Even if you ordered corrugated sheeting of the required length, the sheet may need to be trimmed during the installation process. Sometimes the profiled sheet needs to be shortened or “adjusted”: for example, in the places where the roofing material adjoins the chimney. If you are installing a roof or a fence of complex shape, you may need to trim the corners of the corrugated sheet.

The question arises: how to choose the right cutting tool? Let us formulate general requirements for it. A tool for cutting corrugated sheets should:

- cut corrugated sheets without overheating the metal, do not burn out the polymer and zinc coatings . The corrugated sheet is a “pie” of several layers: a steel base coated on both sides with zinc, primer and a polymer layer (on the front side) or a protective coating (on the back). Each layer performs a specific function: protects the steel base from corrosion, provides the corrugated sheet with an aesthetic appearance, etc. If one or more layers are burned out, this will affect not only the aesthetic characteristics of the corrugated sheet, but also the functional ones - the steel base will be susceptible to corrosion;

- do not create sparks during the cutting process. Sparks from the abrasive disc can damage polymer and zinc coatings. We indicated the consequences of such damage in the previous paragraph;

- leave a clean cut line, do not deform the edges of the corrugated sheet . Otherwise, the resulting “burrs” will need to be bent, and the crushed edges will need to be straightened. This will require a significant investment of time;

- do not melt the edges of the corrugated sheet . Otherwise, this will lead to damage to the protective and polymer layers along the edges of the sheet and, as a result, to the occurrence of edge corrosion.

Let's consider which electric and manual tools are optimal for trimming corrugated sheets, and which ones are prohibited from being used.

Attention: do not forget to treat the cut areas with repair enamel.

Is it possible to cut corrugated sheets with a grinder?

It is STRICTLY prohibited to cut corrugated sheets with this tool for three reasons:

- Spectacular sparks that fly out from under the disk during operation damage the decorative protective layer. They fall on the polymer coating and burn through it and the zinc. Corrosion may occur in areas where sparks hit.

- The abrasive disc cuts profiled sheets due to friction. As a result, the metal heats up, and under the influence of high temperatures, the polymer and zinc coating along the edges are burned out, which leads to edge corrosion.

- The abrasive disc leaves “ragged” edges.

So: you can quickly cut corrugated sheets with a grinder, but it will become unusable. Therefore, the answer to the question “how to cut corrugated sheets with a grinder” is simple: no way.

Is it permissible to cut corrugated sheets with a circular saw?

Cutting corrugated sheets with a circular saw, even if you use a fine-toothed diamond blade, is not the best option. This tool cuts metal using heat; the disc melts the edges, and with them the zinc and polymer coating. Thus, the edges of the sheet are again exposed to corrosion.

During the cutting process there are no sparks that burn through the polymer and zinc coatings. But due to the aggressive effect on the edges of the sheet, we do not recommend using this tool.

Features of cutting corrugated sheets

Profiled material is a thin sheet of laminated metal that can be damaged if cut incorrectly. Since the material is coated on top with a special polymer and galvanized, the use of conventional methods for processing tin sheets should not be allowed (cutting corrugated sheets with a knife or hitting with a chisel is a bad idea).

It is also prohibited to use high-temperature cutting methods (gas), since the sheet coating will immediately deteriorate, despite the initial factory protection methods. As a result of improper processing, the sheet itself will be damaged, and not just the outer protective shell.

To cut polymer-coated corrugated sheets correctly, you cannot use a grinder with an abrasive wheel, since there will be a risk of severely damaging the outer layer of the material, which will inevitably lead to the formation of rust. The service life of such corrugated sheeting will be reduced several times.

The structural features of the profiled sheet do not allow the use of any rough construction tools for cutting. Therefore, it is necessary to know exactly how to process the material.

Is it possible to use an electric jigsaw to cut corrugated sheets?

Yes, this is one of the most popular options, especially a jigsaw with a laser pointer - with this tool you can quickly cut a sheet without losing track of the markings.

In what cases is it used?

When you need to get a figured or straight cut on one or several sheets of corrugated board up to 21 mm high. Do not use this tool to cut a stack of sheets - the jigsaw may fail.

An electric jigsaw is often used for cutting corrugated sheets because:

- Almost everyone has it, there is no need to purchase it additionally.

- They are easy to work with and do not require any special skills.

- Using a jigsaw you can cut corrugated sheets at any angle.

This tool is only suitable for profiled sheets up to 21 mm high (not higher than C-21). If you have chosen a material with higher corrugations, it is better not to use a jigsaw: it will tear the metal. Also, it does not have enough blade length to cut corrugated sheets with high waves. Working with such material will also not have the best effect on the functionality of the tool - it may break.

When working with a jigsaw, there is a possibility of overheating the metal. To avoid this, follow our tips:

- Control the power of the jigsaw. There is no need to turn on the tool at full power, otherwise you risk overheating the metal and burning out the polymer and zinc coating.

- Periodically drip oil onto the blade (any oil will do). This will help reduce friction, which means the metal will heat up less.

Attention: in the process of cutting corrugated sheets with a jigsaw, small metal shavings are formed. It must be promptly removed using a soft cloth (do not use an abrasive brush for this! You may damage the polymer coating). Otherwise, the pieces of metal remaining on the surface may begin to rust and spread corrosion around themselves.

Tips and tricks

When working with corrugated sheets, there is a risk of serious injury from cutting yourself on sharp edges. Therefore, experts recommend starting metal processing only with appropriate clothing:

- Protective gloves will protect your hands from cuts.

- When working with power tools, you should always wear safety glasses to protect your eyes from small metal shavings.

- Construction headphones will protect your ears from the loud noise generated by power tools.

- To protect the body from damage, it is necessary to wear overalls.

- Closed shoes will also help avoid injury.

Another useful safety tip when working with the tool: it is forbidden to use an angle grinder without a protective casing. The fact is that the cutting parts rotate at a very high speed, so special care must be taken when working. These are basic tips and recommendations that experts do not recommend forgetting about.

Is it permissible to use a “cricket” attachment on a drill?

This is also a fairly popular tool. Almost everyone has a drill; you just need to buy an inexpensive attachment with which the drill will work like electric scissors. Also, don't forget to purchase a set of replacement blades.

A drill with a “cricket” attachment carefully cuts metal without deforming the edges of the corrugated sheet. The edges do not bend and do not need to be straightened afterwards; The edges are smooth, without burrs.

In what cases is it used?

For longitudinal or transverse cutting of profiled sheets, for shape cutting, for cutting hard-to-reach areas. The thickness of the metal should not exceed 0.8 mm.

Attention: when cutting, the drill attachment must be positioned strictly perpendicular to the surface of the corrugated sheet. In this position the tool will work correctly.

Are nibblers used for cutting corrugated sheets?

Yes, they do. They have three main advantages:

- They cut metal faster than a jigsaw and are comparable in speed to a grinder.

- With their help, you can start cutting the sheet not from the edge, but from the middle (the tool cuts a hole in the right place on the sheet).

- The edges of the corrugated sheet do not deform. The cut line is smooth.

- They cut corrugated sheets with any wave height and any steel thickness.

The only drawback of the tool is its rather high cost.

In what cases is it used?

For longitudinal and transverse cutting of corrugated sheets, to obtain a straight and shaped cut line in hard-to-reach places (the tool is highly maneuverable).

Attention: Adjust the tool before starting work. The cutting edge must be strictly perpendicular to the surface of the corrugated sheet - this will avoid the appearance of “torn” edges on the sheet.

During the cutting process, a lot of waste is generated - sharp metal shavings. Do not forget to promptly remove it from the surface of the corrugated sheet using a soft cloth.

Is it possible to cut corrugated sheets using slotted shears?

Yes. Along with nibblers, this tool is considered optimal for cutting corrugated sheets. Slotted shears cut corrugated sheets quickly and accurately and do not deform the edges of the corrugated sheets. The cut line is smooth, without burrs.

In what cases is it used?

For longitudinal and transverse cutting of metal with a thickness of no more than 2 mm, for cutting holes of complex shapes.

Attention: when cutting, metal shavings are also formed; they must be promptly removed from the surface of the corrugated sheet.

How to cut corrugated sheets evenly

To cut the material accurately and evenly, you need to place corrugated sheeting with the same profile on the sheet being processed. After this, draw a line and cut along it.

Another way is to place a sheet on top and not remove it, resting its side surface against the end of the corrugated sheet, which lies on top.

Important! With the second option, the top sheet will become unusable if you constantly use it as a guide. Therefore, it is necessary to immediately put this corrugated sheet aside as consumables.

Another effective method is shown in the video:

Is it possible to cut profiled sheets with a hand hacksaw?

A hacksaw is an affordable and easy-to-use tool. Beginners can safely use it, since working with a hacksaw does not require any special skills.

Advantages of the tool:

- there are no restrictions on the thickness of metal sheets;

- the cut line is smooth, there are no “burrs”, the edges are not deformed.

The main disadvantage of a manual hacksaw is its low speed.

In what cases is it used?

Mainly for adjusting sheets (when you need to cut a right angle or a small strip of metal). It is difficult to obtain a shaped cut using a hacksaw.

Attention: when cutting corrugated sheets with a hacksaw, use a special table - the sheet must be securely fixed (if you are working on the roof, cutting the corrugated sheets “on the spot” will not work).

Are hand-held metal shears used for cutting corrugated sheets?

They are used, but the tool requires work experience and certain skills - in their absence, you risk getting deformed edges or “burrs” on the edges of the corrugated sheet.

In what cases is it used?

If you need to get a straight cut on one profiled sheet up to 0.6 mm thick. This tool is not used for cutting several sheets at the same time.

Attention: when choosing perforated scissors, pay attention to the length of the handles - the longer they are, the less effort you will put into the process.

We looked at the main tools that are useful for cutting corrugated sheets with your own hands. Choose the ones that are optimal in your case:

- If you need to cut a sheet lengthwise or crosswise, it is better to choose power tools - a jigsaw, slotted or nibblers, or a drill attachment. Their productivity is higher than that of manual ones. The work goes quickly, while you apply a minimum of physical effort. Also, many power tools are distinguished by their maneuverability; with their help, you can obtain straight and curved cutting lines. They are characterized by high cutting quality: there are no “burrs” on the metal and no edge deformations.

- If you need to cut a small hole of a simple shape or carefully cut off a small part of the metal, you can use hand tools - a hacksaw or cutting shears (they are also used as auxiliary, and not the main tools for cutting).

They have their advantages. Hand tools:

- More secure. The risk of injury during operation is minimal.

- They are low cost, so they are available to almost everyone.

- Minimal impact on the polymer coating and zinc layer.

- If you need an effective and inexpensive power tool, consider an electric jigsaw or a cricket attachment for a drill.

- If a clean cut line, maneuverability and fast work speed are paramount, electric shears for cutting corrugated sheets (nibblers or slotted) are optimal.

- If you choose manual cutting shears, we recommend that you first practice cutting corrugated sheets. This tool requires experience, otherwise the result of the work will be unsatisfactory - deformed edges of the corrugated board, “burrs”.

- If you have no experience working with hand tools, choose a hacksaw - it cuts slowly, but is easier to work with.

The categories mentioned in the article are:

Profiled sheet

Profile cutting tools

Let's figure out how to cut profiles for drywall (guides, racks, etc.) It is important to know what tools are needed for this, as well as take into account the features and methods of cutting.

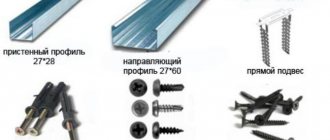

There are several main types of metal profiles:

- Rack-mounted

Used for partitions. They remain level and bear the weight of plasterboard boards.

- Bearers

They are placed vertically and fixed inside the guide channels.

- Guides

Typically installed at the bottom and top of the frame.

Depending on the specific task, arched, corner, beacon, and ceiling profile types can be used.

During the process of assembling the frame, all types of profiles have to be cut into several pieces in order to achieve the required structure. This can be done in several ways and tools. The main thing is that some requirements are met:

- The selected tool must be suitable for metal work

- The surface of the profile must retain its shape and not deform.

- Ease of use of the selected tool

Before cutting the metal profile for drywall, you need to prepare a set of tools:

- Felt pen (marker) for marking

- Roulette

- Metal ruler

- Tool for cutting metal profiles

Let's look at some of them, and you can make the choice yourself.

Metal scissors

They do not require special skill to operate and are inexpensive. Any type of profile can be cut. There is no dependence on electricity. The amount of debris and noise level are minimal. It is the most common cutting tool in construction work with plasterboard boards.

Metal file and jigsaw

The cutting area is even and smooth. With this method, the noise level is higher and debris (metal shavings) remains after work. The costs of purchasing power tools are increasing.

Hacksaw for metal

This can be considered the worst choice of cutting method. It is possible to cut a metal profile, but it is inconvenient (due to the thinness of the metal, the hacksaw blade will stick).

Cutting machine

It is convenient to cut metal profiles and the machine is easy to operate.

Disadvantages: the machine is expensive, takes up a lot of space, and is noisy during operation.

Bulgarian

Noisy way, with flying sparks. Use with extreme caution in rooms where wallpaper has already been pasted and/or floor covering has been laid, to avoid sparks and burning of the surface.