself. It must be resistant to corrosion as it operates in a hostile environment. It must also be reliable because it is mainly installed at the bottom of the septic tank and replacing it is not the easiest solution. Its operation should not be accompanied by constant noise, which will naturally irritate those living in the house.

Aerators can be tubular or disc shaped. The tubular model is the simplest option.

The tubular device has positive qualities:

- are flexible;

- long service life;

- minimal likelihood that the holes may become clogged;

- it has a function for maintaining the supplied pressure;

- distributes oxygen evenly throughout the medium; The material is resistant to mold formations.

Positive results

By using a recirculation unit of a new design, in which the recirculating flow is divided into two parts, the following was achieved:

- A new source of air supply has appeared with characteristics equivalent to the use of a membrane compressor and a fine-bubble aerator, with an air capacity of up to 40 liters per minute;

- The hydraulic load on the biofilter was reduced as much as possible, which had a positive effect on its operation and allows us to consider this unit a biofilter with additional aeration of the recirculating flow, and not a mechanical aerator.

The implemented technical solution for additional aeration of the liquid being purified makes it possible to increase the stability of the cleaning technology as a whole and can be used on both newly produced and already in use Eurolos Bio models.

| 40 liters per minute |

The need to replace a standard unit with a modified one may be due to the specific use of Eurolos Bio installations, for example, a short-term increase in the number of users above the permissible limit, accelerated startup of the station, or any other factors requiring an increase in the oxidative power of structures.

Briefly

Ejector Eurolos Bio

, pdf file ~142.79Kb