Wood's alloy cast into polyethylene containers

Low-melting alloys

, these are basically eutectic metal alloys with low melting points (usually below the melting point of tin). Basically, low-melting alloys include alloys that are stable in air, although alkali metal alloys are capable of forming low-melting eutectics and should also be classified as low-melting alloys. To obtain low-melting alloys that are widely used in technology and have great practical importance, lead, bismuth, tin, cadmium, thallium, mercury, indium, gallium and sometimes zinc are used. The lower limit of the melting temperature among all known low-melting alloys is the melting point of thallium amalgam (-61°C), and the upper limit is the melting temperature of pure tin, although currently there are alloys of the sodium-potassium-cesium system with a record low melting point of -78°C !

Types, groups and compositions of low-melting alloys[edit]

Low-melting alloys used in modern global industry:

| Alloy composition | Tpl, | Density g/cm3 | Application area | Note | Other information |

| bismuth 76.5%, thallium 23.5% | 198 | T, P | Acid resistant | Eutectic alloy | |

| tin 89%, zinc 11% | 198 | T, P | |||

| bismuth 47.5%, thallium 52.5% | 188 | T | Eutectic alloy | ||

| bismuth 44.2%, lead 9.8%, thallium 48% | 186 | T | ∑? | Eutectic alloy | |

| tin 62%, lead 38% | 183 | 8,5 | T, P | Eutectic alloy , ~POS 61 | |

| tin 64%, lead 36% | 181 | T, P | |||

| sodium 70%, mercury 30% | 181 | T | Chemical act, Toxic. | ||

| cadmium 32%, tin 68% | 177(178) | T, P | Eutectic alloy | ||

| lead 32%, tin 68% | 177 | T, P | |||

| bismuth 12.8%, lead 49%, tin 38.2% | 172 | T, P | |||

| potassium 80%, thallium 20% | 165 | T | Chemical act | ||

| bismuth 13.3%, lead 46%, tin 40.1% | 165 | T, P | ∑? | ||

| bismuth 10.5%, lead 42%, tin 47.5% | 160 | T, P | |||

| bismuth 13.7%, lead 44.8%, tin 41.5% | 160 | T, P | Eutectic alloy | ||

| bismuth 16%, lead 36%, tin 48% | 155 | T, P | |||

| bismuth 18.1%, lead 36.2%, tin 45.7% | 151 | T, P | |||

| bismuth 25%, lead 50%, tin 25% | 149 | T, P | |||

| bismuth 62.5%, cadmium 37.5% | 149 | T, P | |||

| bismuth 19%, lead 38%, tin 43% | 148 | T, P | |||

| bismuth 50%, lead 50% | 145 | T, P | |||

| lead 32%, tin 50%, cadmium 18% | 145 | T, P | |||

| bismuth 60%, cadmium 40% | 144 | T, P | Eutectic alloy | ||

| lead 42%, tin 37% | 143 | T, P | ∑? | ||

| cadmium 18.2%, lead 30.6%, tin 51.2% | 142 | 8,8 | T, P | ~POSK 50-18 | |

| bismuth 57%, thallium 43% | 139 | T | Eutectic alloy | ||

| bismuth 57%, tin 43% | 138 | T, P | Eutectic alloy | ||

| bismuth 58%, tin 42% | 136,5 | T, P | |||

| mercury 70%, potassium 30% | 135 | T | Chemical act, Toxic. | ||

| potassium 90%, thallium 10% | 133 | T | Chemical act | ||

| bismuth 28.5%, lead 43%, tin 28.5% | 132 | T, P | |||

| bismuth 56%, tin 40%, zinc 4% | 130 | T, P | Eutectic alloy | ||

| bismuth 43%, lead 43%, tin 13% | 128 | T, P | ∑? | ||

| bismuth 27.2%, lead 44.5%, tin 33.3% | 127 | T, P | ∑? | ||

| bismuth 56.5%, tin 43.5% | 125 | T, P | Eutectic alloy | ||

| bismuth 56%, lead 44% | 125 | T, P | |||

| bismuth 55.5%, lead 44.5% | 124 | T, P | Eutectic alloy | ||

| bismuth 33.4%, lead 33.3%, tin 33.3% | 123 | T, P | ~POSV 33 | ||

| bismuth 36.5%, lead 36.5%, tin 27% | 117 | T, P | |||

| bismuth 40%, lead 40%, tin 20% | 113 | T, P | Bismuth Alloy | ||

| bismuth 42.1%, lead 42.1%, tin 15.8% | 108 | T, P | |||

| bismuth 48%, lead 28.5%, tin 14.5%, mercury 9% | 105 | T | |||

| bismuth 53%, tin 26%, cadmium 21% | 103 | T, P | |||

| bismuth 54.4%, lead 25.8%, tin 19.8% | 101 | T, P | |||

| bismuth 50%, lead 28%, tin 22% | 100 | T, P | Rose Alloy(Rose) | ||

| bismuth 50%, lead 40%, tin 10% | 100 | T, P | |||

| bismuth 40%, lead 20%, tin 40% | 100 | T, P, M | |||

| bismuth 47%, lead 35.3%, tin 17.7% | 98 | T, P, M | |||

| bismuth 52.5%, lead 32%, tin 12.5% | 96 | T, P, M | ∑? | ||

| bismuth 52%, lead 32%, tin 16% | 96 | T, P, M | |||

| bismuth 50%, tin 25%, cadmium 25% | 95 | T, P, M | |||

| bismuth 49.9%, lead 43.4%, cadmium 6.7% | 95 | T, P, M | |||

| bismuth 50%, lead 31%, tin 19% | 94,5 | T, P, M | |||

| bismuth 50%, lead 31.2%, tin 18.8% | 94 | T, P, M | Newton's alloy | ||

| bismuth 50%, lead 25%, tin 25% | 93(93,75) | T, P, M | |||

| bismuth 50%, lead 30%, tin 20% | 92(91,6) | T, P, M | Lichtenberg alloy | ||

| bismuth 52%, cadmium 8%, lead 40% | 91,5 | T, P, M | |||

| bismuth 51.6%, cadmium 8.1%, lead 40.3% | 91 | T, P, M | |||

| bismuth 55.2%, lead 33.3%, thallium 11.5% | 91 | T | Eutectic alloy | ||

| sodium 50%, mercury 50% | 90 | T | Chemical act, Toxic. | ||

| sodium 90%, mercury 10% | 90 | T | Chemical act, Toxic. | ||

| bismuth 50%, tin 25%, lead 25% | 90 | T, P, M | ~POSV 50, Rose alloy | ||

| bismuth 53.2%, cadmium 7.1%, lead 39.7% | 89,5 | T, P, M | |||

| sodium 96.7%, gold 3.3% | 80 | T | Chemical act. | Eutectic alloy | |

| sodium 80%, mercury 20% | 80 | T | Chemical act, Toxic. | ||

| bismuth 35.3%, cadmium 9.5%, lead 35.1%, tin 20.1% | 80 | T, P, M | |||

| bismuth 58%, indium 17%, tin 25% | 79 | T, P, M | Eutectic alloy | ||

| sodium 90%, potassium 10% | 77 | T | Chemical act | ||

| bismuth 50%, lead 34.5%, tin 9.3%, cadmium 6.2% | 77 | T, P, M | |||

| bismuth 50%, lead 34.4%, tin 9.4%, cadmium 6.2% | 76,5 | T, P, M | |||

| bismuth 27.5%, cadmium 34.5%, lead 27.5%, tin 10.5% | 75 | T, P, M | |||

| bismuth 33.7%, indium 65.3% | 72 | T, P, M | ∑? | Eutectic alloy | |

| bismuth 38.4%, lead 30.8%, tin 15.4%, cadmium 15.4% | 71 | T, P, M | |||

| bismuth 49.5%, lead 27.27%, tin 13.13%, cadmium 10.1% | 70 | T, P, M | Eutectic alloy | ||

| bismuth 50%, lead 26.3%, tin 13.3%, cadmium 10% | 70 | T, P, M | ∑? | ||

| sodium 70%, mercury 30% | 70 | T | Chemical act, Toxic. | ||

| bismuth 48.8%, lead 24.3%, tin 13.8%, cadmium 13.1% | 68,5 | T, P, M | |||

| bismuth 52.2%, lead 26%, tin 14.8%, cadmium 7% | 68,5 | T, P, M | |||

| bismuth 50.1%, lead 22.6%, tin 13.3%, cadmium 10% | 68 | T, P, M | ∑? | Lipovitsa alloy | |

| bismuth 50%, lead 25%, tin 2.5%, cadmium 12.5% | 68 | T, P, M | ∑? | Wood's alloy | |

| bismuth 50.4%, lead 25.1%, tin 14.3%, cadmium 10.2% | 67,5 | T, P, M | Wood's alloy | ||

| bismuth 50.1%, lead 24.9%, tin 14.2%, cadmium 10.8% | 65,5 | T, P, M | Wood's alloy | ||

| sodium 99%, thallium 1% | 64 | T | Chemical act | Eutectic alloy | |

| bismuth 50.0%, tin 12.5%, lead 25%, cadmium 12.5% | 60,5 | T, P, M, F | |||

| bismuth 53.5%, tin 19%, lead 17%, mercury 10.5% | 60 | T | toxic | ||

| sodium 60%, mercury 40% | 60 | T | Chemical act. Toxic. | ||

| sodium 80%, potassium 20% | 58 | T | Chemical act. | ||

| bismuth 49.4%, indium 21%, lead 18%, tin 11.6% | 57 | T, P, M, F | Eutectic alloy | ||

| mercury 70%, sodium 30% | 55 | T | toxic, reacts with water. | ||

| bismuth 42%, lead 32%, mercury 20%, cadmium 6% | 50 | T | toxic | ||

| bismuth 36%, mercury 30%, lead 28%, cadmium 6% | 48 | T | toxic | ||

| bismuth 47.7%, indium 19.1%, tin 8.3%, cadmium 5.3%, lead 22.6% | 47 | T, P, M, F | ∑? | Eutectic alloy | |

| sodium 50%, mercury 50% | 45 | T | Chemical act. | ||

| bismuth 40.2%, cadmium 8.1%, indium 17.8%, lead 22.2%, tin 10.7%, thallium 1% | 41,5 | T, P, M, F | |||

| sodium 70%, potassium 30% | 41 | T | ∑?Chem.act. | ||

| sodium 60%, potassium 40% | 26 | T | Chemical act. | ||

| gallium 95%, zinc 5% | 25 | 5,95 | T | Eutectic alloy ? | |

| sodium 85.2%, mercury 14.8% | 21,4 | T | Chemical act. | ||

| gallium 92%, tin 8% | 20 | T | Eutectic alloy ? | ||

| sodium 56%, potassium 44% | 19 | T | Chemical act. | ||

| potassium 90%, sodium 10% | 17,5 | T | Chemical act. | ||

| gallium 82%, tin 12%, zinc 6% | 17 | 6,13 | T | ||

| gallium 76%, indium 24% | 16 | 6,235 | T | ||

| gallium 67%, indium 29%, zinc 4% | 13 | 6,355 | T | ||

| potassium 50%, sodium 50% | 11 | T | Chemical act. | ||

| Gallium 67%, indium 20.5%, tin 12.5% | 10,6 | T | |||

| potassium 60%, sodium 40% | 5 | T | Chemical act. | ||

| gallium 62%, indium 25%, tin 13% | 4,85 | 6,44 | T | ||

| gallium 61%, indium 25%, tin 13%, zinc 1% | 3 | 6,4 | T | Russian Alloy | |

| potassium 70%, sodium 30% | -3,5 | T, L | Chemical act. | ||

| rubidium 91.8%, sodium 8.2% | -4,5 | 1,485 | T | Chemical act. | |

| potassium 80%, sodium 20% | -10 | 0,878 | T, L | Chemical act. | |

| potassium 78%, sodium 22% | -11,4 | T, L | Chemical act. | ||

| potassium 77.3%, sodium 22.7% | -12,5 | 0,882 | T, L, I | Chemical act. | |

| cesium 93%, sodium 7% | -28 | 1,765 | T, I | Chemical act. | |

| cesium 94.5%, sodium 5.5% | -30 | 1,778 | T, I | Chemical act. | |

| mercury 97.2%, sodium 2.8% | -48,2 | 13,16 | T | React with water. | |

| mercury 91.44%, thallium 8.56% | -61 | 13,45 | T | The most fusible amalgam | |

| sodium 12%, potassium 47%, cesium 41% | -78 | 1,28 | T, I | React. with water. | Soviet Alloy |

(Note: Several different melting points for the same alloy are the result of different data sources)

- (T - coolant)

- (P - solder)

- (M - model casting alloy)

- (F - for fire alarm sensors)

- (L - laboratory for absolutization of solvents)

- (I is the working fluid of ion rocket engines)

Low-melting alloys. Compound. Properties. Application, requirements

All topics in this section:

SINMA-74 Sinma-74 is an acrylic fluorine-containing copolymer of hot-curing powder-liquid type.

PURPOSE: Sinma-74 plastic is used in the ortope SINMA-M Sinma-M is a hot-curing acrylic plastic of the powder-liquid type. PURPOSE: Sinma-M plastic is used in orthopedic dentistry

Base wax. Compound. Property. Application Composition: 78% paraffin 22% beeswax 0.04% dyes softening t 36-40 C melting t 50-63 C

Group - Thermoplastic impression materials Hard-crystalline impression materials include gypsum and masses consisting of zinc oxide EUGANOL and GUIACOLA (dentol, repin)

Silicone impression materials Currently, this group is increasingly used in dentistry, but the high cost of these materials still limits their use, but the future of impression materials undoubtedly belongs to si

Thiakol impression materials The base is thiacol rubber. Representatives: Tiodent Tiodent-M - consists of 2 pastes: main-white corrective-colored, which are mixed in a ratio of 4:1

Thermoplastic impression materials The entire group of thermoplastic impression materials has one common property - the ability to soften when heated and harden when cooled. Typically composed of thermoplastics with

Composition of dental porcelain. Porcelain masses for metal-ceramic dentures Porcelain masses used in orthopedic dentistry consist of: feldspar (60-75%) quartz (15-35%) kaolin (3-10%)

Protective equipment for dental technicians Protective equipment for dental technicians is divided into PERSONAL and GENERAL. Personal includes: 1 Special

Safety precautions when working on a grinding motor Before starting work: 1 Clean up your work area, remove all unnecessary items, check and prepare the necessary tools for work. 2 Check that the grounding, wires, and sockets are correct.

Safety precautions when working with acids Before starting work, make sure that the container in which the acid is located must have an inscription with the name of the acid it contains. Check if the container is broken or doused with acid.

Ethacryl. Compound. Property. Application. Polymerization mode Ethacryl-02 is a hot-curing synthetic material of the powder + liquid type. Has increased plasticity at the time of formation and good elasticity after polymerization MONOMER-M

Fast-hardening plastics. General characteristics. Compound. Method of application In our country, fast-acting plastic was proposed in the 50s under the name AST. In the 70s, high-speed plastics were allocated to an independent group of materials, which include.

Sielast-03. Compound. Properties application Sielast-05 is a cold-curing filled silicone composition consisting of 2 pastes - the main one (light green color) and

Safety precautions when working with abrasive materials A dental technician uses abrasive materials when processing, grinding and polishing various removable, fixed, clasp, orthodontic, maxillofacial prostheses.

Elastoplast. Boxil. Compound. Scope of application Elastoplast is an elastic plastic based on a copolymer of vinyl chloride with butyl acrylate. Release form: powder + liquid Polymerization: in one hour, bring to

Disadvantages of alginate impression materials Alginate impression materials consist of sodium layers of alginic acid, it is a powder that swells in water and forms a colloidal gel system.

Hardness of materials The hardness of materials is understood as its resistance to deformation on the surface under the established mechanical influence on it of another harder body of a given shape and size, which does not change.

Orthocor Properties: impression material produced in the form of large plates of brown tones. It has high plasticity when cold, so each plate in the package is repositioned

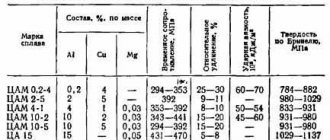

Low-melting alloys. Compound. Properties. Application, requirements They occupy an important place in the work of a dental technician, although they belong to auxiliary materials. It is used 1. when stamping crowns 2. when making dies and counter-dies

Dental PURPOSE: used for modeling crowns, veneers, pin teeth, reproduction of the frame of a bridge. COMPOSITION: contain

Modevax PURPOSE: Modevax is used in orthopedic dentistry for modeling fixed one-piece metal-ceramic and metal-polymer prostheses. Modevax

Basic plastics, stages of maturation. Polymerization mode Any set of plastics includes liquid (monomer) and powder (polymer) MONOMER-MMA-methyl ester of methacrylic acid. Colorless liquid with the odor of ocetone Plot

Polishing agents used in fixed prosthetics The polishing process is not fundamentally different from grinding: under the action of abrasive grains, a layer of material is removed from the surface being treated. Polishing is carried out in order to give the surface

Gold, its alloys, gold samples used in dental prosthetics. Compound. Properties. Application Gold is found in nature in the form of large pieces (nuggets) or loose gold, that is, a mixture of gold with river sand. The only chemical compound of gold in nature is COLOVERIDE.

Thermoplastic impression materials. Compound. Application. Methodology for obtaining models from impressions obtained from thermoplastic masses The entire group of thermoplastic impression materials has one common property - the ability to soften when directed and harden when cooled! As a rule, the composition of thermoplastic

Х18 Н9 Т Stainless steel became widely used in the 30s. Since the introduction of stainless steel into denture practice, it has become possible to almost completely replace expensive metals and prosthetics

Tiodent. Compound. Properties Application Base: thiacol rubber. Representatives: Tiodent Tiodent-M-consists of 2 pastes: main-white corrective-colored, which are mixed in a ratio of 4:1 Quality

VOSKOLIT 03 Used for modeling frames of clasp dentures and its elements Composition: 54% paraffin 22% cerisine 20% beeswax 4% carnauba 0.1% kra

Gypsum. Its property. Gypsum production. Storage Rules Gypsum In our country, gypsum is most widely used in orthopedic dentistry. Using plaster, you can take impressions of denture rows and jaws and prepare masks

Second method Open method. Gypsum is placed in a cooking pot and the temperature is gradually added to 165 C and the temperature is maintained for 10-12 hours, after which it becomes semi-aqueous. Next, the gypsum is sorted on sieves and introduced into

Akrel. Ftorax. Compound. Properties. Application. Polymerization mode FTORAC is hot-curing powder+liquid type plastic. Based on fluorine-containing acrylic copolymers. The powder is pink, but the finished prosthesis is made of fluorex in

Chills for steel and gold. Application, influence on the thickness of products When heating metal objects, intensive oxidation of the surface occurs, which is covered with an oxide film-scale. This film has great hardness and brittleness, in some cases

Stomaplast. Compound. Properties. Application Refers to thermoplastic impression materials. In the form of a greenish mass poured into a metal ladle. Intended for obtaining functionally suction casts of edentulous jaws. WITH

Mechanical properties of materials. Elasticity The ability of a material to provide increasing resistance to deforming forces, change size and shape under their influence, and return to its original state after removing the load is called

Artificial teeth made of plastic. Preparation method. Advantages and disadvantages in comparison with porcelain teeth Acrylic plastics are used to make not only the bases of removable dentures, but also artificial teeth. Unlike porcelain teeth, the technology of factory production of plastic

Soldering agents (fluxes) properties, use in soldering The most common flux for soldering prostheses made of steel and gold is borax. It protects the soldered surfaces and cleans them from acids that prevent the diffusion of solder into the base metal. Spaiv

Advantages 1 Easy preparation of the mass and its introduction into the oral cavity 2 Removal from the oral cavity as a whole 3 The mass is easily separated from the model 4 Little time is spent on removal from

Gypsum. Its property. Gypsum production. Storage Rules Gypsum In our country, gypsum is most widely used in orthopedic dentistry. Using plaster, you can take impressions of denture rows and jaws and prepare masks

Elastic plastics (Eladent, Orthosil, Boxil). Composition, properties. Application of Boxil for the production of bucker tires. Composition: cold vulcanized silicone rubber. Keep in the press for 3 hours. 30 minutes in soda solution, then

Solders for steel and gold. Compound. Properties. Requirements for them. Application Soldering is the process of rigidly joining metal parts by melting filler material - solder, which has a melting point lower than the base metal. Connection from to

Base wax.Composition. Property. Application Composition: 78% paraffin 22% beeswax 0.04% dyes softening t 36-40 C melting t 50-63 C

Gypsum. Obtaining dental plaster. Super plaster. Properties of dental gypsum. Strength of gypsum Gypsum In our country, gypsum is the most widely used in orthopedic dentistry. Using plaster, you can take impressions of denture rows and jaws and prepare masks

Second method Open method. Gypsum is placed in a cooking pot and the temperature is gradually added to 165 C and the temperature is maintained for 10-12 hours, after which it becomes semi-aqueous. Next, the gypsum is sorted on sieves and introduced into

Dentafol. Compound. Properties. Application Dentafol is a thermoplastic impression material. Designed to obtain high-precision functional casts of edentulous jaws, especially with significant atrophy of the mucous membrane of the jaw

Hardness of materials. The concept of hardness. Hardness measurements The hardness of materials is understood as its resistance to deformation on the surface under the established mechanical influence on it of another harder body of a given shape and size, which does not change.

Redont. Compound. Property. Application Redont is a self-hardening plastic, which is a copolymer of methyl and ethyl esters of methacrylic acid, commercially produced in the form of a preparation consisting of powder and liquid.

Molding materials. General information. Compound. Method of application For the production of various materials or their parts in dental laboratories, precision casting or molding methods are used. The essence of these methods is that the material in the molten

Tiodent Tiodent-M- consists of 2 pastes: basic-white corrective-colored, which are mixed in a ratio of 4:1. A high-quality impression can be obtained using theodont and theodont-M

Rules for mixing gypsum. Catalysts and inhibitors. What does the strength of gypsum depend on? The process of accelerating or slowing down the setting of gypsum can be regulated if catalysts are used - substances that accelerate the setting of gypsum, this is a 3% solution of table salt

Thermomass 1; 2; 02. Composition. Properties. Application Thermomass No. 1 is produced in the form of round plates of dark red color. It softens at 50-60 C, hardens at 20-25 C for 3 minutes and is used to remove functional marks.

Elastic plastics. Their scope of application Elastoplast is an elastic plastic based on a copolymer of vinyl chloride with butyl acrylate. Release form: powder + liquid Polymerization: in one hour, bring to

Safety precautions when working with gasoline When working with gasoline, remember that this liquid is flammable, flammable, and if not handled carefully, a fire may occur. Smoking is strictly prohibited during work.

Biological properties of materials The biological properties of materials mean their possible impact on the biological environment in which they are located. Thus, all basic dental materials should not cause negative

Thermoplastic impression materials (Stens, Acrodent, Thermomass 02) composition. Properties. Application. Method for obtaining STENS 02 models - produced in the form of round plates of different tones, softens at a temperature of 45-55 C, hardens at 35-37 C, used in dental practice for the manufacture of auxiliary

THX. Compound. Properties. Applications Silver-palladium alloy was developed in the 30s and was called pollargens. Authors: Kurpansky in collaboration with Tsitrin and Lipets. Each author gives his own recipe for the alloy. But at any time

Silicate molding materials Quartz sands are used for the preparation of molding sands used in casting alloys with a high melting temperature of over 1000 C. SILICON OXIDE is the main component of the mixtures. She will come

Types of porosity formed in plastic Violations of polymerization modes as well as improper mixing, porosity is formed in plastic. There are 3 types of porosity: 1. gas 2. granular 3. compressed porosity

Elastic base plastics Hot curing plastics: MONOMER-MMA-methyl ester of methacrylic acid. Colorless liquid with the odor of ocetone Density 0.955 g/cm3 boiling point 1

Cold-curing plastics are fast-acting or self-hardening. Polymerization of cold-curing acrylic plastics occurs according to the system: ACTIVATOR-INITIATTOR. As an activator that is added to mono

Elastic base plastics are used for the manufacture of: 1. dentures with soft linings. 2. in maxillofacial orthopedics (prosthetics) 3. in the elimination of birth defects 4. for prosthetics

Plastic polymerization mode There are 2 plastic polymerization modes. 1. Water bath: a cuvette with preformed plastic is placed in water at room temperature and the water temperature is gradually increased to 80 C during

Heat treatment of metals and alloys is a process involving heating and cooling. Dental technicians use annealing and hardening. Hardening is the process of heating a metal and rapidly cooling it in water.

Safety precautions when working with plastic When working with plastic, you should be aware that the monomer (liquid) is highly flammable, irritates the respiratory tract and has a negative effect on the skin of the hands. BEFORE WORK STARTS

Repin. Dentol. Compound. Properties. Application REPIN-Czechoslavak mass-zincoxide eugenal paste of white and orange color. The pastes are thoroughly mixed 1:1 and a very plastic mass is obtained, almost non-shrinking. Applies

Types of artificial porcelain teeth used in orthopedic dentistry Artificial crowns, bridges, inlays, and coatings for metal dentures can be made from porcelain masses. In the laboratory, a dental technician makes porcelain teeth

K.H.S Composition. Properties. Application K.H. were introduced for the first time abroad in 1933 under the name VITALLIUM. In our country in 1953, Doynikov co-developed the alloy K.H.

Formative materials used for processing, grinding, polishing removable dentures All parts of dentures and devices after manufacturing in the laboratory must undergo careful finishing, grinding and polishing. They remove excess material, protrusions, irregularities, making the surface dentally

Areas of application of low-melting alloys[edit]

In all areas of application of low-melting alloys, without exception, the main properties in demand for the intended use of these alloys are a specified low melting point. The secondary properties in demand in the areas of application of these alloys are a certain density, tensile strength, chemical reactivity, vacuum tightness, and thermal conductivity. From an economic point of view, the cost of the alloy and its density come first. In this or that case of using low-melting alloys, engineering and economic calculations are required for the most optimal solution for the use of the alloy. Economic indicators are especially pronounced in the large-scale consumption of a low-melting alloy of one grade or another. Currently, the main areas of application of low-melting alloys are:

- Production and use of liquid metal coolants in energy and mechanical engineering.

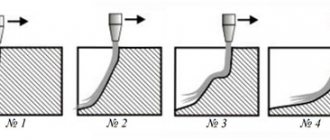

- Foundry (production of lost wax models).

- Fire early warning systems (temperature sensors, fire extinguishing valves, etc.).

- Thermometry (working fluid for thermometers of various types).

- Vacuum technology (seals, soldered seams, etc.).

- Microelectronics (solders, coatings, temperature sensors, fuses, etc.)[1].

- Medicine (bone fixation, prosthetics, etc.)[2].

- Use as a meltable metal lubricant.

Scroll

In accordance with the main classification (melting point no more than 500°C), the following elements are included in the list of light alloys:

| Name | Melting point (°C) |

| Zinc | 419 |

| Palladium | 327 |

| Lead | 327 |

| Cadmium | 321 |

| Thallium | 303 |

| Bismuth | 271 |

| Polonium | 254 |

| Tin | 232 |

| Indium | 157 |

| Sodium | 98 |

| Potassium | 63 |

| Rubidium | 39 |

| Gallium | 30 |

| Cesium | 28 |

| Mercury | – 39 |

Mercury is the most fusible metal. She is the only one of the group who melts in the cold.

Gallium is called a metal that melts in the hands (the normal human body temperature is almost seven degrees higher than the melting point of the substance).