Vacuum casting is a process of producing products of various shapes and configurations by pouring molten material into pre-prepared molds. Using this technology, parts are manufactured from plastic, metal or resin. At the same time, they comply with all technological requirements and quality standards. The resulting products are widely used in a variety of sectors of production, industry, mechanical engineering, aircraft modeling and other segments.

The casting process under rarefied vacuum conditions allows us to obtain products of high quality and the required chemical composition. At the same time, the required level of surface smoothness of the manufactured parts is achieved, exact compliance with established geometric shapes and standards. The use of this method eliminates the need for mechanical processing of the resulting product.

Vacuum casting

Vacuum molding of plastics

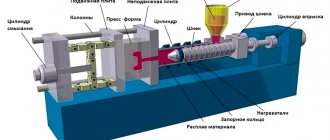

Vacuum casting of plastics is carried out in special silicone molds - this technique can significantly reduce the cost of production, because the silicone mold can be used an unlimited number of times. The plastic molding process itself takes place using special equipment. The plastic molten mass is located in the screw; under the action of a special piston, the mass moves through the channels, after which it fills the prepared forms.

When exposed to high temperatures, plastic molecules begin to move randomly. After entering special molds, the hot mass cools and the crystallization process begins, running from the edge to the center of the product. When operating vacuum chambers for plastic injection, it is necessary to strictly maintain the time and temperature of the composition, otherwise the products will be uneven, with visible defects and defects.

Vacuum molding of plastics

Casting in a vacuum environment requires special equipment and tools. In general terms the method looks like this:

- Granules of polymer material are loaded into the injection molding machine.

- Transferring the material to the plasticization unit - a special cylinder with a screw inside.

- Heating to a set temperature, melting the plastic mass.

- Pouring liquid material into molds for further hardening.

Vacuum casting is a very common technology that is successfully used to produce high quality parts and products. When choosing suitable equipment to ensure the technical side of this process, a number of factors should be taken into account: the volume of products produced, the technical characteristics of the equipment, the production time of a certain batch, the type of material used.

Who are we, why and why

For more than 25 years, we have been helping designers, sculptors and jewelers in the manufacture of their products, including more than 12 years in the format of custom-made jewelry and souvenir production.

We develop new technologies for processing and finishing metals, technical maps and build technological processes. We provide production of serial and exclusive products at our production facilities. We help launch new projects and give new impetus to existing ones.

Development of models of jewelry and souvenirs for serial production. 3D modeling, prototyping, casting, making molds, finishing products after casting, tumbling, setting stones, applying galvanic coatings, textures, patinas, etc.

Initiative and creative, full of ideas, wanting to change something for the better, we are on the same path)

For you, we convert our more than 25 years of experience into the creation of new or vintage, trendy or classic products, collections, souvenirs and simply art objects.

Creation of corporate symbols, cabinet sculpture, interior items, household items and religious accessories.

The embodiment of any fantasies in our production.

Creation of technological maps and production cycles individually for your products. Consultations on technologies of modern souvenir and jewelry production, legal and technological aspects.

3D technologies and jewelry production from professionals and for professionals.

In general, all jewelry production is for you from A to Z.

Our foundry is pleased to offer you a wide range of services related to artistic, jewelry and sculpture casting.

We offer you precision quality vacuum casting using the best equipment and using only certified consumables. Thanks to the use of alloys only from the world's leading manufacturers, we guarantee the stability of the alloy composition. At least six injection cycles per week ensures a high speed of fulfillment of your requests. We offer fulfillment of orders of any volume (from the smallest to the largest) within a reasonable time frame.

A democratic pricing policy will lift your spirits. And daily casting will please you with the speed of execution of your requests!

Conveniently located service office: ideal transport accessibility when traveling both by public and private transport! Opening hours from 10.00 am to 19.00 pm!

Since 2013, the Foundry Shop has been part of the 3D Avtozavod group of companies.

Only here! Casting of any polymers!!!

Any form of payment: Cash, non-cash, payments through Sberbank cards, electronic payment systems.

And also delivery to any point on the map by a transport company!

Vacuum injection molding machine

Various types of materials can be used for the vacuum casting process:

- Polyurethane.

- Polyurethane rubber.

- Transparent plastic.

- Metals and alloys of various compositions.

The choice of a vacuum injection molding machine is determined by the characteristics of the materials and products.

The vacuum injection molding method itself involves pumping out gases and air from the working space and molds. This avoids the formation of gas bubbles in the manufactured products, which significantly increases their quality and strength.

Vacuum injection molding machine

Vacuum injection molding is a modern, popular method that has a whole range of advantages:

- Density and uniformity of the structure of the resulting products, excellent mechanical properties.

- Minimal porosity, absence of air-filled cavities, which allows for subsequent heat treatment of the product.

- Increasing the surface quality of products, which significantly reduces the labor intensity of the polishing process for electroplating.

- Casting of large parts is carried out at low specific pressure, which significantly reduces energy consumption.

- Production of durable castings with walls of the required thickness.

- Casting of large-sized parts.

Vacuum injection molding systems come in a variety of shapes and configurations. They are divided into several categories depending on the place from which air is removed (casing, split mold plane); type of working chamber (cold, hot); loading type (vertical, horizontal); level of workflow automation. The optimal type of devices should be selected taking into account the specifics of production, the functional equipment of the models, their size, performance level and other important factors. Using the vacuum casting method, parts are manufactured whose surface quality requires special requirements. Often such elements are subjected to galvanic treatment or coating with special protective and decorative enamels.

Equipment used for vacuum casting has special requirements. It must meet all standards, be convenient and safe to use. Compliance with the manufacturer's recommendations can significantly increase the service life of the units. Connection, repair, and maintenance of devices for vacuum casting should be carried out only by experienced craftsmen who work within the framework of the regulations and provide a guarantee for all types of operations performed.

Melting and casting in vacuum. Recommendations for developing a gating system.

General principles of gating system design. A properly designed gating system should ensure fast and laminar (smooth, uniform flow) filling of the casting mold at the required speed, continuous supply of molten metal to the solidifying casting, and release of gases from the mold cavity. Material speed is important because if the melt moves too slowly, it may cool before it completely fills the casting cavity. To prevent the turbulent nature of the melt flow, it is necessary to ensure soft transitions between the gates in the direction of the flow of liquid metal and appropriate sizes of the elements of the gate system. The turbulent (with turbulence, stormy) nature of the movement of the melt along the gating channels does not contribute to the optimal movement of the melt jet. Because of this, it cannot immediately form and fill the cavity. In this case, the probability of the formation of shrinkage cavities in the casting and the heterogeneity of the structure of the prosthesis frame significantly increases.The location of the elements of the gating system in the flask is the most important criterion for ensuring high-quality casting. The casting objects must be cooled first and therefore must be placed outside the thermal center of the flask. It is considered correct to place them at a minimum distance from the side surface of the flask and its bottom. In practice, it is usually necessary to maintain the following distances: 4...5mm from the side surface of the flask and 4...5mm, respectively, from its bottom. Smaller values of these dimensions are limited by the mechanical strength of the flask material. The sprue channel(s) and manifold should be the last to cool and, therefore, should be located as close as possible to the thermal center of the flask. Ideally, the collector should be located in the middle of the height of the flask, i.e. in the zone of maximum temperature (thermal center). At the same time, the collector ensures that the casting objects are fed with liquid melt at the stage of their crystallization, preventing their uncontrolled shrinkage.

Based on the above conditions for the location of the collector, the length of the gating channels is determined. It should be remembered that too long channels increase the melt path, impair its flow and increase the amount of residual air in the mold. Taken together, this leads to an increased risk of poor-quality casting (for example, leaks in the thinnest parts of the wax model). When directly feeding a casting, it is necessary to strive to ensure that in the thermal center of the flask there is a section of divergence of the sprue canolas to the casting objects. To obtain predictable, high-quality casting of objects with similar parameters, it is necessary to take into account the density of the alloy used. The smaller its specific gravity, the larger the diameter of the gating channels should be. To obtain predictable, high-quality casting, special attention must be paid to the choice of geometric dimensions of the gating system elements: gating channels, manifold, feeders. This choice is determined by many factors: the type of gating system (with direct feeding of the casting or using a casting reservoir (manifold)), the size of the casting objects, their type and quantity.

Vacuum casting of metals

Vacuum casting of metals is widely used in various metallurgical enterprises. Using this method, parts of various shapes are produced, including small nuts and washers. Thanks to preliminary pumping of air from the molds, it is possible to avoid the formation of air voids inside the products and obtain a flat, smooth and high-quality surface.

Ferrous and non-ferrous metals are used for casting. The use of vacuum for technical support of this process can significantly reduce the cost of raw materials in the manufacture of thin-walled products, while they meet the necessary requirements for strength and reliability.

Vacuum casting of metals

A separate category of vacuum casting is casting into vacuum film molds. This method involves the use of quartz sand without additional binding components. The grains of sand are held together due to the action of the vacuum environment that is created inside the mold. Preliminary blanks for castings are made of plastic or wood and have a long service life due to the lack of contact with the material of the future product. The molds are covered with a special film that prevents them from coming into contact with grains of sand. This technique refers to precision casting - it can be used to produce products with small wall thickness. The materials used for this type of casting are magnesium, aluminum, cast iron or steel. The output is high quality products that have a clean and smooth surface without the need for additional processing. This significantly reduces production costs.

Centrifugal casting

When centrifugal casting (Fig. 3) it is important that the poured alloy displaces the volume of air from the hollow mold of the flask as quickly as possible. Air is inevitably displaced through the pores of the corresponding investment material. When filling on the vibrating table, the investment material settles, i.e. large particles settle faster than small ones. Smaller particles form a dense layer on the surface of the flask, which, during centrifugal casting, slows down the displacement of air through the flask. In this case, it is recommended to grind the surface of the investment box with a trimmer to open the pores of the material.

When centrifugal casting, it is necessary to use a larger amount of alloy, since (Fig. 4) the centrifugal force exerts a sufficiently high pressure on the alloy, which allows it to be poured even into the thinnest parts of the flask (Fig. 5).

Rice. 3. Casting process using a centrifugal induction casting unit.

Rice. 4. Alloy in the crucible of a centrifugal casting installation.

Rice. 5. An object made of a noble alloy on a centrifugal installation.

Vacuum suction casting (essence of the process, features, advantages and disadvantages)

The essence of the vacuum suction casting process is that the melt, under the influence of vacuum created in the mold cavity, fills it and solidifies, forming a casting. By changing the difference between atmospheric pressure and the pressure in the mold cavity, you can regulate the rate of filling the mold with the melt, controlling this process. Vacuuming the mold cavity during pouring allows you to fill the molds of thin-walled castings with a wall thickness of 1-1.5 mm, eliminate the entry of air into the melt, and increase the accuracy, tightness and mechanical properties of castings.

In production, two main types of installations are used.

Installations of the first type (Fig. 4.5) have two chambers: lower a and upper b. The lower chamber is a dispensing oven with electric or gas heating, in which crucible 1 with the melt is located. Upper chamber b is located on cover 2 of the lower chamber; in the lid 2

installed at the metal plant.

Form 4

is installed and secured in chamber b.

so that, sprue. 5 was connected to metal wire 3.

The upper chamber b is hermetically connected by clamps

6

with lid

2.

The cavity of the upper chamber b is connected through a vacuum wire

7

to a receiver in which a vacuum is created by a pump, regulated by a control system.

At the initial moment, the control valve opens,

a vacuum is created

b a

(atmospheric) and

b

(less atmospheric), rises through metal pipe

3

and fills the mold cavity.

After the casting has solidified, the valve of the control system connects the cavity of chamber b with the atmosphere, the pressure in the upper and lower chambers becomes equal, and the remains of the unsolidified melt are drained from metal wire 3 into crucible 1. Chamber b

is removed, mold

4

with the casting is removed and the cycle can be repeated.

Vacuum suction casting improves the mechanical properties of castings. For example, the tensile strength of castings made of aluminum alloy AL9 increases by 5-10 %,

and the relative elongation is 30% compared to die casting.

This is explained by better conditions for feeding the shrinkage of the casting through the metal wire than from the profits. Installations of the first type are also used for the production of castings in the following [options: first, a vacuum is created in chamber b

of the installation, and then the mold is filled with a melt and the castings are solidified under low pressure created in chamber

a;

the mold is filled according to the first option, and the casting hardens under all-round air pressure |

in chamber B of the installation.

Installations of the second type are used for casting bushings, ingots and blanks of simple configurations into water-cooled molds. The toe of a metal water-cooled crystallizer (Fig. 4.6) is immersed in the melt located in crucible 2

holding furnace.

The working cavity of the crystallizer, which forms the casting, is connected by a vacuum wire to the vacuum receiver 3.

The vacuum in the system is created by a vacuum pump

6

and is regulated by the leak 5. By turning the distribution valve

4

the working cavity of the crystallizer is connected to the vacuum receiver

3.

A vacuum is created in the crystallizer cavity,

and the melt is sucked into the crystallizer, rising to a height proportional to the vacuum and inversely proportional to its density. After the casting has solidified, the toe of the mold is removed from the melt bath, by turning tap 4

, the working cavity is connected to the atmosphere and the casting falls out of the mold into the receiving box.

Features of casting formation. The mold can be filled with melt at the required speed, smoothly, without splashing, with a continuous front;

the melt that fills the mold solidifies under vacuum conditions; gases contained in the melt can be released from it, thereby creating conditions for obtaining castings without gas holes and porosity; at the same time, under the influence of air pressure on the melt mirror, the latter constantly feeds the shrinking casting, as a result of which the casting can be obtained dense, without shrinkage defects. However, to obtain dense castings without shrinkage defects, it is necessary to coordinate the intensity of solidification and feeding of the casting. Typically, when casting by vacuum suction of ingots, bushings, the melt is sucked into a thin-walled metal water-cooled mold, due to which the casting solidifies at a high speed; which helps eliminate segregation in castings made from alloys prone to segregation phenomena.

Using the method discussed above, it is possible to obtain hollow blanks such as bushings without rods. In this case, after the melt is sucked into the crystallizer and a crust of solid metal of a given thickness is frozen on the inner walls of the crystallizer, the vacuum is turned off and the unhardened melt is poured back into the crucible. In this way, dense blanks of bushings are obtained without gas and shrinkage cavities and porosity. However, the inner surface of the bushings can be wavy due to uneven hardening. This necessitates an increase in the allowance for machining the inner surface of the sleeve. To reduce the allowance, such workpieces can be cast using a rod installed inside the mold.

The method makes it possible to produce castings from light non-ferrous alloys, copper alloys, cast iron and steel. Most often, this method is used for casting blanks of bushings, liners, and plain bearings from scarce and expensive copper alloys. In this case, the main advantages of this method are most fully manifested: quiet filling of the mold with a melt at an adjustable speed, which makes it possible to eliminate defects in castings associated with filling the mold; reduction in metal consumption due to the elimination of sprues and profits; automation of the mold filling process, which allows for comprehensive automation of the process of obtaining castings.

Ticket12

1. Classify shaking molding machines according to the type of air distribution.

According to the type of air distribution, pneumatic shaking mechanisms are: 1) with piston distribution; 2) with distribution using a simple single-seat valve; 3) with distribution using a two-seat changeover valve; 3) with spool valve distribution.

In the first mechanisms, the air control element is a shaking piston, which, when moving, opens and closes the inlet and exhaust ports. The piston air distribution is simple, but not adjustable.

The diagram of a pneumatic shaking mechanism with air distribution by a simple single-seat valve is shown in Fig. 4.

Fig. 4 Diagram of a shaking mechanism with air distribution by a simple single-seat valve:

a – lower position; b – top position; 1 – shaking piston; 2- valve; 3- air intake; 4- exhaust

When the shaking piston moves upward by the amount of filling stroke se, the valve plate sits on the seat and cuts off the air, stopping its access to the cylinder cavity. The exhaust port is opened by the piston as it rises further. A valve of this kind is relatively simple in design, but is difficult to access for adjustment, since it is located inside the shaking piston.

In Fig. Figure 5 shows a pneumatic shaking mechanism with air distribution carried out by a reversible double-seat valve. The lower valve plate opens an opening through which compressed air enters the shaking cylinder. The upper valve plate opens the exhaust port, communicating the shaking cylinder with the atmosphere. In the lower position of the shaking piston (Fig. 5, a), the valve is pressed upward by compressed air pressure. The exhaust port is closed and the air intake port is open. The shaking piston with the table rises. As the shaking table rises, it is followed by a plunger located in the valve. The plunger moves upward under the action of compressed air pressure on its lower end, all the time resting its upper end against the adjusting screw screwed into the shaking table.

When the shaking piston passes the filling path se, compressed air through the lower channel in the plunger enters the space above the valve piston, and the valve will swing to the lower position, closing the inlet port and opening the exhaust port. As the shaking table moves downwards (Fig. 5b), the valve will keep the exhaust hole open until the space above the valve piston communicates with the atmosphere through the upper channel in the plunger. This will happen when there is some distance left until the end of the stroke (pre-intake). At this moment, the air from the space will escape into the atmosphere, and the valve will again move to the upper position, closing the exhaust and opening the inlet.

This air distribution device is easily adjusted with a screw. By unscrewing this screw, the lifting height of the shaking table increases. This type of air distribution valve is widely used in large and medium-sized shake molding machines.

Rice. 5 Shaking mechanism with air distribution by double-seat changeover valve:

a- lower position; b- top position; 1- shaking piston; 2- changeover valve; 3- plunger; 4- adjusting screw; 5- valve piston; 6 - supra-piston space; 7- air intake; 8-exhaust

Fig.6 Shaking mechanism with spool air distribution: a- lower position; b- top position; 1- shaking piston; 2- spool; 3- upper adjusting nut; 4- lower adjusting nut; 5- air intake; 6- exhaust.

A pneumatic shaking mechanism with spool air distribution is shown in Fig. 6. The spool does not have a rigid attachment to the shaking table: it can slide relative to the table by an amount x, which is adjusted by rearranging two nuts, upper and lower, on the spool rod.

When the shaking piston moves upward (Fig. 6, a), the table first passes path x, selecting a gap to the upper adjusting nut, and then pulls the spool along with it. At the beginning of the fall of the shaking piston with the table from the upper position (Fig. 6, b), the spool is delayed and lags behind the table, since, being much smaller in diameter than the shaking piston, it has relatively greater friction. Therefore, when moving down, the table will also first select the gap x, which will now appear between it and the lower adjusting nut, and then begin to push the spool down.