To install a budget option for an autonomous sewer system, many buyers opt for a domestic septic tank. This structure operates on the principle of a sump and does not require connection to electricity.

In this article, we looked at the main models of the brand, their features, operating principles, pros and cons of this septic tank, and prices. We also added additional information: useful tips from experts, important technical points and information, operation, step-by-step installation instructions.

The review contains additional materials such as videos, tables, photos, diagrams.

Description

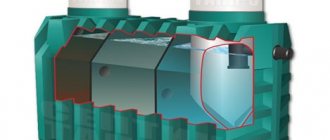

The local treatment plant has three working chambers that act as settling tanks. Under the influence of gravity, runoff masses disintegrate into heavy and light fractions (silt and suspension), followed by decomposition of biomass and clarification of the water resulting from the activity of anaerobic bacteria.

The device is made by machine winding from durable fiberglass. That is, it has no seams on the body, which ensures resistance to soil influence. A positive aspect is the weight of the entire structure. It is approximately 1.5 times less than competitors with similar models. The company has been producing such treatment facilities for more than ten years and guarantees the high-quality operation of its products for up to 30 years.

The capacity of the device, depending on the model, is 1.5-10 cubic meters. When choosing a model, you should take into account that according to standards, one person consumes from 170 to 210 liters per day.

The manufacturer produces three main Flotenk models, which are deservedly popular among customers.

- STA is a basic model designed to serve five to seventeen people. Volume from 1.5 to 10 cubic meters. meters, depending on modification. The younger model is distinguished by its compact dimensions (up to 3.9 meters in length, 1-1.2 meters in diameter) and relatively light weight of 149 kilograms.

- Bio Purit is a four-chamber deep cleaning system. The station operates both with and without power supply. When connected to an electrical network, aeration and better cleaning are provided. When the power supply is turned off, the biomass settles and rots, as in any standard septic tank.

- SeptiX is an upgraded basic three-chamber model, equipped with an additional filter that extends the service life of the filtration fields.

Design and main characteristics

The material for the manufacture of the body of the Flotenk STA septic tank is durable fiberglass. The housings of the units are manufactured in the factory under strict quality control, so there is no doubt about their tightness and reliability.

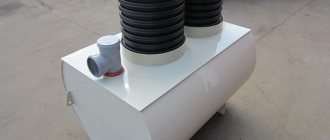

Externally, the body of the Flotenk STA septic tank resembles a regular tank, that is, it is a horizontal cylindrical container. Inside, the container is divided into three sections by partitions. Containers are produced in different volumes and, accordingly, different performance.

The lineup

Today, 7 variants of the Flotenk STA septic tank are produced. The junior model in the line is capable of processing 500 liters of contaminated liquid per day, and the total capacity of the tank is 1.5 cubic meters. The most productive model in the series can clean 3.3 cubic meters of sewage drains per day, and its total volume is 10,000 liters.

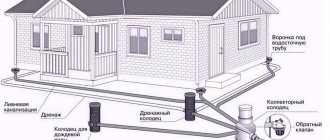

Installation diagram

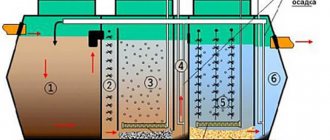

There are three insulated tanks inside the Flotenk STA septic tank. During treatment, wastewater flows sequentially through all three sections of the treatment plant:

- The receiving section of the Flotenk STA installation performs the functions of a settling tank in which the largest impurities undissolved in water are deposited;

- The sediment at the bottom of the settling tank undergoes anaerobic (taking place without access to air) fermentation. Conventionally, this rather complex process is divided into two stages. At the first stage, the so-called acid fermentation occurs, in which organic matter decomposes with the formation of fatty acids, alcohols, hydrogen sulfide and carbon dioxide. Next, methane fermentation occurs, during which fatty acids and alcohols decompose to form methane, water and carbon dioxide;

- Having settled, the water, through an overflow device, enters the second section, where the process is repeated. The wastewater settles again, and particles that did not have time to settle in the first section are separated from the water. The sludge is also subjected to anaerobic processing;

- Already clarified water enters the third section; during the settling process, small particles in the form of suspensions are released from the wastewater;

- Then the water is removed from the installation and supplied to filtration platforms or filter wells.

Principle of operation

All basic models are equipped with three sealed working sections and operate on the sump principle.

The first camera plays the role of a receiver. Here the wastewater undergoes primary settling. Coarse sediment in the form of large biological impurities settles to the bottom. Acid fermentation occurs and proteins, fats and carbohydrates are broken down into fatty acids.

Partially clarified waters enter the second chamber. Here the second stage of settling occurs. Methane fermentation ensures the breakdown of fatty acids into simple compounds - hydrogen, methane and carbon dioxide.

The third chamber produces the final clarification of sewage waste due to the settling and settling of organic particles suspended in the water to the bottom.

The flow of liquid between sections and its flow from the third compartment to the filtration field is carried out by gravity. Each section is equipped with a special water seal that prevents the reverse flow of water. Clarified water is discharged into the ground through filtration fields to ensure additional purification, and the sludge that settles to the bottom is processed by anaerobic bacteria - an active process of rotting and decomposition occurs.

To ensure proper operation of the device in the cold season, the upper part of the septic tank must be insulated! This activates the processes of fermentation and rotting.

The structure of this septic tank

The material for the manufacture of the sealed frame is durable and wear-resistant fiberglass. Wastewater treatment is based on the separation of particles into sludge and suspension with simultaneous anaerobic decomposition of biomass. The initial cleaning in the septic tank ends with the drainage of water to the filtration platform.

A septic tank does not purify wastewater 100%, so further treatment occurs in specially designed structures - filtration tunnels

produces not only septic tanks for household waste, but also other treatment facilities, for example, equipment for storm drainage, fuel tanks

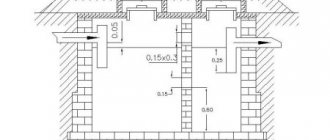

The treatment plant is presented in the form of a container divided into three interconnected chambers. Each of them performs its own function:

- A – primary settling tank, in which coarse sediment is retained;

- B – secondary settling tank for deeper cleaning;

- C – wastewater illuminator.

The diagram shows the standard design of a Flotenk septic tank. The housing consists of three cleaning sections, the largest of which is the receiving section (A)

The first chamber is connected to the supply pipe, then to the second compartment through a blocking system. The second and third chambers are connected using a water seal. In order for the installation to operate stably, its upper part is insulated, creating the desired temperature regime.

Advantages and disadvantages

The advantages of any Flotenk model are the following parameters:

- resistance to aggressive environments;

- long service life (30 years or more);

- resistance to temperature changes and soil pressure;

- light weight;

- complete waterproofing;

- sludge cleaning from one to three times a year, depending on the intensity of use;

- ease of installation and maintenance;

- independence from power supply;

- affordable price for junior models.

The disadvantages experts and users include:

- dependence on filter fields;

- inability to use sludge as a fertilizer (it contains methane impurities).

Market prices

The cost of septic tanks from this manufacturer directly depends on the volume and model.

Prices for STA models:

- 1.5 cu. meter - 27,700 rubles;

- 2 cu. meter – RUR 36,700;

- 3 cu. meter – 47,700 rub.;

- 4 cu. meter – RUR 76,700;

- 5 cu. meters - 92,700 rubles;

- 6 cu. meters - 112,700 rubles;

- 8 cu. meters - 137,700 rubles;

- 10 cu. meters - 182,700 rub.

Prices for Bio Purit models:

- 250 l – 73,000 rub.;

- 350 l – 101,000 rub.;

- 550 l – 129,000 rub.;

- 850 l – 199,000 rub.;

- 1.2 cu. meter – 237,000 rub.;

- 1.8 cu. meter - 337,000 rub.

SeptiX models starts from 367,000 rubles (volume 600 l).

Overview of the Flotenk septic tank

Overview of the Flotenk septic tank

Using a primitive pit is inconvenient and unsafe from an environmental point of view. A simple and, at the same time, effective solution is to install a local treatment facility; an example of such a facility is the Flotenk septic tank. Companies that produce equipment for local sewage systems offer septic tanks of different capacities. Models designed for a relatively small volume of wastewater are used for landscaping summer cottages and private houses. One of the options for a septic tank that can be used, including in private households, is the Flotenk septic tank.

How is it arranged?

First, you should get acquainted with the design of the treatment plant. The body of the Flotenk septic tank is made of a polymer material – fiberglass. The main cleaning method used in this septic tank is mechanical settling, as well as biological decomposition of organic matter.

A prerequisite for using Flotenk septic tanks is the organization of post-treatment, therefore, simultaneously with the installation of a treatment plant, it is necessary to build filtration fields or install infiltrators. Externally, the Flotenk septic tank resembles a cylindrical tank having:

- three necks, closed with hatch covers (each compartment has a separate neck);

- an inlet pipe that connects to an external pipeline leading from the house;

- an outlet pipe from which a pipe runs that directs water to the sites for post-treatment.

The internal structure of the installation is quite simple; it is divided into three sections, unequal in volume:

- the first is the largest, it is connected to the sewerage pipeline and serves as the primary receiver and sump;

- the second section is medium in size, it is also used as a sump;

- the smallest is the third chamber, in which the final clarification of the water takes place before being sent for further treatment.

The sections are connected to each other by overflow holes equipped with special blockers that retain solid sediment, preventing it from penetrating into the next compartment.

How is recycling done:

Operating principle of the Flotenk treatment plant:

- through the sewerage pipeline, wastewater (by gravity or forcedly when using a pumping station) enters through the inlet pipe into the primary settling tank;

- here they remain for a long enough time to have time to settle, the largest particles of contaminants fall to the bottom of the chamber, and a layer of soap flakes, fat and other substances that are lighter than water forms on the surface of the liquid;

- Simultaneously with settling, biological purification processes take place without access to oxygen. The first stage of anaerobic purification is fermentation, as a result of which hydrogen sulfide, alcohols, fatty acids and a number of other organic compounds are formed from organic compounds. The second stage is methanogenic decomposition, during which previously formed complex organic compounds decompose into simple substances - carbon dioxide, water, methane;

- the next stage is secondary sedimentation, the clarified water entering the next compartment continues to be freed from small undissolved impurities, anaerobic reactions continue to occur;

- water enters the last compartment, which practically no longer contains undissolved inclusions, from here it is directed to the outlet and enters the infiltrator or filtration platforms. There, the liquid undergoes aerobic biological treatment and is absorbed into the soil.

The lineup

Flotenk septic tanks are produced in different capacities, so among the models you can find a suitable option for almost any facility. In private households, the following models are most often used:

- sta 1.5 is a compact model with a total capacity of 1.5 cubic meters; the installation disposes of no more than 500 liters of waste per day;

- sta 2 – the model has a capacity of 2 thousand liters, utilizes 0.7 m³ of liquid per day;

- sta 3 - such a septic tank is suitable for serving five people, it has a volume of 3 m³ and can process up to 1 thousand liters in 24 hours;

- sta 4 – the model has a volume of 4 cubic meters, its productivity is 1.3 cubic meters per day;

- sta 5 – a five-cc model capable of recycling up to 1.7 thousand liters per day;

- sta 6 - an installation with a total volume of 6 thousand liters, it is suitable for servicing a facility that uses up to 2 thousand liters of water per day;

- sta 10 is a productive installation that purifies up to 3.3 m³ of liquid per day, the total volume of the installation is 10 cubic meters.

To choose a Flotenk septic tank model, you need to decide on the amount of wastewater generated per day. This indicator depends on the number of residents and the plumbing equipment of the house.

So, if you plan to accommodate 2-3 residents, then the sta 1.5 model is ideal, for a facility with accommodation for 6-7 people, you need to choose the sta 4 model, and for a large facility where 15-17 people will use the sewer system, the sta installation is suitable 10

It should be taken into account that with increasing productivity, the overall dimensions of the installations increase, as well as their cost.

Advantages and disadvantages

Before purchasing and starting to install a Flotenk septic tank, you should get acquainted with the advantages of this equipment and pay attention to its disadvantages.

pros

The main positive aspects of using a septic tank of this brand:

- The device is as simple as possible, there are no mechanical components inside the septic tank that could break, and there are also no thin pipes in which a blockage could form. Therefore, the probability of breakdown is practically zero;

- ease of use; the septic tank requires virtually no attention during operation. Maintenance, which consists of cleaning the chambers from accumulated sediment, should be carried out no more than once a year;

- This is a factory-assembled model, so it is completely ready for installation, no adjustments or modifications are required;

- the septic tank does not require time to enter normal operation; you can start using the sewer system as usual immediately after completion of installation work;

- the installation is completely autonomous, there is no need to connect a power supply to it, such an installation is especially convenient where sewerage is used periodically, for example, at dachas where people do not live permanently, at recreation centers, etc.

Negative points

A significant negative aspect of using a septic tank is the insufficiently high degree of wastewater treatment. It is impossible to discharge water without additional treatment; it is necessary to install an infiltrator or build platforms for filtration.

Another disadvantage is the light weight of the septic tank.

If you install it without anchoring, then during the spring rise of soil waters it can be pushed to the surface, and this will lead to the destruction of the sewage system. Septic tank Flotenk is an autonomously operating treatment plant for local sewage systems. The model has a simple design, so it is reliable and durable. The quality of treatment is not high enough to allow water to be discharged onto the ground. It is necessary to organize additional purification by constructing filtration fields.

Design features general information

The product is a cylindrical container divided into working chambers. The compartments are connected to each other in series. The drain holes are equipped with water seals. The outlet openings of the compartments are located below the level of the drains, which prevents blockages of the pipes by fatty films floating to the surface.

The first chamber has a volume from 1,500 to 7,500 liters, the second from 400 to 5,000 liters (depending on the model). The case diameter is from 1 to 1.8 meters. Length from 2.1 to 6.2 meters.

Each section has hatches to ensure free pumping of sludge, equipped with pipes leading to the surface.

Model range: technical features

Flotenk septic tanks are two- or three-section (depending on the modification) containers with holes in the upper part for the necks and in the end walls for the inlet and outlet pipes.

Housings for septic tanks are made of waterproof composite material – polyester fiberglass. It consists of polyester resins and glass-reinforcing components.

Exterior view of the Flotenk septic tank. Source – official website www.flotenk.ru

Flotenk STA treatment facilities, in addition to fiberglass tanks, are equipped with:

- 160 mm cuffs (for fastening necks);

- 100 mm cuffs (for mounting pipes);

- PVC outlet;

- technical passport;

- recommendations for the use of bioenzymes (if the installation technology provides for their use).

Additionally, septic tanks can be equipped with neck extensions in the form of PVC pipes and plugs.

Flotenk STA with a volume of 1.5 m³

Septic tank Flotenk STA - 1.5 is the lowest-power unit of the entire model range. It consists of a one-piece two-section body.

The unit simultaneously carries out mechanical and biological wastewater treatment with the participation of anaerobic microorganisms. The cleaning process occurs in the following sequence:

- The wastewater flows by gravity through the inlet pipe into the primary settling tank (section A). At this stage, the liquid settles. Solid components settle to the bottom of the chamber, fatty components collect on the surface in the form of a film (over time they turn into a crust), and water remains in the middle part.

Simultaneously with mechanical settling, biological anaerobic processes occur in section A. They are launched as a result of the vital activity of a special type of bacteria, for which the best living conditions are an oxygen-free environment.

As a result of fermentation, biological substances (proteins, carbohydrates, fats) break down into methane, carbon dioxide and hydrogen.

- From the primary settling tank, partially purified liquid flows through the blocker holes (located in the middle part of the tank, below the greasy film, but above the solid sediment) into section B. In this chamber, wastewater treatment by anaerobic microorganisms and mechanical settling continue.

- From chamber B, the wastewater is sent through the outlet pipe for post-treatment to the filtration fields.

Note! Effluents that have been purified in the unit cannot serve as a drinking liquid, since they have output values that do not meet the established sanitary standards for drinking water.

In the product data sheet, the manufacturer provides a table of the main technical indicators of wastewater quality before and after treatment in Flotenk STA septic tanks.

Table: characteristics of wastewater leaving the Flotenk septic tank

Characteristics of wastewater with explanation of parameters according to the official website www.flotenk.ru

Dimensions of the Flotenk STA septic tank – 1.5. Source – official website www.flotenk.ru

Flotenk STA from 2 m³

Units with a volume of 2 m³ or more have a fiberglass body divided into three compartments.

Diagram of three-section septic tanks Flotenk STA. Source – official website www.flotenk.ru

The units are presented in models of various capacities from 2 to 25 m³.

Technical parameters of Flotenk STA septic tanks with a capacity of 2-25 m³ according to the official website www.flotenk.ru

When selecting a device model, the manufacturer recommends being guided by SNiP 2.04.01-85 standards, which regulate the average water consumption per person.

The cleaning process in the installations follows the same principle as in the STA - 1.5 model. Chambers A and B act as primary and secondary settling tanks. However, these septic tanks have a chamber C, in which the final clarification of the liquid occurs. Zone B is connected to zone C by a blocker (hydraulic seal). The treated wastewater is sent to the infiltration fields through the outlet pipe from zone C.

Construction of a three-section septic tank Flotenk STA. Source – official website www.flotenk.ru

Flotenk STA YES

The new Flotenk STA YES septic tank can be called a modified version of the two-chamber unit described above. The device works on the same principle and also has a fiberglass body. The treatment plant differs only in its increased dimensions. According to the manufacturer, a device of this capacity can serve up to 5 people.

Exterior view of the Flotenk STA YES septic tank. Source – official website www.flotenk.ru

Dimensions of the Flotenk STA YES septic tank. Source – official website www.flotenk.ru

Flotenk product range

The most famous sewerage and engineering structures of the Flotenk brand include the following.

Integrated surface runoff treatment system Flotenk OP-OM-SB is a unified monoblock sand-oil-gasoline separator that provides the most complete treatment of both domestic and industrial wastewater with the possibility of their subsequent discharge onto the ground or into a surface reservoir.

Integrated surface runoff treatment system Flotenk OP-OM is a monoblock VOC that includes a sand and gasoline separator, but does not include a sorption filter. It provides a high level of wastewater treatment, sufficient for its discharge into the collector of the city sewer system.

The Flotenk OP sand trap is designed to remove mineral particles of various granulometric compositions; it can be used both as part of VOCs and separately.

The Flotenk OM coalescent module retains finely dispersed petroleum products, promoting the enlargement of their droplets, which accelerates the rise of oily contaminants to the surface.

The Flotenk SB sorption block is used for post-treatment of wastewater before its discharge onto the ground (into a surface reservoir). Structurally, it is a fiberglass tank filled with a hydrophobic sorbent.

The Flotenk UF UV disinfectant neutralizes the biotic component of organic wastewater contaminants and is effective against all microorganisms known to science, as well as their spore forms.

The Flotenk PR fire tank is used for long-term storage of scheduled water supplies and is suitable for use as part of fire water supply systems of any complexity.

The Flotenk KNS complete pumping station is a universal pumping station, the price and operating parameters of which demonstrate the optimal ratio for today. Can be used for both municipal and industrial needs.

The Flotenk KNS Dry high-pressure station is an improved complete pumping station in which the pumping units operate without direct contact with the pumped medium.

The Flotenk PNS fire extinguishing pumping station is a specialized high-reliability pumping station, made of fire-resistant fiberglass and equipped with high-pressure pumping units.

The Flotenk EN storage tank is suitable for the collection and long-term storage of any non-aggressive liquid media and has wide technical compatibility.

The Flotenk ENA storage tank is designed to average wastewater discharged into VOCs (thereby mitigating the negative consequences of burst discharges).

The Flotenk EV drinking water storage tank is manufactured using Aropol K530 TB polyester resin, which is completely harmless to humans, and has the highest service life in the niche, which is 25 years.

Flotenk ET fuel tank is made from isophthalic acid based polyester resins and is therefore highly resistant to diesel fuel. Technologically oriented for operation in conjunction with autonomous boiler systems.

Flotenk OJ grease separators (grease traps) effectively remove any vegetable and animal fats. They are used both independently and in combination with other treatment facilities.

Arrangement of infiltration fields

The design of the wastewater treatment plant is developed before installation work begins. It necessarily provides for a system of soil-based wastewater treatment.

The design of structures for soil additional filtration is selected taking into account:

- soil type;

- terrain;

- groundwater rise level;

- climate features.

The soil treatment system can be:

- Filter well. Installed in areas with sandy and sandy loam soil. This structure is usually built of brick or reinforced concrete. The bottom of the well and the interior space are filled with crushed stone. The filter backfill must be at least 0.5 m above the groundwater level.

- Absorption trench. Suitable for sandy and sandy loam soils. It is mounted from perforated pipes laid to a depth of 0.6-0.9 m. The bottom of the structure is covered with crushed stone, gravel or broken brick.

- Filter trench. Settles on low-filtration soils (loam, clay). This is a depression filled with sand or crushed stone, with a network of irrigation pipes. It is installed near natural ravines, swamps, and reservoirs in such a way that treated wastewater flows into them by gravity from the filter trench.

- Infiltration tunnel . This is a ready-made facility for soil post-treatment of wastewater, part of the product range of the manufacturer Flotenk STA. Used on different types of soil. Can consist of any number of modules. The required number of elements is calculated depending on the capacity of the septic tank and the type of soil.

Table for selecting the number of infiltration tunnels

Table for selecting the number of infiltration tunnels according to the official website www.flotenk.ru

Appearance of the infiltration tunnel

Good to know! According to the manufacturer, one infiltration tunnel with a volume of 300 liters can replace a filter structure consisting of 36 meters of drainage pipes and 800 kilograms of crushed stone.

Installation of the Flotenk treatment plant

Installing a Flotenk septic tank is not much different from installing other treatment facilities: you need to dig a large hole under the tank and connect pipelines to it on both sides. Domestic wastewater moves into the septic tank by gravity, so when laying sewer pipes, a small angle of inclination should be ensured - approximately 4-6 cm/meter. If pipes are laid in a zone where the soil freezes, you need to consider their insulation.

The sewer pipeline is laid in holes laid using diamond drilling. The soil is removed by hand, and a sand cushion is placed at the bottom of the hole.

Before pouring the sandy base with concrete mortar, it is strengthened using reinforcement: a frame connected in the form of a lattice is placed on the bottom

Prepare a concrete solution and fill the base of the pit so that a strong slab is formed. It guarantees stability and immobility for the treatment equipment.

The septic tank is installed in a pit. To ensure immobility, additional fixation is used - a stainless steel cable attached to anchor rings mounted in the base

The treatment plant is backfilled by placing the excavated soil in the pit. Before using the septic tank, pour clean water inside

The supply pipes must be thoroughly insulated, then a fan riser must be installed. The last thing to do is install the top extension necks.

Together with the septic tank, an infiltration tunnel is installed, equipped with plugs and connected by a pipeline.

The foundation pit for the filtration tunnel is dug taking into account what will be located above it. If you install it at a depth of 50 cm, then you can arrange a driveway or parking above it

The filtration system can be represented by several modules, which are located in one serial or several parallel lines.

How to install?

When installing septic tanks, it is necessary to take into account that these devices do not provide complete wastewater treatment. Therefore, in addition to installing the septic tank itself, it is necessary to allocate space for a filtration field - a special system of trenches and pipes that provides additional purification of pre-clarified water.

Installation work includes the following steps:

- Digging pits and trenches. A trench 1.5 meters deep is dug from the house to the installation site of the septic tank. A sewer pipe will be laid here. The pit is dug with a margin of 0.6 meters around the perimeter to ensure easy installation of the septic tank in the ground.

- A network of filtration field trenches is removed from the pit. Each family member requires approximately 10 meters of trench. The bottom of the trenches is covered with agrofibre and filled with crushed stone to a depth of 40 centimeters.

- The bottom of the pit is being concreted. Reinforcement must be used! After the concrete hardens, a septic tank is installed. It must be secured using cables and loops already installed in the concrete base.

- A pipe is being laid from the house. It must be insulated by placing it in a special “sleeve” made of heat-insulating material, and then connected to the body of the septic tank using a fitting.

- Perforated pipes are laid on the filtration field. They are covered with agrofibre on top and covered with crushed stone.

- At the final stage of work, the pit and trenches are covered with soil and compacted. Technical pipes for pumping out sludge are first installed in the upper sockets (hatches). The upper part of the septic tank is insulated.

Advantages of installations

Before purchasing a Flotenk septic tank, you should get acquainted with the advantages of the model, and also find out whether the model has any disadvantages. Advantages of the models:

- The body of the Flotenk STA treatment plant is manufactured using seamless technology using industrial equipment. Thanks to this, the model has high strength indicators.

- The inside of the Flotenk STA unit has an absolutely smooth surface without protrusions or roughness; this circumstance ensures operation and cleaning.

- Flotenk STA units are non-volatile, that is, they do not require connection to a power line during installation. This allows you to operate a septic tank even in villages with unstable power supply. In addition, after the installation is put into operation, its maintenance costs will not increase.

- All connections are made using elastic cuffs, this facilitates installation work and ensures complete tightness of the connections.

Recommendations for use

The performance of the Flotenk wastewater treatment system depends on many factors:

- temperature of liquid discharged into the sewer (10-35˚C is considered optimal);

- presence of organic components in wastewater (the more of them, the better);

- amount of chemicals (there should be as few as possible), etc.

After all, colonies of microorganisms are involved in the process of wastewater treatment. Therefore, the operation of the entire system directly depends on how favorable the conditions are for the life of bacteria inside the septic tank.

Owners of autonomous sewers must:

- monitor the load on the sewer system (both overloads and long downtimes are harmful to it);

- do not throw garbage and leftover food into drains;

- do not use chlorine-containing detergents;

- Avoid acid-based cleaning products;

- Use low-foaming powders for washing.

Remember!

Flotenk septic tanks are easy to operate and do not require special maintenance except for ensuring timely pumping of sludge from all settling tank chambers.

Calling the sewer trucks is required from one to three times a year, depending on the intensity of use of the sewer system.

To ensure uninterrupted operation of the system, it is necessary to adhere to the operating principles of any autonomous sewer system. It is prohibited to throw large mechanical debris into it. The pipeline must be without sharp turns and with the required slope. It is also necessary to take care of the insulation of the septic tank.

Do you recommend Flotenk septic tanks to our readers? Feedback from our readers is very important to us. If you do not agree with the survey results, leave your comment justifying your choice. Your opinion will be useful to other users.

Service

Most of the time, a Flotenk brand septic tank does not require the attention of the owners. The system operates autonomously, no human intervention is required. However, once a year you will need to contact a company that provides sewerage services. It will be necessary to pump out the sediment collected at the bottom of the settling tanks. The owners will need to provide access for the sewage disposal truck to the treatment plant.

If pumping is not carried out in a timely manner, the sediment at the bottom will gradually begin to thicken. This will lead to a decrease in the volume of settling chambers, and this will lead to the fact that the wastewater will not have time to settle, that is, the quality of treatment will decrease.

Once every 10-15 years, it will be necessary to move the filtration fields to a new location or replace the filter layer, since over time it silts up. To extend the life of post-treatment plants, it is recommended to periodically use bacteria for anaerobic septic tanks.

So, the Flotenk septic tank is a simple and very reliable installation that can be installed to service a private home or cottage. The installation of a treatment plant is not difficult, so if desired, it is quite possible to install a Flotenk septic tank with your own hands. When planning your own installation, you need to remember that high functionality and reliability of the Flotenk septic tank is only possible if the installation work was carried out correctly, in accordance with the instructions.