Well with plastic casing

When planning to drill a well on your site, you need to study its structure, types, operating principle and many other features in advance in order to avoid possible problems and unreasonable costs in the future during construction and operation. One of the main issues that requires close attention is what materials to use, and in particular, whether plastic pipes for a well are suitable as a casing or production string.

Using threaded pipes

Metal casing pipe for wells is made of grade 20 steel.

Its thickness is about 5 mm. If we assume that the corrosion rate is 0.1 mm/year, then its service life is 50 years. At the same time, the pipes withstand any movement of the soil and do not clog the water with anything other than rust.

Many people believe that filtering rust that gets into the water as a result of the oxidation process is an expensive task. But this issue can be resolved by using household water filters or settling it, since rust does not dissolve in water.

The biggest harm from rusty water is the increased likelihood of pumping equipment failure. But this problem can also be solved. It is necessary to install a more technologically advanced pump.

Use of galvanized casing pipes

Galvanizing is used to prevent metal corrosion.

But it makes no sense to use it against corrosion in well pipes: the service life of products made of black steel is already quite long. At the same time, filtration of water from a well is necessary in any case, and not only for rust. The main thing here is that galvanized pipes can cause harm to the human body due to zinc compounds, so it is not recommended to use this procedure for drinking water.

Use of plastic casing pipes

Such products use so-called “food grade plastic” or polyvinyl chloride (PVC) and polyethylene (PE). They are chemically inert and do not pose any danger to the human body, which is confirmed by many years of research and experience. In addition, they are not susceptible to corrosion.

Plastic casing pipes have excellent mechanical strength, good stability, light weight and low cost. They are sufficiently protected from corrosion, which guarantees an uninterrupted supply of clean drinking water. An additional confirmation of the reliability of such pipes is their frost resistance.

What is better: threaded connections or conventional welding?

Welded joints are used quite often in practice because they are cheaper. But they are not reliable, since during the welding process the metal is deformed, causing the column to deflect with each welded pipe. Also, the weld is the weakest point of the entire structure.

From the above it follows that in wells it is best to use drilling steel or plastic pipes with a threaded connection.

Creating water wells is a labor-intensive hydrological process that requires a lot of attention and the use of a variety of equipment.

This type of work is carried out only by qualified specialists who can ensure that the assigned tasks are completed accurately. The main difficulty is that the water lies at different depths, and certain forces must be applied to extract it. Drilling holes for water and organizing a well in accordance with all requirements takes from one to twelve days. It depends on the complexity and volume of work.

Well casing device

Let's assume that the well has been drilled. In this case, the hole must be perfectly level, otherwise the pump may break down, since it must hang in the well according to the principle of a plumb line. If the well offers the installation of both metal and plastic pipes, then the metal is installed first.

To do this, the hole must be widened towards the top, and it is drilled first in line. When installing metal, it is best to use threaded connections so that the metal in this place does not corrode in the future. Metal pipes are quite heavy, so it is best to hold them with special installations on drilling machines.

As for plastic, in the very first pipe, which will be located at great depths, it is worth equipping a filter by drilling many holes along the entire plane up to 1 m. You can use geotextiles for additional protection from dirt.

About 3 people should participate in the work. One person will hold, another will bring, the third will screw.

The pipe should be screwed in step by step, pre-lubricating the threaded connections with a special agent for reliable tightness.

The product should be lowered into the recess so that it does not reach the bottom of the well by about 1 meter. In this case, the water column must be significant. In the upper part, the plastic pipe is trimmed to the required size.

Next, pumping equipment is installed, which is fixed to a metal cable and lowered with a reserve of the water column. The hose from the pump passes through the well head, which, in turn, is fixed to a metal casing for the well. The head is screwed on with bolted connections or simply put on the casing, supporting it with its weight due to the load under the pump.

Casing pipes: what are they and how are they used?

To solve the problems, a variety of materials and tools can be used. Each of them has its own characteristics and technical parameters. Only experienced specialists are able to correctly select everything necessary to perform a particular task.

The casing pipe is the most important element designed to create a casing string. It, in turn, protects the created well from destruction and ensures proper isolation.

Thus, there are several main tasks of the casing:

- Creation and strengthening of the well; Stabilization of the entire structure; Protection against the ingress of polluting elements from the soil, etc.

In this regard, the requirements for casing pipes are quite high. You cannot ignore the requirements of specialists, as this can lead to unforeseen consequences.

Selection of casing pipes for wells

Many parameters have a significant impact on the choice of pipes, and therefore it is always necessary to approach this carefully. These indicators include:

- Purpose of the well; Depth of drilling and water occurrence; Geological features of the soil; Climatic and other terrain features, etc.

Currently, there are many materials on the market designed to perform such tasks. Modern innovative solutions are replacing traditional pipes. This opens up significant opportunities.

The most common types of casing pipes currently are:

- Metal; Polyethylene.

In the modern construction field, plastic is gradually replacing metal, because in many of its properties it is in no way inferior to it, and sometimes even superior.

Briefly about the main thing

The casing pipe in a well performs the following number of tasks:

- Keeps walls from collapsing.

- Protects against external water flowing into the well.

- Prevents it from clogging.

- Protects the well from destruction and compression by soil masses.

When deciding which casing pipes are better for a well - plastic, asbestos-cement or steel, it is necessary to proceed from the drilling depth, operating conditions and cost of work. When choosing a casing pipe, you should take into account not only the type of material and its properties, but also the way its segments are connected and the diameter, calculated according to the peak flow rate of water consumption. The casing procedure is carried out by specialized companies using special equipment according to the developed technology plan.

Ratings 0

The use of metal and polyethylene pipes for creating wells

Now it is impossible to say that one or another material is definitely better or worse than another, so specialists do not replace them during work. Creating wells is a labor-intensive process that requires special attention to technical details. And specific types of pipes allow this to be done.

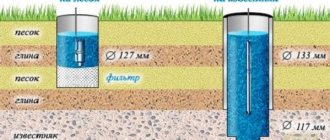

Metal casing pipes demonstrate excellent stability in floating and unstable soils. They are perfect for artesian wells, providing the necessary level of strength and reliability. In this case, pipe models with a thickness of 7 mm and a diameter of 127 mm are used.

Polyethylene pipes are traditionally considered a modern and innovative material, although they have appeared quite a long time ago.

They significantly simplify the tasks assigned and also reduce the costs of completing them. Such pipes are most often used to create casing strings in small (shallow) wells for domestic purposes. The water is pumped out using a centrifugal pump, and then enters the water supply system of the cottage or country house.

Any polyethylene materials have certain characteristics:

- High level of protection against corrosion; Reduced overall cost of a water well; Possibility to expand the diameter by increasing the strength characteristics of the pipe itself; Durability and reliability during long-term operation.

Metal pipes, despite their strength, have a number of disadvantages. The most significant of these is the effects of corrosion, subsidence and deformation over time. Polyethylene is a great opportunity to avoid this.

But we must never forget that only experienced and certified specialists should select materials and create wells!

Auger drilling as a popular technology in modern construction

Casing pipe - what is it?

This name is unfamiliar to a wide range of people. Of course, in order to go as deep as possible into this issue, you need to have special knowledge, which is given at least in a vocational school. However, an ordinary person does not need such detailed specifics, so we will limit ourselves to general concepts.

In this article we will deal with the following questions:

- Casing pipe - what is it? Where is it used? What is it used for? What types are there?

Casing wall thickness

The question of what wall thickness to choose for the casing pipe is relevant when constructing a well from plastic pipes. It must be calculated based on the depth of the well and the type (group) of soil. For wells up to 30 m deep, pipes with walls up to 7.5 mm thick are usually sufficient. There is still 14 mm of wall thickness left, which is enough to construct wells with a depth of 100 meters or more. Each standard size of steel pipes has 4–6 wall thickness options, but in the case of water wells, the minimum value of this indicator is enough.

Purpose of casing pipes

In order to understand a casing pipe - what it is and which of them are used to construct a well, it is necessary to clearly understand the purpose of this structural element.

It is on this basis that the material with the most suitable performance characteristics is selected.

Let's consider the tasks that such a pipe should perform:

The main task of casing is to ensure the integrity of the well walls throughout the operational period. Casing pipes must have good strength to withstand any ground movement.

With the right material, the service life of the well should be more than 50 years on soils of any complexity. The second main task that you should pay attention to before choosing equipment (especially for soils with a high amount of aquifers that are unsuitable for drinking purposes) is ensuring the tightness of the structure. Threaded casing pipes must prevent the penetration of topwater and water from other horizons into the well. All water intake is carried out only from a certain aquifer, suitable in terms of its physical and chemical characteristics.

Therefore, when choosing pipes, you need to pay attention to the method of joining them. Preference should be given to threaded connections.

Any specialist can tell you in detail what a casing pipe is. In simple words, this is an ordinary reinforcing material.

However, it is necessary to choose it correctly, since the operation of the entire system will depend on the quality. In practice, different types of pipes are used to casing water wells of various depths. The main ones include metal, plastic and asbestos-cement.

The entire range of these products is manufactured in accordance with GOST 632-80.

How to install casing pipes in a well

The well is cased with plastic pipes after the drilling of the structure has been completed.

Recommendations:

- The diameter of such a pipe should be slightly smaller than the diameter of the well.

- All connections, if the well is quite deep, are made on the surface of the soil, and not inside the structure.

- Checking such connections can be done using a hose and a powerful pressure of water directed into the inside of the connected products.

- The pump that will be used in the well must also have a smaller diameter than the pipe. This will allow you to freely lower and raise the equipment if necessary.

Work process:

- Initially, the well is drilled with large equipment.

- The depth of such drilling should reach 5 m.

- After this, you need to take a smaller drill and continue work.

- The next depth will be the water on the sand.

Note. If a deeper well is required, then drilling with a large drill should be carried out to a distance of 1-1.5 m from the aquifer.

- As soon as water appears, they are inserted into the structure, hermetically connected to each other.

Advice. The well drilling must be level. Otherwise, the pipes, which are then inserted into the structure, may break. As a result, the well will begin to crumble.

- After installing the pipes, the operation of the pumping equipment is established.

- It is installed at a certain distance from the bottom of the structure.

Metal pipes

Steel casing for well construction can be used for structures on sand and limestone (artesian wells). This type is characterized by good strength and resistance to any mechanical stress.

The diameters of steel casing pipes vary from 114 to 508 mm. With a wall thickness of five to six millimeters, this equipment will last at least 50 years. In addition, it is worth accepting the fact that if a well becomes silted, it is possible to use a drilling tool to restore its functionality, and this is not available for other types of pipes.

But black steel also has a number of significant disadvantages.

First of all, its tendency to corrosion is striking, which leads to the appearance of rust in water (although this problem is solved by modern filters). The second and, perhaps, most important thing is the high cost of thick-walled pipes. That is why the main area of application of steel casing is the construction of deep wells with a significant operational life. For drilling shallow wells in sand, it is advisable to use cheaper materials.

Selection rules

There are two types of criteria, consideration of which allows you to accurately decide which pipe is best to use for a water well, these are:

- Technical.

- Operational.

Factors of the first category include:

- Diameter.

- Method of connecting pipe sections.

- Type of material.

Choosing the diameter of the casing pipe Source ytimg.com

The diameter of the casing pipe for a well is calculated using a special formula, taking into account a number of parameters. It is generally accepted that along the internal contour its value should be at least 110 mm. This is due to two reasons - optimal water intake conditions and the selection of submersible pumping equipment of suitable dimensions.

The well will have better performance characteristics when the pipe segments are fastened with a threaded connection. It will ensure maximum tightness, strength and durability of the casing. In most cases, the installation company decides what diameter the installed pipe string should be and what type of connection is required for it in a particular case.

Factors of the operational category of criteria for choosing a pipe for casing:

- Inertness of the material relative to aggressive environments.

- Resistance to external compression of soil masses.

- Endurance relative to mechanical loads - to ensure integrity during transportation and installation.

- Increased resistance to corrosion.

- Long service life.

- Optimal cost.

Three modern materials meet the requirements: steel, plastic and asbestos cement.

Note! Which pipes are best to use for a water well must be decided in advance - before searching for an installer. Typically, a company works with only one material and has in its arsenal special equipment and proven technology for a specific type of pipe.

Casing pipe with thread Source vostokpipe.ru

See also: Catalog of companies that specialize in water supply, sewerage and related work

Asbestos cement pipes

Another traditional material used for well casing is asbestos cement.

The main advantage of such pipes is their low cost, resistance to corrosion and chemical exposure to aggressive environments; in other respects they are inferior to steel products. The main disadvantage is increased fragility, which leads to the need to increase the wall thickness, and this entails the need to drill a well with a larger diameter. In addition, this material cannot be used in the construction of filter columns.

The main area of application for such casing is artesian wells (for limestone), their depth is no more than one hundred meters.

Plastic pipes

Recently, plastic casing pipes for wells with threads have become increasingly popular, the manufacturers of which guarantee a significant service life. Of course, it is still difficult to judge durability, but the fact that such products are inexpensive, do not corrode, and are chemically neutral can be said with a high degree of confidence.

Basically, materials made of PVC (UPVC), polypropylene or low-density polyethylene are used for casing. The design of such pipes has a low specific weight, they are quite simply installed due to the presence of threaded connections.

The disadvantages include poor resistance to mechanical damage; re-drilling such a well is quite problematic, and most often it is simply impossible.

The main area of application for such pipes is sand wells, the depth is no more than 50-60 meters; in addition, they are ideal for installing filter columns.

It is not recommended to independently decide on the choice of material for casing wells; this should be done by a specialist who is able to assess all the features of the soil at the drilling site. Remember that, despite the significant range of materials for this purpose, any error at the design stage will lead to a decrease in the operational life of the well.

Casing pipes for wells have only one purpose - for drilling or strengthening wells of various types. Manufacturers are currently producing a huge number of such pipes. Classification is primarily carried out according to the material of manufacture.

Casing pipes for wells

In order to more accurately understand the concept, you should decide on what is commonly called the word well. Essentially, this is a hole that has a small diameter and large depth.

So, the casing pipe serves to either make this very well, which is carried out at the moment when these pipes are installed, or to strengthen the walls of the well in order to prevent their destruction or wastewater from entering inside.

Use of pipes for bored supports

Casing parts are widely used in the construction field. Here they are used for bored supports, which are made by concreting a finished well. The diameter of this design can be from 300 to 1500 mm. The most popular are products with a diameter from 300 to 600 mm.

For installation of bored piles, a sectional type casing pipe is used. The connection of this design occurs using threads. The lower section of such a column has a special drilling element that passes through the soil during drilling. The casing parts are installed using mobile drilling machines (MDMs).

Casing pipes with bored piles are used in construction in difficult conditions

In addition, there are types of bored piles that are made by hand. Using such a manual installation, you can drill a well with a depth of up to 3 m and a diameter of up to 30 cm. In this case, the role of the casing pipe is usually played by rolled roofing material, which is used to line the walls of the well or ordinary plastic casing parts.

Types of casing pipes

Casing pipes can be made of various materials:

- Metal;PVC;Asbestos and others.

Metal pipes (GOST 632-80) for wells, in turn, are divided into the following types:

- Enameled; Stainless steel; Galvanized; Steel.

It must be said that each of these pipes also has its own GST.

Enameled products are very vulnerable, since the top layer of enamel can simply crack and crumble. In the case when the pipe installation is carried out using special equipment, the use of enameled pipes is not recommended.

Enameled casing pipes

Stainless steel pipes for wells have the advantage that they are not subject to corrosion. But they also have a drawback - their cost.

Galvanized casing products are also not subject to corrosion. But, as in the previous case, there is one significant drawback - zinc compounds can release substances harmful to human health.

Steel casing pipes cope well with the movement of soil layers. However, such products for wells are more susceptible to corrosion.

Advice! When choosing steel pipes, special attention should be paid to seamless materials. They have greater rigidity.

Indeed, steel elements are chosen precisely when it is necessary to withstand large lateral loads, so seamless products will be the best option.

If the choice is between metal products and PVC (GOST 51613-2000), then it is better to choose the second option. They are also seamless.

In addition, HDPE casing pipes are distinguished among them. Made from low-density polyethylene (HDPE). The main purpose of these pipes is to casing artesian wells, that is, drinking wells.

This type of PVC products (GOST 52134-2003 or GOST 22689.0-8) does not pollute the environment. They are durable and quite strong.

PVC casing pipes

This material appeared on our construction market relatively recently, so there is no information yet that would be based on experience of long-term use. But in the short time that these pipes have been used, only a positive opinion has already been formed about them.

It should also be said that the PVC casing pipe can have a thread (GOST 18599 - 2001). Such pipes are more expensive, but the connection is easier. Welding is not required in this case.

As for strength, the pipes are capable of withstanding loads whose equivalent weight is 5 tons.

Advantages and disadvantages of all types

The process of drilling with casing will be easy and correct if it is chosen correctly. Taking this into consideration, it is worth studying in more detail all the disadvantages and all the advantages, classifying the columns only by the material of manufacture.

So, steel pipes for wells certainly last a very long time.

In addition, they are able to withstand enormous weight, which means very high soil pressure. Conventional welding is used to join several columns together. Welding can be done independently, which in itself is a positive quality.

Among other things, such products have the following advantages:

- Resistance to movement of soil layers; High degree of strength.

Disadvantages include the oxidation process and the cost of products.

Asbestos cement casing pipes

Asbestos-cement products for wells have a very long service life, moderate cost and a high degree of corrosion resistance.

One of the disadvantages is that to install such a column you need a very large diameter well, since the walls are very thick. However, despite this, the walls still remain quite fragile. In addition, asbestos-cement products are strictly prohibited from being installed in areas with moving soils.

PVC products can serve for an extremely long time without losing their positive properties.

They do not rust and do not emit harmful substances. They have a relatively low cost and are very easy to use. The work is also made easier by the fact that, compared to the two materials described above, PVC is very light in weight.

The joining method is either welding or connection using special elements.

The only disadvantage is that they have less strength compared to steel casing pipes.

Advice! To construct a well with your own hands, it is best to use plastic pipes, since working with them is very simple, and their welding can be performed even by unqualified specialists.

Types of materials and their characteristics

Metal casing pipes

Structures based on metal columns are the most reliable and have been proven over many years of use. Steel pipes with a diameter of 133-159 mm are installed in individual wells, but the wall thickness can be different. When choosing a drilling company and design, it is important to pay close attention to this. For a well to operate for more than 50 years, the pipe wall thickness must be at least 4.5 mm - photo 1.

Polymer pipes

PVC-U pipes.

Some drilling companies believe that metal pipes can be replaced entirely with pipes made of dense, unplasticized polyvinyl chloride. For many, to this day, this is a rather controversial issue. But still, since 2011, uPVC pipes have been used as the main casing - photo 2.

Disadvantages of uPVC pipes:

- Ground movements and interlayer pressure lead to column flattening, wells fail and cannot be repaired;

- The thread cannot withstand the load and, when twisted, cracks in the internal threaded connection. And such a connection becomes not airtight;

- Unplasticized polyvinyl chloride is prone to drying out and cracking over time, so there is no need to talk about reliability and durability;

- The caisson is attached to the uPVC casing through a clamping coupling, so the caisson often comes off, which complicates installation work.

PVC-U pipes have only one advantage - the pipes do not corrode.

At the Customer’s request, we can also use PVC-U pipes in our work in accordance with GOST P 51613-2000, but our engineers still recommend installing time-tested metal pipes.

HDPE pipes are low pressure polyethylene.

HDPE pipe is less durable; it is installed with an additional internal pipe in a two-pipe structure (metal + HDPE or uPVC + HDPE).

Rolled steel casing pipes

Advantages of rolled steel pipes:

- Structural strength (suitable for shallow and deep wells);

- Reliable assembly between each other;

- Steel does not emit harmful elements when in contact with water;

- High maintainability – high strength allows cleaning and additional drilling.

Galvanized casing pipes

When in contact with water and soil, the pipe walls are more resistant to corrosion. Galvanized pipes can be installed in a well for individual water supply. But such pipes are used less often than steel pipes due to the difference in price.

Stainless steel casing pipes

A stainless steel pipe has similar advantages to a rolled steel pipe, but has a very high cost. Stainless steel is not subject to corrosion and therefore lasts a very long time. It is almost not in demand due to the high price.

How to choose the right diameter

It must be said right away that the standard casing diameters are the following: 60, 90, 108 and 125 mm. These numbers are typical for plastic.

It must also be said that performance does not depend on size, or rather, it depends slightly.

Wells with a diameter of 108 and 125 mm differ in that the drill for them has a slightly larger diameter. Therefore, a space is formed between the outer walls of the products and the walls of the well itself, which is extremely difficult to fill with anything, especially if the depth is large. This leads to water from the upper layers entering clean water, which is inferior in quality.

Steel casing pipes

As for products with a diameter smaller than 125, for example, the same 60 mm, here this problem is completely solved. And the solution was found to be very simple - the drill has a diameter even smaller than the internal diameter of the product itself, that is, casing pipes for wells are first installed, and only then drilling begins inside them.

Now one logical question arises: why make wells with a diameter of 125 mm or even more? The answer is simple.

Very often the water level is very low, deeper than 10 meters. At such a depth, a surface pump is simply not able to work, and it is used with small diameter pipes. Therefore, it is necessary to use submersible pumps, which can only be installed in wells with a diameter of 90, 108 and 125 mm or more.

Now it remains to make a simple conclusion: if the water level is above 8 meters, then columns with a diameter of 60 mm can be used, but if the water is below this mark, then columns with diameters of 90, 108, 125 mm or even larger are used.

Casing size calculation

The parameters for choosing casing pipes depend on the magnitude of the need for life-giving moisture. It is determined depending on the maximum one-time consumption when using the maximum number of water points, such as:

- bathrooms and showers;

- faucets;

- washing machines and dishwashers;

- household storage devices (tanks);

- storage devices for household purposes (watering tanks).

In practice, reliable results of real consumption have been obtained, determining the need for 3 cubic meters per hour.

Considering the technical characteristics of pumping equipment, we found that the main types of pumping equipment with such productivity have a size of about 75 mm. This refers to submersible and deep well pumps.

Attention! Vibrating pumps, which contribute to the rapid destruction of the casing, are strictly not recommended for this purpose.

Next, it is necessary to take into account the mandatory gap of 4 - 5 mm between the pump and the well wall, which gives an internal diameter of the pipe of 85 mm. We add the wall thickness, which for such a diameter is 4.5 - 5 mm, and we get the final result for the outer size - 95 mm. That is, you can use a standard 95 x 5 mm pipe.

Watch the video

However, we recommend taking into account one circumstance that will help to at least double the life of the well. If signs of damage to the integrity of the casing appear in the form of an increased amount of mechanical impurities or the appearance of the smell of hydrogen sulfide in the water, it becomes necessary to stop operating the well.

Fistulas have appeared on the casing pipe, and unfiltered soil fluid is entering it. But if, when choosing a casing, the possibility of installing a pipe of a repair size is taken into account, it is possible to insert a second pipe of a smaller diameter with a standard filter inside the primary casing, and the operation of the water intake can continue. Then, taking this circumstance into account, the size of the primary casing must be increased to the next standard size, for example, use a pipe 108 x 5-6 mm, or 118 x 6.