The simplest and most common option for assembly in a private home is a sewer system made of concrete rings. Construction of a well from 1-3 elements assembled from special standard concrete components.

This concept, among other things, implies the use of amenities provided by connecting housing to the main utility networks of the public infrastructure. There are not always central communications for water supply and disposal of household waste in the area of residence. Therefore, amenities, in the form of an autonomous sewerage system, have to be created independently.

All property owners want to make permanent residence in a private home and seasonal stay at their favorite dacha comfortable. Let's look at what a sewage system made from concrete septic tanks is like.

Benefits of concrete

A septic tank for receiving household waste can be made of brick, polymer materials, stone, metal, concrete. The resulting structure is not overly loaded; its durability is affected by the resistance of the source material to aggressive substances and constant humidity. Constructing the walls of a sewer well from concrete rings is considered an ideal option for the following reasons:

- Concrete elements are used when constructing a septic tank on various soils; their resistance to compressive deformations allows them to withstand pressure from displacement of soil layers and groundwater.

- Availability of material.

- High speed of sewerage installation using concrete products.

- Sewerage made from concrete rings is durable and easy to maintain.

- Rings allow you to make a device of the desired depth and diameter.

- Resistance of the material to aggressive substances, groundwater composition and temperature changes.

- Easy to install yourself.

- A large selection of waterproofing materials to protect the walls of the future well.

- Thanks to metal reinforcement elements, concrete products are highly durable.

- Factory-produced products are designed for tight joining.

Concrete products are durable, but they also have their disadvantages.

The main disadvantages during operation: weight, certain difficulties with delivery and loading, the possible need to use lifting equipment and additional labor.

Modern local sewer system

Provided that a family of several people lives in a country house, who regularly use a washing machine and a bathtub, which means a large amount of water is wasted, an internal sewerage system and a filter well are installed.

First of all, you need to calculate the size of the septic tank, the distance of the septic tank from the house and the volume of the sewer ring - then you can calculate the number of reinforced concrete products that need to be purchased. Let's say we know both the volume of the septic tank and what rings are needed.

To build a treatment plant you will need:

- three rings measuring 1000x900 millimeters;

- for concreting a pit - a mixture of sand and cement;

- gravel;

- sand;

- concrete cover with hatch.

A drainage well is necessary so that the liquid from the septic tank becomes purified and clarified and is then directed into the soil. The wastewater flows through sewer pipes into a septic tank, which is designed in a similar way to a drainage pit. Waterproofing is also needed.

If a family consists of 4 people, it uses about 150 liters of water daily, and the volume of the septic tank should be 3-4 cubic meters. The minimum slope of the sewer pipeline should not be less than 2 centimeters, and the maximum - 5 centimeters per linear meter.

Types and types of concrete components

There are two types - wall and additional .

wall products in the shape of a ring can have the following dimensions: internal diameter - 0.7-2.0 m ; wall thickness – 70-100 mm ; standard height – 890 mm . With their help, the necks of any wells are erected. For sewerage in a private house, built from concrete rings with your own hands, products with an internal diameter of 1.5 m .

Additional products differ from wall products in their non-standard height. With their help, the required depth is adjusted when it is not a multiple of the height of standard rings.

The following types of rings are used in this work:

- Having a solid bottom . Needed for overflow sewers, the settling wells of which accumulate silt at the bottom (periodically removed with special equipment).

- Without a lock . Conventional straight rings, for the connection of which cement mortar is used.

- With locking connection . This type is distinguished by notches on one side and protrusions on the other. Installation of products consists of inserting and fixing them by inserting the protrusions into the recesses. Such a lock will prevent the elements from moving during operation of the sewer well.

- Filtration . Walls with evenly spaced holes allow liquid to escape into the ground. These rings are intended for the construction of filtration wells.

example

Choice of sizes and shapes

For the equipment of septic tanks, special rings are used, made of different materials, which may differ in quality characteristics. Sewage systems can install waste pipes of different diameters. In this case, when reducing the thickness of the pipe structure, it is advisable to increase the angle of inclination to prevent the formation of blockages.

To calculate the volume of the septic tank, you need to multiply 600 liters by the number of people living in the building. It is this volume of liquid (600 l) that a citizen will consume within three days.

Stages of installing a sewer well

Let's look at how to make a sewer system in a private house with your own hands from concrete rings. And if a decision is made to entrust the work to a specialized organization, then the information received will help to carry out high-quality control over the installation progress and facilitate communication with workers.

Selecting a location

The location of the sewer septic tank is selected taking into account certain standards and requirements. It should be no closer than: 5 m – from the boundaries of the estate; 5-10 m – from a residential building (so as not to wash away the foundation); 30 m – from the shore of the nearest body of water; 20 m (50 m) – from the water intake on clay (sandy) soil; 3 m – from paths, roads, trees, bushes, vegetable gardens. The bottom of the well should always be above the groundwater level in the area. An access road must be provided to the selected location or subsequently built for periodic pumping of sludge using special equipment.

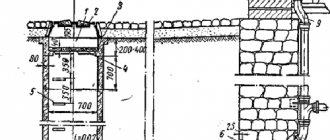

Calculations and septic tank diagram

To install a sewer system in a private house with your own hands from concrete rings, you will need a construction diagram drawn up based on preliminary calculations of the volume of water consumption by all residents. The volume of the septic tank must correspond to the amount of water consumed by residents in three days. The daily norm for one resident is 200 liters. The final figure for the minimum internal volume of a septic tank is obtained by simple multiplication.

The obtained value is very important if you are building a sewer system in a private house with your own hands. The ring scheme provides for the presence of 1-3 septic tank chambers. The number of wells depends on the composition of the family, the number of sanitary devices and mechanisms, and the intensity of their use. A septic tank of three chambers can be considered a real biotechnical complex. Its construction and maintenance will cost more, but the productivity and quality of wastewater treatment is significantly increased.

From three chambers:

- 1st – settling of received wastewater;

- 2nd – purification of liquids (already clarified) from contaminants;

- 3rd – filter chamber.

In treatment chambers, the lower concrete ring must have a solid bottom to protect against leakage of untreated liquid waste. The third chamber is distinguished by the presence of a lower ring with perforation, as well as a drainage layer at the bottom of the well. After passing through the drainage, the purified liquid is absorbed into the soil. Inlet holes are made in the predetermined walls of the rings to connect the wells with overflow pipes. In the first chamber of the septic tank, a hole is also prepared for the pipe coming from the house. This pipe must be below the freezing level of the soil. All pipes are laid with a slope to ensure gravity flow of wastewater.

Each connecting pipe leading to the next chamber must be lower than the level of the wastewater inlet in the previous well. Violation of this requirement will lead to looping of the stream and incorrect operation of the system.

For all wells, round concrete slabs with holes for installing inspection hatches and ventilation pipes are purchased.

Drawing up a preliminary sewerage diagram helps to prevent possible errors, outline the order of work, make high-quality preparations for a set of construction activities, and calculate the number of necessary products and materials.

You may also like: Sewerage in the country - choice and design

Installation of concrete rings for sewerage and operation

The popularity of concrete rings in the presence of plastic analogues on sale is easily explained. Precast concrete products have many advantages, which include affordable cost and the ability to carry out preventive maintenance along with a long period of operation.

Reinforced concrete rings for sewerage are durable and can be used for up to 5 years.

The products are resistant to low winter temperatures. Possessing high-quality insulation, they are not affected by alkalis, water and acids.

Concrete rings are used as a septic tank for sewerage, the implementation of which is possible in several modifications:

- single-chamber structure - made of one concrete ring;

- a multi-chamber septic tank is a kind of sewage system that has several drains.

When deciding to build a septic tank and thinking about how to install concrete rings for sewerage on a site, you need to understand: such work requires certain knowledge and skills.

But awareness of the options for implementing a septic tank simplifies the process of creating it. By choosing the right reinforced concrete rings, you can create a sewer system that works as efficiently as possible.

Do-it-yourself installation of concrete rings for sewerage - step by step

Before you begin arranging a receiving sewer for wastewater, you should prepare for installation work. The septic tank is calculated by volume, which is influenced by the number of people living in the house and the volume of drains.

In accordance with the project, it is necessary to purchase ring elements of the required diameter and configuration, purchase and deliver sand, crushed stone, cement, bitumen and liquid glass to the site.

If the system is planned to be constructed using a mechanized method - using special equipment, you need to agree in advance to rent a crane. To ensure smooth entry of vehicles into the site, access roads must be prepared in advance.

Sewerage from concrete rings is installed in stages. The most difficult thing is to carry out excavation work. To equip a septic tank, you need to follow several steps:

- Digging a hole . Sometimes the earth is undermined manually evenly along the contour of a concrete ring, which is gradually immersed in the ground to its entire height. Another concrete element is placed at the top, undermining the soil further. Another installation method is preliminary digging of a pit using special equipment or manually. The dimensions of the pit should be greater than the diameter of the concrete ring by 0.4-0.5 m, and greater than the height of the reinforced concrete structure by 0.2-0.3 m.

- Formation of a sand cushion . The bottom of the pit is leveled and compacted, adding coarse river sand and moistening the soil.

- Concreting the bottom . Pouring concrete can be replaced by another sequence of work. Sometimes concrete rings with a bottom for sewerage are installed first, although these are more expensive, their price is completely justified. If there is no ring with a bottom, the base is poured with concrete yourself. First, pieces of brick or concrete blocks are placed on which lattice reinforcement is placed. A solution is poured onto the frame, which is prepared from cement (suitable brand M400), crushed stone, river sand and water in a ratio of 1: 3: 2: 0.5. To pour concrete once, you need to immediately prepare the required volume of solution. Then you won’t have to do additional mixing, and the system will be stronger and more airtight.

- Installation of ring elements.

The septic tank ring is equipped with special loops for installation - the so-called ears. Lifting equipment slings are attached to them. Concrete products are lifted by 4 ears at once so that the cables are tensioned evenly. The lower ear is leveled, then the remaining ones are lowered one by one. During construction, the structure is simultaneously sealed. A sealant containing cement is applied to the joints, and the external and internal surfaces in the shape of a cylinder are filled with hot bitumen or other waterproofing agent. - Installing the cover . The gap between the cover and the upper concrete element is carefully sealed. At the end of the installation work, the cover is covered with earth, as is the gap that remains between the rings and the walls of the pit.

Increasingly, instead of the usual cesspool, sewerage is made in the form of a septic tank - a well or a system of wells in which wastewater is consistently fermented, purified and filtered. This modification of the sewer system relieves the home owner from the need to use sewerage services. Installation of a septic tank costs approximately 30,000-35,000 rubles.

Design calculation

Although the prices for sewer concrete rings are through and with a bottom at an acceptable level, you need to select reinforced concrete products with a suitable diameter so as not to overpay for the rings and make the installation process easier.

The volumes of the most popular models KS 10-9, KS 15-9 are 0.23 and 0.40 m3, respectively.

The volume of the septic tank is calculated as the product of the number of residents in the house, the daily rate of individual water consumption (150-200 l) and the number of days during which the well is filled with water (usually 3 days).

Another calculation option is to multiply the total daily volume of water consumption in the house by a factor in the range of 2.5-3.

Soil development

The pit for the chambers can be individual (for one well) or common, in which all the structures of a unified system for receiving and treating wastewater will be erected.

For a separate well, the dimensions of the pit should be 25-30 cm greater than the diameter of the outer surface of the concrete ring selected for installation. The resulting gap will facilitate the process of installing and displacing sewer rings using special equipment. The main disadvantages of such pits: work with the soil is carried out manually, the impossibility of high-quality sealing of joints and waterproofing work on the outside of the rings with a sufficient depth of the structure being built.

A common pit facilitates all types of construction work. Using special equipment, it will be ready in 1.5-2 hours.

In places where the receiving chambers are installed, the bottom of the pit is compacted, lined with waterproofing roll material (usually roofing felt) and filled with concrete mixture. Such a pedestal will not be needed if the lower rings were purchased with a ready-made concrete bottom. At the site of future installation of the filtration chamber of the septic tank, a crushed stone cushion (from 0.5 m) is installed. It allows the purified liquid to pass to the ground without obstacles and be absorbed into it. In addition, such a pillow performs final purification of the liquid.

Waterproofing and ventilation

When interacting with moisture in concrete products, the process of leaching of limestone develops, and various growths and stalactites begin to appear on the surface. Magnesium salts, which are a component of groundwater, contribute to the destruction of the material.

In order to increase the strength characteristics of installed concrete rings, you can use finishing materials specially designed for this purpose.

Such means include:

- Using specially developed technical devices, the rings are treated with sprayed mixtures;

- With the help of injection protection, concrete septic tanks are also strengthened. Only this option is considered the most expensive. For processing, substances based on polyurethane, epoxy resin, or mineral substances are used;

- Bitumen processing mixtures are film-like compositions that, with repeated processing, create a moisture-resistant layer;

- Rolled materials should be used specifically for adhesive waterproofing. These substances are applied to fabric, geotextiles, or fiberglass. Special bitumen mastic is used as a base;

- Penetrating mixtures create crystalline hydrates in the concrete layer that cannot be dissolved in water. The water resistance of the septic tank is ensured only at the depth specified by the manufacturer.

In the modern construction market, there are numerous building materials available to choose from that provide high-quality waterproofing. Various waterproofing technologies have certain differences in reliability, as well as in the periods by which the operational period of septic tanks increases. For example, bitumen protection can crack after the first few years, and the service life of the mastic is much longer.

Final work

Holes for pipes are punched in the designated places of the concrete rings. A house drain pipe is inserted into the first well. Then pipes connect all the chambers of the system. The joints are carefully sealed with mortar.

The next stage is waterproofing the joints of the rings, joints with pipes, and the outer (and preferably inner) surface of the concrete well.

Now each well is covered with a concrete cover, monolithic inspection hatches and ventilation pipes are installed. The work is completed by backfilling the soil into the remaining space of the pit, compacting the layers every 0.2-0.3 m.

The resulting sewage system made of concrete rings, whether built with your own hands or with the help of professional workers, will ensure the removal and high-quality treatment of household wastewater, protect the soil and groundwater on your personal plot from pollution, and eliminate the inconvenience of living in a private house. An inexpensive and effective treatment system will last at least 50 years.

A simplified method for installing a concrete septic tank

If for some reason (lack of funds, lack of space for equipment to operate) you do not have the opportunity to build treatment facilities exactly in accordance with the recommended technology, you can do something simpler.

This method is used in the construction of drinking wells from concrete rings, and it is suitable in our case. It consists in the fact that the ring is installed on the ground exactly at the point of the future septic tank, and the soil is removed from its internal perimeter. At the same time, the soil is being excavated under the walls of the ring, as a result of which it gradually sinks down.

During the digging process, the ring sinks into the ground under its own weight

When the upper edge of the ring drops to ground level, install the next one on it, seal the seams and continue working. The bottom of the tank is poured after excavation is completed and only inside the ring.

The method is not without its drawbacks. In particular, it does not allow waterproofing of seams from the outside, and the reliability and stability of the structure is reduced due to the small bottom area.

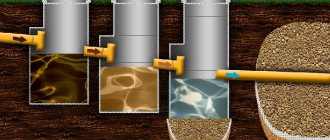

How does a septic tank system work?

A durable concrete well, designed for the quality of sewerage, ensures consistent movement of wastewater:

- water with contaminants enters the first container and is divided into elements of different densities. Heavy fractions remain at the bottom, and light fractions rise to the surface;

- the purified liquid is fed into the second tank, where the organic matter is broken down;

- the third container without a bottom discharges purified water into the ground. The liquid is pre-filtered in a drainage well.

Three-level filtration eliminates soil contamination.