Silver casting technology

Silver casting in a factory environment is carried out using industrial technologies that require expensive equipment, significant energy consumption and the use of rare and dangerous components. Traditional technologies, proven over thousands of years, are more suitable for casting silver at home or in a workshop.

The most common of these is lost wax casting. The use of special modeling wax as a model material is also popular. The material used to create the mold is gypsum or clay-sand mixtures.

Silver ingots for casting

Silver for casting can be purchased at a savings bank or jewelry store in the form of ingots. In this case, its composition is precisely known and is stamped as a sample. If you decide to use grandma's spoons or scrap silverware, be prepared for the fact that you will have to carry out an operation to clean the scrap from impurities. For example, silver is purified from impurities of base metals such as lead, copper and others by melting it in a crucible with the addition of saltpeter, borax and soda. Nitrate binds base metals, oxidizing them. Soda and borax transfer these oxides into solution, forming liquid slag. The silver remains at the bottom of the crucible in the form of an ingot.

Lost wax casting. This silver casting technology is most accessible for beginners to master. The model is made of a material whose melting point is lower than that of the melt being poured. A mold of plaster or sand-clay mixture is poured or molded around the model.

Lost wax casting

The most common materials for lost wax models are wax and paraffin. When the melt is poured into the mold, the model material melts and is forced out of the mold through a specially provided hole. The place of the model is gradually taken by silver. There is a variation of this method in which the wax model is burned out by heating the mold to a high temperature, and casting silver is poured into the now empty mold.

Manicure with gold and liquid stones

Very often, cast nail designs are decorated with liquid stones. They create a very delicate, rich, luxurious nail look. The stones seem to sparkle like real ones on the nails, turn into real jewelry, and act as a key design element, for example, owl eyes, turtle shell, etc.

It is not difficult to make casting with liquid stones; the technique is as follows:

- The nails are covered with a base - gel polish of the selected color, and dried. Then the sticky layer is removed from them.

- A substrate of any shape for liquid stone is made using gel paint of the selected color. The background is painted with a thin brush.

- Take a gold or silver colored manicure transfer sheet and press it onto the backing.

- A pattern is made around the substrate, the intended design.

- The matte side of the sheet is adjusted to the pattern and removed with a sharp movement of the hand. Can be repeated several times. In place of the applied pattern there should be a casting.

- To create voluminous nails, a transparent gel is used. The gel is mixed with colored shellac on the foil in order to create the effect of natural stone: turquoise, malachite, onyx, amber, amethyst, agate, etc. Take a small ball of mixed gel paint with a brush and place it on the substrate. Dried in a lamp.

- The nails are covered with a topcoat and dried in a lamp for 2 minutes. The sticky layer is removed.

To create liquid stones, you can use a special polymer coating or sculpting gel. With these materials the stones will look naturalistic and more convex.

Forming tools and casting fixtures by model

To cast precious metal products at home you will need

- Crucible for melting or cleaning metal.

- Muffle furnace or gas burner.

- Steel tongs.

- Fireproof stand.

- Scales

- Modeling wax. Candle wax will not work.

- Molding sands

- Container for diluting the mixture

- Scalpel, knives and files for processing the model and for finishing the finished product.

- Casting mold

- Hammer for breaking the flask.

- Protective gloves, glasses and apron.

- Fire extinguisher.

- Dremel (mini drill)

- Vices, Crossbars and Mandrels

It’s worth going into a little more detail on making a mold for casting silver. First, a model of the future product is created from wax by sculpting and cutting out small parts with a scalpel, completely repeating its shape, but having a thin protrusion in the form of a round rod.

Wax model for silver casting

This is the sprue that will carry the molten metal into the mold. Next, the model is placed in the flask and the molding mixture is poured.

If dry molding mixture is used, then the vibration compaction method is used for molding. Next, the model wax is burned out, and the mold is ready for pouring the melt.

Varieties of casting designs on nails

A manicure with imitation casting can be done with both varnish and gel. Only in the first case, the design is made with gel paint on top of regular varnish, then it is dried, foil is sealed on top, and finally the nail is covered with a varnish top coat.

When making a casting design on your nails for the first time, we recommend trying a simple design, for example, a French manicure with streaks, simple patterns, a geometric manicure, or nails in a fruity cherry style.

After the girl gets the hang of it and tries various materials for the casting technique, gel paint, shellac, various types of foil, she can begin more complex design options. For example, combining various techniques in manicure, making castings with complex designs, decorating nails with liquid stones, etc.

By the way, casting can be done on both long and short nails. You just need to take into account that on a long plate the drawing turns out to be solid and complete.

Casting in French manicure looks very beautiful. At the same time, it is the smile line that is decorated with golden casting.

Nails with the effect of luxury of precious metals can be done both on a single-color coating and on a multi-colored, gradient one.

Thanks to the gel and foil, you can create a real jewelry masterpiece on your fingers. With the help of casting, you can turn even the most ordinary manicure into a design of extraordinary beauty. And by adding liquid stones, you will get a voluminous, three-dimensional, unique, luxurious design that will be ideal for special occasions.

Model casting in earth molds

Casting in so-called earth molds is the oldest method, proven over thousands of years. Molding mixtures do not actually consist of black soil, but are a mixture of fine-grained quartz sand and plastic clay in certain proportions. For casting small products with thin relief and a large number of parts, mixtures containing 12-15% clay are used, for large castings - up to 25%. Gases generated during casting must escape freely through the walls of the mold.

Casting silver according to models in earthen molds

The model for casting into earthen molds is made absolutely exactly repeating the original, but a little larger in size. This is an allowance for shrinkage and subsequent processing of the product. Models were traditionally made from wood, wax and plaster. Today, plastic models are becoming increasingly popular. The plastic holds its shape well and is easy to process.

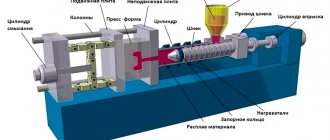

Lost wax casting technology

Lost wax silver casting equipment is relatively uncomplicated and available for home use. The essence of the method is that a model made of a low-melting material, upon contact with the liquid metal being poured, melts and is forced out of the mold through specially provided holes. The metal occupies the void formed in the place of the model and accurately repeats its spatial shape.

It is necessary to pour the metal in a thin stream to allow the material of the lost wax model to leave the mold, in order to avoid the formation of splashes of molten metal.

Detailed instructions for creating nail casting for beginners

In order to make such precious beauty on your fingers, you need to prepare the following materials:

- foil (gold or silver);

- acrylic gels;

- thin cysts for creating patterns;

- UV lamp;

- fixative

We perform a manicure with casting step by step:

Step 1

We prepare the nail plate: we make corrections, polish, and degrease the surface.

Step 2

We apply the selected color gel to the nail - the basis for the future design. You can decorate your nails with colorless gel. Dry in a UV lamp for 2 minutes, remove the sticky layer.

Step 3

Using dark-colored gel, we draw patterns on which gold or silver leaf will be applied in the future. And again we send our fingers into the lamp.

Step 4

Take the foil and press its matte side to the nail. Tear it off sharply and dry it in a lamp for 3 minutes. We cover the nails with a layer of fixative, and again put our fingers in the lamp. Finally, remove the sticky layer.

As you can see, making a cast manicure is not difficult, and the end result is striking in its beauty, sophistication and sense of complexity in the design.

Silver casting at home

Important! Casting silver with your own hands is a complex and fire-hazardous process. Your workshop should have fireproof stands and fire extinguishers designed to extinguish live electrical equipment. Be sure to wear fire-resistant gloves, an apron and goggles.

For casting silver at home, beginning craftsmen usually choose the following technologies:

- wax modeling

- earth casting

- heating the crucible with a gas burner.

Of course, if you have a muffle furnace with adjustment and maintenance of a given temperature, a vibrating table and a centrifuge, your castings will only get better.

Casting silver at home is a complex process, but quite feasible with proper preparation and perseverance. Good luck in mastering this branch of metallurgy!